LED material strap manufacturing method

A technology for a light-emitting diode and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of assembly fees, time and labor, and achieve the effect of simplifying the manufacturing method and subsequent processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

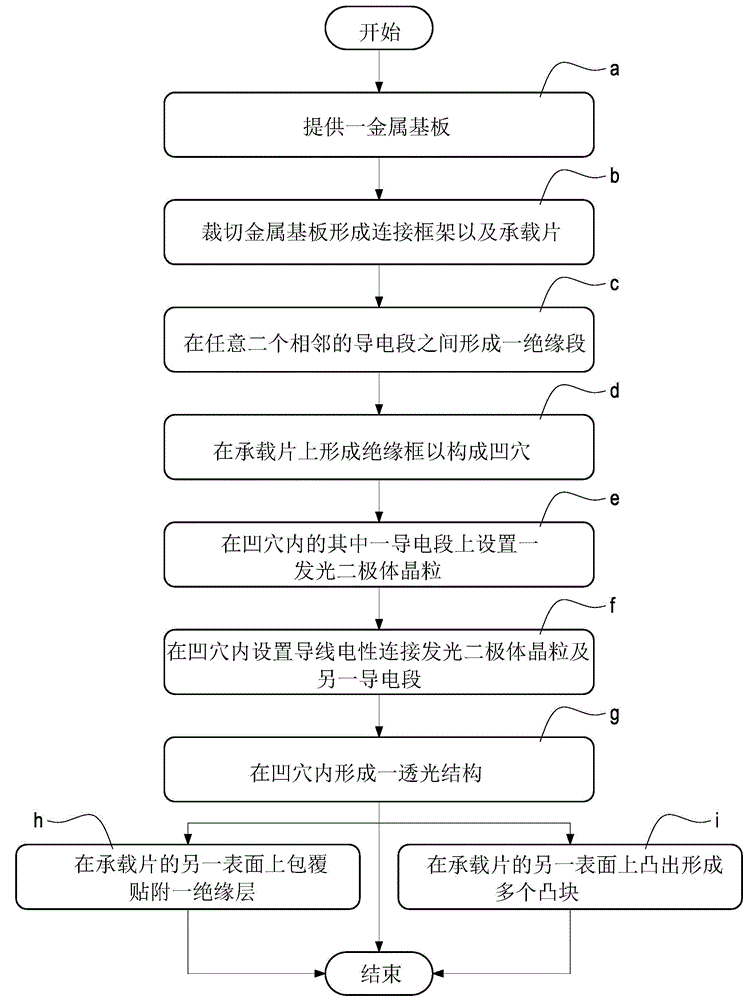

[0032] refer to figure 1 , the invention provides a method for manufacturing a light-emitting diode strip, the method at least comprising figure 1 Steps a-d shown in . The manufacturing method of the light-emitting diode strip provided in the first embodiment of the present invention preferably includes the following steps:

[0033] refer to figure 1 and figure 2 , In step a, a metal substrate 100 is provided, and the metal substrate is preferably a strip-shaped metal sheet.

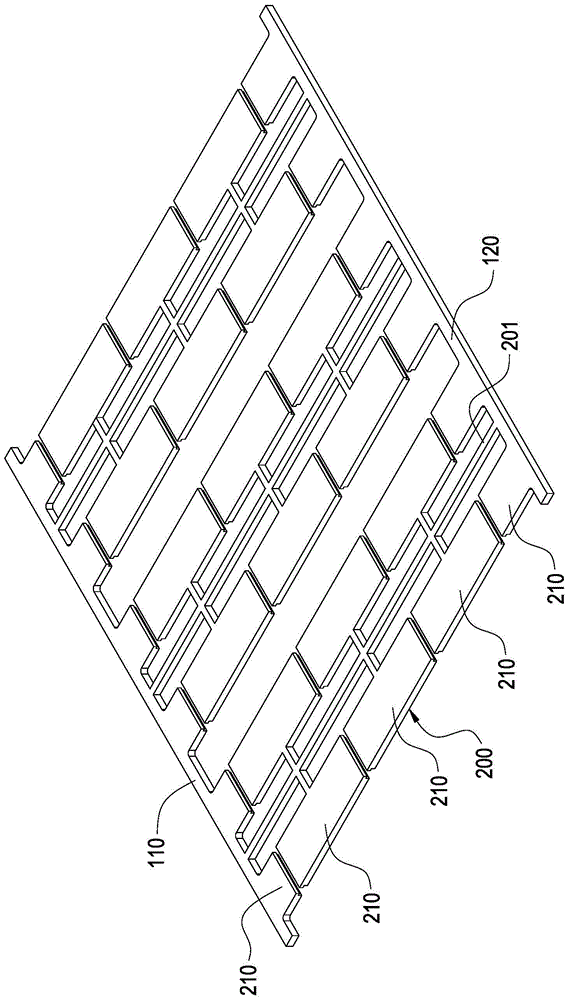

[0034] refer to figure 1 and image 3 In step b, the metal substrate 100 is cut to form the connection frame 110 / 120 and the carrier sheet 200 . In this embodiment, the metal substrate 100 is preferably stamped and cut with a knife, and the two longitudinal sides of the metal substrate 100 are cut to form two elongated connection frames 110 / 120 arranged in parallel and spaced apart. Each carrier sheet 200 is elongated and its two ends are respectively connected to one of the connection frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com