Preparation method of large-size titanium alloy hollow blank

A titanium alloy and hollow billet technology, which is applied in the field of large-scale titanium alloy hollow billet preparation, can solve problems such as difficulties and no mature and economical methods, and achieve the effects of overcoming low plasticity, significant economic benefits, and avoiding surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing a large-scale titanium alloy hollow billet specifically comprises the following steps:

[0029] Step 1: Coating the titanium alloy ingot 1 with a hard sheath to form an assembly. Coating heating anti-oxidation paint on the surface of the sheath;

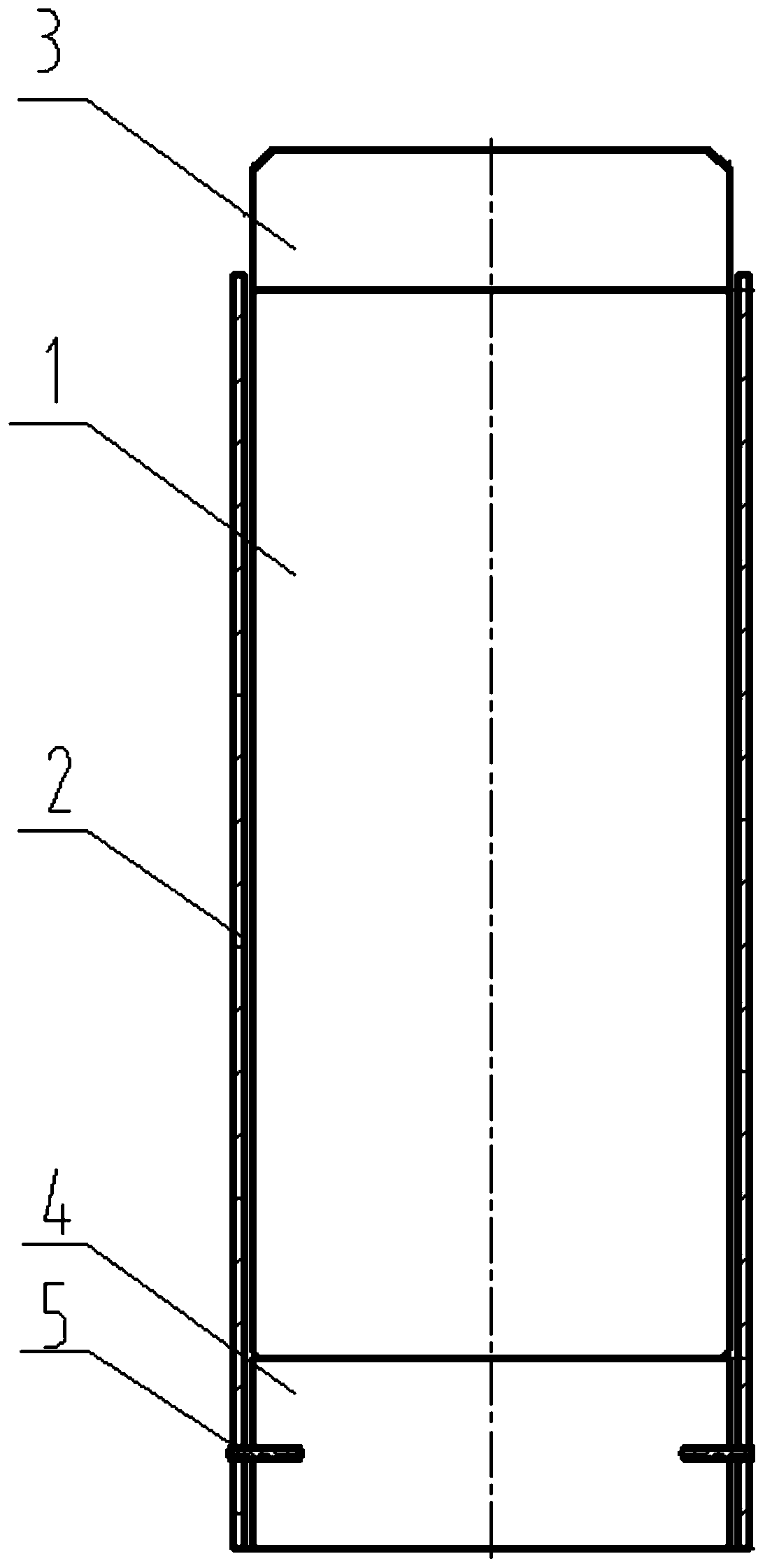

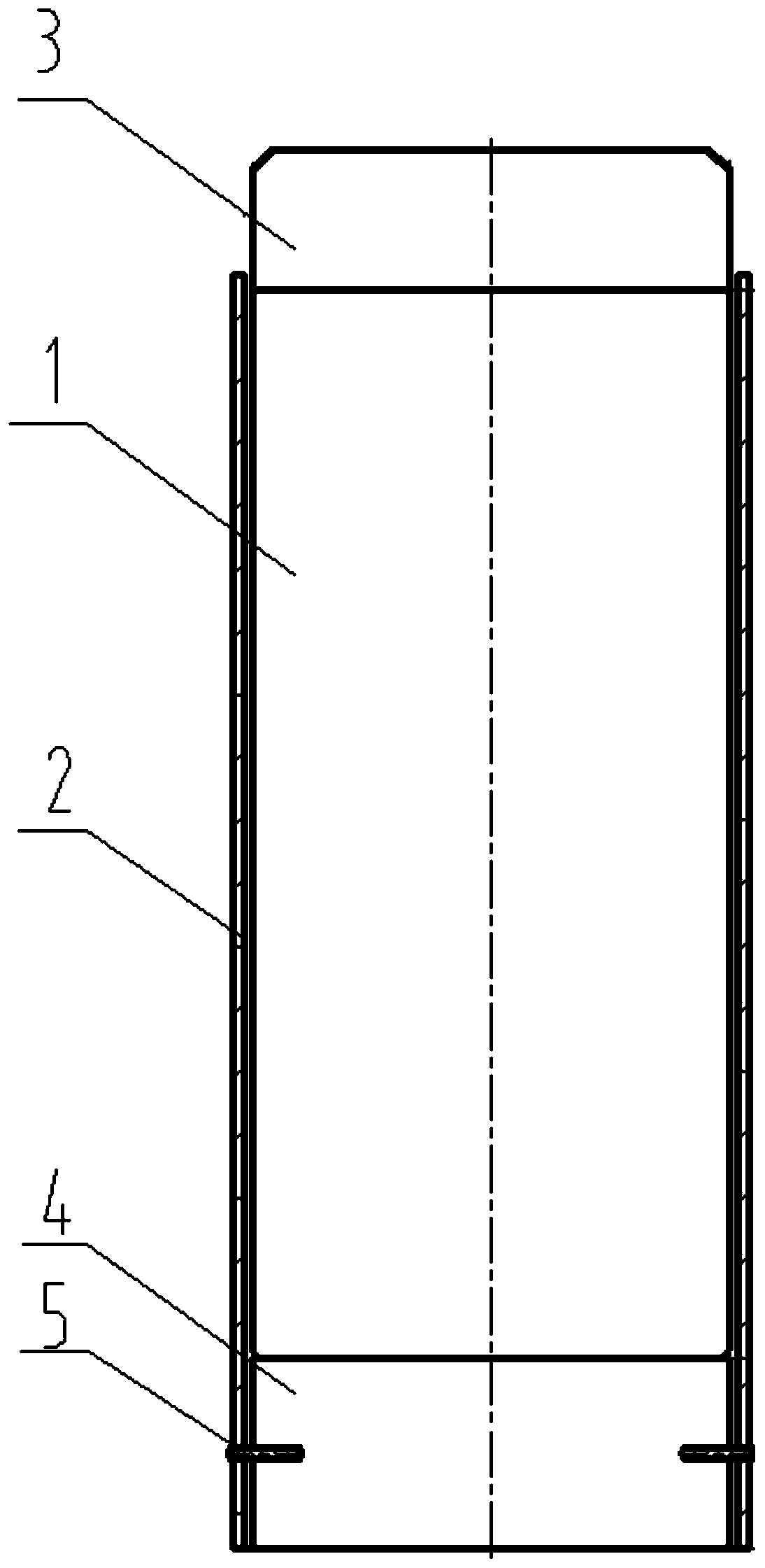

[0030] Such as figure 1 As shown, it is a schematic diagram of the assembly of the ingot package in the present invention, that is, an assembly.

[0031] The package includes: package sleeve 2, upper spacer 3, lower spacer 4, connecting pin 5; 2 have a pin hole on the side wall of the bottom, and the lower pad 4 has a fixed counterbore on the side wall; the connecting pin 5 passes through the pin hole and is inserted in the fixed counterbore to prevent the lower pad 4 from coming off. The cladding sleeve 2 is made of stainless steel, the wall thickness is ≥15 mm, and the inner diameter is 5 mm larger than that of the titanium alloy ingot 1 . The upper pad 3 is made of low carbon steel, the diameter...

Embodiment 1

[0040] Material: TC4 titanium alloy

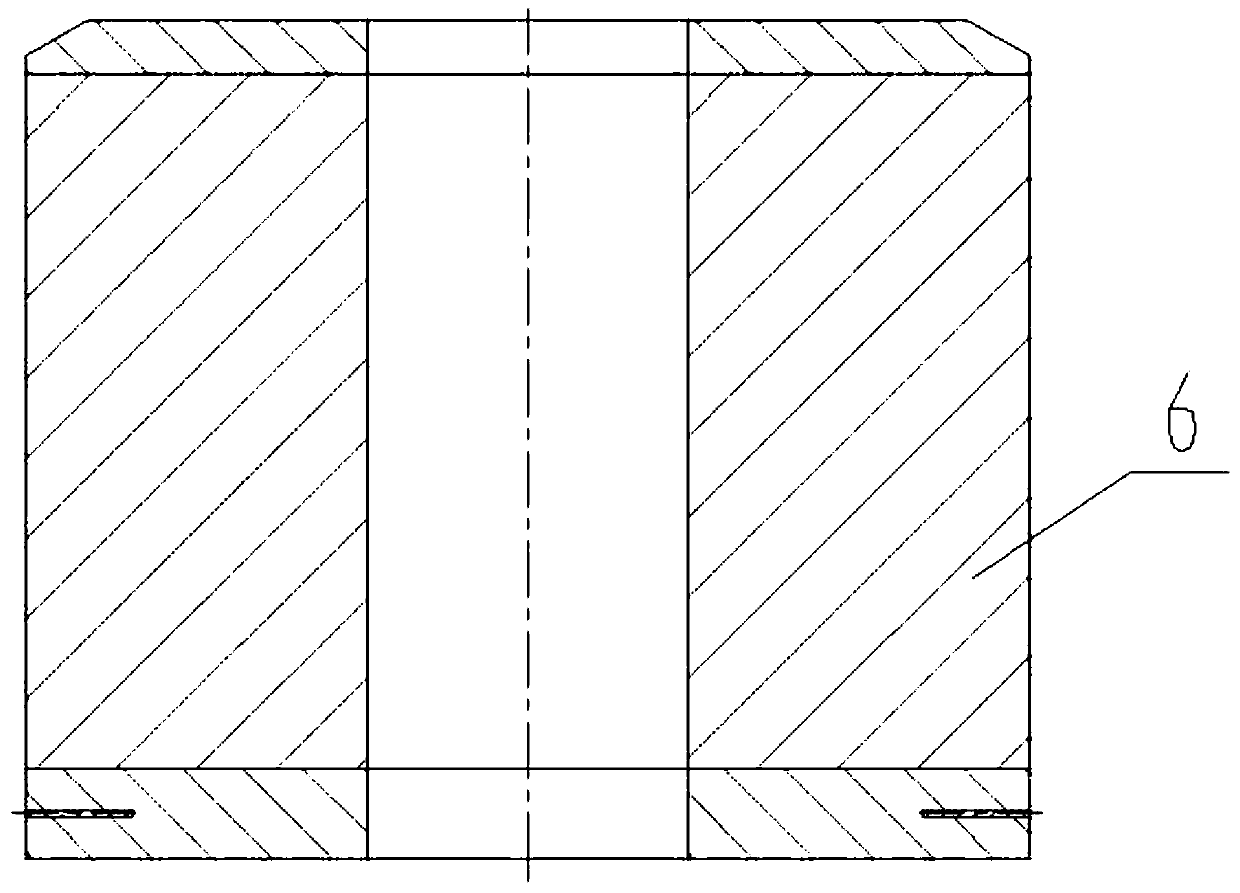

[0041] Hollow blank 6 specifications: φ1125mm×φ360mm×690mm

[0042] 1. Titanium alloy ingot preparation;

[0043] According to the requirements of GJB 220-94, the TC4 titanium alloy ingot is smelted, the riser is not removed after peeling, the diameter is 620mm, the height of the ingot is 1350mm, the ingot weight is 1.8 tons, and the temperature of the β transformation point is 995°C.

[0044] 2. Production of end caps and bags;

[0045] (1) Use 304 stainless steel cylinder, specification 720*15*1840mm, to make bag sleeve 2;

[0046] (2) Cut out the upper cushion block 3 and the lower cushion block 4 by using thick steel plate (forgings can also be used).

[0047] The thickness of the upper block is 200mm, and the diameter is D1. In order to improve the utilization rate of materials, excess process materials are added at the bottom, with a thickness of 310mm and a diameter of D1.

[0048] 3. The outer surface of the sheath is coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com