Bamboo inner joint breaking machine easy to clamp

A clamping and bamboo breaking technology, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of easy production of fine particles, difficulty in maintaining hygienic conditions, and unsuitability for the food industry, etc., to achieve easy centering, convenient operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

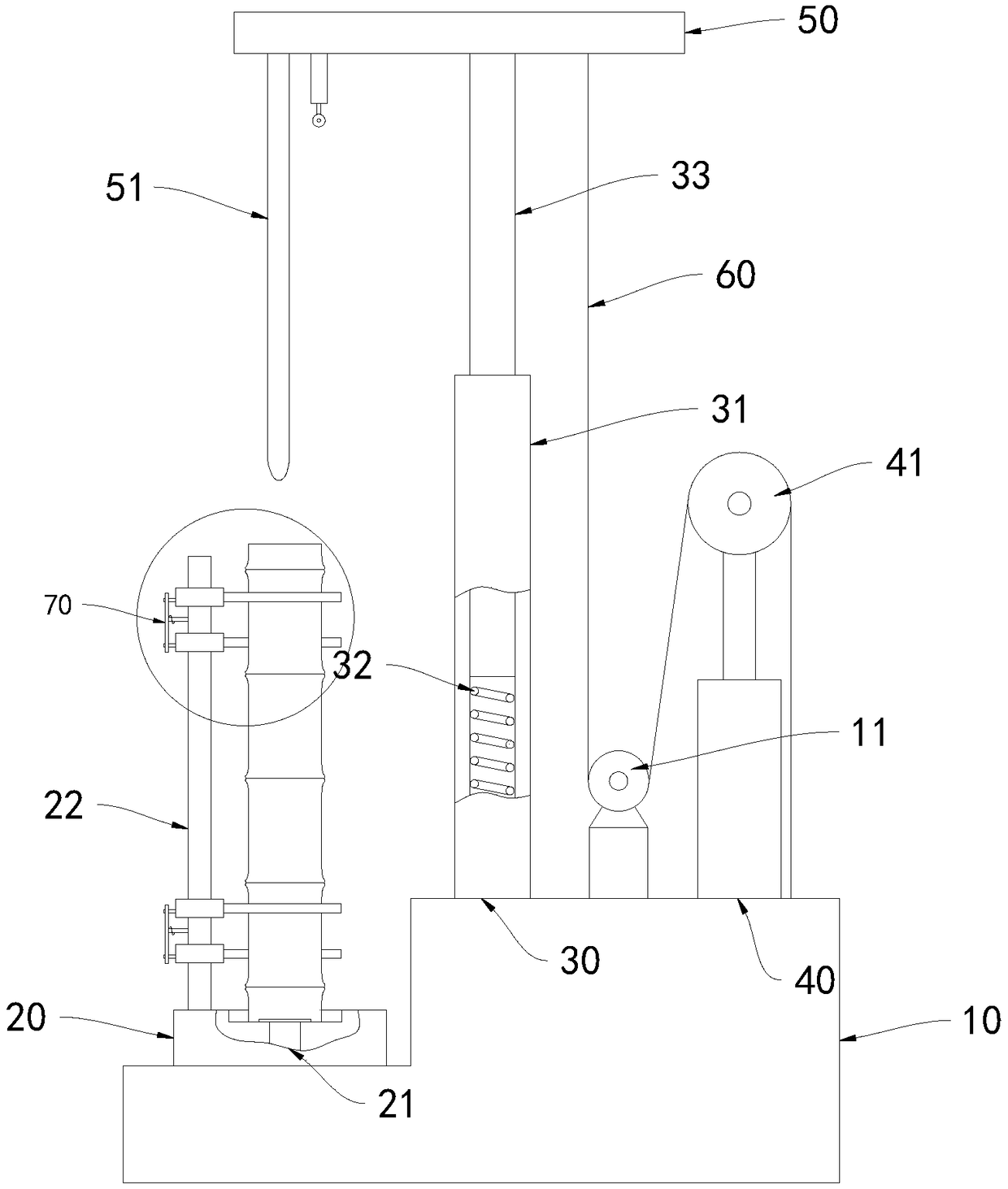

[0020] Embodiment: a machine for breaking bamboo inner knots that is easy to clamp includes a machine base 10, which is provided with a bamboo placement seat 20, an elastic expansion device 30 and a cylinder 40; the elastic expansion device 30 is stretchable in the vertical direction The upper beam 50 is fixed on the top of the elastic telescopic device 30, and the upper beam 50 is provided with a push rod 51 facing the bamboo seat 20; the piston rod of the cylinder 40 is provided with a sprocket 41, and the sprocket 41 is wound A power chain 60 is provided, one end of the power chain 60 is fixed on the base 10, and the other end of the power chain 60 is fixed on the upper beam 50;

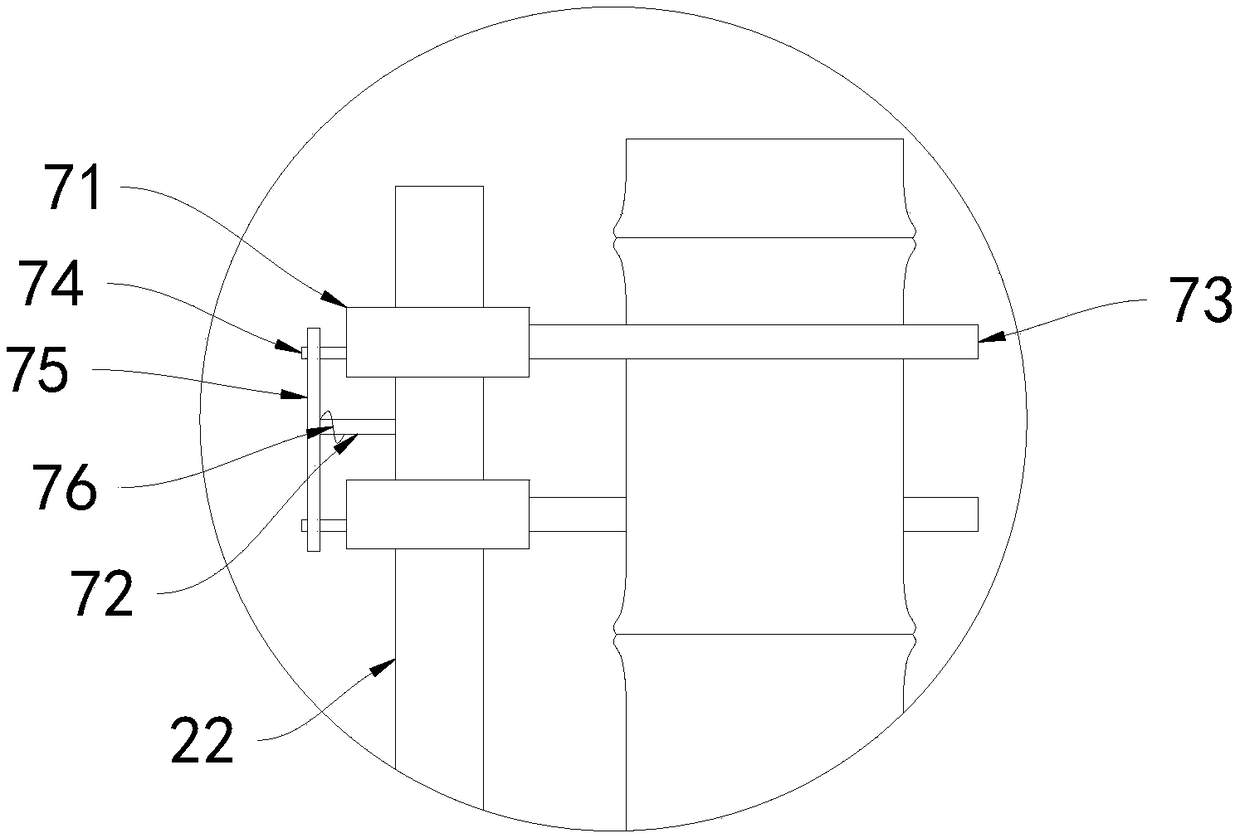

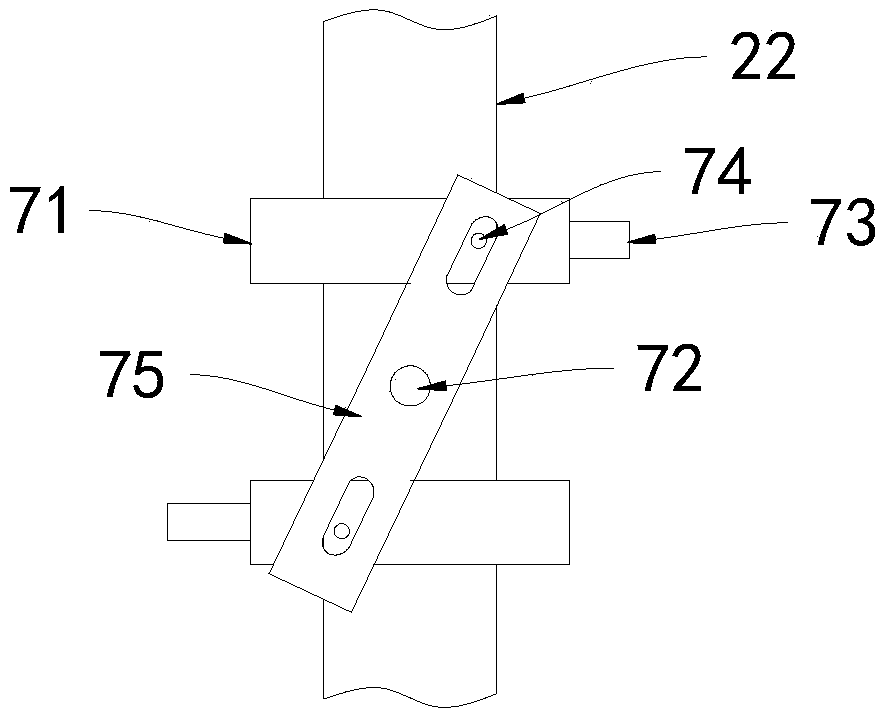

[0021] The bottom of the bamboo placement seat 20 is provided with a liquid outlet pipe 21, and the side of the bamboo placement seat 20 is provided with a vertical clamping rod 22, and the clamping rod 22 is provided with at least two assembly clamping devices 70 , the clamping device 70 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com