Method and system for separating MTP (Methanol to Propylene) reaction mixed gas

A separation method and mixed gas technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, hydrocarbons, etc., can solve the problems of restricting the development of MTP process, complicated system operation, high investment cost, etc., and reduce the energy consumption of the device and equipment investment, simplification of subsequent processes, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

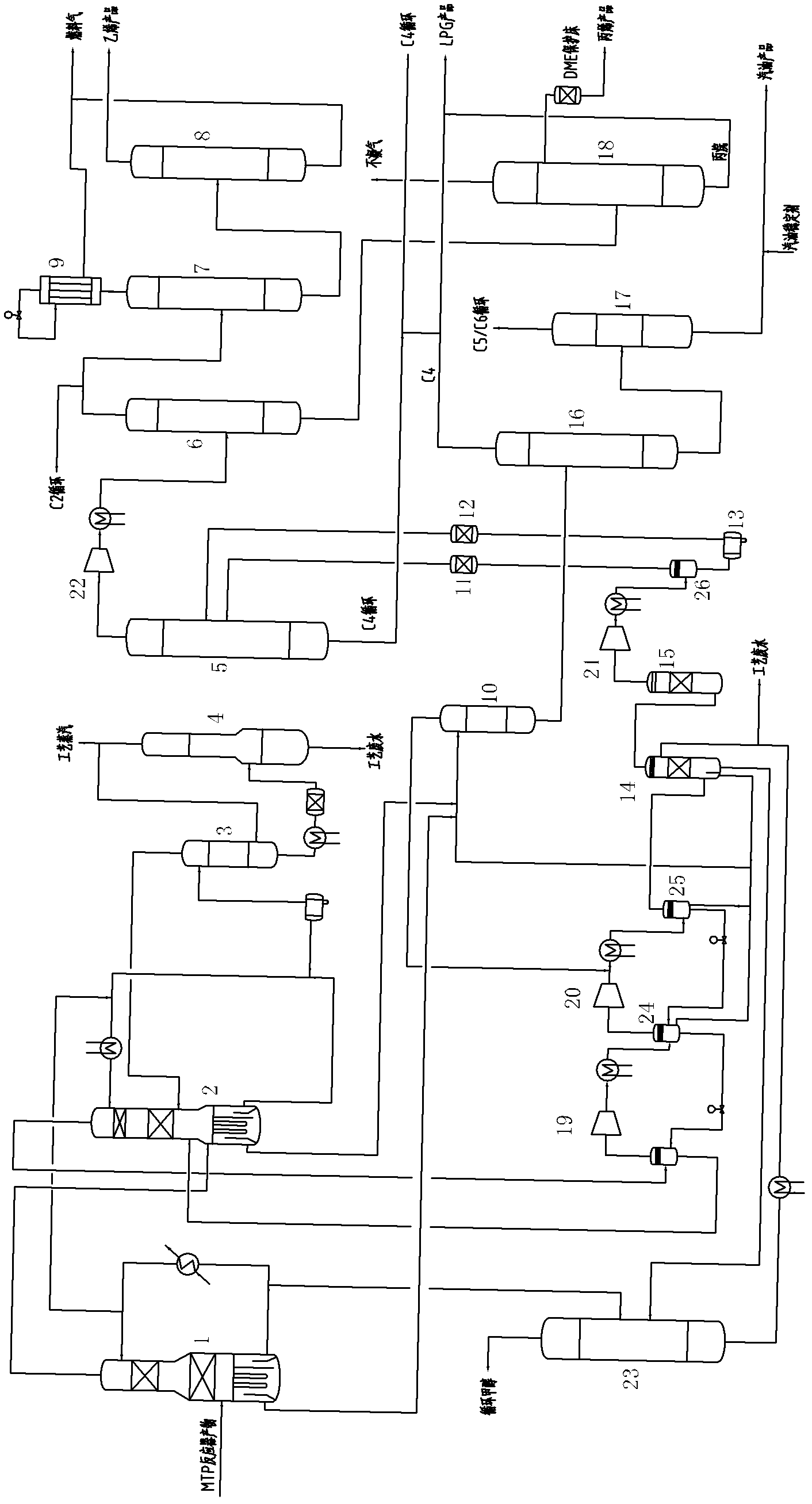

[0031] Embodiment 1: as figure 1 Shown, a kind of MTP reaction mixed gas separation method of the present invention comprises (1) the step of quenching the mixed gas; (2) the step of compressing the mixed gas; (3) the step of refining the mixed gas.

[0032]The reaction mixture gas obtained from the MTP reactor is about 190°C, first enters the pre-quench tower and is washed with pre-quench water, then enters the quench tower after the temperature drops to about 50°C, cools to about 40°C, and then is sent to the compression unit for compression. Part of the process water obtained at the bottom of the pre-quenching tower is used to supplement the process water at the top of the quenching tower after heat recovery, and the other part is returned to the pre-quenching tower, and the rest of the process water is sent to the methanol recovery tower. Part of the process water obtained at the bottom of the quenching tower is passed through After cooling, it returns to the quench tower,...

Embodiment 2

[0040] Embodiment 2: as figure 1 Shown, a kind of MTP reaction mixed gas separation system of the present invention comprises pre-quick cooling tower 1, quick cooling tower 2, process steam tower 4, compressor, depropanizer 5, debutanizer 16, condensate stripping tower 10, The compressor is provided with compression I to IV sections 19, 20, 21, 22, and the water outlet of the quench tower 1 is communicated with the liquid inlet at the top of the quench tower 1, and the water outlet of the quench tower 1 is also connected in series with the first condenser 27, Process water stripper 3, ion exchanger 28 and process steam tower 4, pre-quick cooling tower 1 water outlet and methanol recovery tower 23 water inlets, pre-quick cooling tower 1 top water inlet and quench tower 2 top water inlets communicate; The stripper 10 is located between the compression sections, the liquid hydrocarbon outlet of the separation tank 24 between the compressor I and II sections, the liquid hydrocarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com