A process method of axial compression expansion forging of hollow structural parts with large cross-section difference

A hollow structure and process method technology, applied in the field of industrial manufacturing, can solve the problems of uniform axial wall thickness of parts, cannot be manufactured with parts, and cannot improve the wall thickness, etc., and achieves good corrosion resistance, reasonable design, beautiful shape and precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

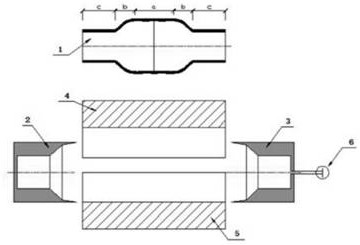

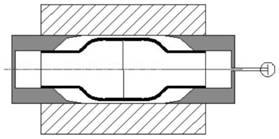

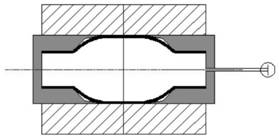

[0026] Such as Figure 1-6 As shown, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Method 1: Step 1. Form a preformed part (1) with a large cross-section difference, which can be changed by hydraulic forming or spinning forming; the preformed part (1) is divided into three characteristic areas, the large diameter area a, Transition area b and small diameter area c; in the aforementioned process of changing the diameter, the wall thickness of the large diameter area a is smaller than the wall thickness of the transition area b and the small diameter area c, and the preforming quality requirement for the preformed part (1) is its small diameter area c The shape of the final forming part (7) is the same as the shape of the small diameter area c; the shape of the transition area b is close to the final forming part (7), and the specific shape error does not exceed 30%; the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com