Method for controlling automatic detection of leakage rate of vacuum chamber

A vacuum chamber, automatic detection technology, applied in the direction of detecting the occurrence of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, semiconductor/solid device manufacturing, etc., can solve pollution, production capacity and yield decline, Issues such as technical solutions for leak detection are not mentioned to achieve the effect of simplifying the subsequent process and making up for the waste of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

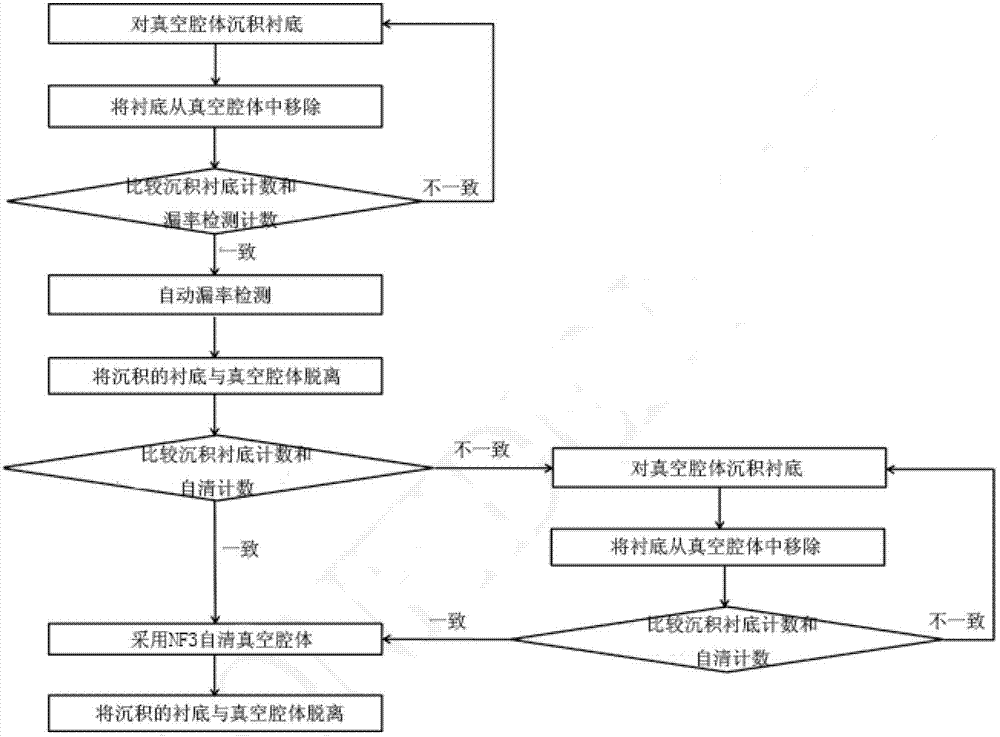

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and specific embodiments, but it is not a limitation of the present invention.

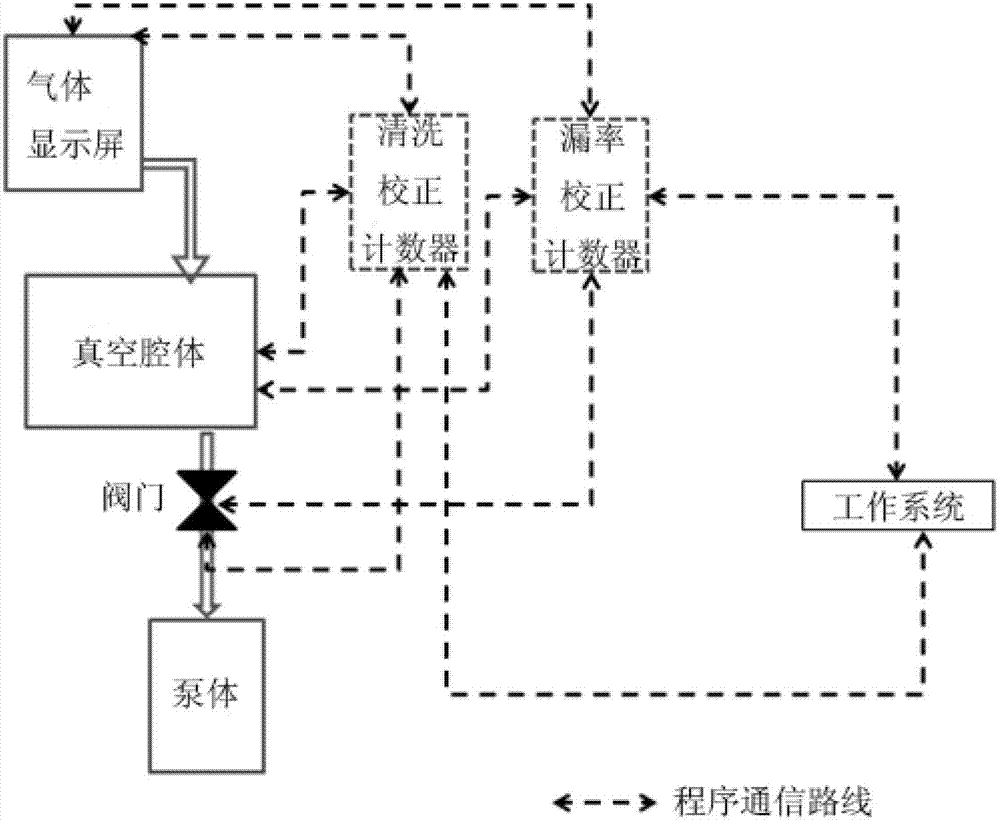

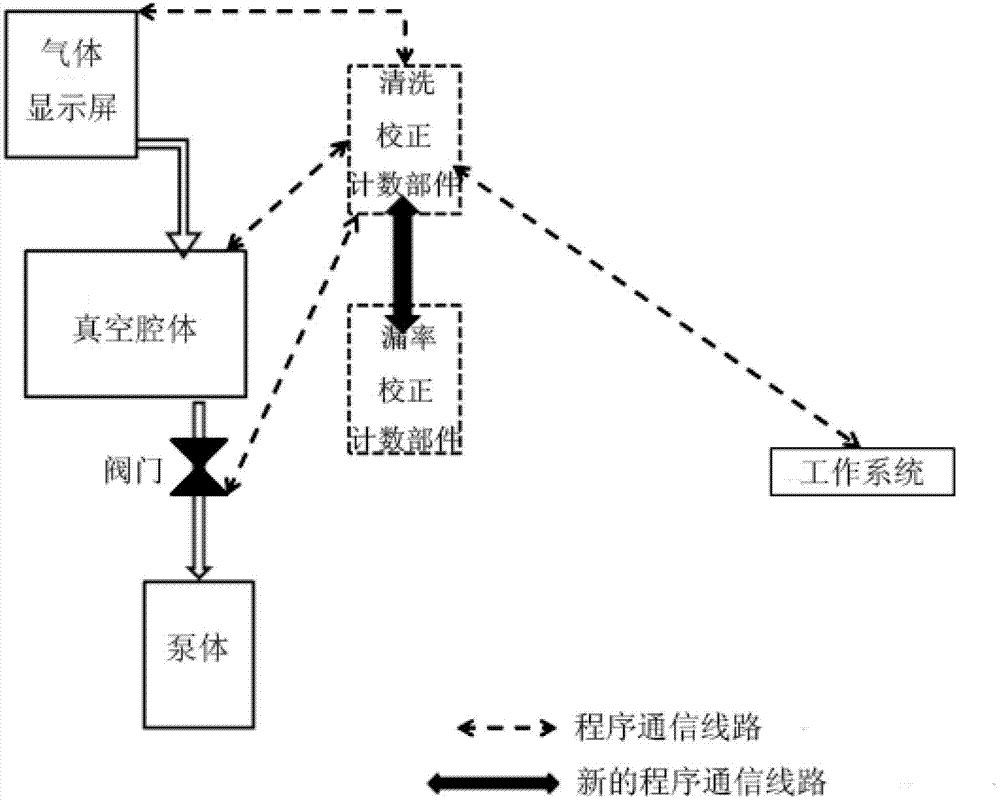

[0029] Such as image 3 As shown, in the embodiment of the present invention, the new type of basic equipment for automatically detecting leak rate (ie, the vacuum chamber detection system) includes a vacuum chamber and a counter for detecting the leak rate. The vacuum chamber is connected to a gas display screen and passes A valve is connected to a pump body; the counter includes two interconnected parts: a cleaning calibration counting component and a leak rate calibration counting component. The cleaning calibration counting component is respectively connected to the vacuum chamber, the gas display screen and the external working system, and passes through the valve Connect the pump body.

[0030] The cleaning correction counting component is used to calculate the self-cleaning count; the leak rate correction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com