Rapid-punching punching machine

A punching and fast technology, applied in the field of presses, can solve the problems of high energy consumption, residual products, scrapped products, etc., and achieve the effect of solving the accumulation of impurities, simplifying the subsequent processes, and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

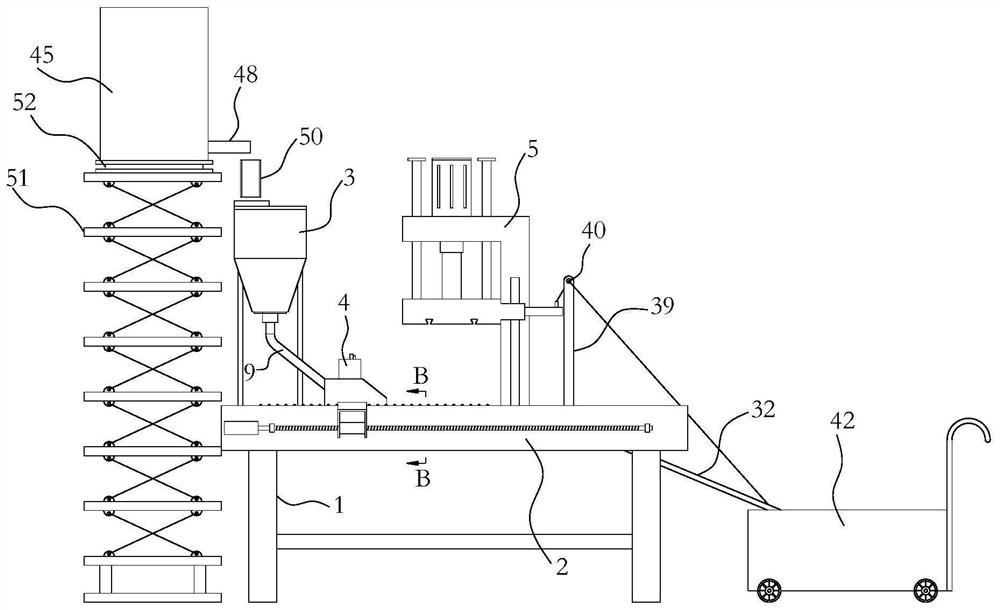

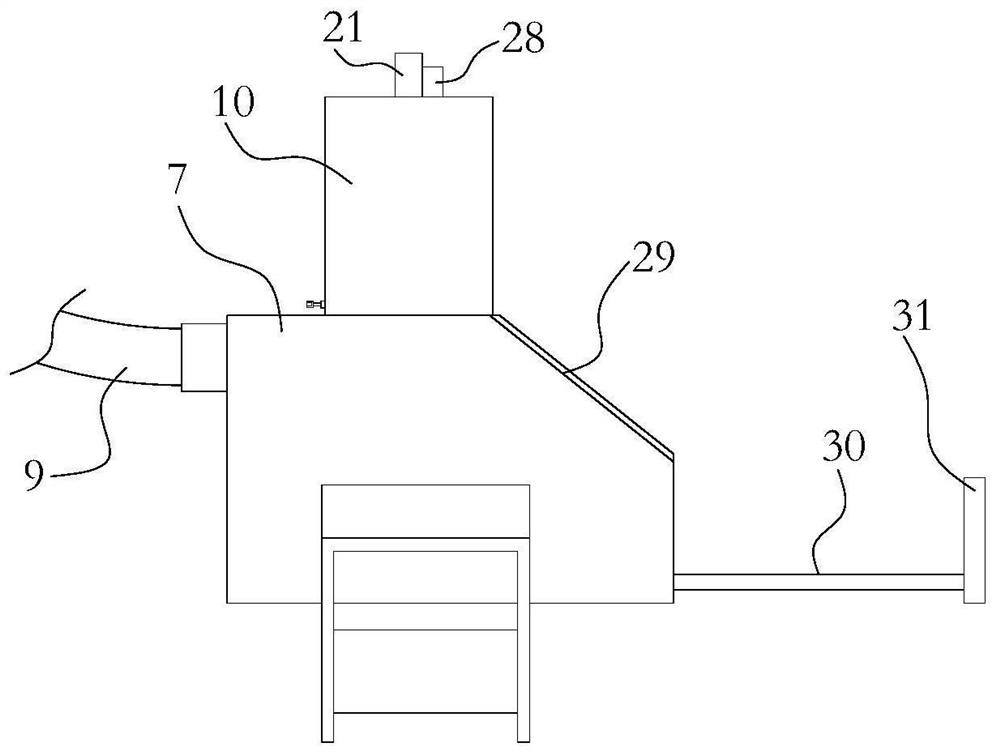

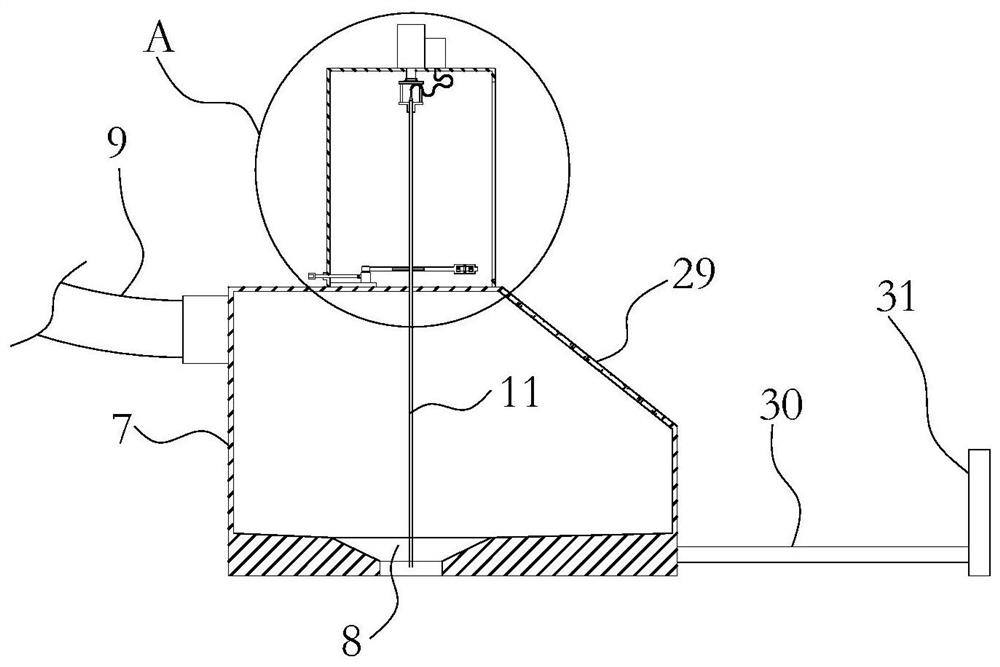

[0033] Such as Figure 1-13 As shown, a punching machine is used for powder metallurgy, which directly compresses powder raw materials. The basic structure of the present invention is the same as that of a traditional powder metallurgy punching machine, including a frame 1 and a raw material storage mixing cylinder 3, a filling trolley 4, and a stamping forming device 5 arranged sequentially on the working table 2 of the frame 1, and the stamping forming device 5 A molding die 6 is arranged below. The frame 1 is used as an installation basis, and the workbench 2 on it is used for the installation of various devices of the present invention; the raw material storage mixing cylinder 3 is used for storing powdery raw materials, and for stirring and mixing the powdered raw materials. A stirring mechanism is arranged inside to ensure the uniformity of raw material mixing in the raw material storage mixing cylinder 3 . The filling trolley 4 is used to walk on the workbench 2 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com