Multifunctional efficient lens cleaning equipment for glasses processing

A cleaning equipment and multi-functional technology, applied in lighting and heating equipment, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of affecting the cleaning effect, low lens efficiency, etc., to simplify the follow-up process, not easy to block, Increase the effect of using the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

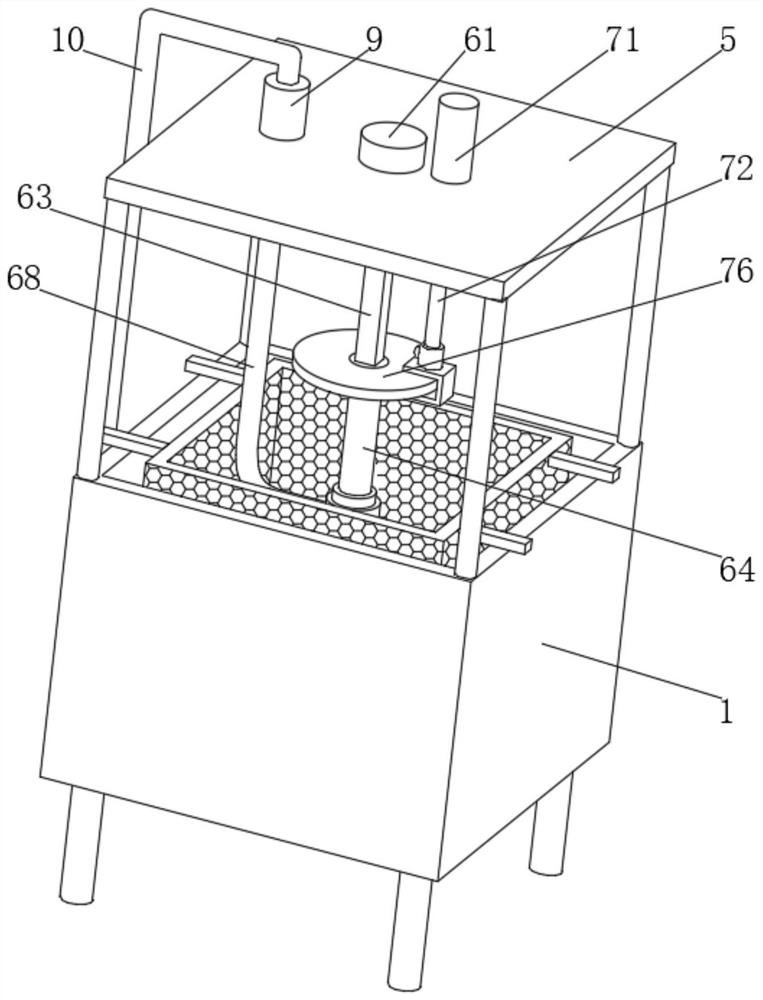

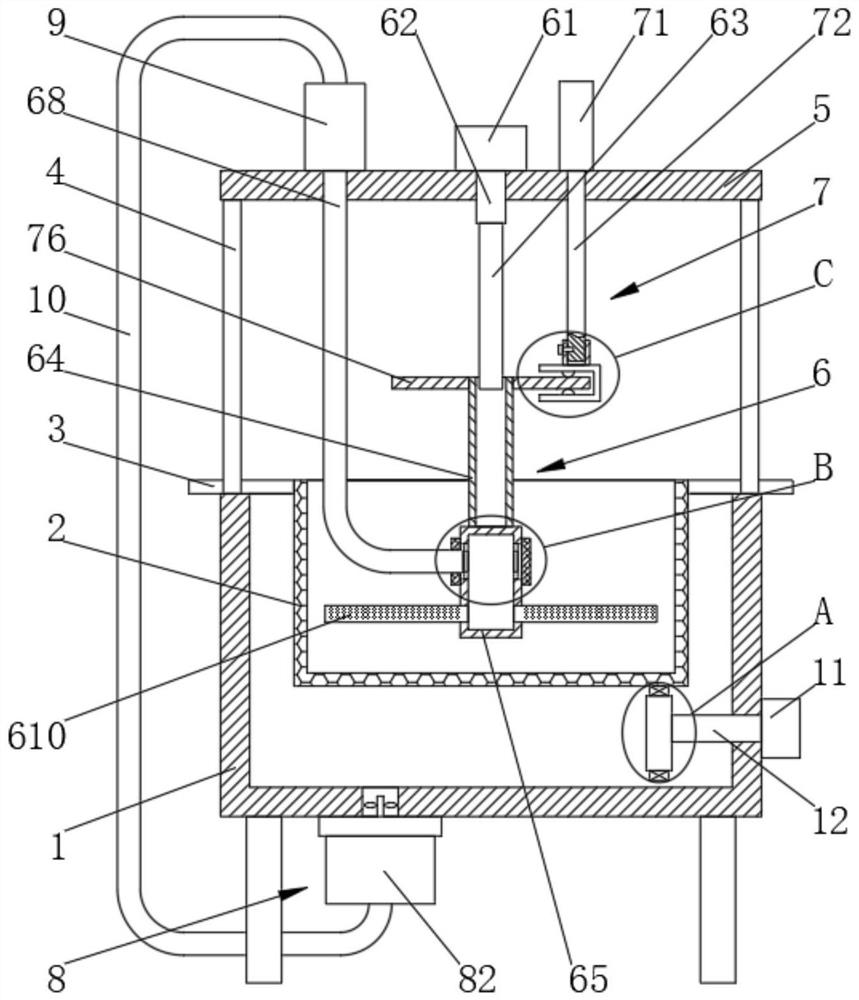

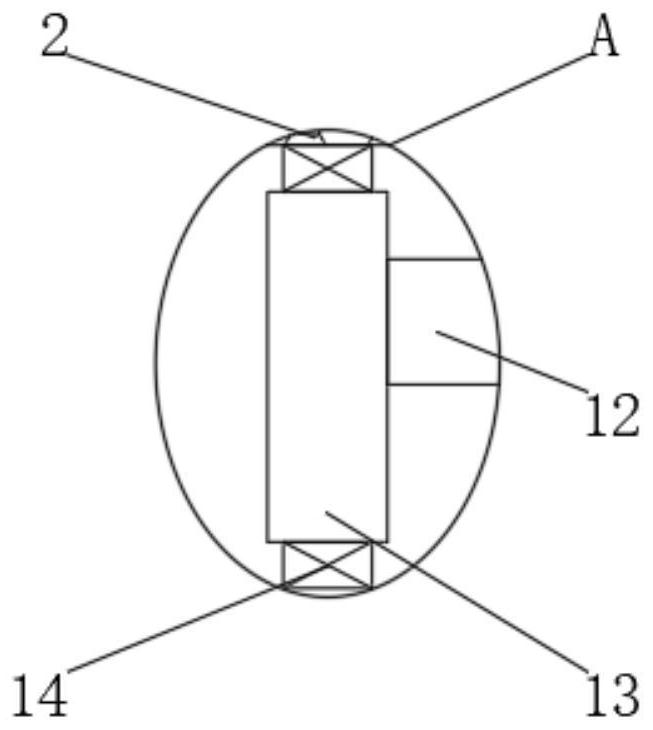

[0026] A multifunctional high-efficiency lens cleaning equipment for glasses processing, including a box body 1, a filter frame 2, a retaining rod 3, a support rod 4, a top plate 5, a rotating mechanism 6, a lifting mechanism 7, a filtering mechanism 8, a suction pump 9, and a water pipe 10. Motor 11, drive shaft 12, eccentric wheel 13 and bearing 14. The filter frame 2 is slidably connected in the box 1, and the filter frame 2 is welded with a blocking rod 3. The blocking rod 3 and the casing 1 contact, the box body 1 is welded with a support rod 4, the support rod 4 is welded with a top plate 5, the top plate 5 is provided with a rotating mechanism 6, the top plate 5 is provided with a lifting mechanism 7, and the box A filter mechanism 8 is arranged on the body 1, a suction pump 9 is fixedly installed on the top plate 5, a water pipe 10 is arranged on the suction pump 9, a motor 11 is fixedly installed on the box body 1, and the motor 11 The drive shaft 12 is rotationally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com