Patents

Literature

43results about How to "Simplify subsequent processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

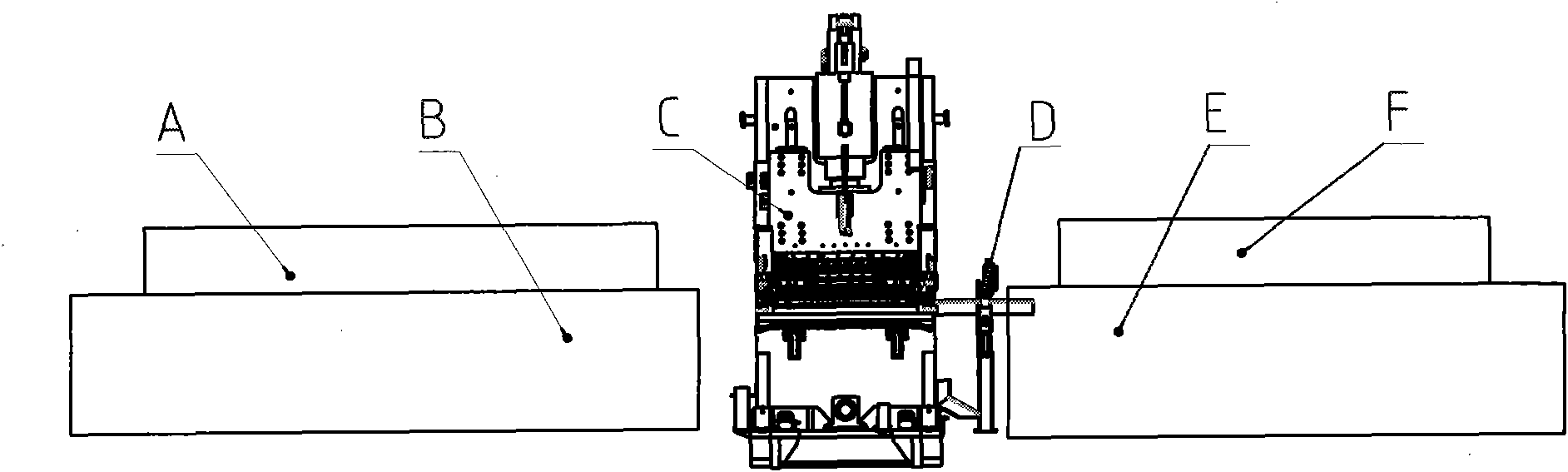

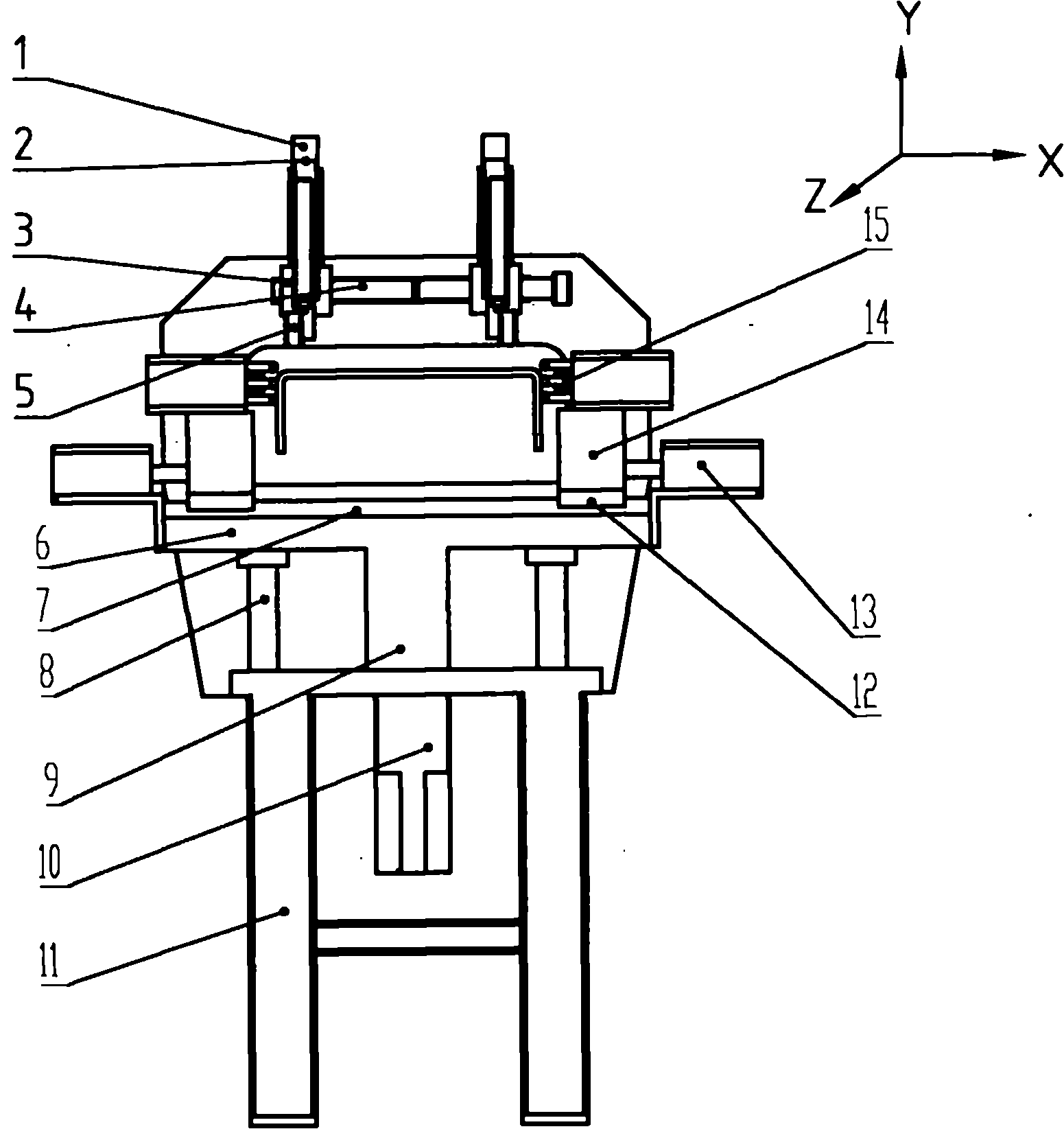

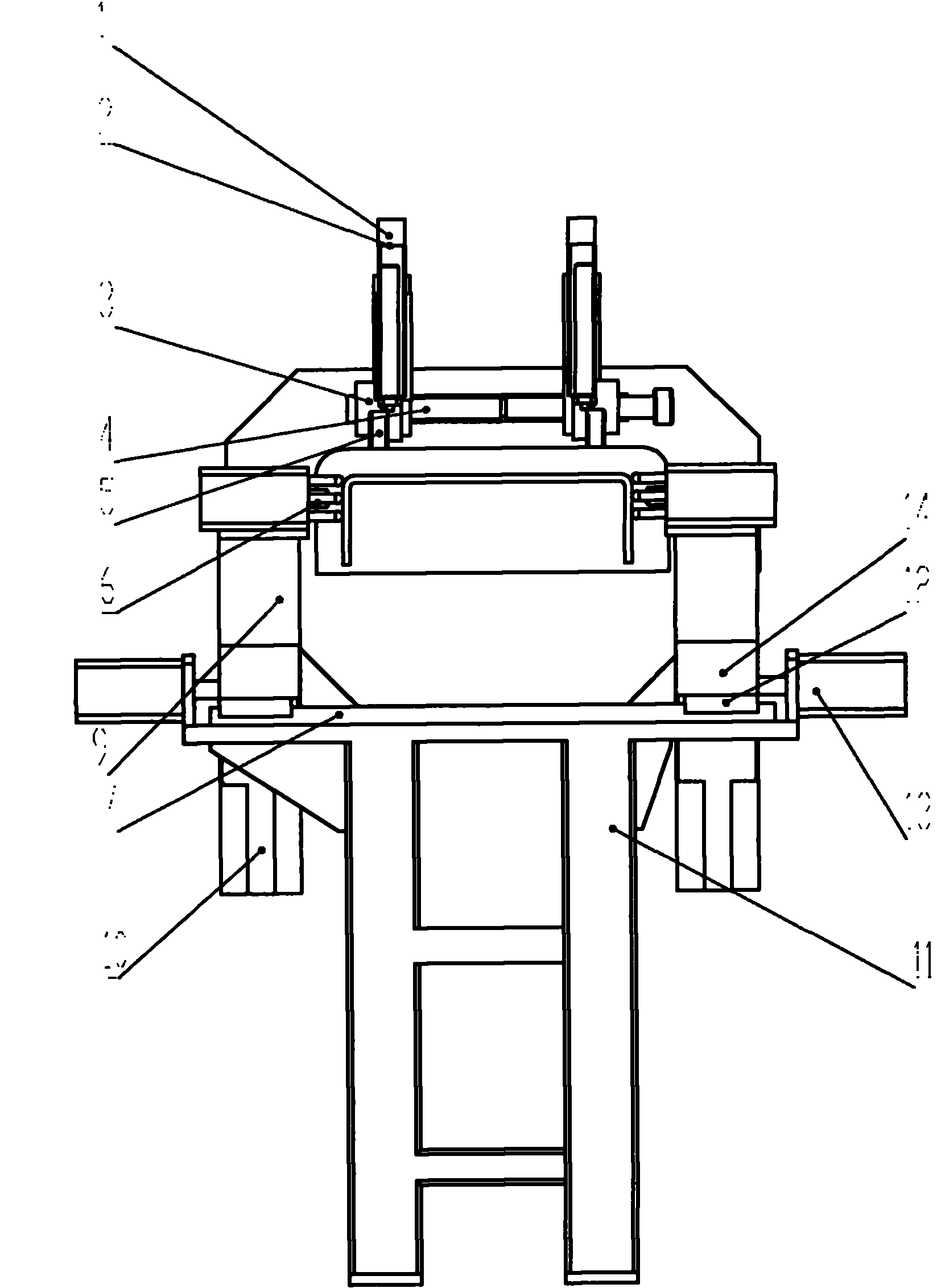

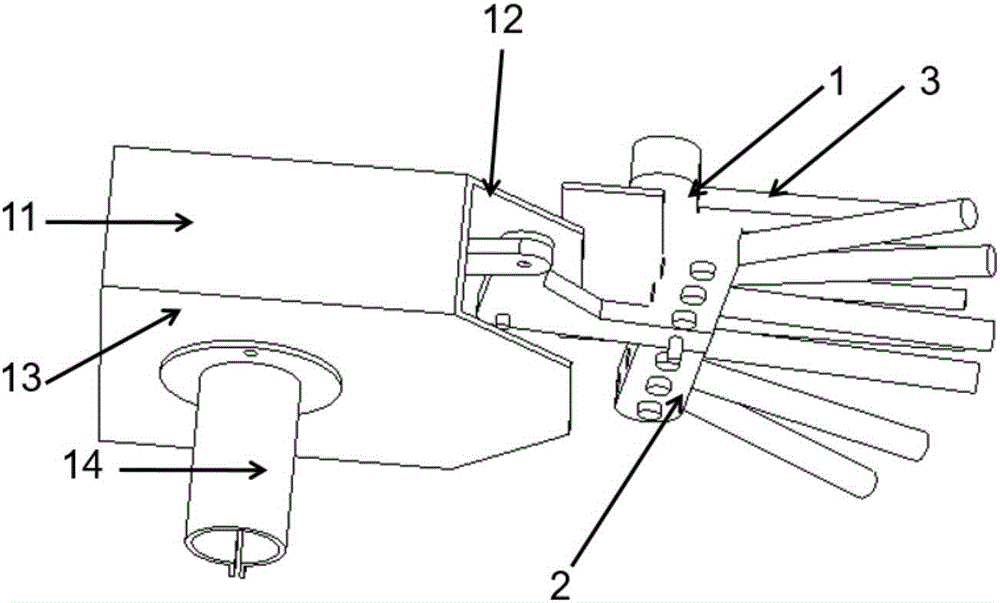

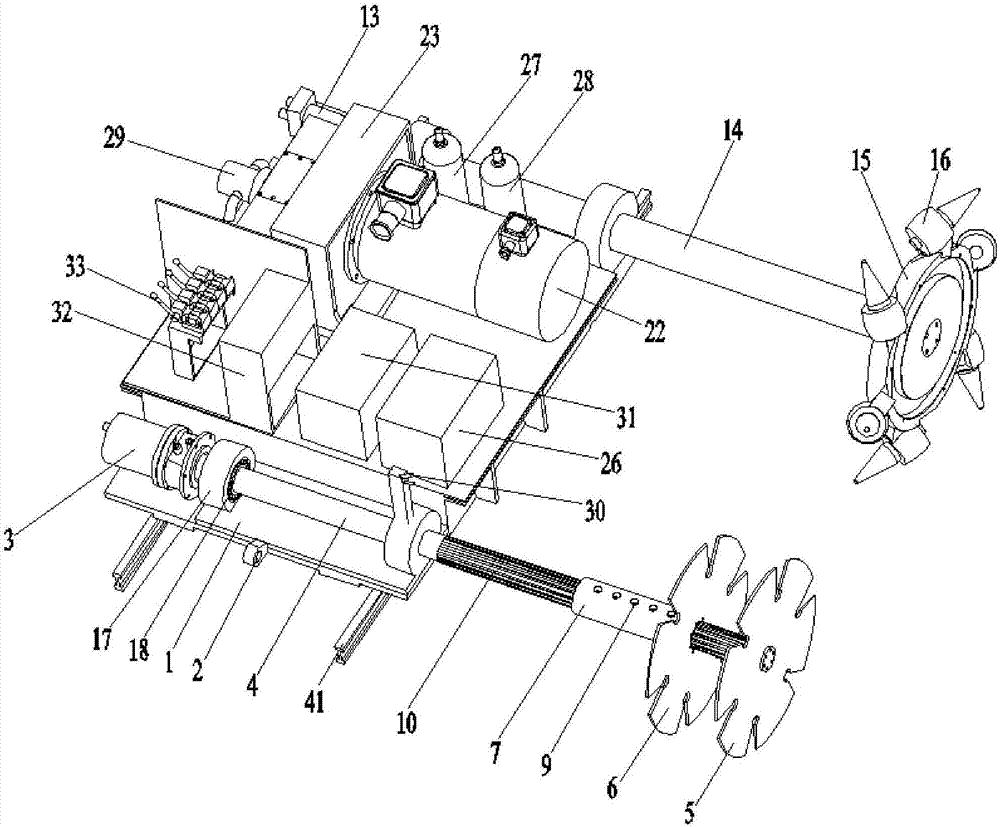

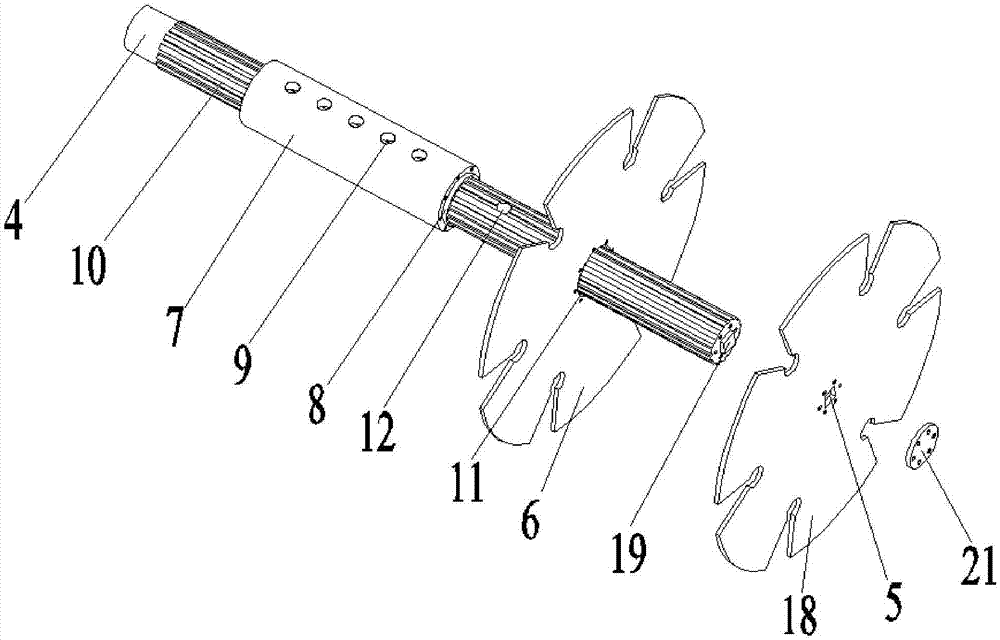

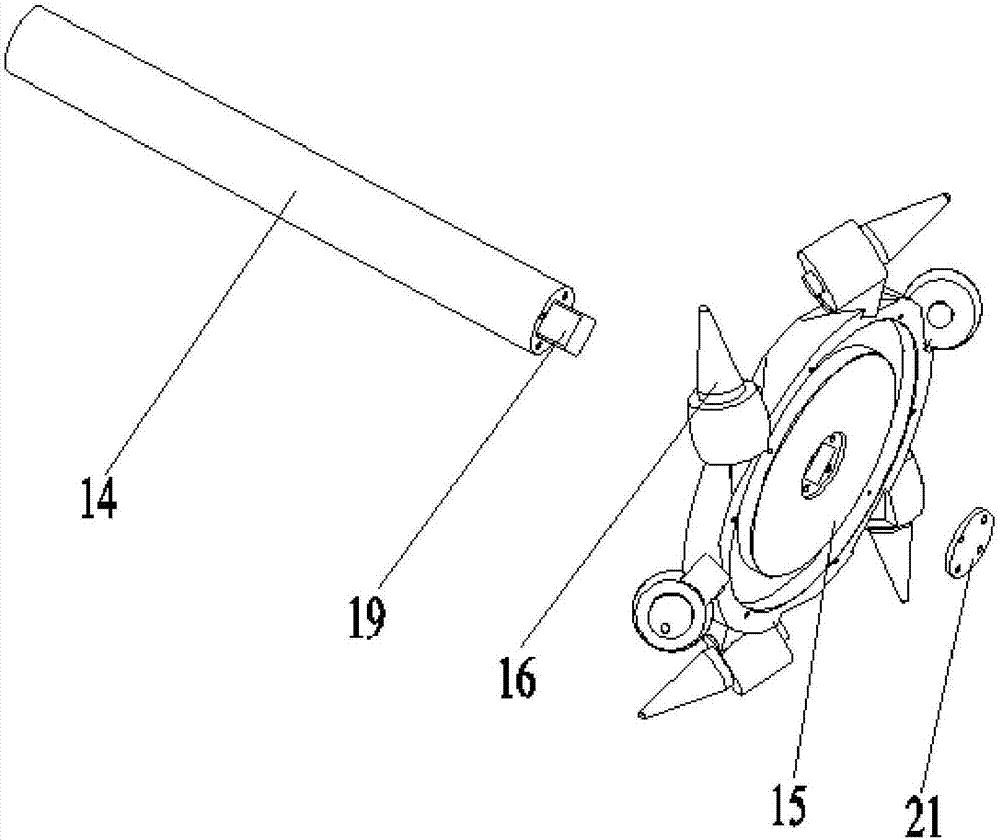

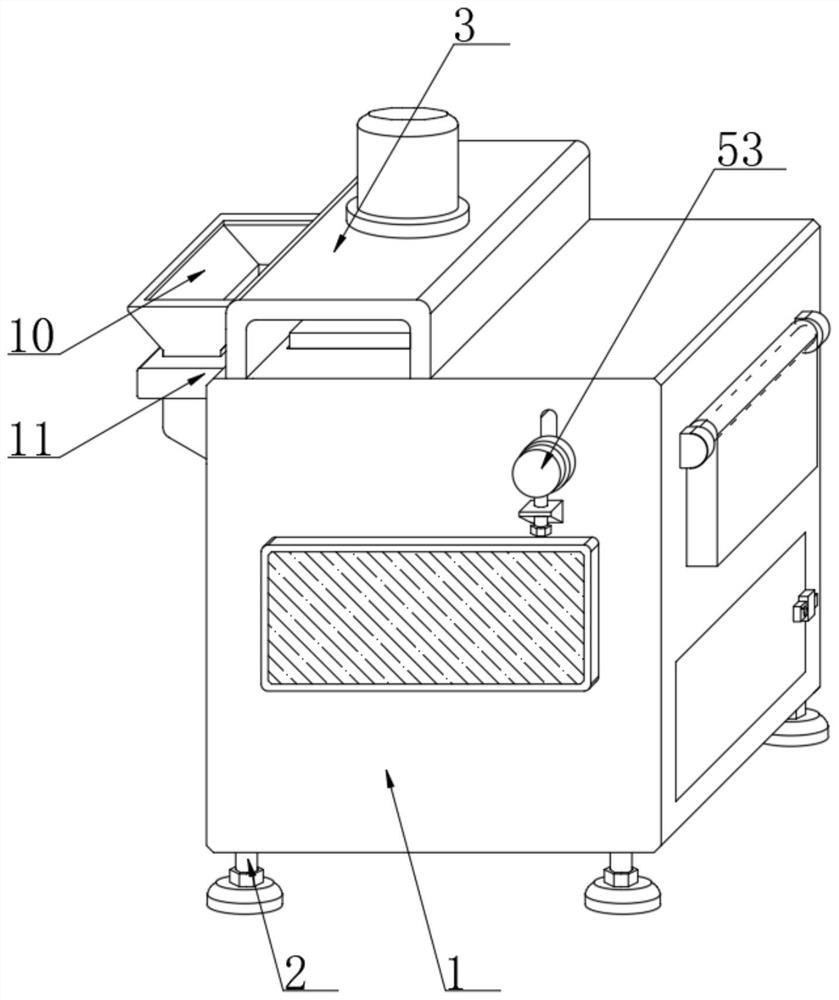

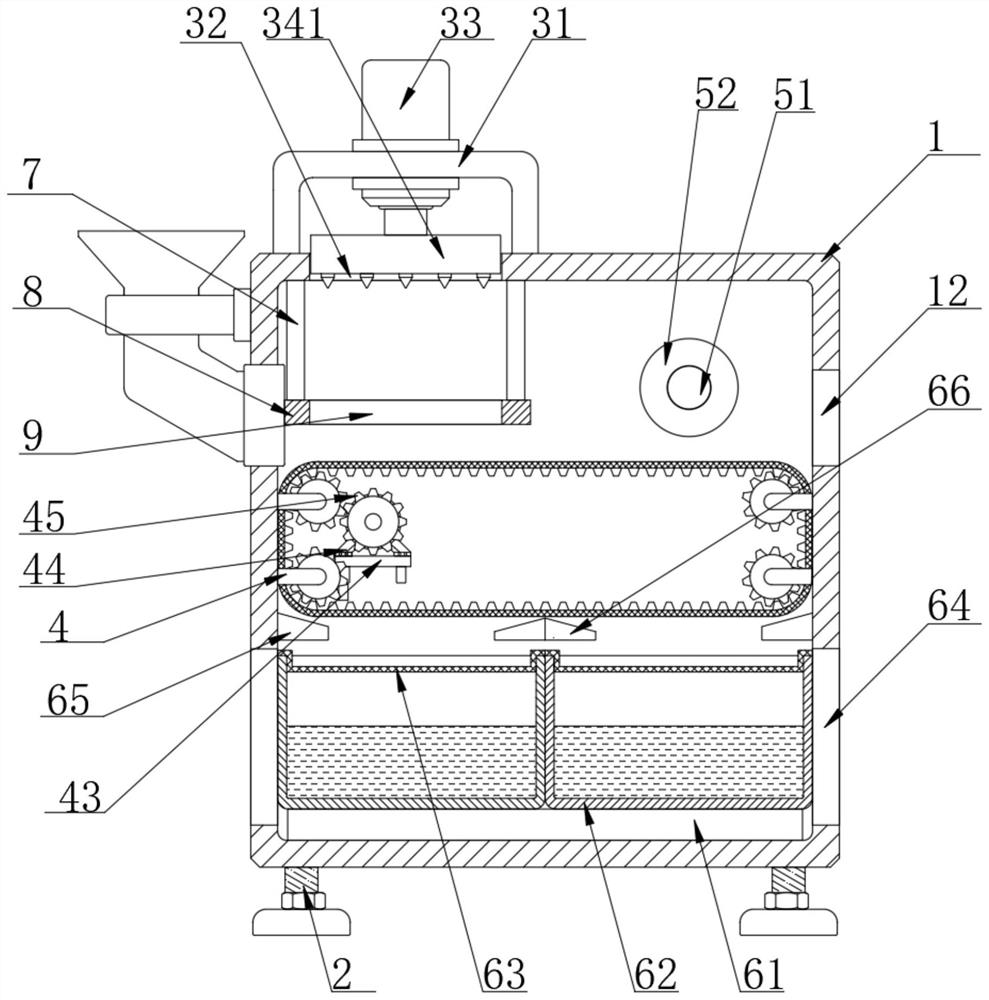

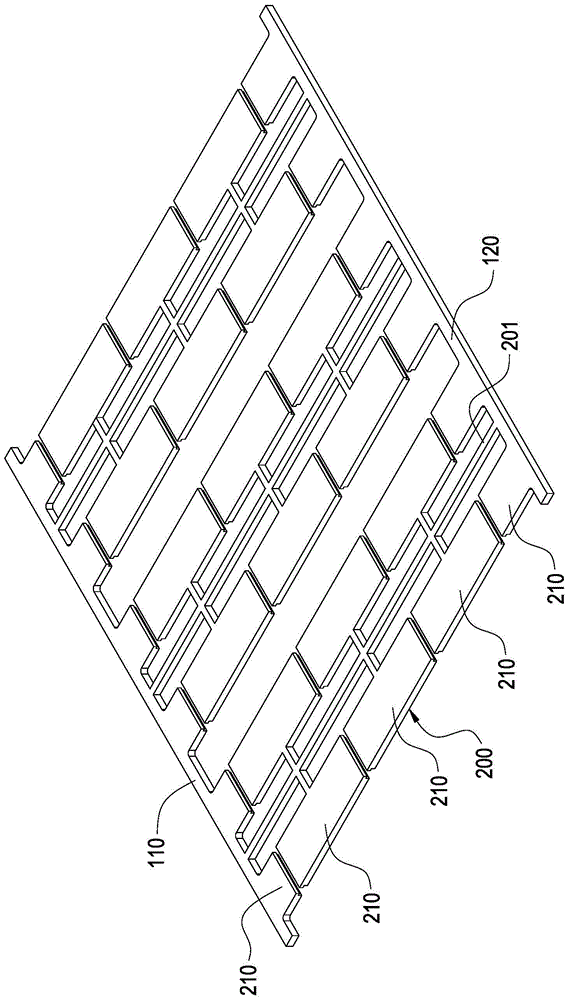

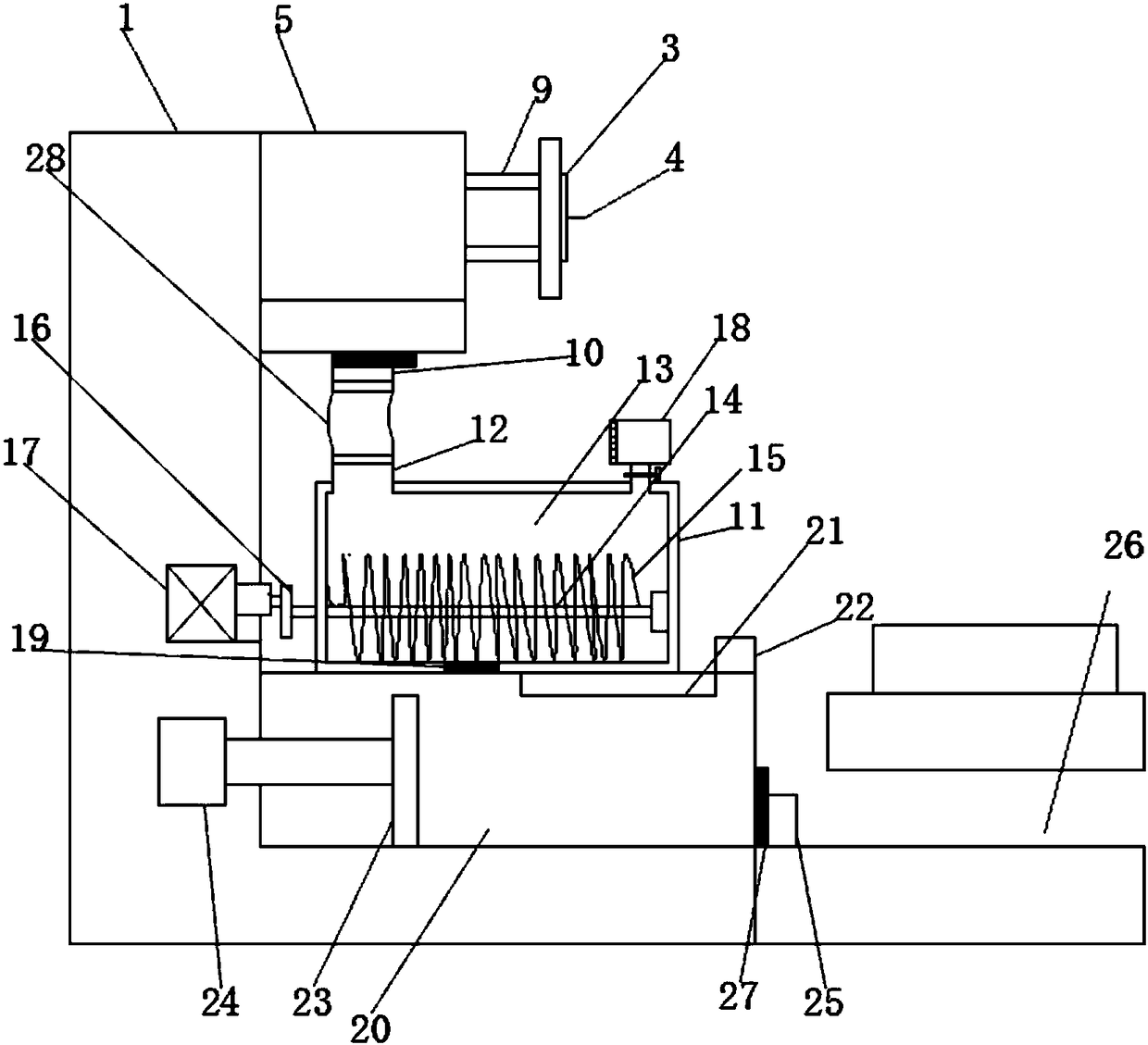

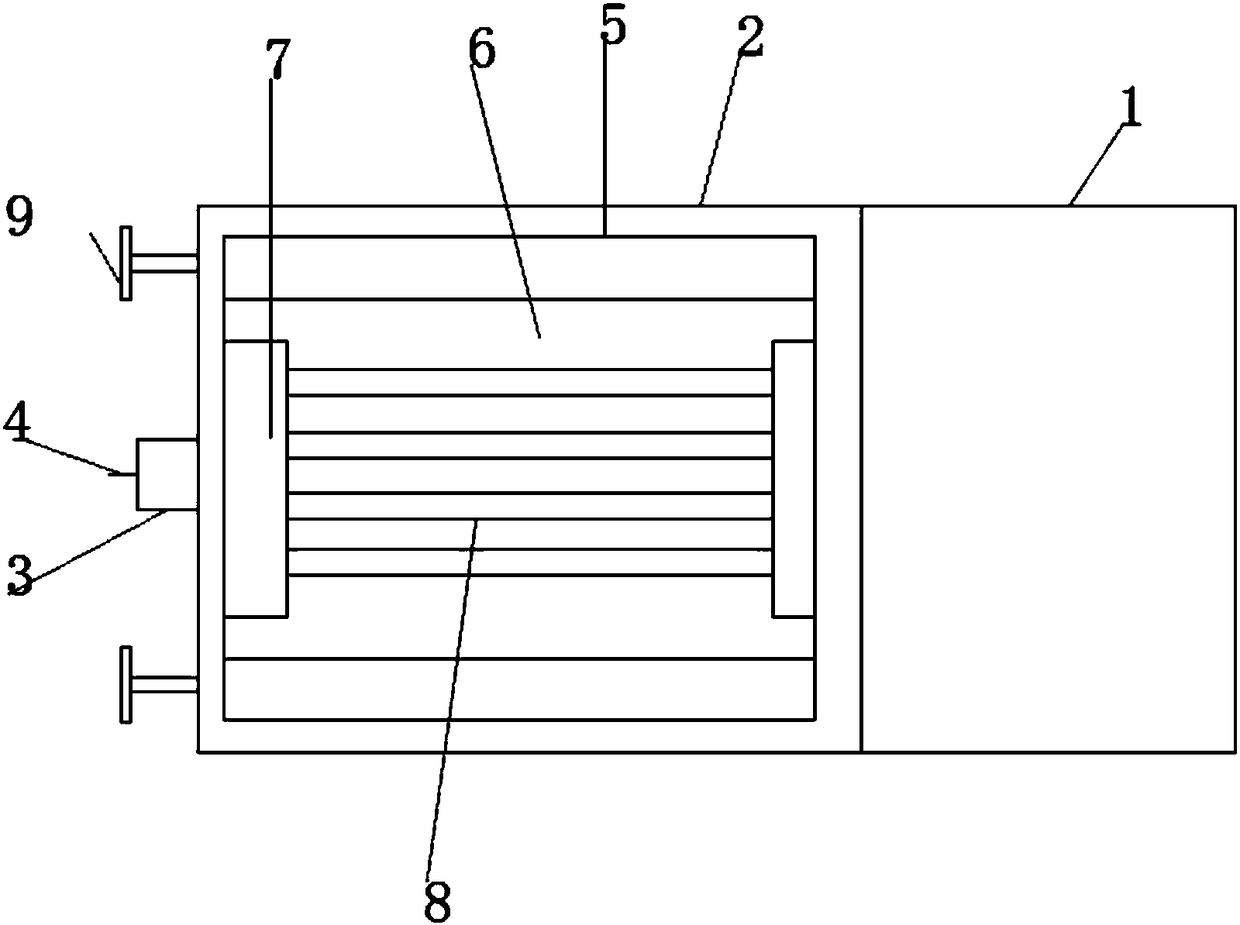

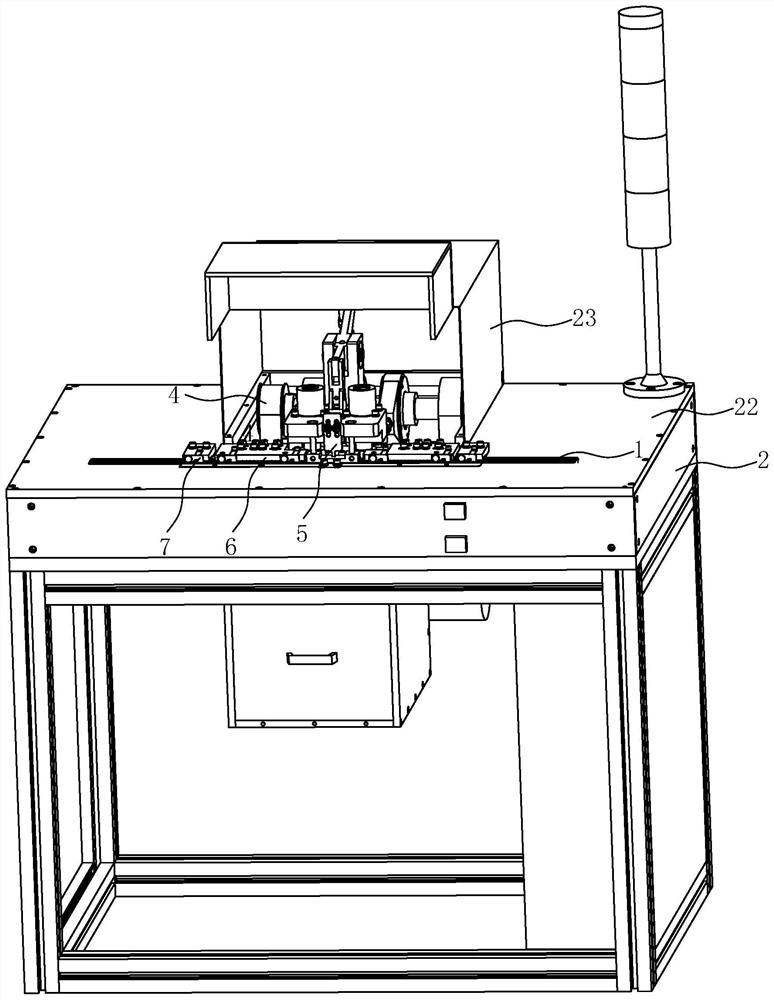

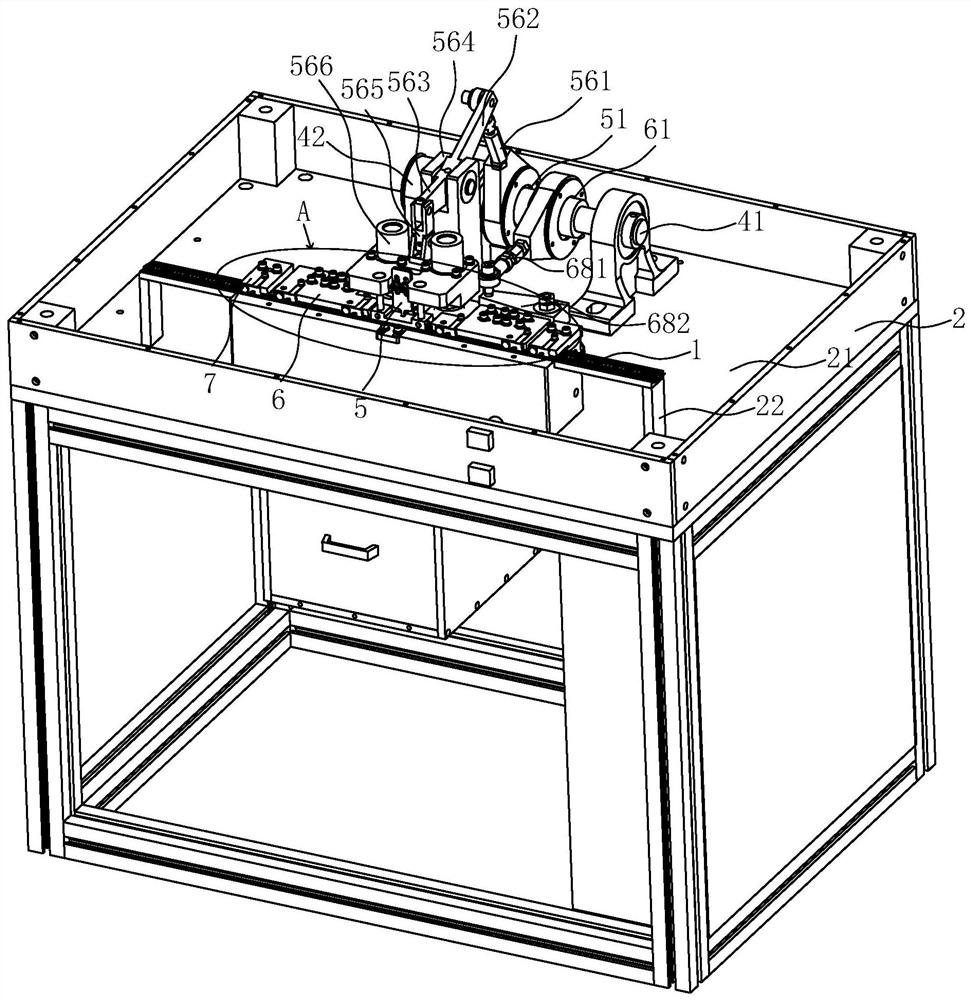

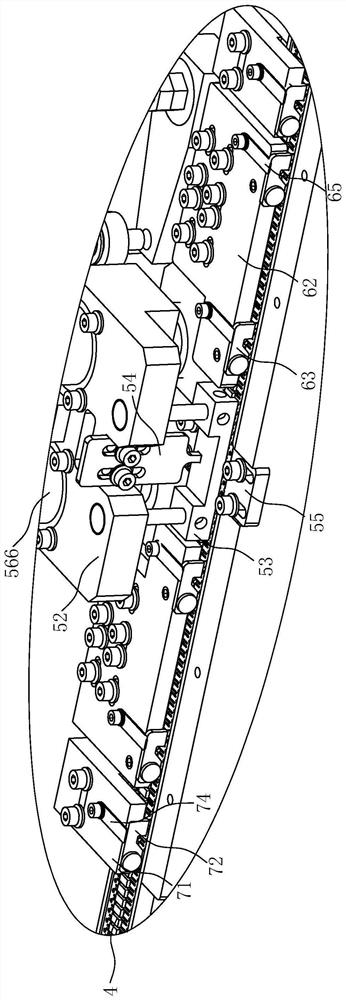

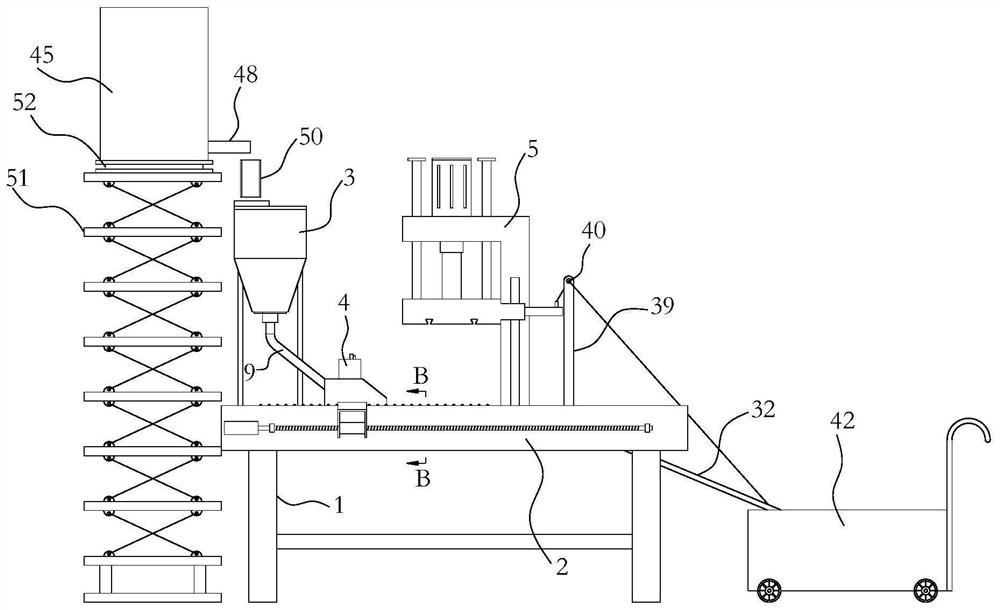

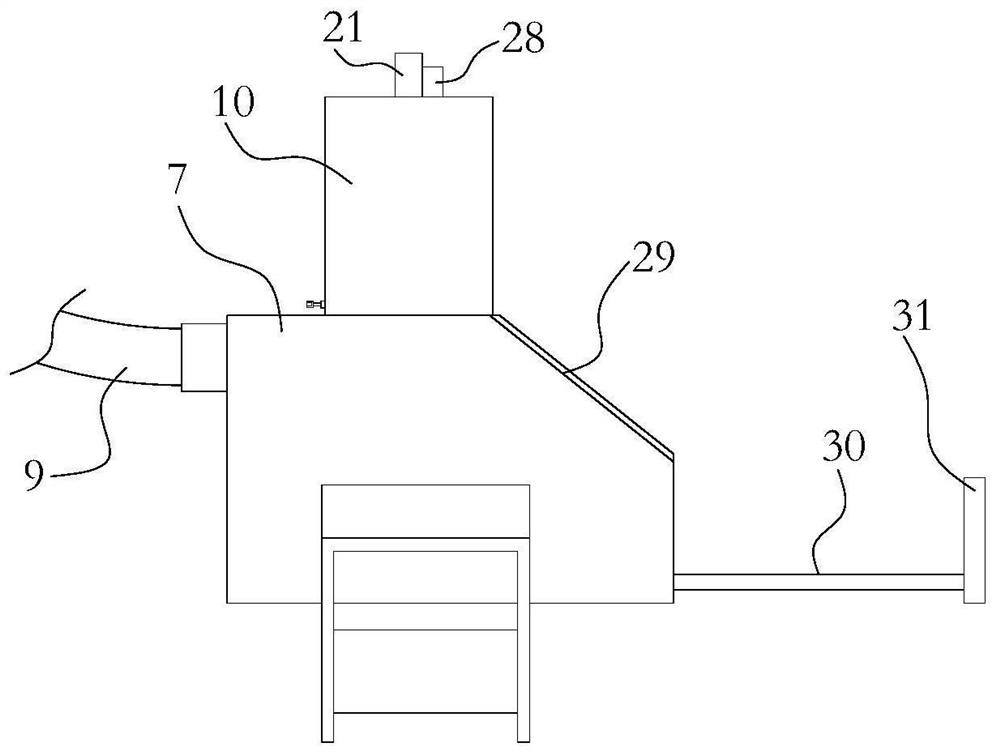

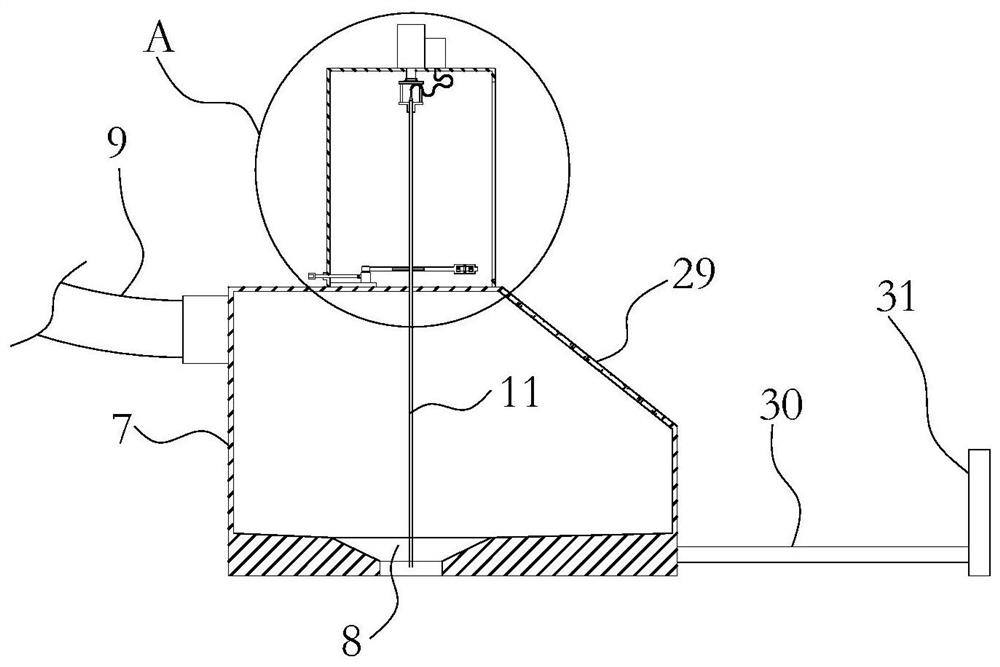

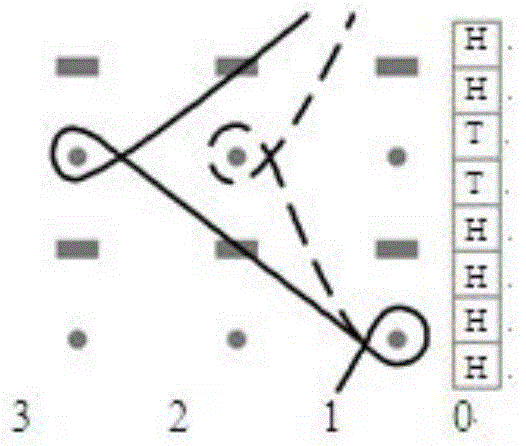

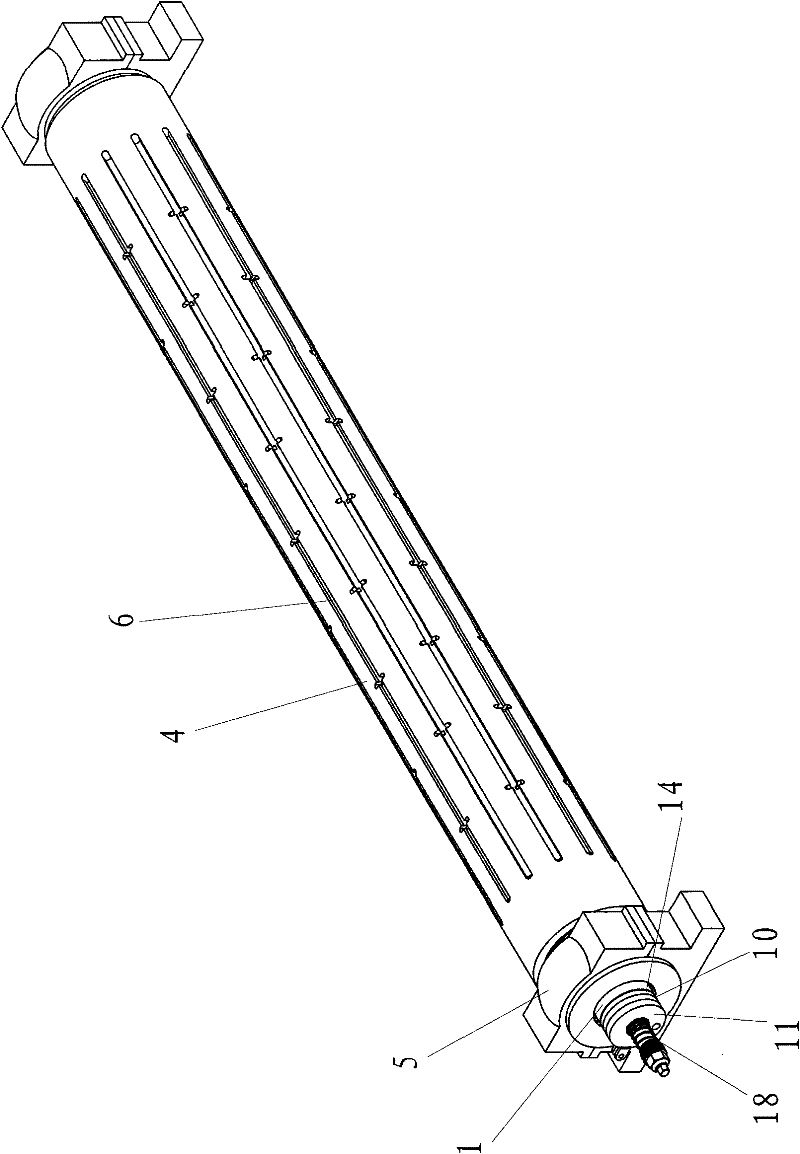

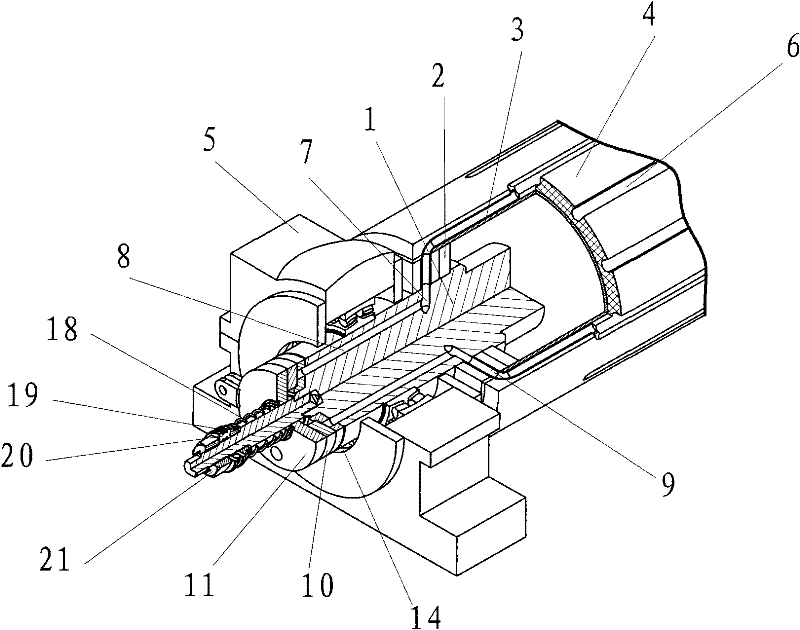

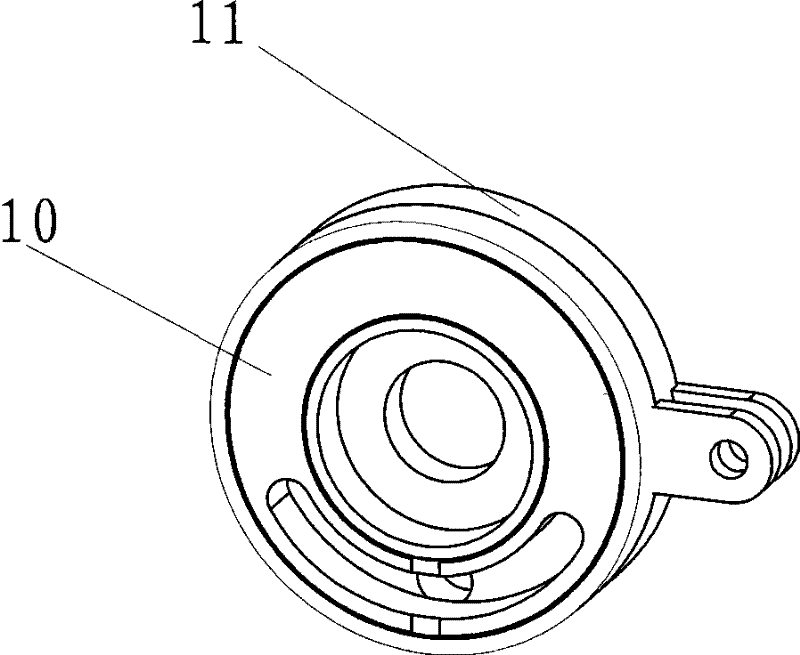

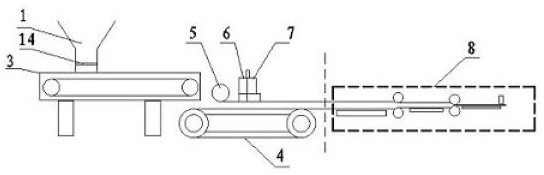

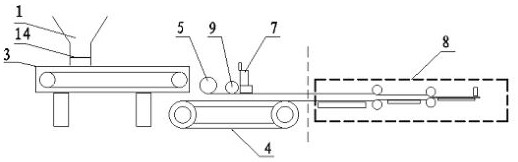

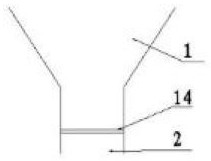

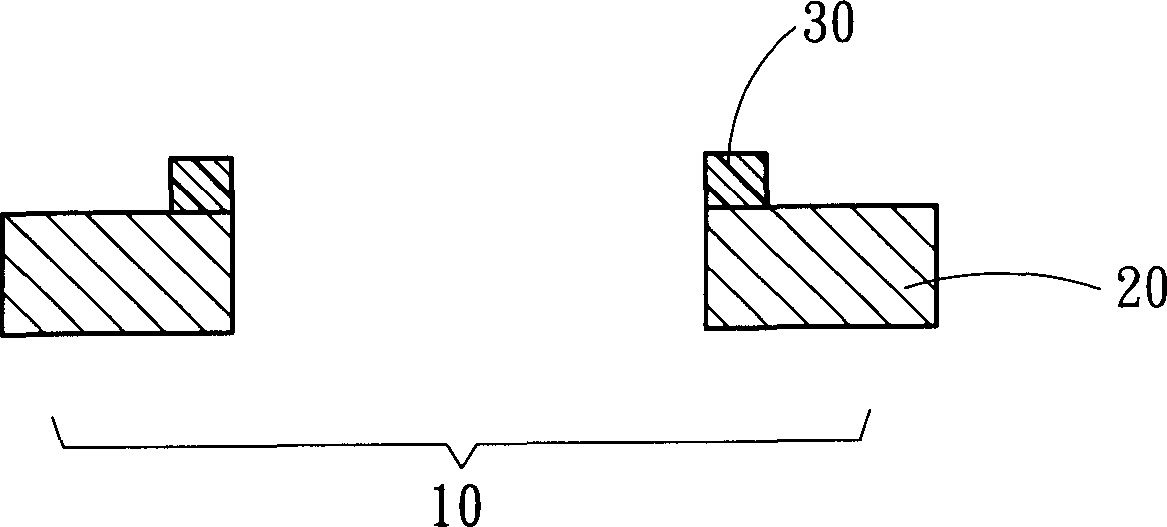

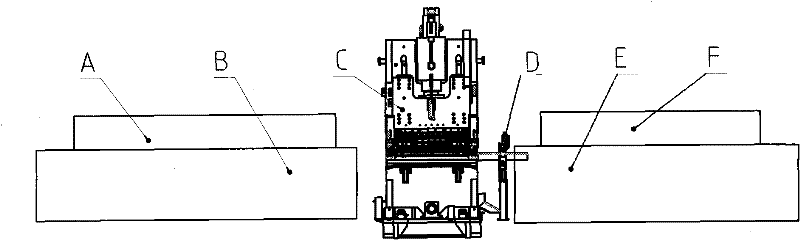

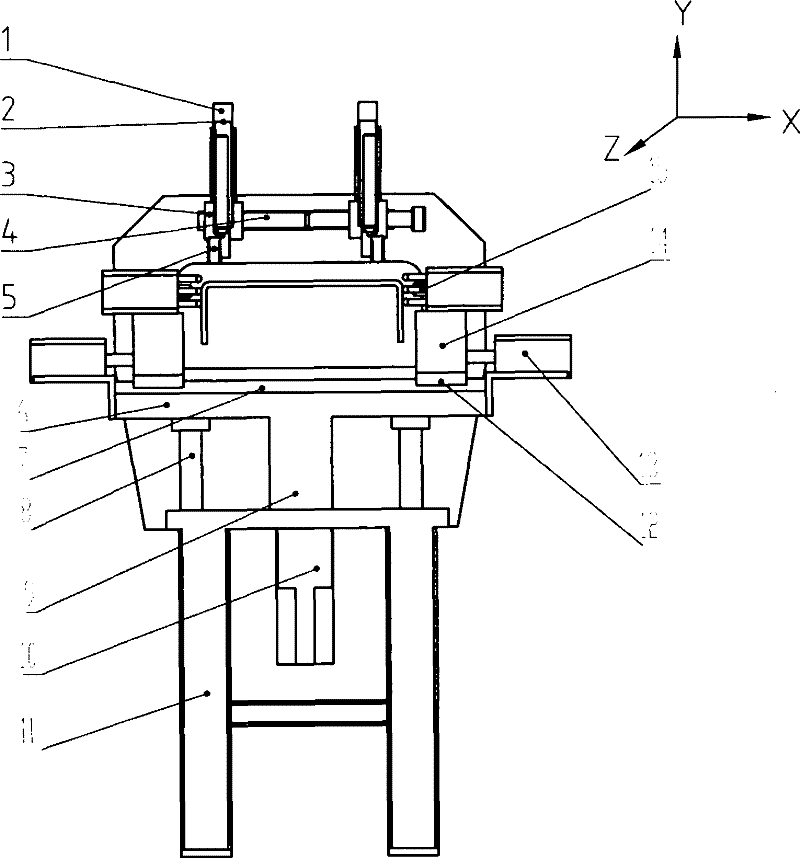

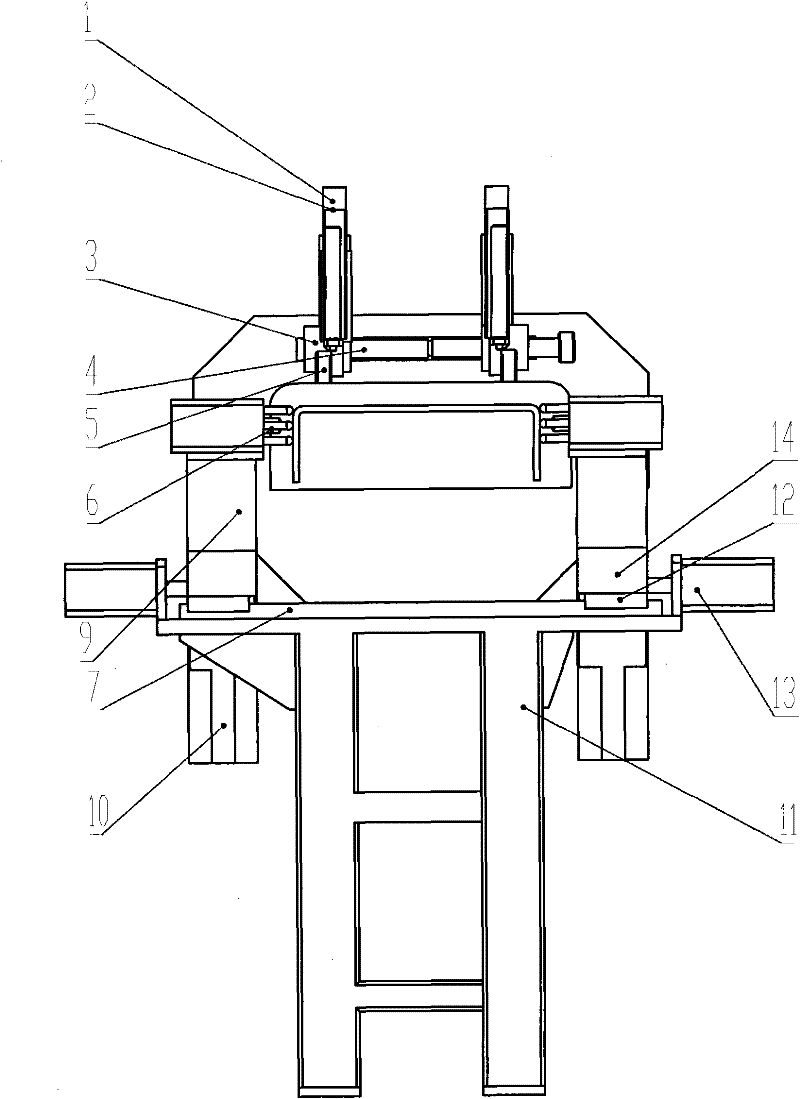

Production line and process for punching U-shaped beam

The invention discloses a production line and a process for punching a U-shaped beam. The production line for punching a U-shaped beam comprises a feeding mechanism, a workpiece feeding device, a punching main machine for punching the ventral side of the U-shaped beam, a blanking feeding device and a blanking device, wherein a wing-surface punching machine for punching and marking the wing surfaces of the U-shaped beam is arranged at one side of the punching main machine. The process for punching a U-shaped beam comprises the following steps of: (1) placing the U-shaped beam on the workpiece feeding device; (2) conveying the U-shaped beam in the punching main machine and punching the ventral side; (3) enabling the U-shaped beam to enter the wing-surface punching machine from the punching main machine and marking at corresponding positions of the wing surfaces of the U-shaped beam; and (4) conveying the U-shaped beam to the next working procedure by the blanking device. The invention has the advantages that the subsequent working procedures are simplified, the production efficiency is improved, and the production cost is decreased because the hole positions of the left wing surface and the right wing surface of the U-shaped beam are punched and marked before or after the ventral side is punched so as to avoid repositioning hole positions in the next working procedure.

Owner:SHANDONG TUOWEI CNC EQUIP

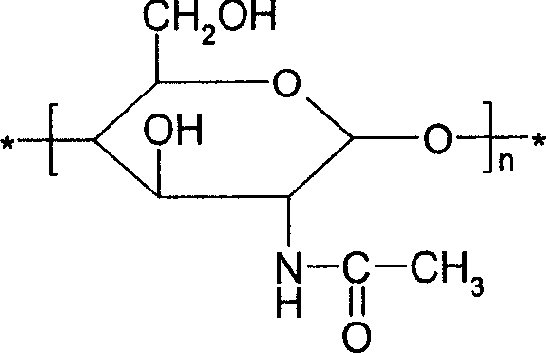

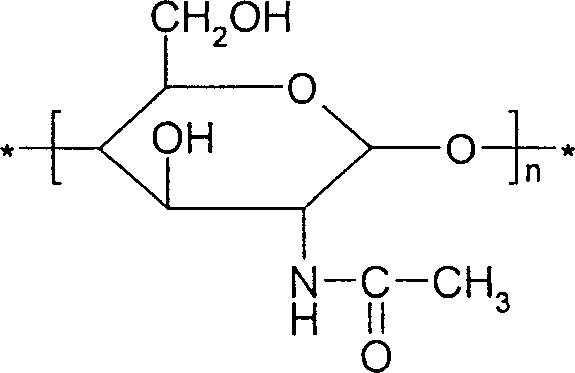

Absorption additive chitosan-Cu compound used in cigarette filter tip and its preparation method

InactiveCN1596783AGood removal effectAchieve focus reduction and harm reductionTobacco smoke filtersOrganic solventTar

Owner:JIANGNAN UNIV

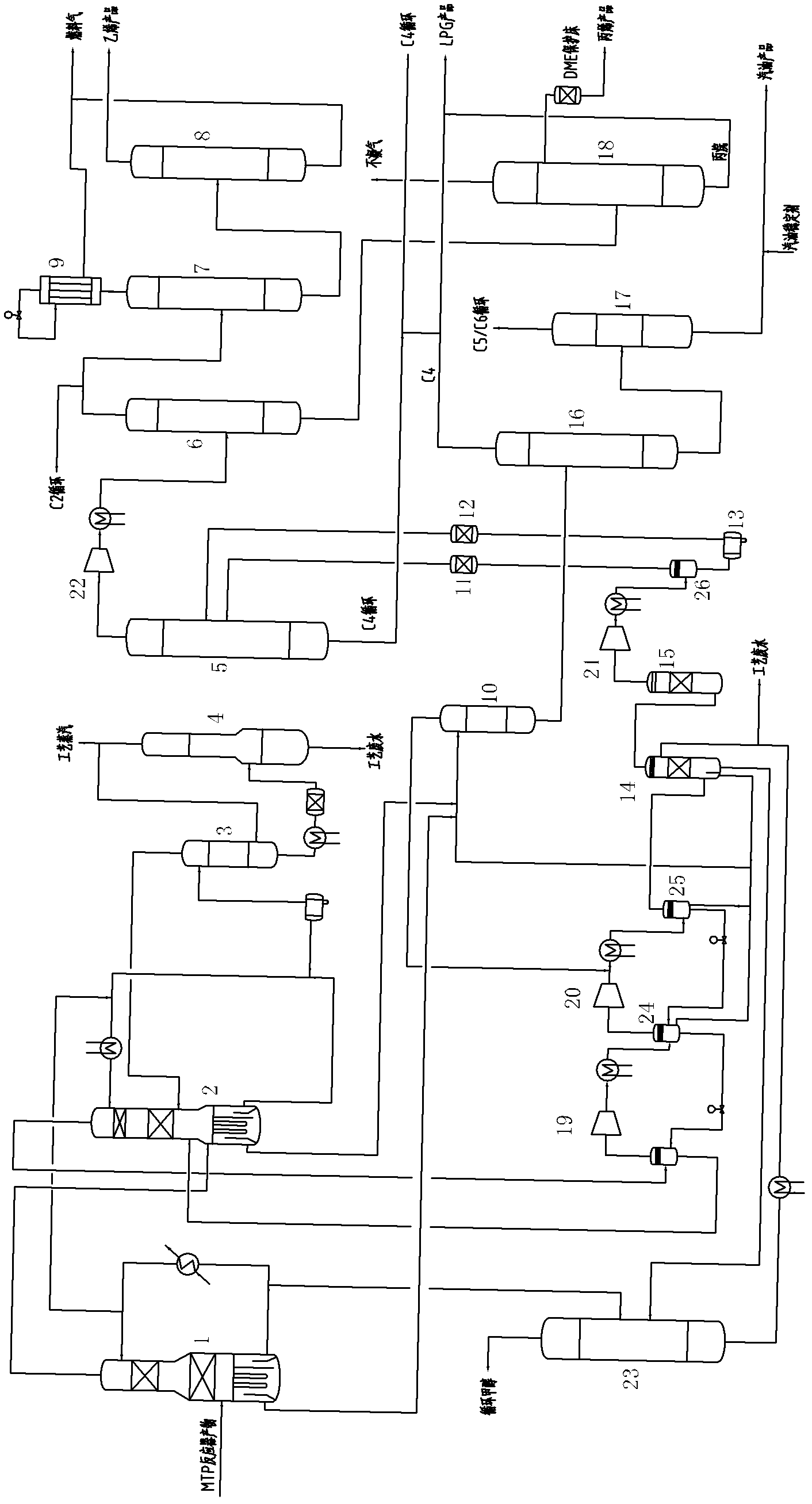

Method and system for separating MTP (Methanol to Propylene) reaction mixed gas

ActiveCN102304009BReduce corrosionReduce circulationChemical industryHydrocarbon purification/separationLoss rateQuenching

The invention relates to a method and a system for separating MTP (Methanol to Propylene) reaction mixed gas, wherein quenched water of a pre-quenching tower and a quenching tower kettle is respectively treated; gas hydrocarbon obtained at a compression II section is water-washed and alkali-washed and then enters a compression III section; the gas hydrocarbon obtained at the compression III section and liquid hydrocarbon not containing heavy hydrocarbons of C6 and more are respectively dried by the gas hydrocarbon, are flocculated by the liquid hydrocarbon and are dried, and then are conveyedinto a depropanization tower; a condensate stripping tower is arranged between the compression sections and is used for separating the condensate between the compression sections; light hydrocarbon components are returned back to the outlet of the compression II section and a heavy hydrocarbon components are respectively conveyed to a debutanization tower to be refined; the depropanization tower is arranged between the compression III section and a compression IV section and utilizes a regular rectification; the tower top of a demethanation tower is provided with a differential condenser for recycling refrigeration capacity thereof and reducing the loss rate of ethylene. The method and the system provided by the invention can effectively optimize technical flows, reduce system power consumption, reduce pipe corrosion and reduce investment cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

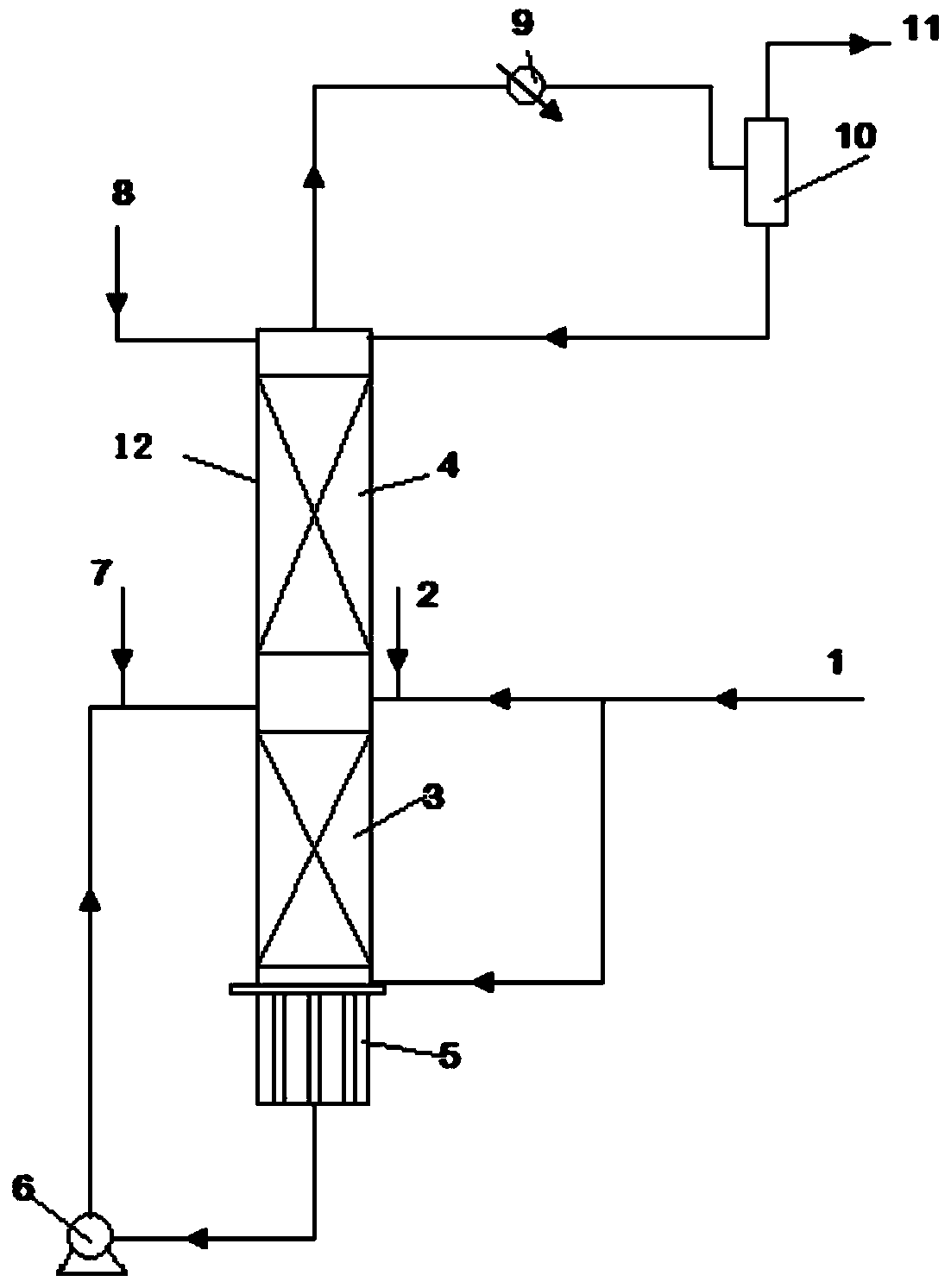

Methyl nitrite regeneration method

ActiveCN103936591AHigh regeneration rateFull recoveryChemical recyclingNitrous acid preparation ester preparationAlcoholReboiler

The invention discloses a methyl nitrite regeneration method, and is used for solving the problems of low regeneration rate of methyl nitrite, poor operational stability of a system caused by improper side reaction control, increase of operating cost and the like. The methyl nitrite regeneration method comprises the following steps: forming recycled gas containing 5-20% of nitric oxide after synthesis of methyl nitrite and carbon monoxide carbonyl, and entering the recycled gas to a methyl nitrite regeneration reactor in two parts, wherein a small part of recycled gas enters the lower section of the regeneration reactor from the bottom, the rest part of recycled gas and supplementing oxygen gas enter the upper section of the regeneration reactor from the middle part together; spraying fresh methyl alcohol into the tower top of the regeneration reactor, discharging methyl nitrite-containing gas from the tower top, pressurizing tower bottoms led out from the tower by using a pump and entering the tower bottoms to the lower section of the regeneration reactor from the middle part of the regeneration reactor; arranging a reboiler on the tower of the regeneration reactor, filling the lower section of the regeneration reactor with a catalyst, and arranging stuffing and / or a tower plate on the upper section of the regeneration reactor. The methyl nitrite regeneration method is simple in process, low in equipment investment and operating cost and high in regeneration rate of methyl nitrite and can be used for effectively solving the side reaction problem.

Owner:WUHUAN ENG +2

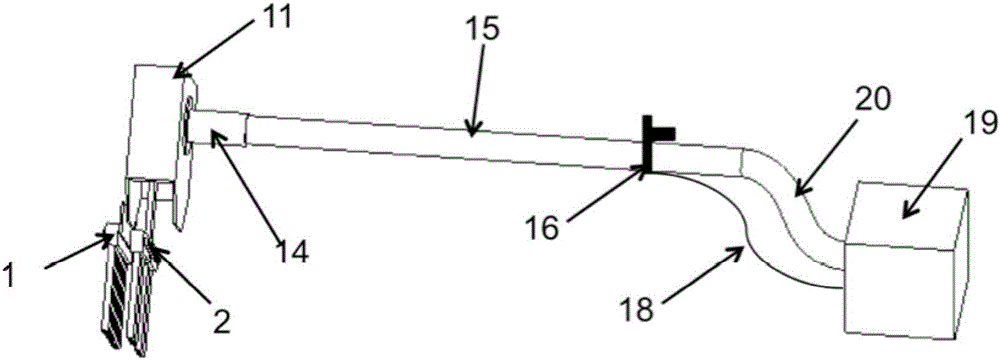

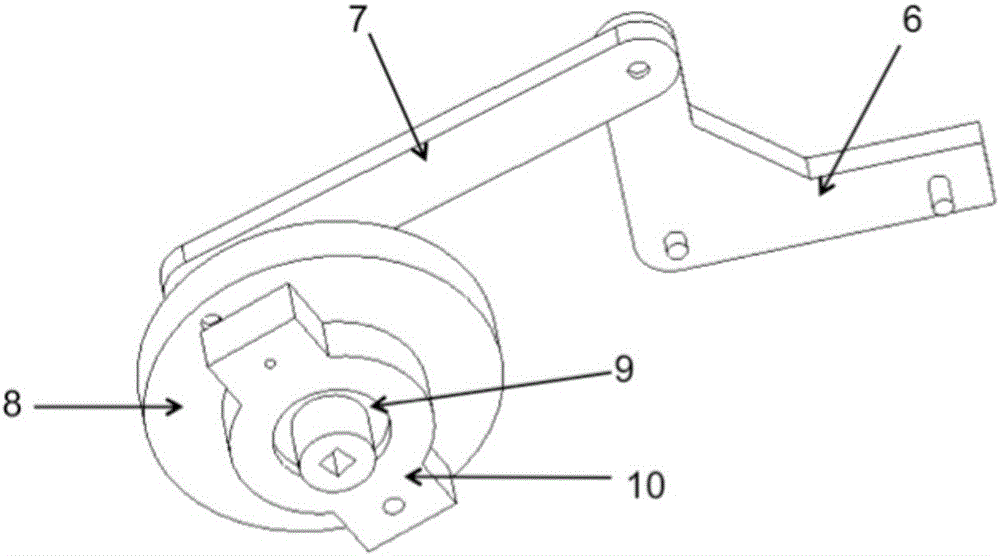

Combined vibrating comb type fruit picking device

ActiveCN106576603AImprove recovery rateSimplify subsequent processesPicking devicesEngineeringElectrical and Electronics engineering

Owner:SOUTH CHINA AGRI UNIV

Traction type hydraulic driving water tank cutting machine and using method thereof

ActiveCN107355256ASimplify subsequent processesSpeed up the progress of the projectDrainageStone-like material working toolsVehicle framePiston pump

The invention discloses a traction type hydraulic driving water tank cutting machine and a using method thereof. The cutting machine comprises a frame; a first hydraulic motor and a second hydraulic motor are arranged on the frame; the output end of the first hydraulic motor is connected with a first drive shaft; a first cutting piece and a second cutting piece which are arranged in a spaced mode are fixed to the first drive shaft; and the output end of the second hydraulic motor is connected with a second drive shaft, a rotating disc is fixed to the second drive shaft, and a plurality of cutting teeth which are arranged by certain angles are arranged on the rotating disc. An electric motor is arranged on the frame; the output end of the electric motor is connected with a crank piston pump; the two sides of the crank piston pump are connected to an oil tank through a first double-valve body and a second double-valve body correspondingly; and an oil outlet of the crank piston pump is connected to oil inlets of the first hydraulic motor and the second hydraulic motor; and a travelling part is arranged at the bottom of the frame. Machines are adopted to replace manual work, the time and labor are saved, convenience and high efficiency are achieved, a water tank with the two level sides can be opened, the subsequent process is facilitated, the situation that accumulation water in a roadway is discharged in time is facilitated, the project progress is accelerated, and the work efficiency is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

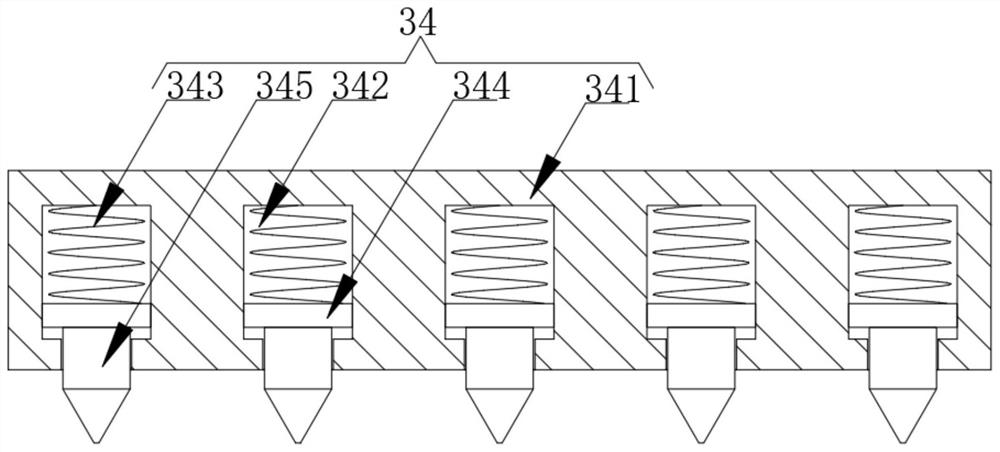

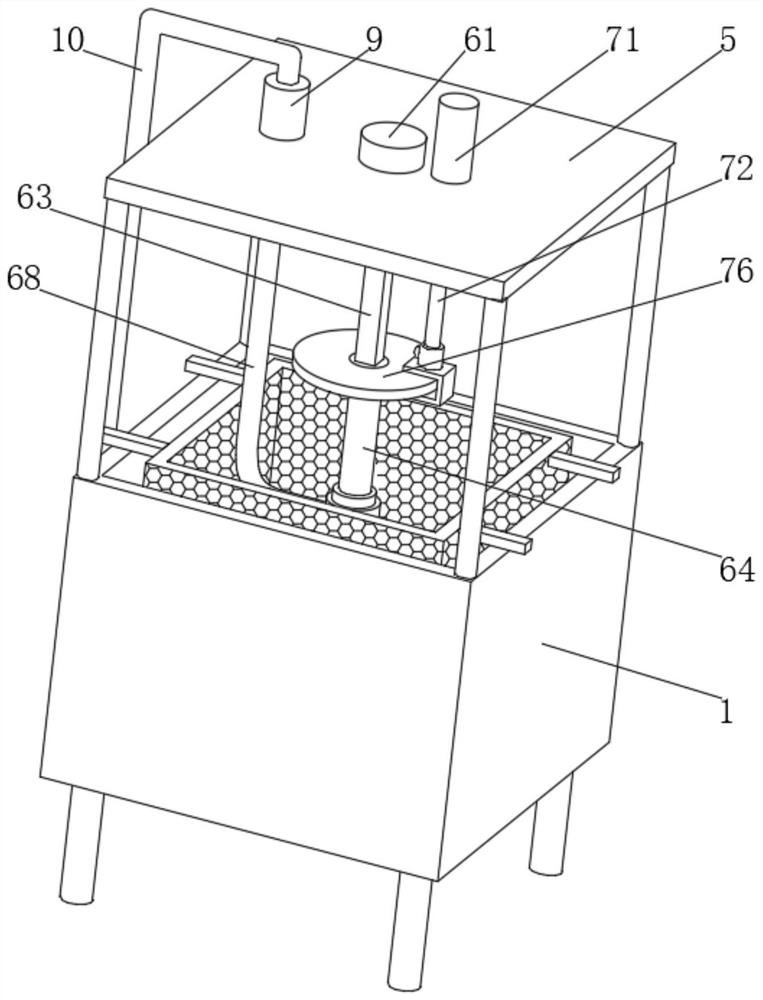

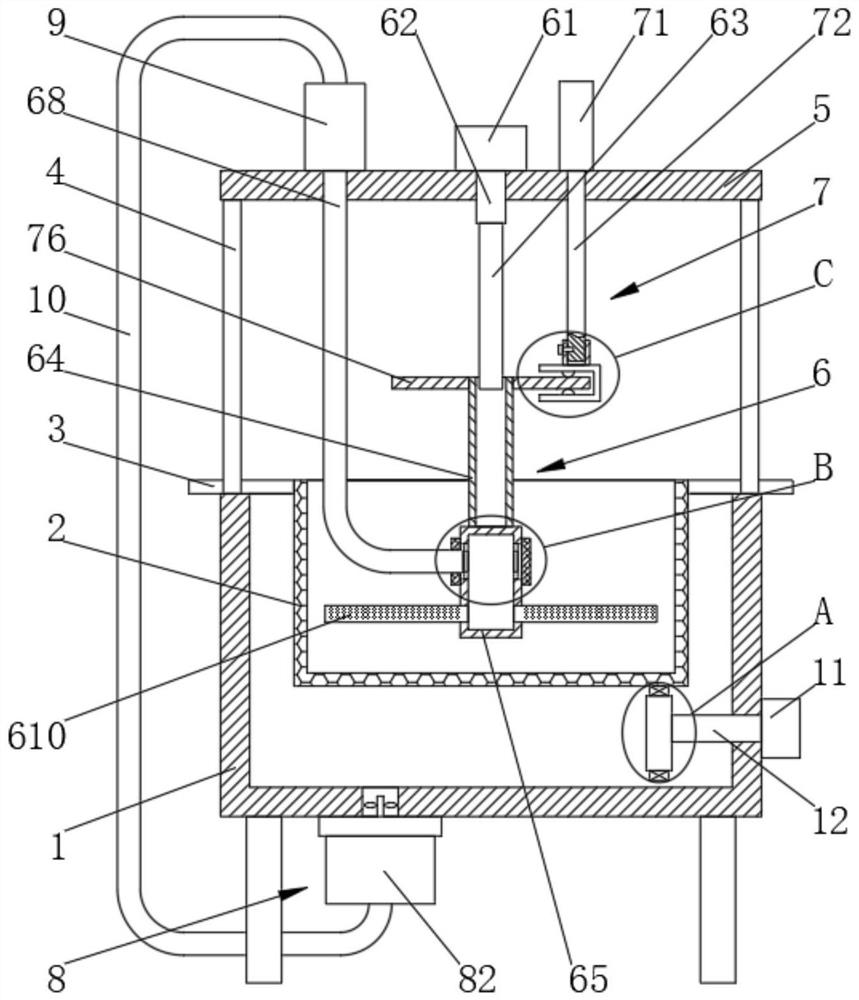

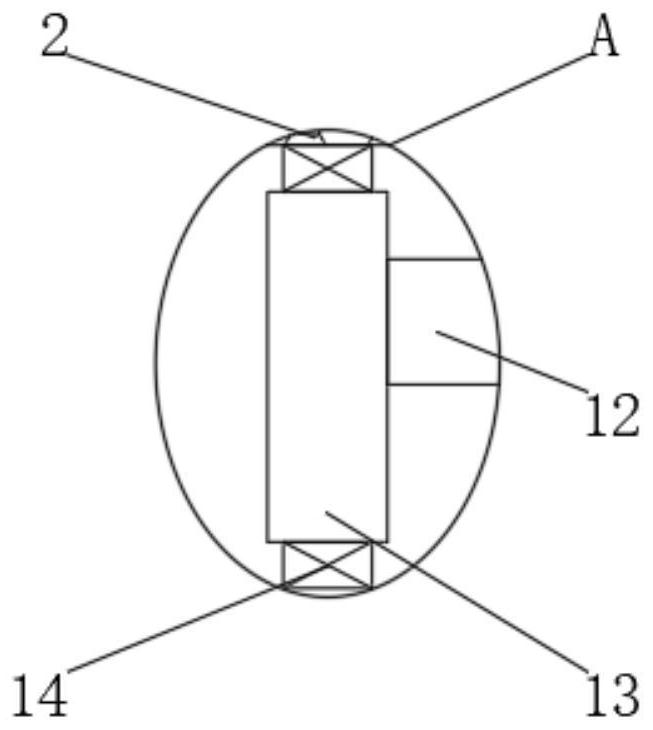

Plant active ingredient extraction device capable of performing secondary extraction

ActiveCN111746023ASimplify subsequent processesImprove practicalityPressesBiotechnologyBULK ACTIVE INGREDIENT

The invention discloses a plant active ingredient extraction device capable of performing secondary extraction. The plant active ingredient extraction device comprises an extraction box, the peripheryof the bottom of the extraction box is fixedly connected with adjusting bases, and the top of the extraction box is fixedly connected with a primary extraction mechanism. The invention relates to thetechnical field of extraction. According to the plant active ingredient extraction device capable of performing secondary extraction, the primary extraction mechanism is arranged at the top of the extraction box and matched with a needling mechanism at the bottom end of an electric extendable rod, then a compression spring in the needling mechanism and a pricking needle at the bottom of a slidingplate are utilized, and when the electric extendable rod moves downwards, under the action of the compression spring, a storage plate can make contact with storage stalks as much as possible, so thatthe pricking needle can prick thin plant stalks; when the pricking needle meets thick stalks, under the action of the compression spring, the pricking needle does not move, and the storage plate moves downwards; and the structure is simple, the device can adapt to the stalks of different thicknesses, and the practicability of the device is improved.

Owner:东莞市国丰化妆品有限公司

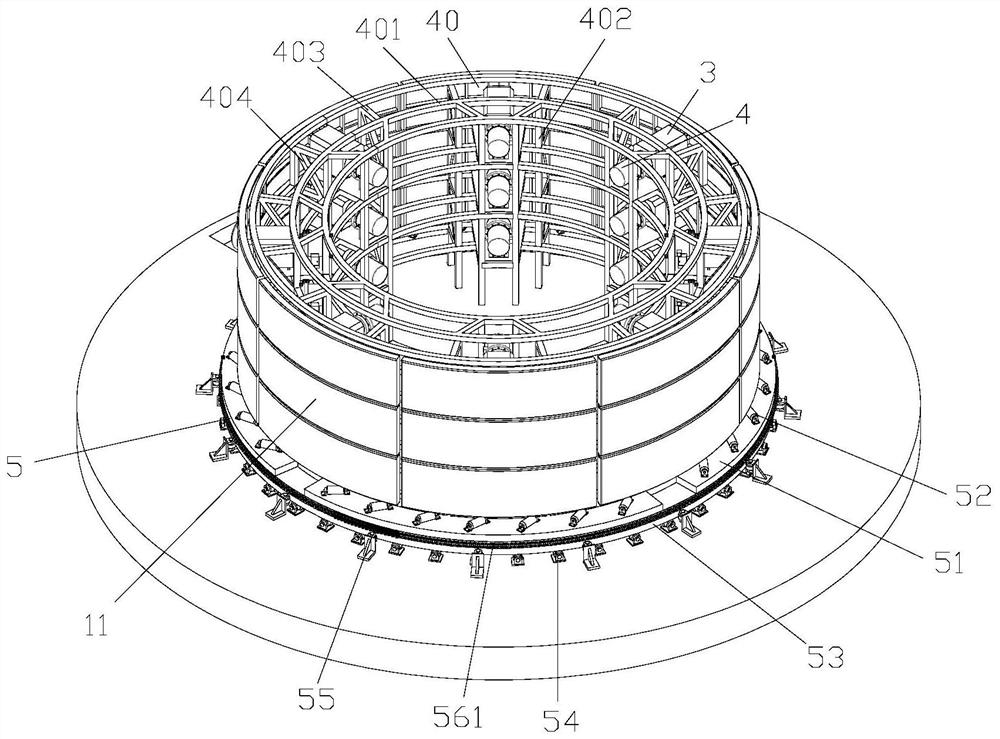

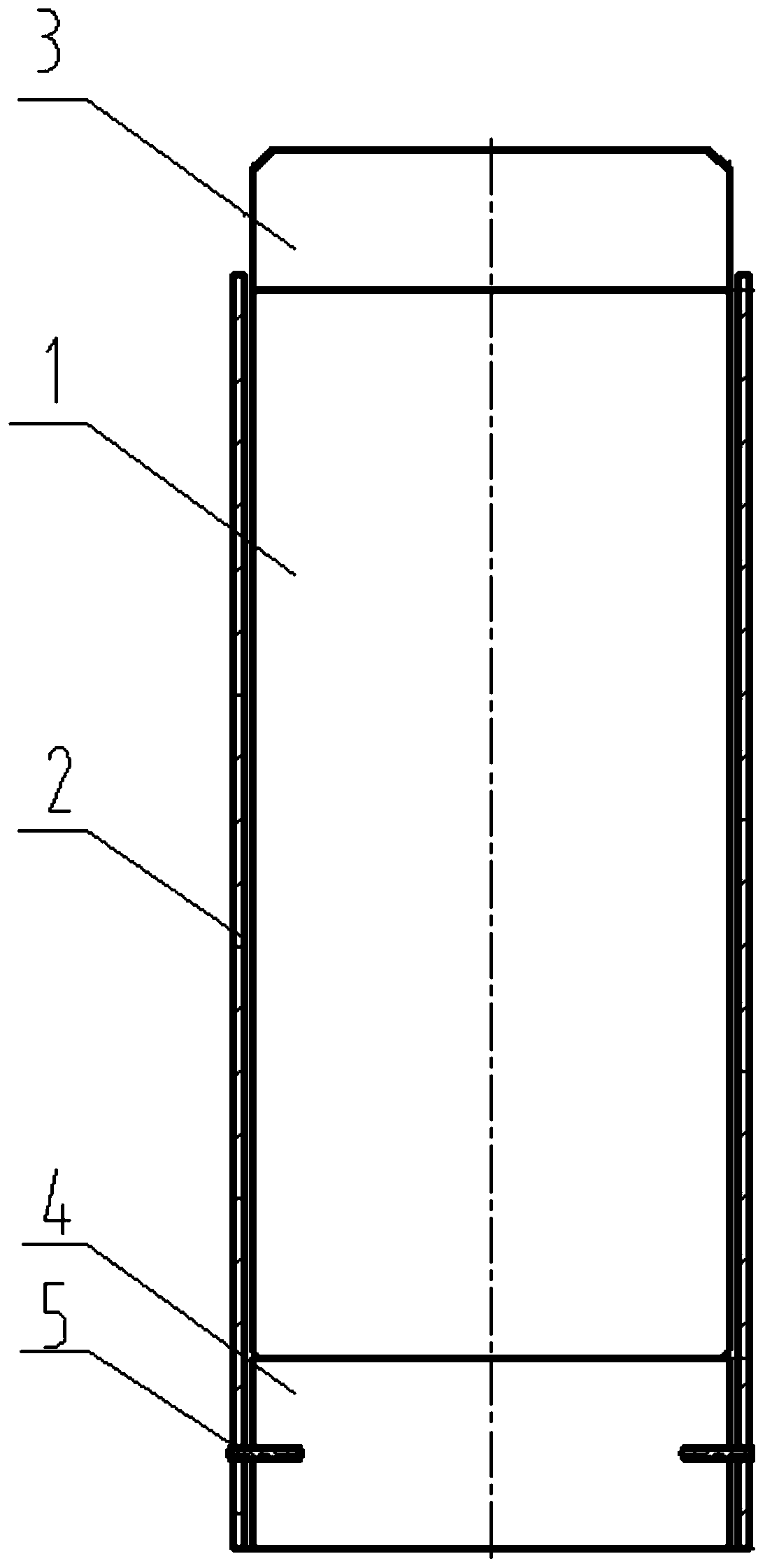

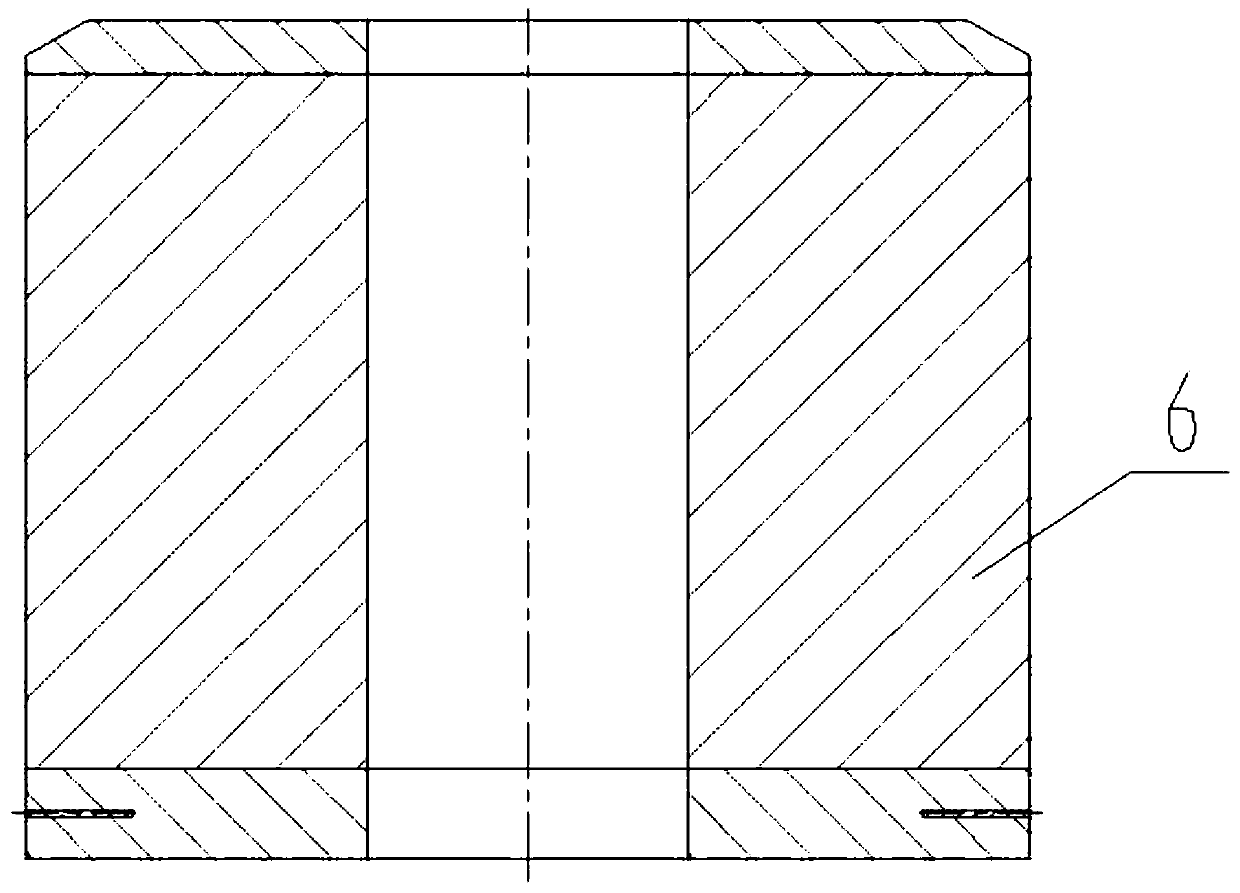

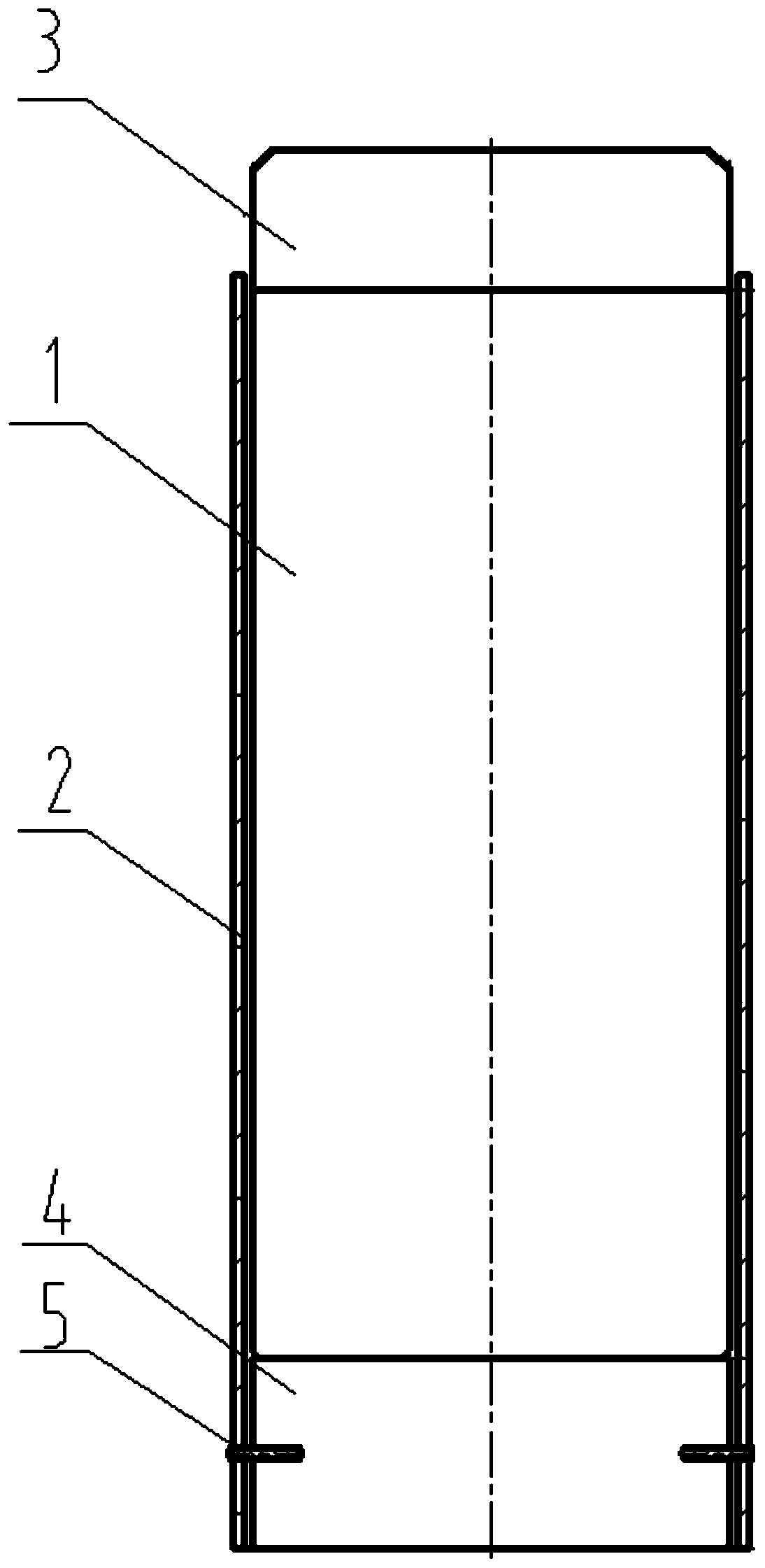

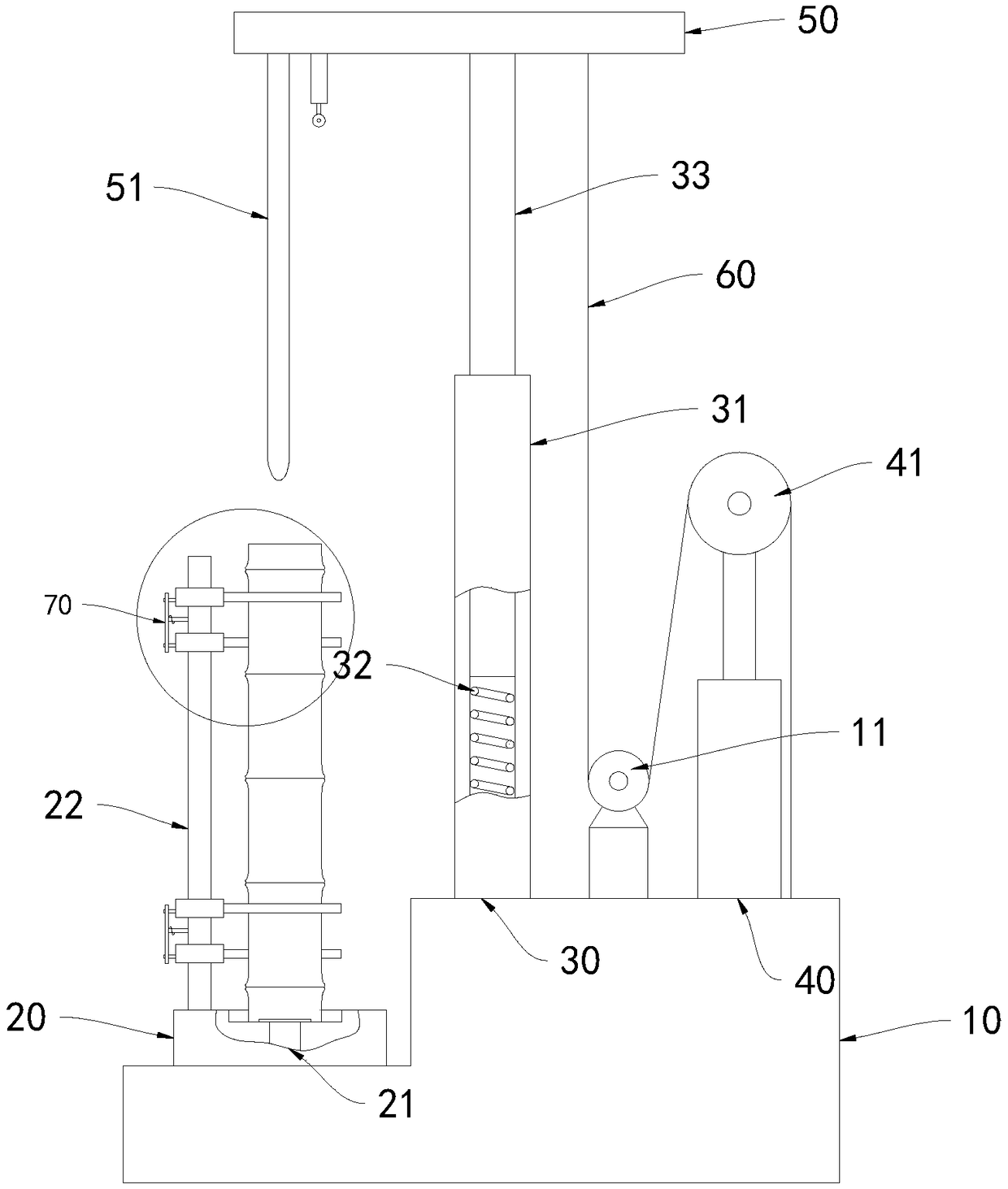

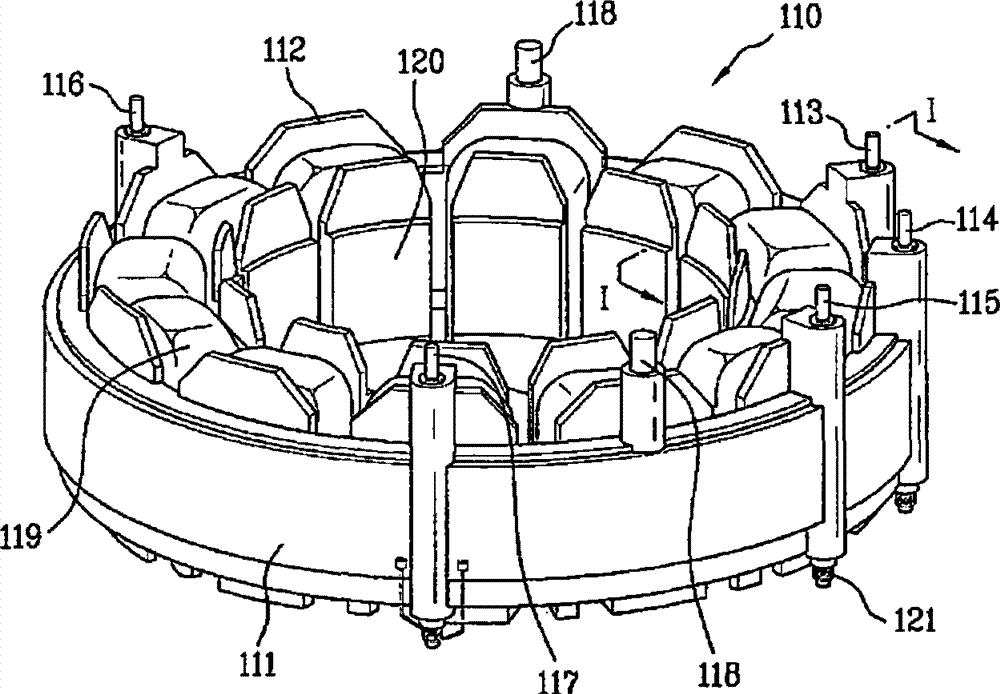

Thin-walled cylinder precise shape control equipment

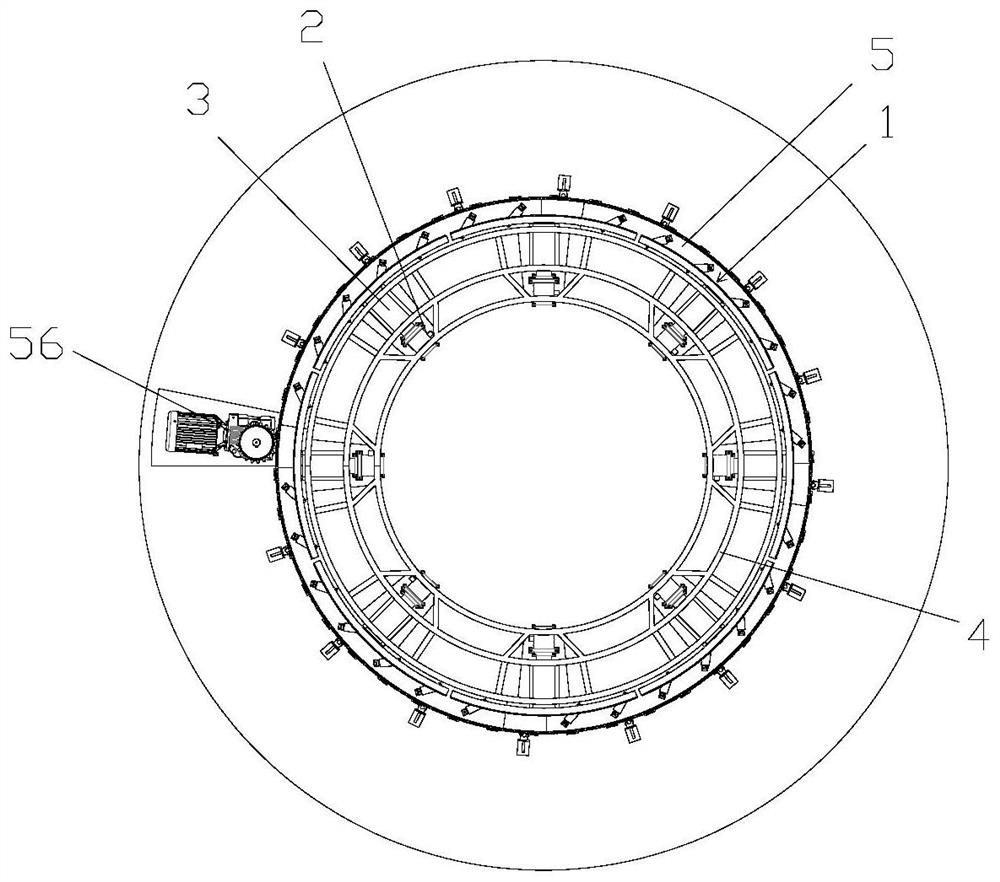

PendingCN111822548AHigh shape control accuracyNo wall thickness reductionShaping toolsMetal working apparatusMechanical engineeringPiston rod

The invention provides thin-walled cylinder precise shape control equipment. The equipment comprises a rotary supporting table used for supporting a workpiece in the shape correcting process and rotating the workpiece in the cooling shrinkage process, precise shape control inner tube molds uniformly distributed around the circle center of the rotary supporting table and are used for providing an arc surface required during shape control and shape correction force conduction during working, a hydraulic push cylinder which is connected with the precise shape control inner tube molds and is usedfor precise precise shape control inner tube mold micro-distance movement, a guide device which is arranged on a piston rod of the hydraulic push cylinder and is used for guiding the axial movement ofthe hydraulic push cylinder and positioning the guide direction, and a support which is annularly mounted on the ground by taking the circle center of the rotary supporting table as the center and isused for fixing the hydraulic push cylinder and the guide device. The equipment is used for precisely controlling the shape of the ultra-large-diameter thin-walled cylinder, the shape control precision is high, the wall thickness is not reduced, the residual stress after precise shape control is small, and subsequent procedures can be simplified, and meanwhile, the taper of an inner tube mold isadjustable and can adapt to precise shape control of workpieces such as conical barrels.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH +1

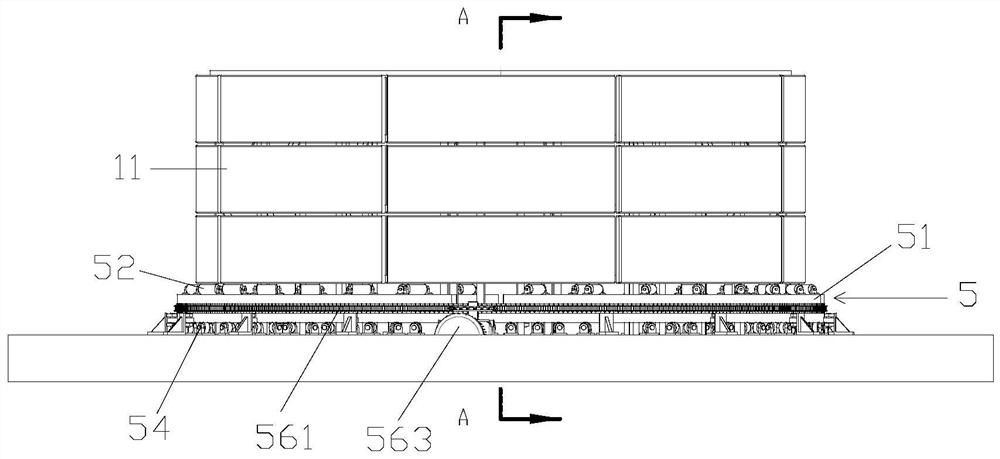

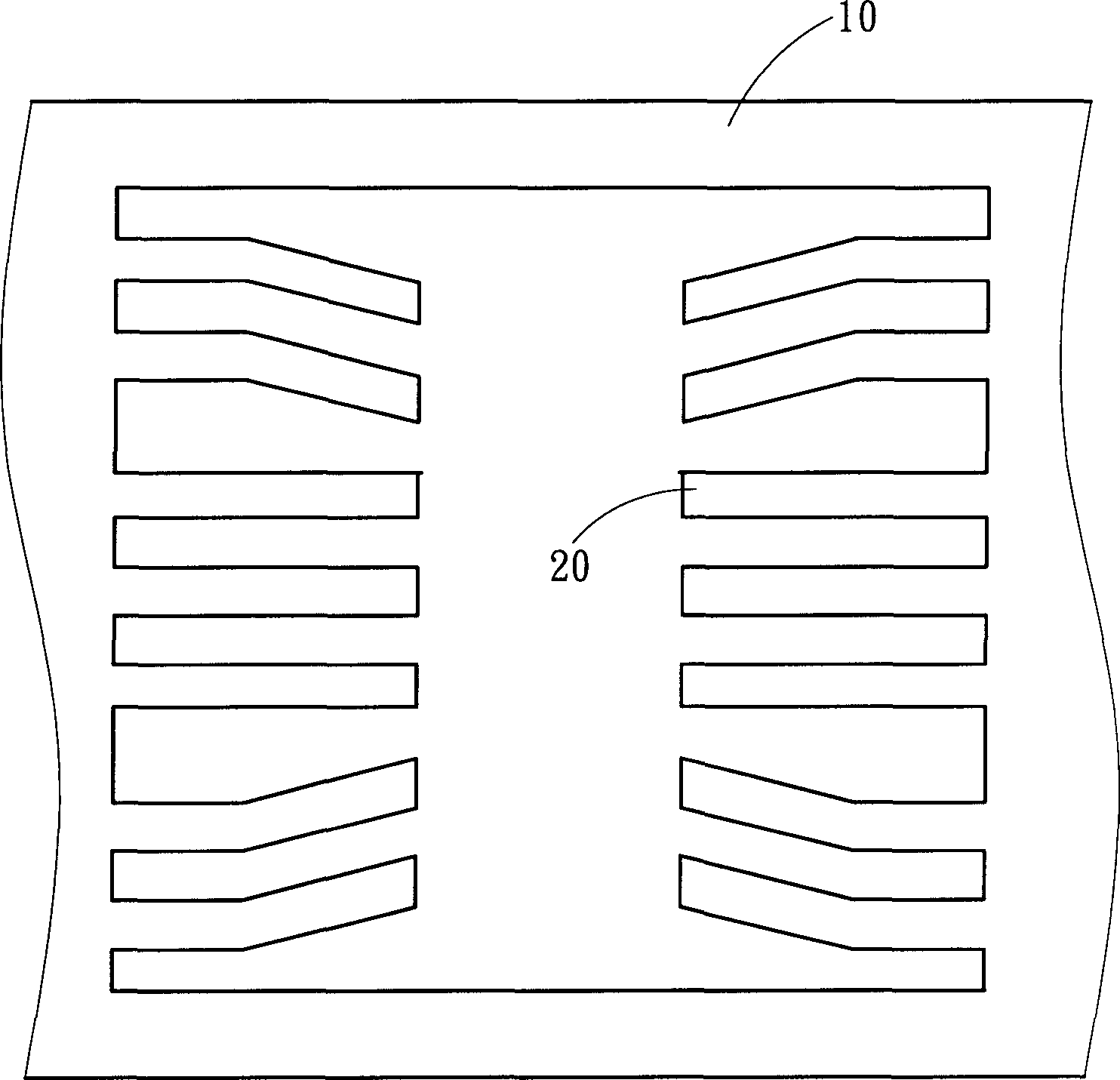

LED material strap manufacturing method

Provided is an LED material strap manufacturing method, including the steps of: providing a metal substrate; cutting the metal substrate to form a connection framework and a plurality of bearing sheets, wherein one end of each bearing sheet is in connection with the connection framework, and each bearing sheet includes a plurality of conductive segments arranged at intervals; an insulation segment formed between any two adjacent conductive segments so as to connect the two conductive segments; and a plurality of insulation frames arranged at intervals on each bearing sheet, wherein each insulation frame corresponds with the position of one of the insulation segments to enclose a recess on the upper surface of each carrying sheet, and each insulation segment and two conductive segments connected by insulation segments are exposed in corresponding recesses.

Owner:I CHIUN PRECISION ELECTRIC IND CHINA

Preparation method of large-size titanium alloy hollow blank

The invention discloses a preparation method of a large-size titanium alloy hollow blank. A hard sleeve is used to sleeve a titanium alloy ingot, a heating anti-oxidation coating is applied on the surface of the sleeve, the sleeve is placed in a heating furnace for preheating and then is heated to 150-200 DEG C above the beta phase transition point of the titanium alloy ingot for heat preservation, the sleeve is subjected to closed upsetting a plurality of times on a large blank making press, and the deformed titanium alloy ingot is punched to obtain the titanium alloy hollow blank. The methodsolves that difficult problem of preparing large hollow blanks with a diameter phi greater than 950 mm, avoids the problems of surface cracks and wrinkles, and has uniform blank deformation.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Absorption additive chitosan-Cu compound used in cigarette filter tip and its preparation method

InactiveCN1286408CGood removal effectAchieve focus reduction and harm reductionTobacco smoke filtersOrganic solventTar

Owner:JIANGNAN UNIV

Burning-free and steam curing-free brick and preparation method thereof

InactiveCN108568893AGood mixing effectImprove the use effectMixing operation control apparatusCeramic shaping plantsBuilding materialEngineering

The invention relates to the technical field of building materials and in particular relates to a burning-free and steam curing-free brick and a preparation method thereof. The burning-free and steamcuring-free brick comprises a body, and is characterized in that the right side of the body is fixedly connected with a crushing box; the right side of the crushing box is fixedly connected with a fixing shaft; the right side of the fixing shaft is fixedly connected with a threaded rod; a crushing port is formed in the top of the crushing box; a crushing groove is formed in the bottom of the crushing box; rotating shafts are symmetrically and fixedly arranged on the left and right sides of inner walls of the crushing box; a crushing roller is fixedly connected between the rotating shafts; regulating valves are symmetrically arranged on the crushing box and positioned on the fixing shaft; a discharging hole is formed in the bottom of the crushing box; a feeding hole of a proportioning cavity is formed just under the feeding hole; and a stirring device is arranged inside the proportioning cavity. According to match of the crushing box, the crushing roller and a filter box, the mixing effect of ingredients is excellent by virtue of the stirring device, the using effect is enhanced after proportioning, the brick quality is improved, the using effect is excellent, and the practicality is high.

Owner:夏高莺

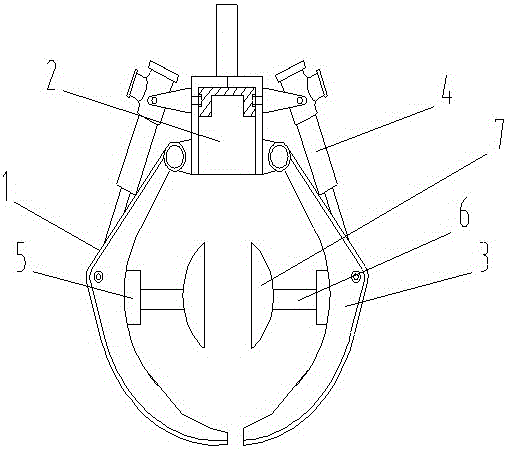

Grab bucket with internal material compressing function

InactiveCN105776005AReduce material occupation spaceSimplify subsequent processesLoad-engaging elementsEngineering

Owner:WUXI PETROCHEM CRANE CO LTD

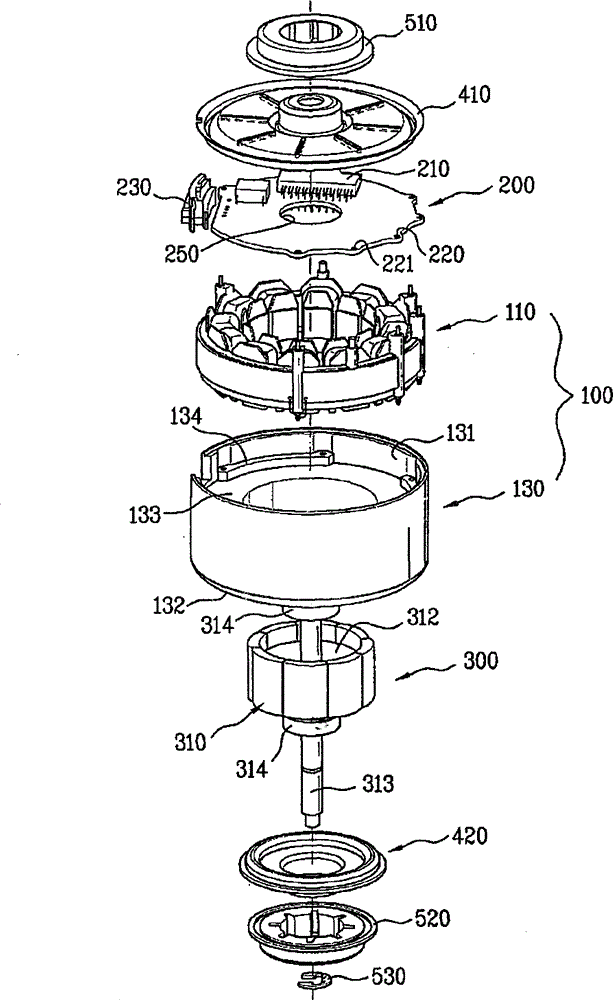

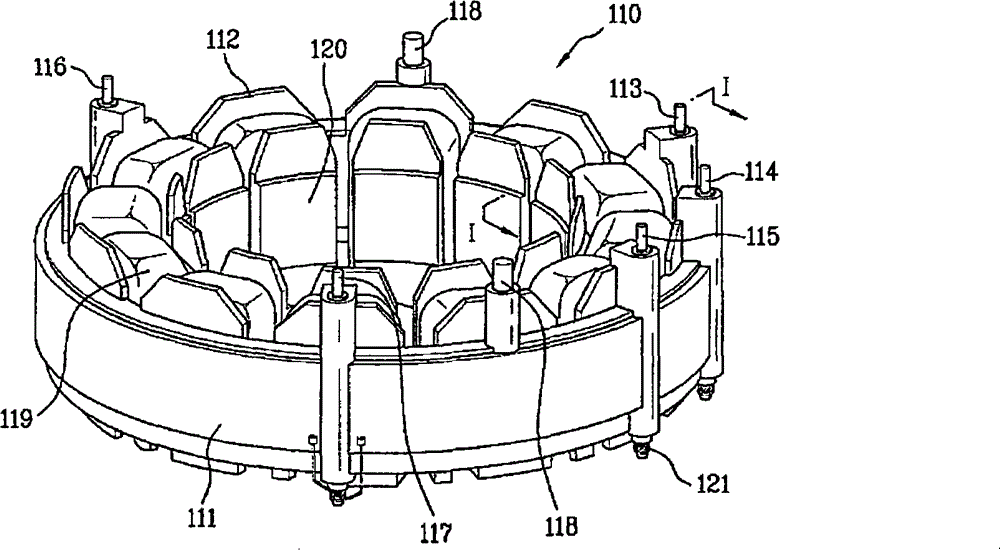

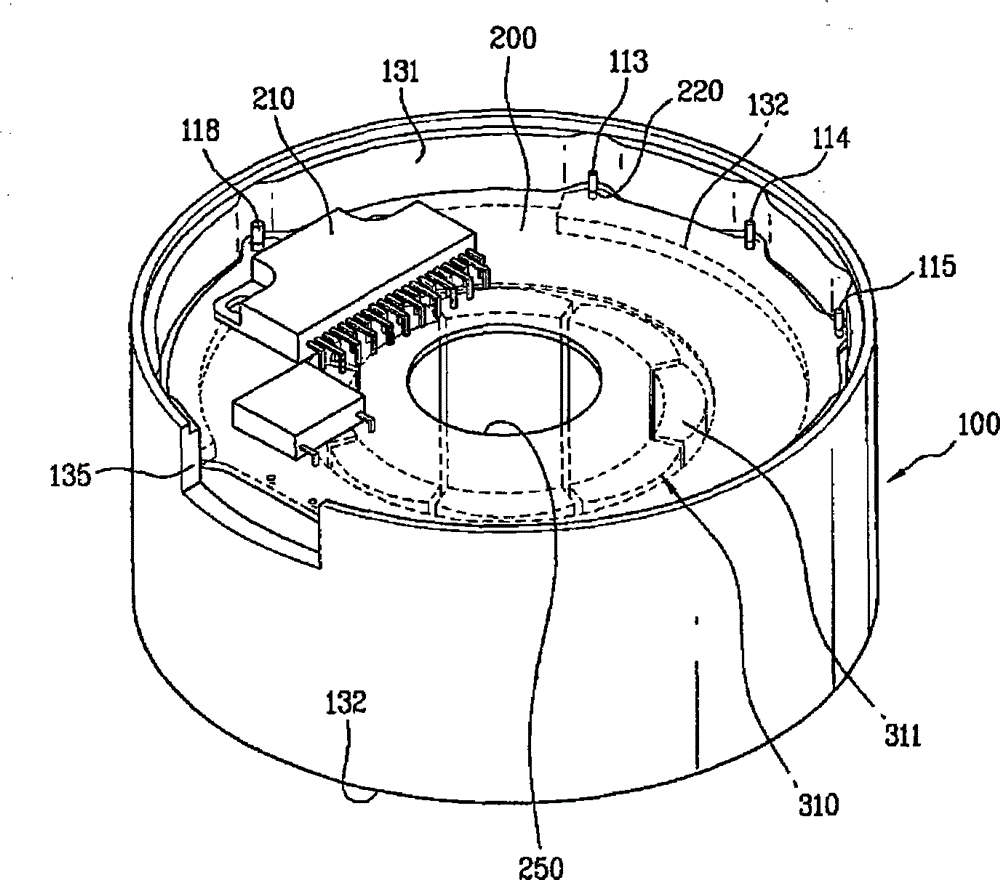

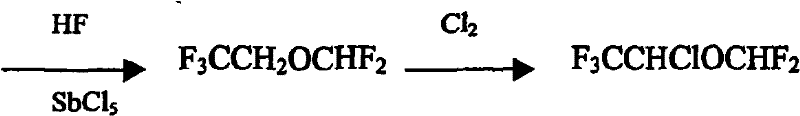

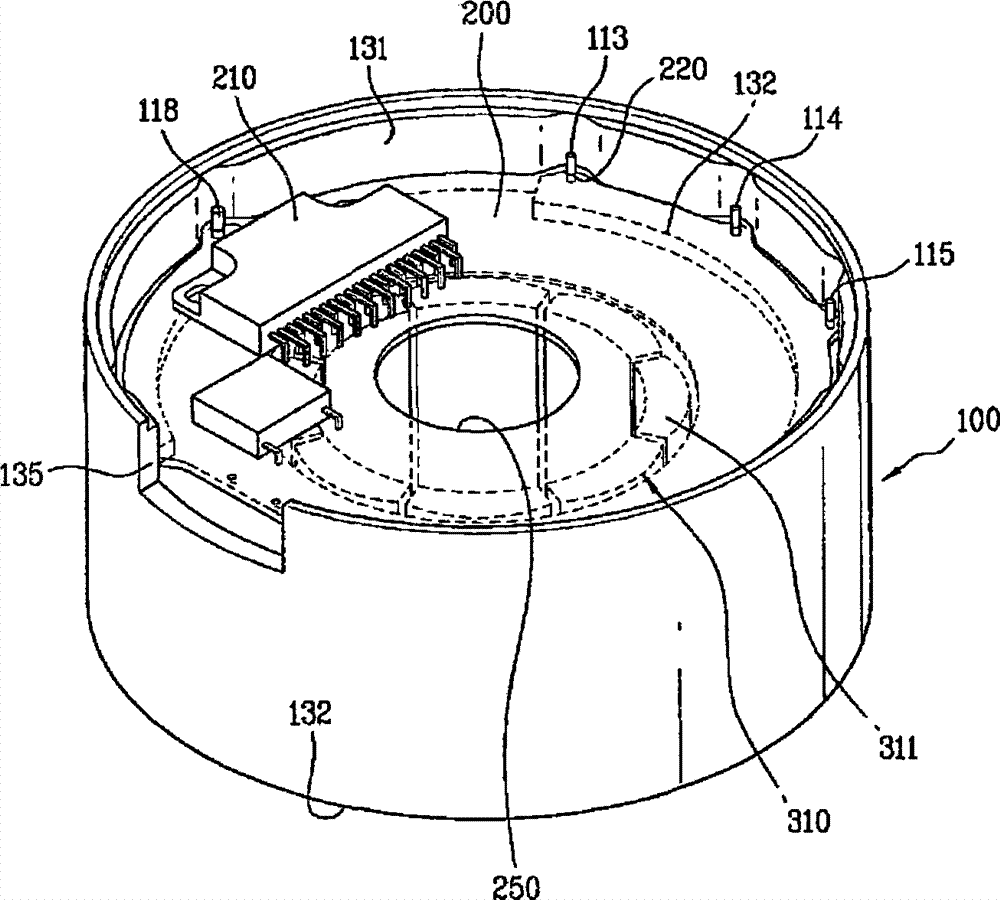

Motor

InactiveCN101588089BEasy to manufactureSmall form factorAssociation with control/drive circuitsWindings insulation shape/form/constructionEngineeringPrinted circuit board

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Continuous and stable coarse slime sorting machine heavy product discharging device and method

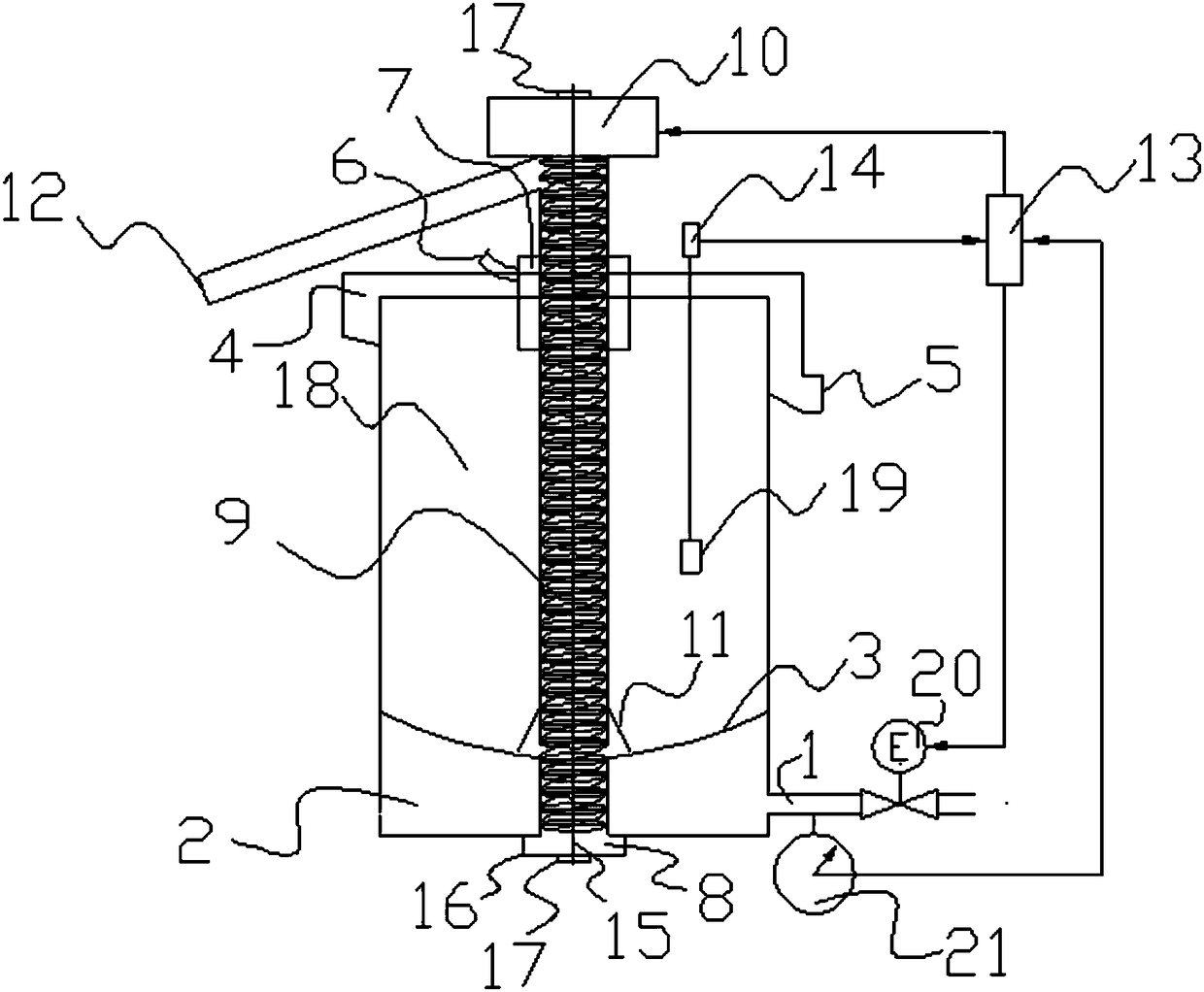

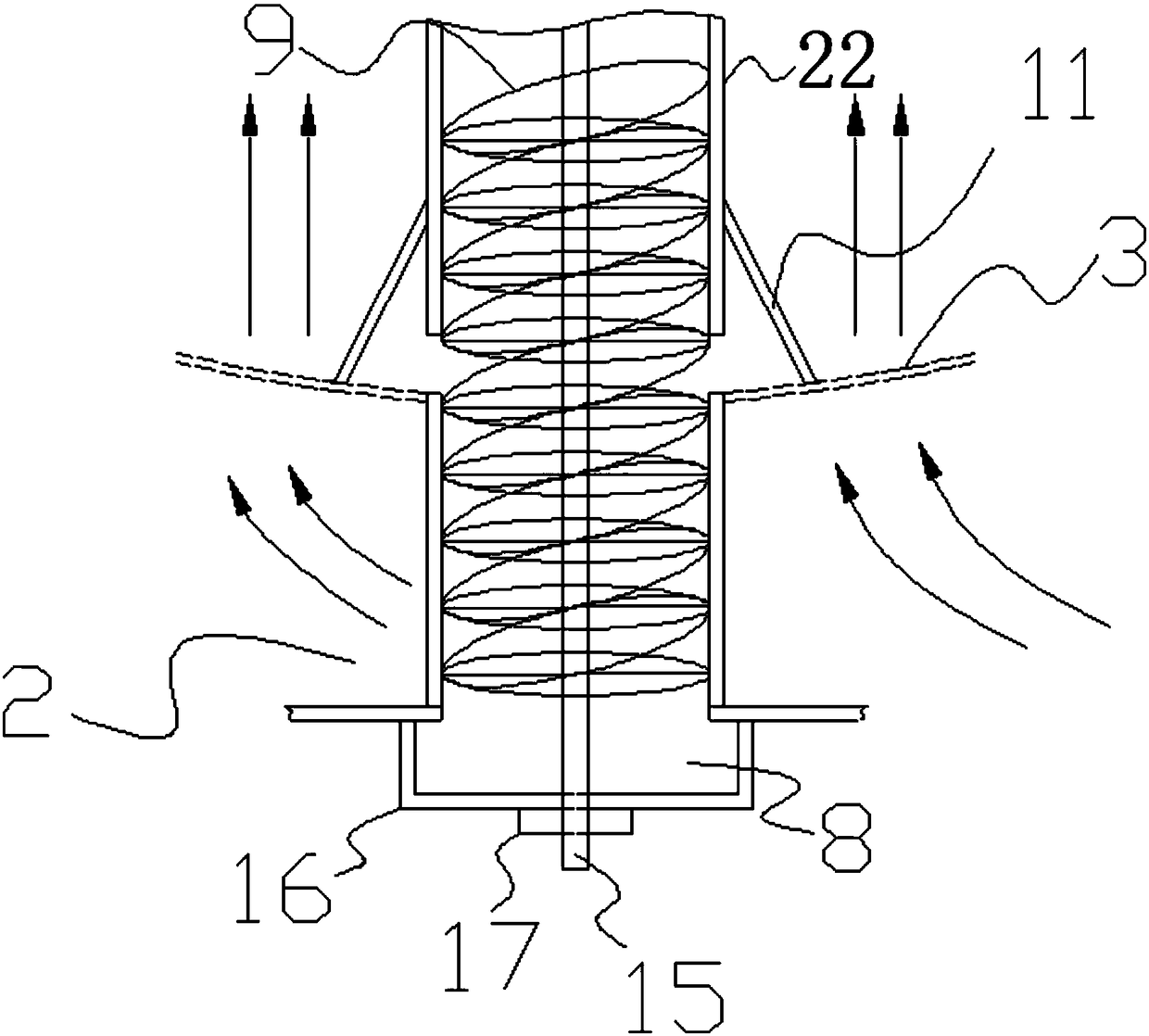

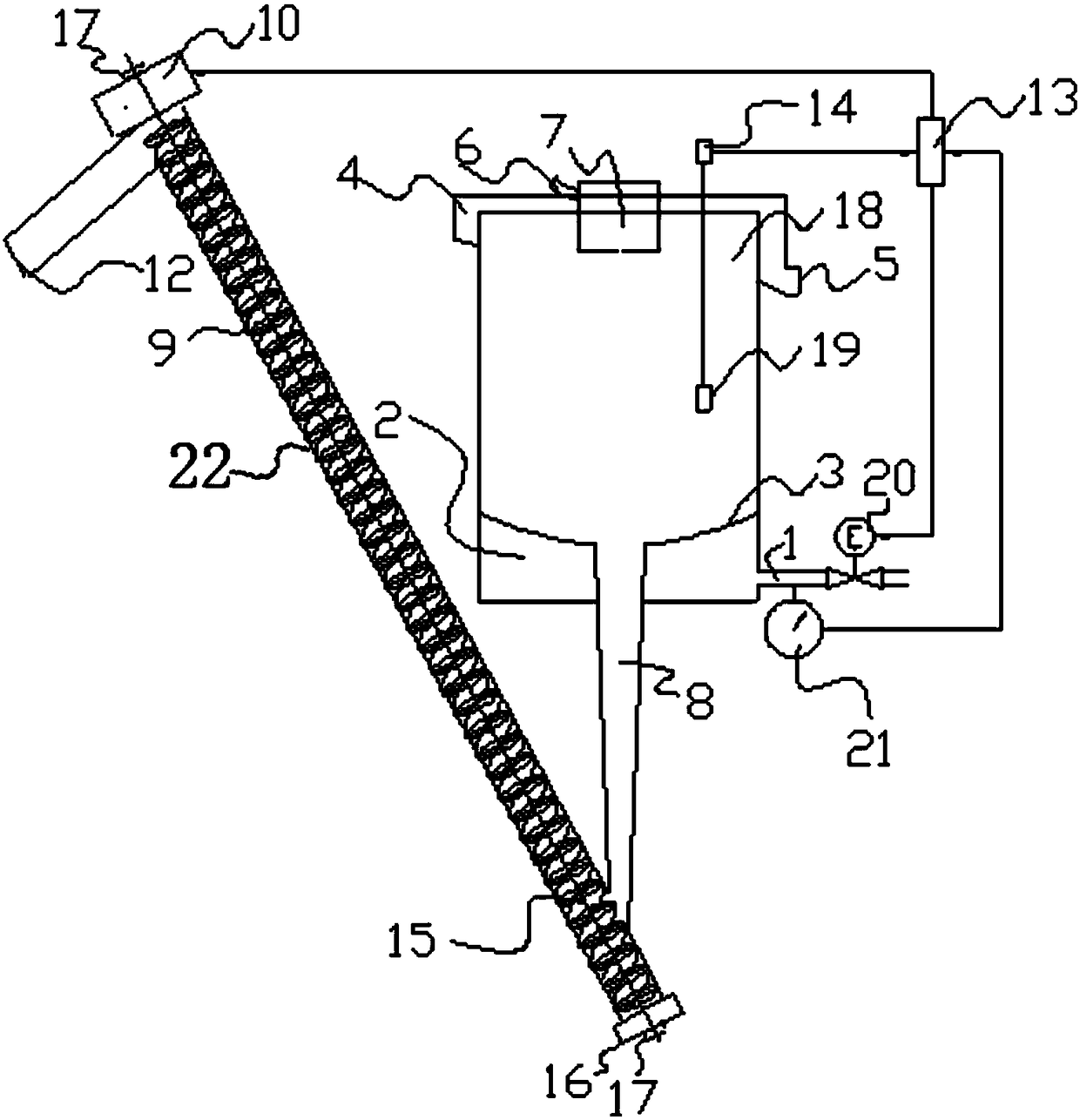

ActiveCN108057512AContinuous and stable dischargeImprove sorting efficiencyWet separationAutomatic controlControl system

The invention discloses a continuous and stable coarse slime sorting machine heavy product discharging device and method. The device comprises a sorting machine body, a water feeding system, a feedingsystem, a light product overflow system, a heavy product discharging system and an automatic control system. The water feeding system comprises a water tank arranged at the bottom of the sorting machine body. A water flow distributor is arranged at the upper portion of the water tank and provided with a plurality of holes. The feeding system is arranged at the center position of the top of the sorting machine body. The light product overflow system is arranged on the outer side of the upper portion of the sorting machine body .The heavy product discharging system comprises a heavy product collecting tank, a heavy product outlet and a spiral elevating device. The automatic control system comprises an automatic controller, a density measurer, a density sensor, a control valve, a water feeding pressure intensity meter and a control circuit. By means of the continuous and stable coarse slime sorting machine heavy product discharging device and method, disturbance on sorting from discharging is reduced, the sorting efficiency is greatly improved, the property of heavy products is stable, the water content is low, and the heavy product water removal treatment is reduced.

Owner:CHINA UNIV OF MINING & TECH

Bamboo inner joint breaking machine easy to clamp

ActiveCN108724370AEasy to disassemble and cleanImprove filtering effectCane mechanical workingEngineeringPiston rod

The invention discloses a bamboo inner joint breaking machine easy to clamp. The bamboo inner joint breaking machine comprises a machine seat. The machine seat is provided with a bamboo storing seat,an elastic telescopic device and an air cylinder. An upper beam is fixed to the top end of the elastic telescopic device and provided with a jacking rod for breaking bamboo inner joints. A chain wheelis arranged on a piston rod of the air cylinder. A power chain is wound around the chain wheel. One end of the power chain is fixed to the machine seat, and the other end of the power chain is fixedto the upper beam. A liquid outlet pipeline is arranged at the bottom of the bamboo storing seat. A double-claw linkage clamping device is arranged beside the bamboo storing seat. The bamboo inner joint breaking machine has the characteristics that cleaning is easy, tiny particles are avoided, and clamping is easy.

Owner:陈立新

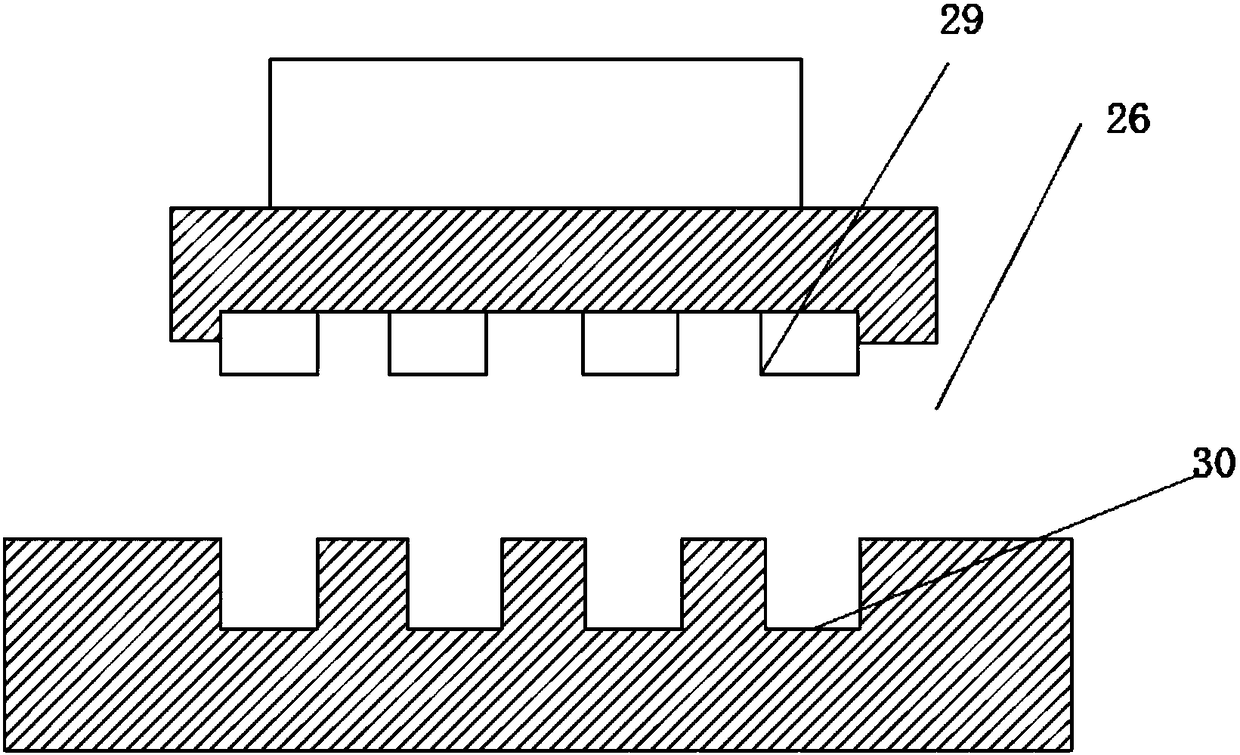

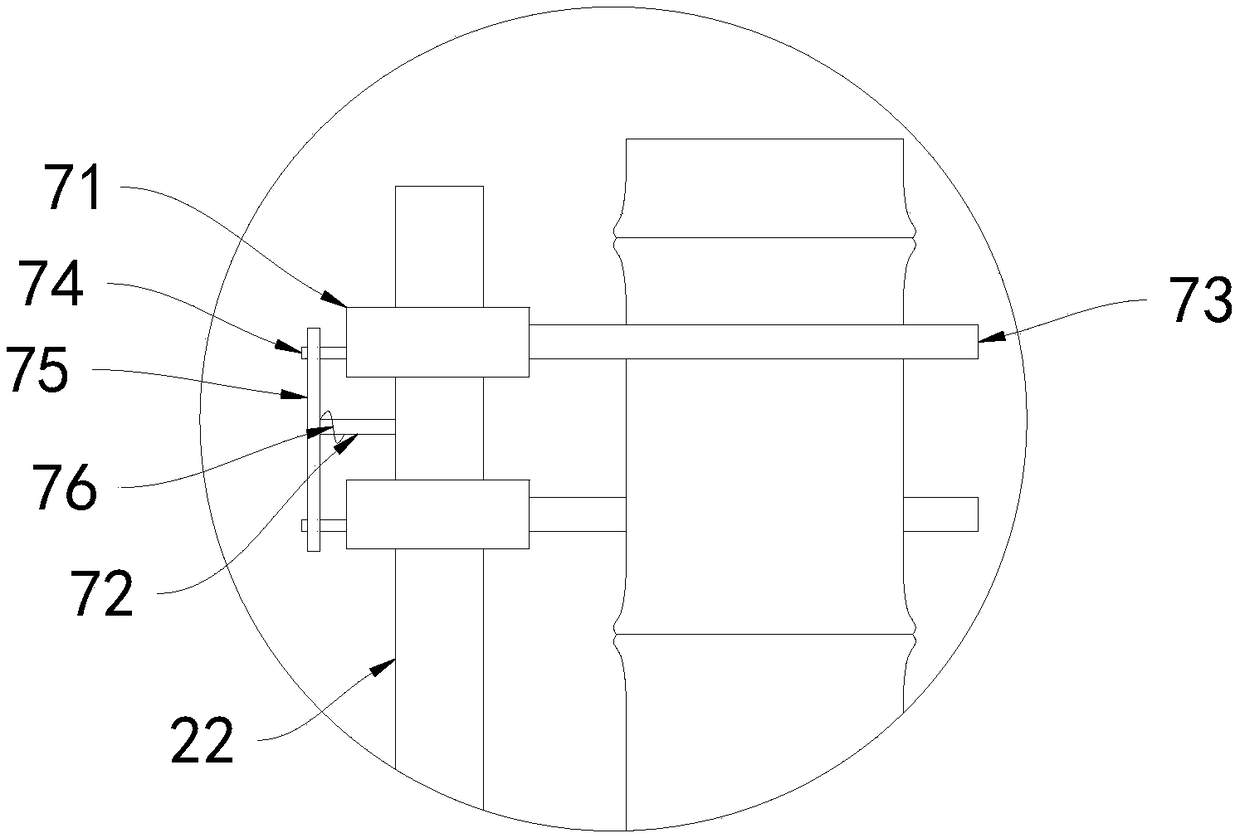

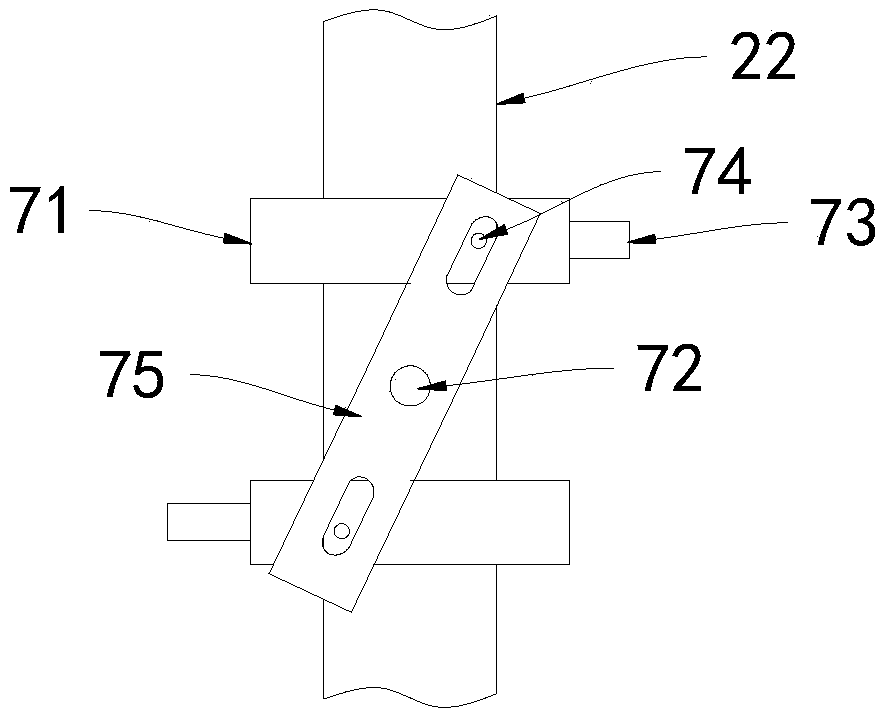

Multi-core-group capacitor strip trimming machine and working method thereof

PendingCN112786315ASame lengthSimplify subsequent processesCapacitor manufactureElectrical and Electronics engineeringWaste material

The invention provides a multi-core-group capacitor strip trimming machine and a working method thereof. The machine comprises an operation table, a limiting track transversely arranged on the operation table and used for placing a capacitor strip, a rotating mechanism arranged on the operation table, a first eccentric wheel and a second eccentric wheel which are arranged on the rotating mechanism at an interval, and a punching mechanism arranged above the limiting track and driven by the second eccentric wheel to slightly move up and down, two traction mechanisms arranged above the limiting track in a spaced mode and driven by the first eccentric wheel to slightly move left and right, two limiting mechanisms fixedly arranged above the limiting track in a spaced mode, and a cut frame which can pass through the waste channel. According to the invention, the capacitor can be continuously trimmed one by one, the length of pins of the trimmed capacitor can be ensured to be consistent, the subsequent process is facilitated, the operation is simple, and the trimming process does not need manual participation.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Rapid-punching punching machine

The invention relates to the technical field of press machines and provides a rapid-punching punching machine which is capable of effectively removing extra impurities on a workpiece. The punching machine comprises a rack, a raw material storage mixing cylinder, a material filling trolley and a punching forming device; the raw material storage mixing cylinder, the material filling trolley and thepunching forming device are arranged on a workbench of the rack in sequence; a forming mold is arranged below the punching forming device; a downwardly inclined material unloading plate is arranged onthe workbench on the side where the forming mold is away from the raw material storage mixing cylinder; the material unloading plate is composed of a plate body and a rubber cushion which is arrangedon the upper surface of the plate body; a plurality of flanges are arranged in parallel on the rubber cushion and extend towards the width direction of the material unloading plate; the sections of the flanges are in semicircular shapes; and a plurality of slag leakage holes are evenly formed in the material unloading plate and penetrate through the rubber cushion and the plate body. The punchingmachine can rapidly remove powder impurities adhered to the surface of a formed workpiece, the structure is simple, the manufacturing cost is low, promotion is convenient, and following working procedures are simplified.

Owner:应开法

Multifunctional efficient lens cleaning equipment for glasses processing

InactiveCN114273309AEasy to cleanIncrease the use of functionsDrying gas arrangementsCleaning using liquidsEyewearStructural engineering

The invention discloses multifunctional efficient lens cleaning equipment for glasses processing, which comprises a box body, a filter frame, a stop lever, a support rod, a top plate, a rotating mechanism, a lifting mechanism, a filter mechanism, a suction pump, a water pipe, a motor, a driving shaft, an eccentric wheel and a bearing, the filter frame is slidably connected in the box body, the stop lever is welded on the filter frame, and the stop lever is in contact with the box body; a supporting rod is welded to the box body, a top plate is welded to the supporting rod, a rotating mechanism is arranged on the top plate, a lifting mechanism is arranged on the top plate, a filtering mechanism is arranged on the box body, a suction pump is fixedly installed on the top plate, a water pipe is arranged on the suction pump, and a motor is fixedly installed on the box body. And a driving shaft of the motor is rotationally connected with the box body. The invention relates to multifunctional efficient lens cleaning equipment for glasses processing. The multifunctional efficient lens cleaning equipment has the characteristics that the lens cleaning efficiency of the equipment is high, and impurities in water in the equipment are convenient to remove.

Owner:佛山市埃科机器人科技有限公司

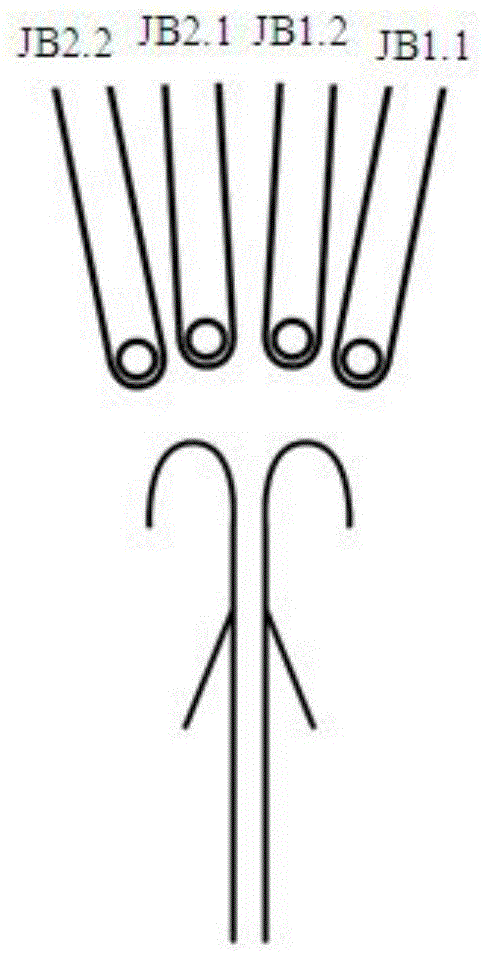

Weaving method of warp knitted seamless bottomless jacquard stockings

The invention relates to weaving method for warp knitting a seamless bottomless jacquard weave silk pantyhose. A two-needle bar warp knitting machine is used for production, and the weaving method comprises the steps that 1, a pantyhose waist portion is thick fabric, and the side seams of the pantyhose waist portion are thick edge-connected fabric; 2, a pantyhose body portion is plain stitch thin fabric, and the side seams of the pantyhose body portion are thin edge-connected fabric; 3, a pantyhose crotch portion is thick fabric, and thick needle supplement fabric is added at the connection portion of the right side of the thick fabric of the pantyhose crotch portion and the plain stitch thin fabric of the pantyhose body portion; 4, a pantyhose crotch stitching portion is thick stitching fabric, and the right side of the thick fabric is thick needle supplement fabric; 5, stocking leg portions are entirely plain stitch thin fabric, and partly provided with thick fabric and small-mesh jacquard weave fabric, thick needle supplement fabric is added between the right side of the thick fabric and the plain stitch thin fabric, and small-mesh needle supplement fabric is added between the right side of the small-mesh jacquard weave fabric and the plain stitch thin fabric; 6, pantyhose point portions are thick fabric, and pantyhose point stitching portions are thick stitching fabric. The weaving method for the warp knitting the seamless bottomless jacquard weave silk pantyhose has the advantages of being capable of achieving the production of the seamless bottomless jacquard weave silk pantyhose with the fine, smooth, thin and transparent texture, breathable and capable of preventing scattering.

Owner:YIXING HUAYI KNITTING

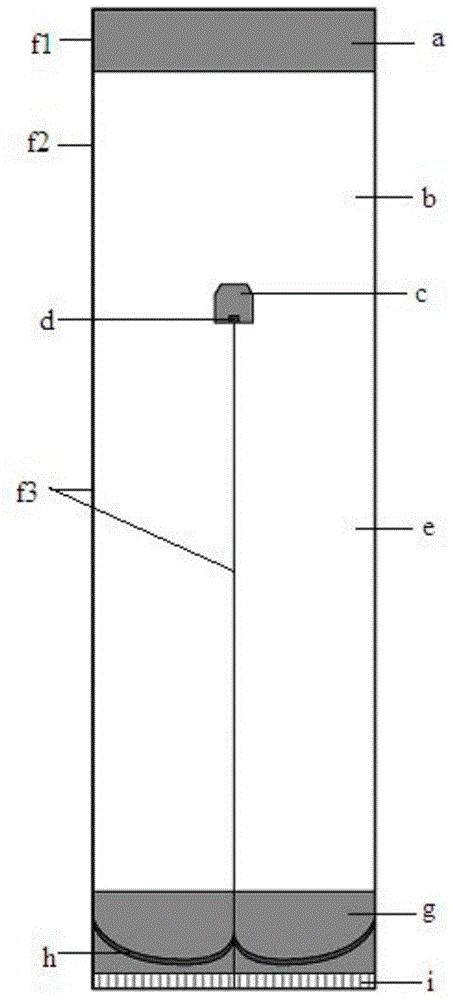

A splitting process for laser optical glass cutting

ActiveCN108971772BSimple processSimplify subsequent processesGlass severing apparatusLaser beam welding apparatusPlastic packagingLaser cutting

Owner:杭州千皓科技有限公司

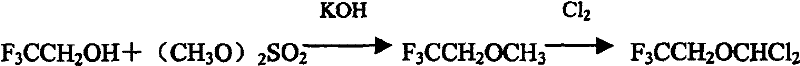

Preparation of furane used as inhalation anesthetic

InactiveCN101462929BHigh yieldLow costOrganic chemistryOrganic compound preparationState of artMedicine

The invention belongs to the technical field of medicine and chemical engineering and in particular relates to a preparation method of isoflurane for inhalation anesthetics. The method solves the problem that the conversion rate is low, the cost is high and the fatalness is high in the prior art; in order to overcome the problems in the prior art, the technical proposal is as follows: the preparation method of isoflurane for inhalation anesthetics comprises the following steps in sequence: (1)reaction: HFE with water content less than 50ppm and lewis acid which are taken as raw materials to take reaction according to the mole number ratio of 1:0.8-3; (2) hydrochloric acid is dropwise added, the mixture stands for layer separation and then oil phase is obtained; (3) the isoflurane product is obtained by neutralizing, washing and rectifying the oil phase. Compared with the prior art, the method has the advantages of high yield, low cost, low hazard and convenient separation and purification.

Owner:中国中化股份有限公司 +1

Motor

InactiveCN101588096BEasy to manufactureSmall form factorWindings insulation shape/form/constructionMagnetic circuit stationary partsChemical combinationPrinted circuit board

The invention discloses a motor comprising a stator assembly, an opening part, a bracket and resins. The stator assembly is integrally formed by a stator and a moulding part surrounding a stator iron core and an insulator; the opening part is communicated with outside of the stator assembly; the opening part is connected with the upper part of the moulding part through a plane part; the outside diameter of the bracket is less than the inside diameter of the outside inner wall; a tail end along a radius direction is mounted on the plane part and keeps a certain gap with the outside inner wall to enclose the opening part; and the resins are coated in the gap. The invention has the advantages that the motor is a stator moulded-type motor, and the printed circuit board is accurately combined with the stator assembly to prevent coils from being damaged; the bracket and the moulding part are combined with each other more firmly via mechanical and chemical combination so as to prevent the bracket from being separated as a result of vibration during the operation process of the motor and avoid electric leakage caused by water penetration to the utmost extent. The motor is easy to manufacture and convenient to assemble, thereby greatly improving the production efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

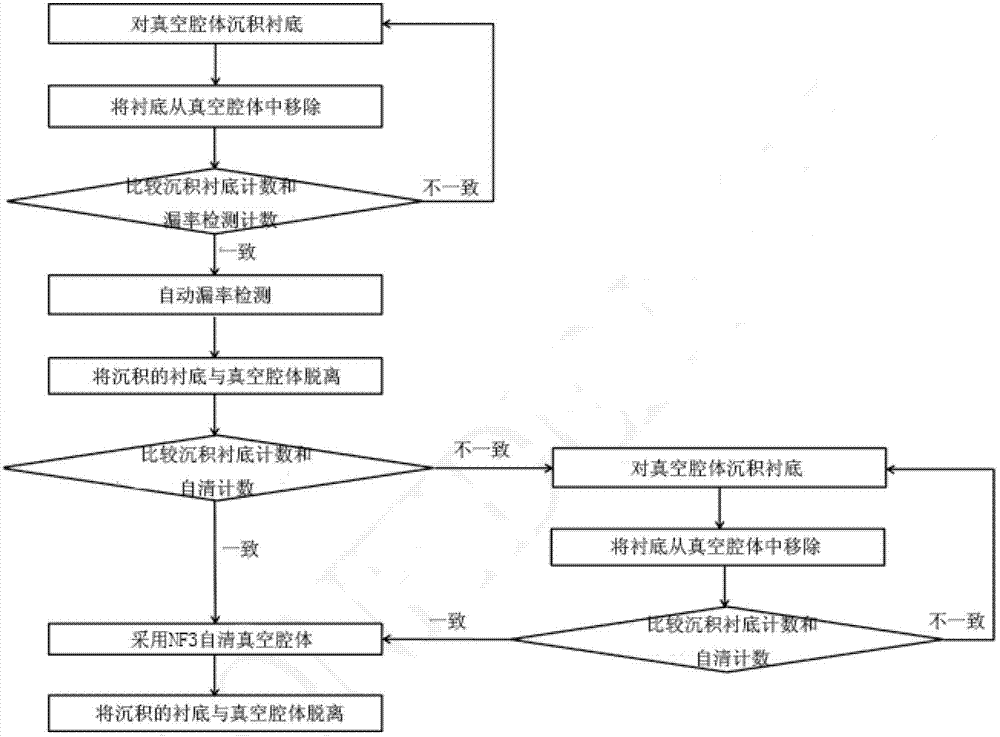

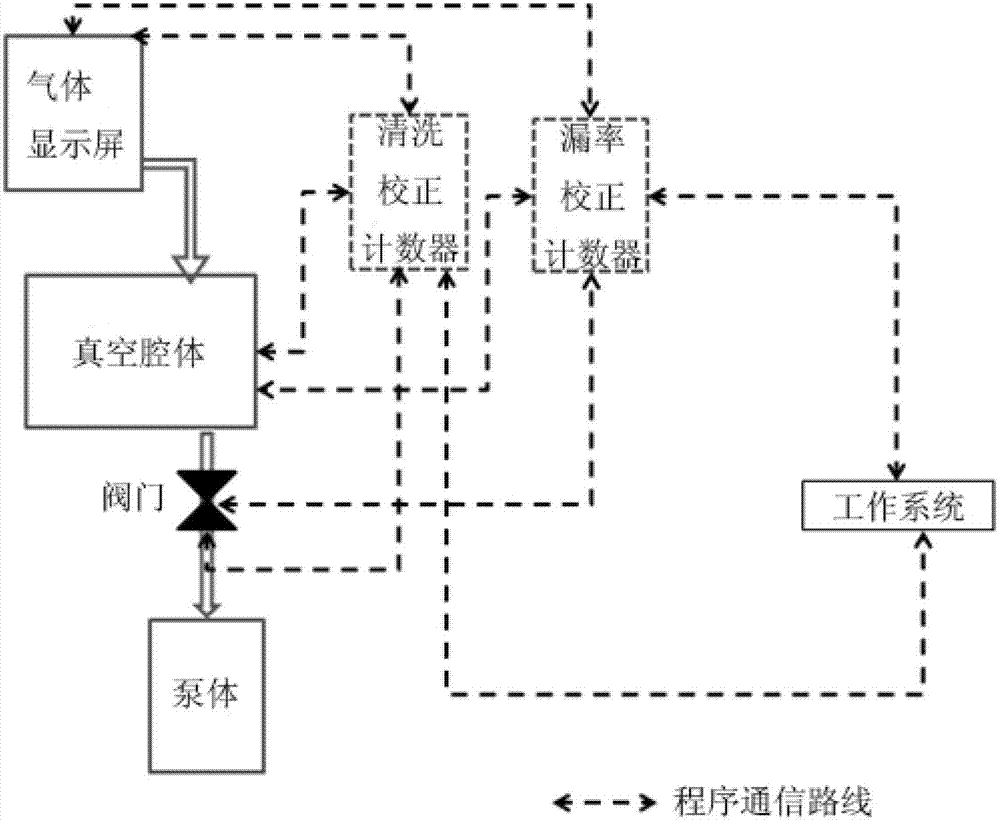

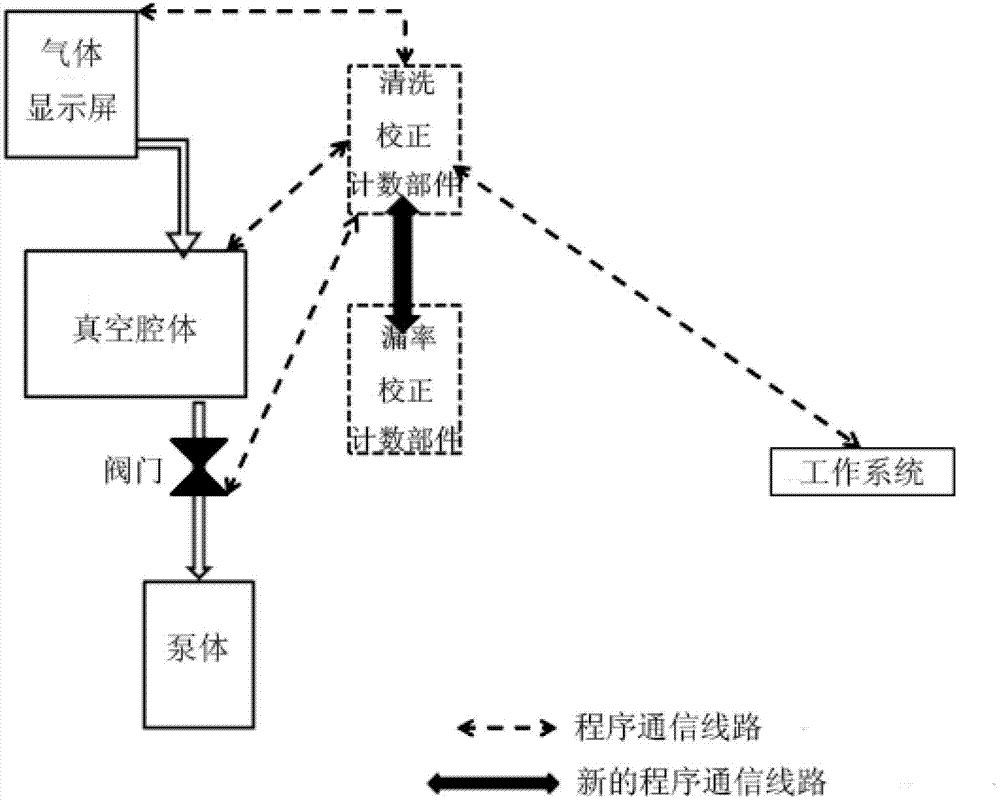

Method for controlling automatic detection of leakage rate of vacuum chamber

InactiveCN103162914ASimplify subsequent processesMake up for gas wasteDetection of fluid at leakage pointSemiconductor/solid-state device manufacturingLeakage rateEngineering

The invention discloses a method for controlling automatic detection of the leakage rate of a vacuum chamber, belongs to the technical field of vacuum chambers, and is applied to a vacuum chamber detecting system. The vacuum chamber detecting system comprises the vacuum chamber, a pump and a counter, the vacuum chamber is connected with the counter, the counter is connected with an external operating system, the vacuum chamber is further connected with the pump through a valve, and the pump is connected with the counter through a valve. The method includes the steps: depositing substrates on the vacuum chamber; removing the substrates; comparing a deposited substrate count with a self-cleaning count; continuing to compare the deposited substrate count with a leakage rate detecting count if the deposited substrate count is consistent with the self-cleaning count; detecting the leakage rate of the vacuum chamber if the deposited substrate count is consistent with the leakage rate detecting count; self-cleaning the vacuum chamber; and detaching the deposited substrates from the vacuum chamber. By the aid of the technical scheme, the method has the advantages that the follow-up manufacture procedure of detecting the leakage rate of the vacuum chamber is simplified, and the shortcomings of gas waste and productivity and yield reduction of the follow-up manufacture procedure in the prior art are overcome.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

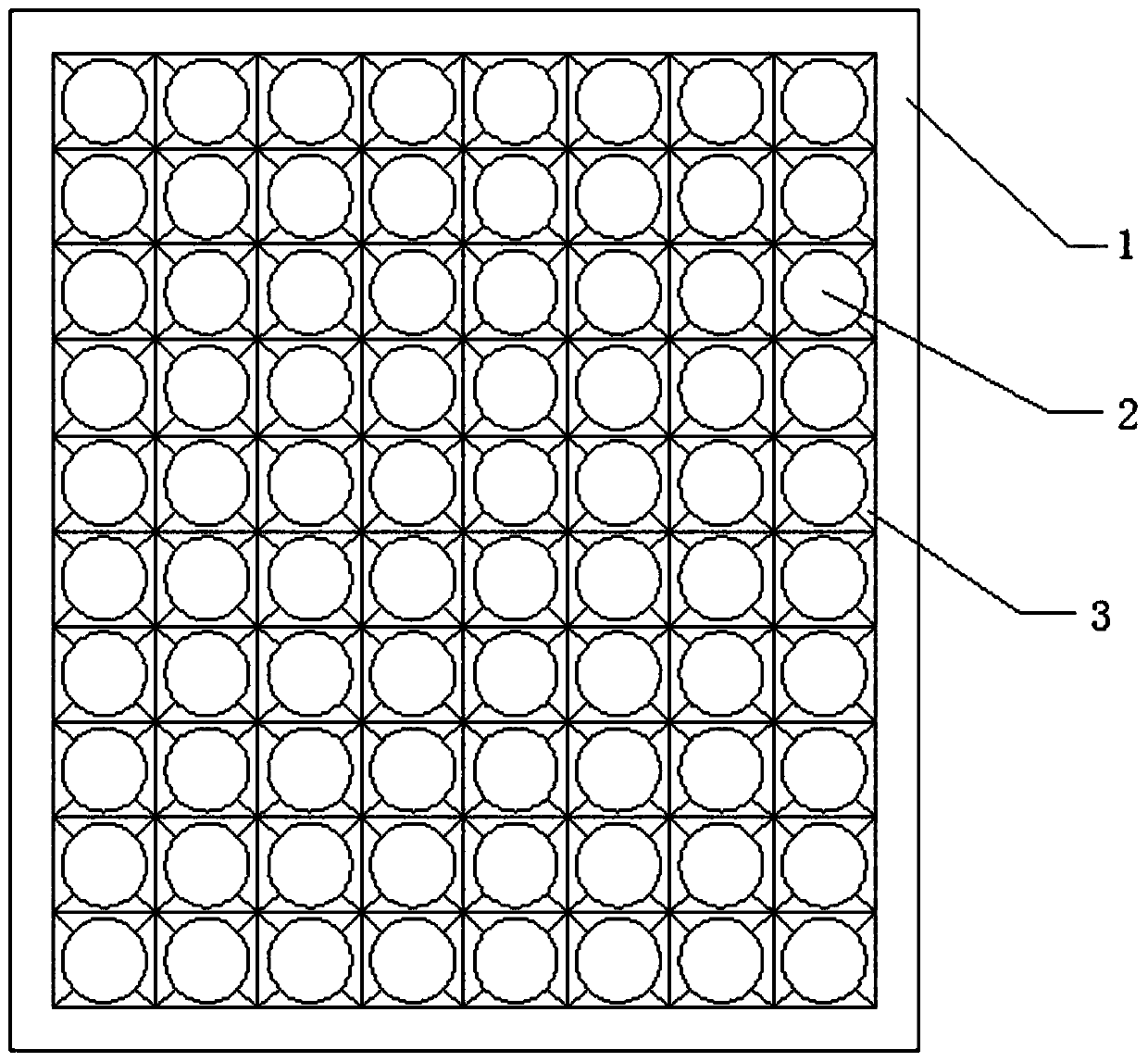

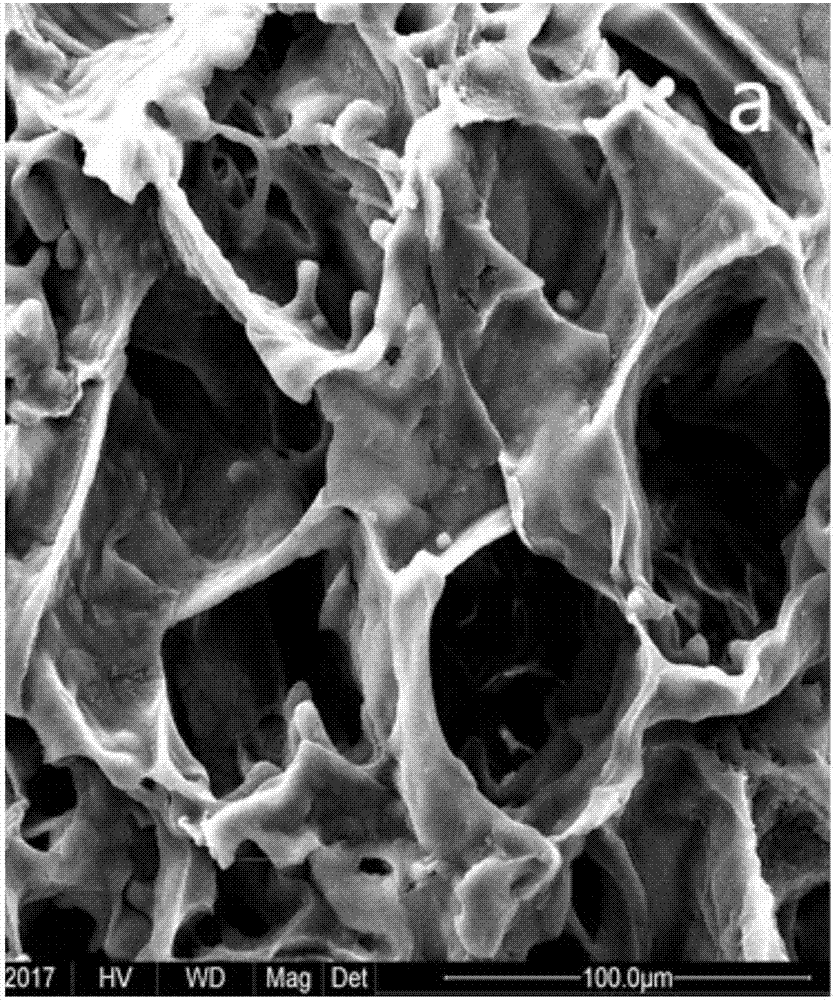

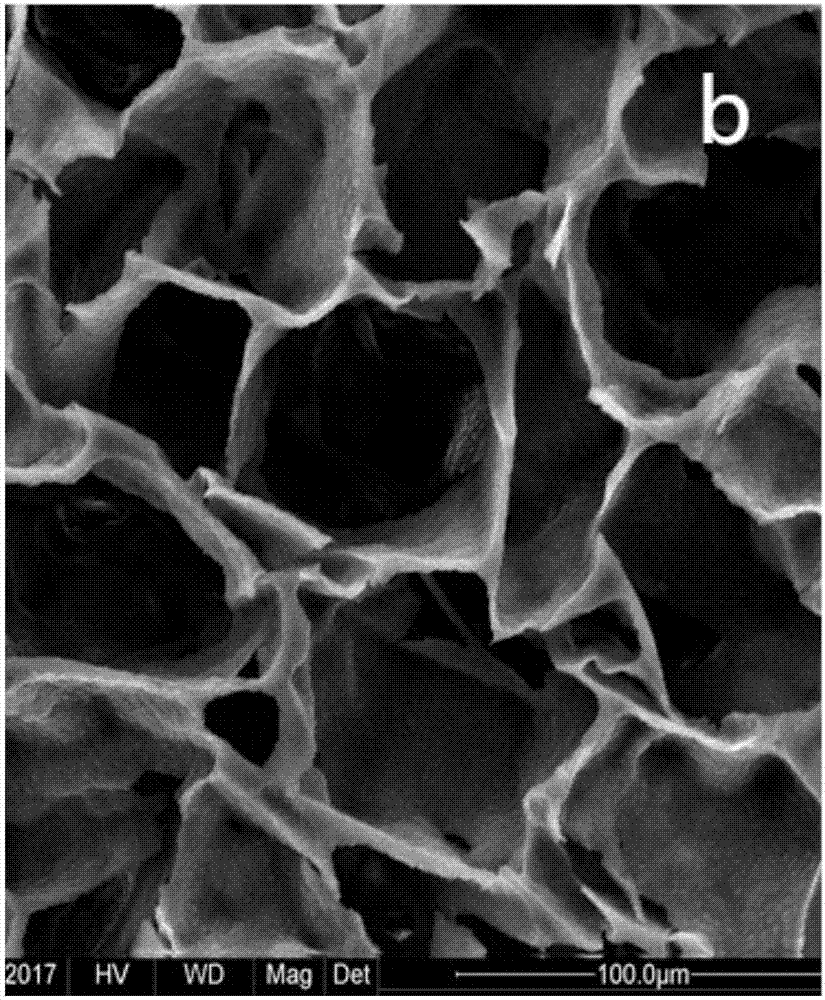

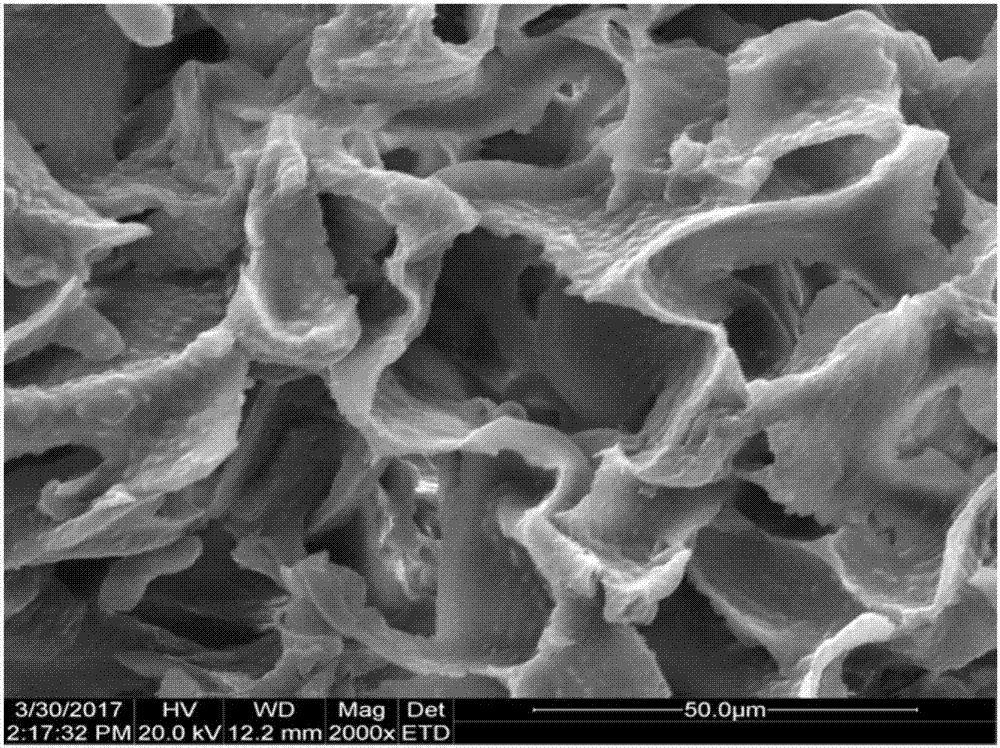

Preparation method of Cu<2+>-chelated hydroxypropyl polymethacrylate supermacroporous crystal gel medium

ActiveCN107141403AEasy to operateSimplify subsequent processesOther chemical processesAbsorption capacityBiological macromolecule

The invention relates to a preparation method of a Cu<2+>-chelated hydroxypropyl polymethacrylate supermacroporous crystal gel medium. The preparation method comprises the following steps: (1) preparing a hydroxypropyl polymethacrylate supermacroporous crystal gel medium; and (2) preparing the Cu<2+>-chelated hydroxypropyl polymethacrylate supermacroporous crystal gel medium. The Cu<2+>-chelated hydroxypropyl polymethacrylate supermacroporous crystal gel medium is prepared by carrying out free radical polymerization at a low temperature by taking water as a pore-forming agent and is environment-friendly, sanitary and easy to store, the operation process is convenient, and subsequent procedures are simple; the crystal gel medium has super-large pores which have the sizes of 5-100 microns and are mutually communicated, and the porosity is large and reaches 75%; the crystal gel medium has a large specific surface area and capable of effectively adsorbing biological macromolecules; the crystal gel medium has good water absorbing property and can absorb water to expand within 1-2 seconds after being extracted, and the water absorption capacity reaches 10.2g (water) / g (crystal gel medium); and the crystal gel medium has good reusability and good thermal stability and further has wide application prospects in the separation of biological macromolecules.

Owner:QILU UNIV OF TECH

Vacuum pumping-type squeezing roller structure removing free water

InactiveCN101670679BImprove press dehydration rateSimplify subsequent processesPressesVacuum pumpingPulp and paper industry

The invention relates to a vacuum pumping-type squeezing roller structure removing free water, which comprises a roller shaft, an end plate, a roller body, a rubber coating and a mounted bearing, wherein a plurality of keyway-shaped water troughs are uniformly distributed on the surface of the rubber coating in the axial direction; the end surface of the roller shaft is provided with a plurality of axial water through holes that are uniformly distributed along the circumferential direction; the circumferential surface of the roller shaft is provided with a plurality of radial water through holes that have the same size and the same amount with the axial water through holes and are crossed and communicated with each axial water through holes respectively; a water pipe is arranged between each radial water through hole of the roller shaft and each water trough of the rubber coating so that the radial water through hole is communicated with the water trough one-to-one correspondingly; and a vacuum pumping component is arranged at the axial water through hole of the roller shaft. In the invention, one vacuum pumping component that can be connected with the external vacuum equipment pumps the free water that flows into the internal water hole after being squeezed, thus improving the squeezing dehydration rate.

Owner:湖州旺能环保科技有限公司

Dry method electrode film preparation device and its battery production line

ActiveCN113619143BFlat thicknessSelf-supportingElectrode rolling/calenderingFlat articlesProduction lineElectrical battery

The invention provides a dry electrode film preparation device and its battery production line, including a preforming mechanism for preforming the mixed raw materials into a self-supporting semi-finished dry electrode film and a preforming mechanism for rolling the semi-finished dry electrode film It is the rolling mechanism of the finished dry electrode film. The preforming mechanism includes a conveying workbench, a material distributing mechanism and a compacting mechanism arranged above the conveying workbench. The rolling mechanism corresponds to the discharge end of the conveying workbench, and the material distributing mechanism is close to the The feeding end of the conveying table is used to flatten the raw material into a raw material layer; the compacting mechanism is provided with a compacting surface corresponding to the table surface of the conveying table, used for compacting the raw material layer. The raw material is preformed into a self-supporting semi-finished dry electrode film by the preforming mechanism, and then rolled by the calendering mechanism, so that the electrode film is not easy to be broken during production, and the required dry product can be achieved without multiple rolls. The thickness of the electrode film.

Owner:三一技术装备有限公司

Crystal-covering package method and structure for covering crystal

InactiveCN1677630AAvoid defectsSimplify subsequent processesSemiconductor/solid-state device detailsSolid-state devicesElectroplatingComposite crystal

Using semi-etching method etches out composite crystal soldered blocks in time of preparing conducting wire holder. Gold, silver, or soldering tin etc. metals are plated on composite crystal soldered blocks. Soldering pads of chip on wafer are connected to composite crystal soldered blocks so as to form conducting connection. Finally, filling packing material forms encapsulation. The method does not need to develop composite crystal soldered blocks on soldering pads of chip, and the original equipment for preparing conducting wire holder is available. Thus, the invention simplifies manufacturing procedure and lowers cost.

Owner:LINGSEN PRECISION INDS

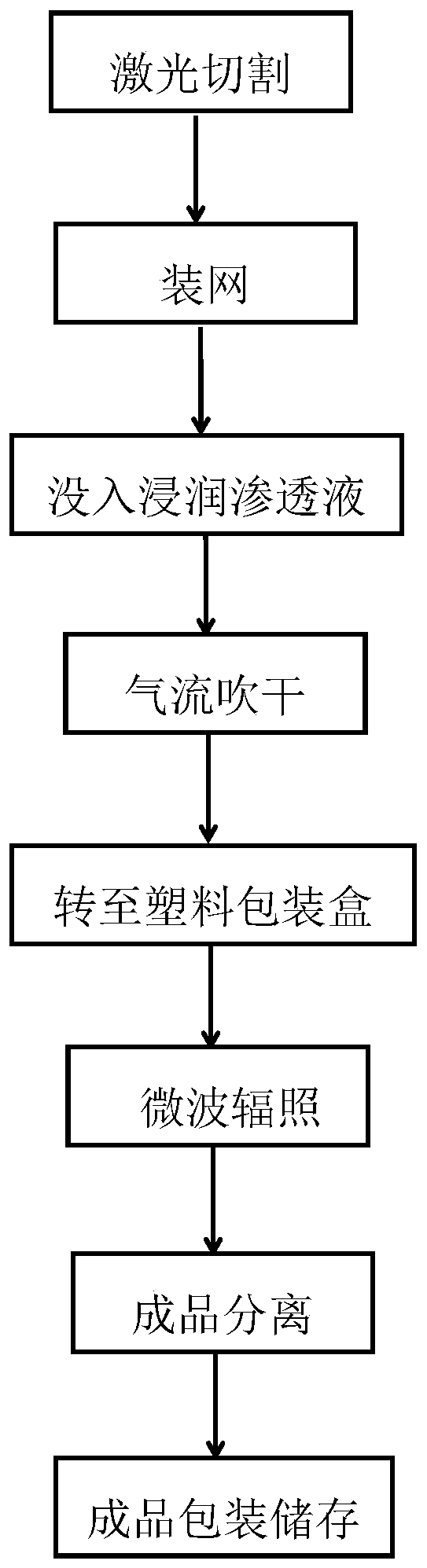

Splitting process for optical glass laser cutting

InactiveCN113522865ASimple processSimplify subsequent processesDrying gas arrangementsFlexible article cleaningPlastic packagingWaste product

The invention discloses a splitting process for optical glass laser cutting. The splitting process comprises the following steps: S1, carrying out laser cutting on an optical glass plate; S2, placing the optical glass plate subjected to laser cutting machining in a clamp lifting basket; S3, completely immersing the clamp lifting basket filled with the optical glass plate into wetting penetrating fluid; S4, carrying out airflow blow-drying on the wetted optical glass plate; S5, placing the blow-dried optical glass plate in a plastic packaging box; S6, transferring the plastic packaging box loaded with the optical glass plate into a microwave work station to be subjected to microwave treatment; S7, taking out the finished glass plate and frame waste products in the plastic packaging box; S8, performing polishing / acid pickling for impurity removal on the finished glass plate; and S9, packaging and storing finished products, namely packaging and storing the finished glass plate. Automatic splitting batch production of wafers is realized; splitting efficiency is improved; process use cost is reduced; cleanliness after splitting is guaranteed; and cost of laser splitting equipment of similar processes is reduced.

Owner:湖南振添光学玻璃科技有限公司

Production line and process for punching U-shaped beam

The invention discloses a production line and a process for punching a U-shaped beam. The production line for punching a U-shaped beam comprises a feeding mechanism, a workpiece feeding device, a punching main machine for punching the ventral side of the U-shaped beam, a blanking feeding device and a blanking device, wherein a wing-surface punching machine for punching and marking the wing surfaces of the U-shaped beam is arranged at one side of the punching main machine. The process for punching a U-shaped beam comprises the following steps of: (1) placing the U-shaped beam on the workpiece feeding device; (2) conveying the U-shaped beam in the punching main machine and punching the ventral side; (3) enabling the U-shaped beam to enter the wing-surface punching machine from the punching main machine and marking at corresponding positions of the wing surfaces of the U-shaped beam; and (4) conveying the U-shaped beam to the next working procedure by the blanking device. The invention has the advantages that the subsequent working procedures are simplified, the production efficiency is improved, and the production cost is decreased because the hole positions of the left wing surfaceand the right wing surface of the U-shaped beam are punched and marked before or after the ventral side is punched so as to avoid repositioning hole positions in the next working procedure.

Owner:SHANDONG TUOWEI CNC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com