Thin-walled cylinder precise shape control equipment

A thin-walled cylinder and precise technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of difficult to achieve precise shape control of the cylinder, thinning the wall thickness of the cylinder, unable to meet product size and performance requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

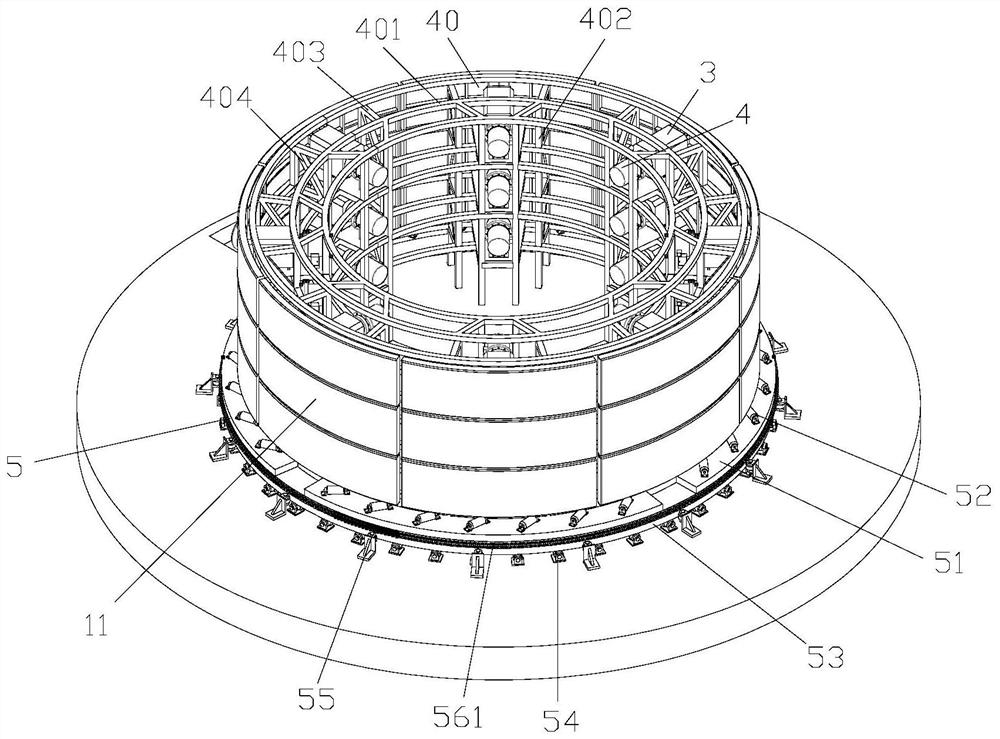

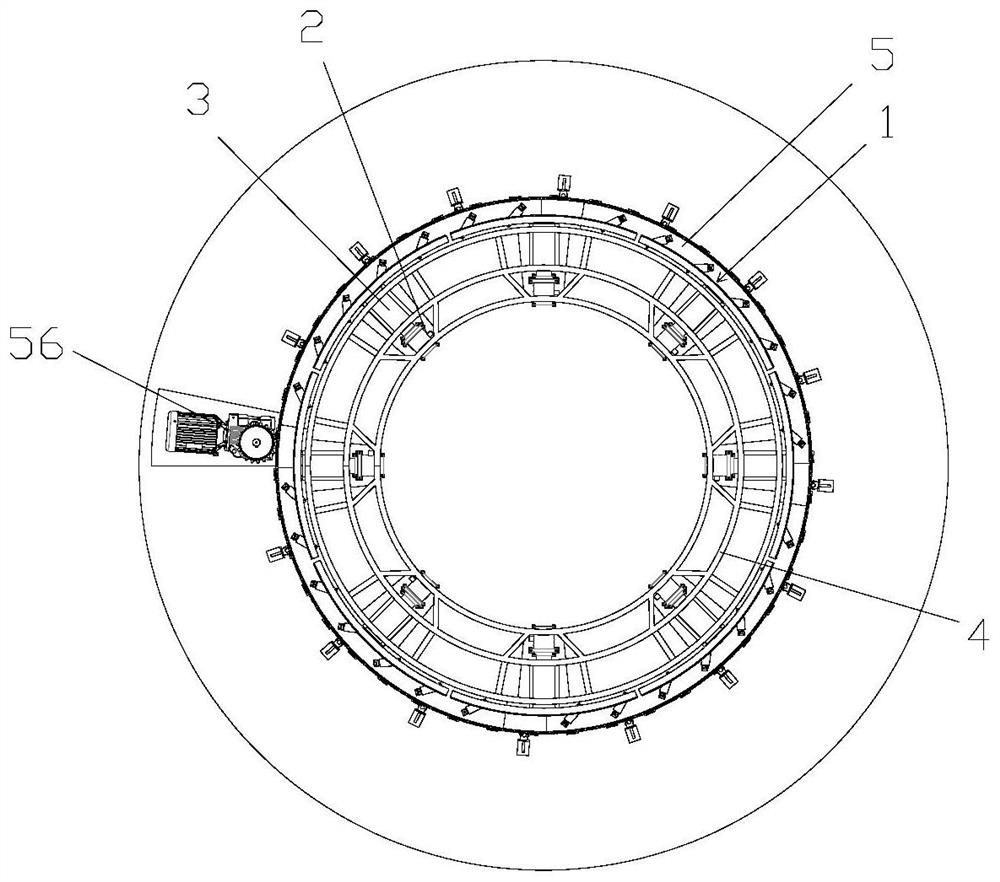

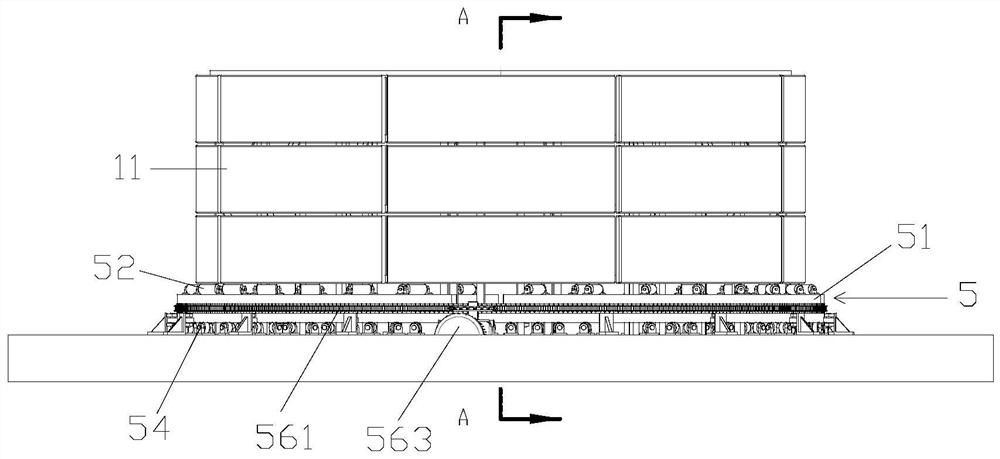

[0037] Example 1. The thin-wall cylinder precision shape control equipment provided by the preferred embodiment of the present invention includes a precision control shape inner tire mold 1, a hydraulic push cylinder 2, a guide device 3, a bracket 4, a rotating support platform 5 and a control system, and the control system is mainly monitored by sensors The hydraulic position and action are controlled by PIC.

[0038] Depend on figure 1 , image 3 As shown, the precision-controlled inner tube mold 1 is composed of multiple sets of high-rigidity inner tube molds 11. Its function is to use the shrinkage effect during the cooling process of the high-temperature workpiece to limit the thin-walled cylindrical part by controlling the position of the membrane surface of the inner tube mold 11 with a specific radian. The range of shrinkage to make it meet the size requirements of the workpiece. In this embodiment, the tire membrane surface is composed of 8 groups of 24 (can also b...

Embodiment 2

[0046] Example 2. The front and rear movement of the inner tube mold is used to control the shape of the super large thin-walled cylindrical part.

[0047] Specifications: The inner diameter of the cylinder is 12000-12500mm, the wall thickness of the cylinder is 70-80mm, and the height of the cylinder is 4000mm.

[0048] Finishing accuracy: cylinder roundness is not greater than ±2.5mm.

[0049] Calibration process:

[0050] By controlling the hydraulic push cylinder 2, the inner tube mold 11 is moved to the center of the rotating support table 5, and the diameter is the arc position of the workpiece size, and the rotating rotating support table 5 is rotated, and the position of the inner tube mold 11 is detected by a size detection device to make the roundness error Not more than ±1.0mm.

[0051] Use a special lifting tool to hoist the red-hot cylindrical workpiece after ring rolling to the thin-walled cylindrical precision control equipment, and use the size detection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com