T-shaped large-diameter composite tee joint technology

A large-diameter, three-way technology, applied in the field of T-shaped large-diameter composite three-way technology, can solve problems such as reducing the amount of deformation, and achieve the effects of reducing the amount of deformation, refining the pressing process, and high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] A kind of T type large-diameter composite tee process, it specifically comprises the following steps:

[0026] Step 1: Use the composite tube blank as the material for the tee joint, and determine the size of the composite tube blank by the coefficient of the finished tee;

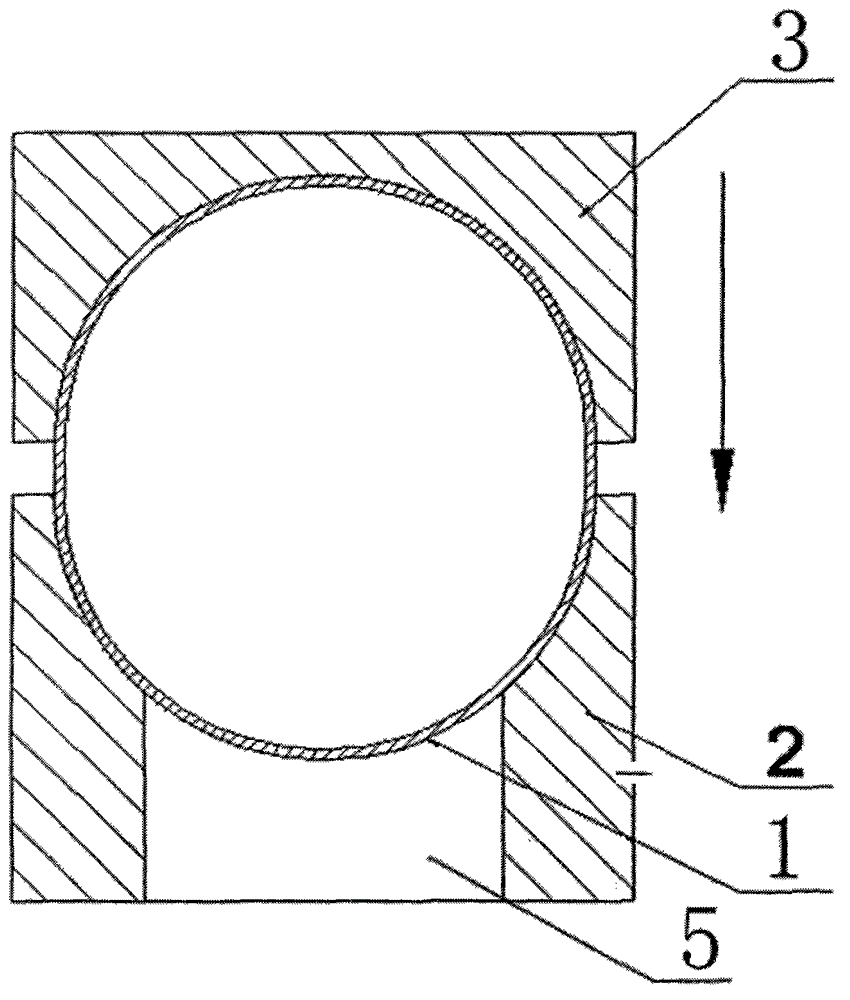

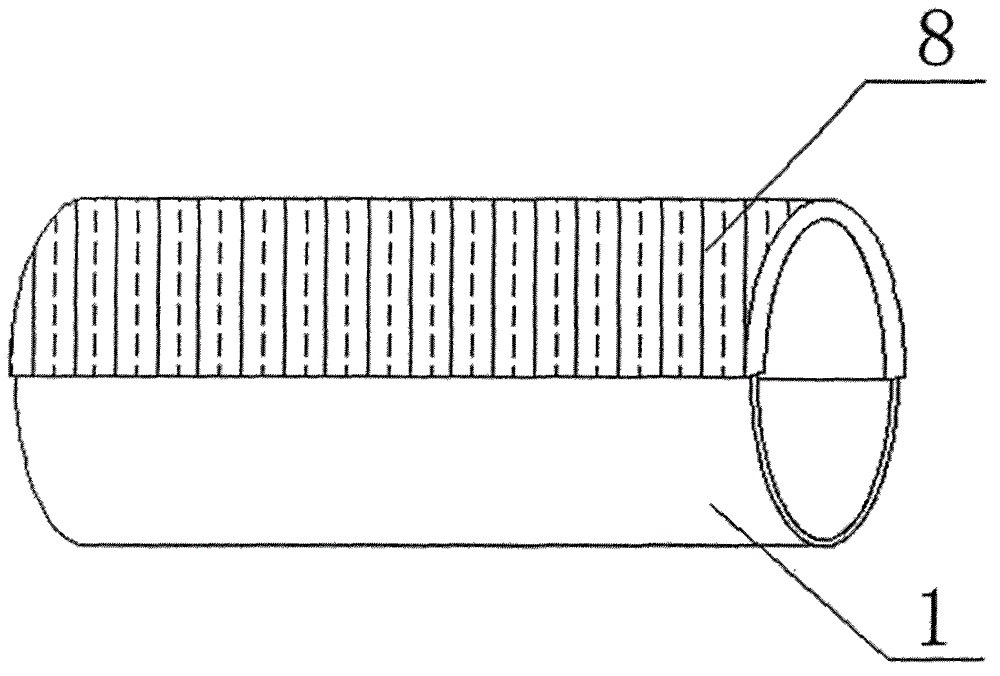

[0027] Step 2: If figure 1 As shown, when the tube blank 1 is placed horizontally, the upper half of the tube blank is completely wrapped inside and outside with a heat insulating material 8;

[0028] Step 3: According to different substrate tube materials, heat the lower half of the tube blank to 700°C-900°C;

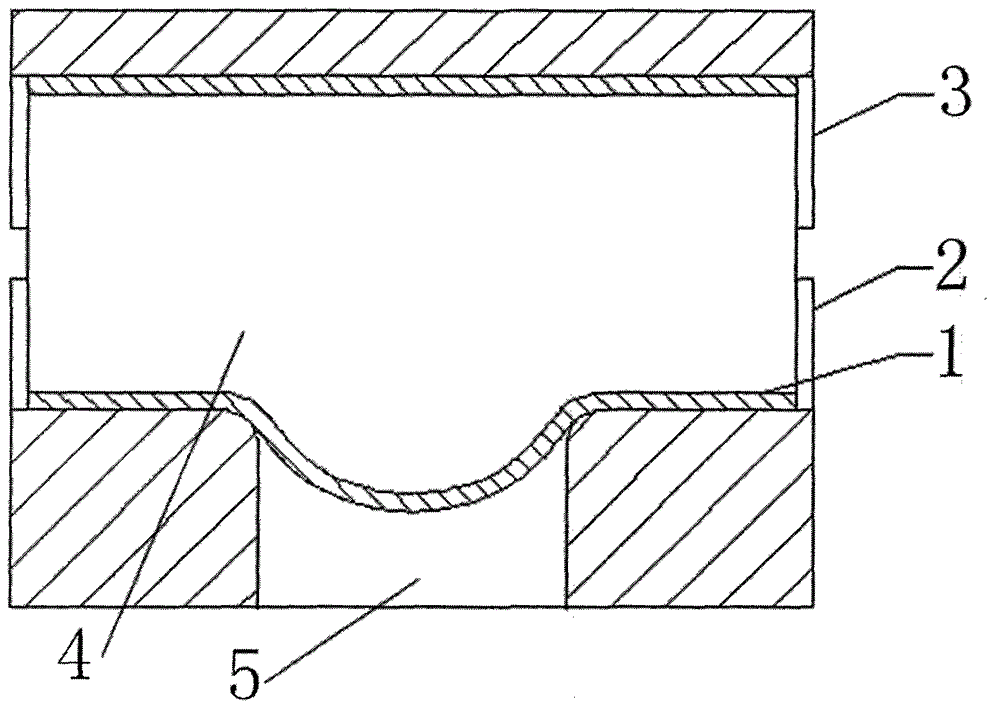

[0029] Step 4: If figure 2 and 3 As shown, the heat insulating material 8 is removed, and the heated tube blank 1 is placed on the first set of molds. The first set of molds is composed of an upper mold 3 and a lower mold 2. A T is arranged in the middle of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com