Novel heavy load wheel without inner tube

A technology for wheels and inner tubes, which is applied to rims, vehicle parts, transportation and packaging, etc. It can solve the problems of easy deviation of installation, low wheel edge height, and tire prolapse, so as to achieve the goal of not easy to leak and wear tires, and the overall surface quality Good, the effect of preventing the tire from falling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

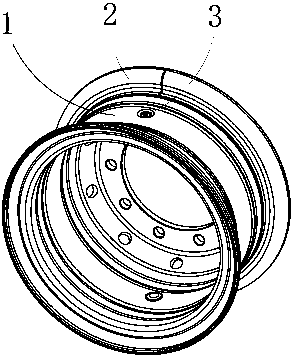

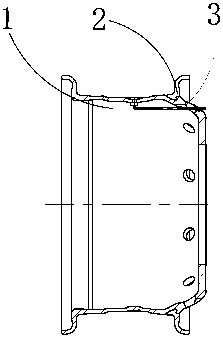

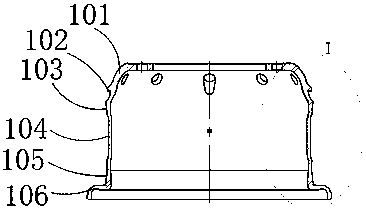

[0029] Example 1, a new type of heavy-duty integrated tubeless wheel, the spoke and the rim are integrally formed by spinning, there is no welding seam on the rim and the joint between the rim and the spoke, and the whole wheel is made of a round cake through three spinning , two forgings and one rolling process, and the annular circlip 2 is made of strip-shaped steel; through integral spinning and rolling, the spokes of the wheel body 1 and the middle and lower parts of the rim body The outline of the rim body is fully formed, and the shape of the middle and lower part of the rim body is as follows: a partial circumferential depression 104 in the middle, which is used as a way to facilitate the insertion of the tire when loading the tire; and two opposite slopes are formed on both sides of the middle part—bead seat, tire The ring seat is a smooth slope with a certain inclination, and as the most important part for assembling with the tire, it can ensure that the tire and the w...

Embodiment 2

[0039] Embodiment 2, a new type of heavy-duty combined welding tubeless wheel, the spoke and the rim are welded together, the outer circle of the spoke is pressed and welded together with the inner wall of the annular rim 106 of the rim, and the weld is between the rim and the inner wall of the annular rim 106 At the junction of the spokes, the wheel as a whole is formed by welding the rim and the spokes through different processes, while the annular circlip 2 is rolled from strip-shaped steel; Give way, it is convenient to insert the tire when installing the tire; and two opposite slopes are formed on both sides of the middle part - the bead seat, the bead seat is a smooth slope with a certain slope, as the most important part of the tire assembly , can ensure that the assembly of the tire and the wheel main body 1 is tight without leakage.

[0040] The big end of the rim is partially forged to form an annular rim, which is used to limit the one-way axial displacement and det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com