Weaving method of warp knitted seamless bottomless jacquard stockings

A technology of seamless and stockings, which is applied in the weaving field of warp-knitted fabrics and warp-knitted seamless bottomless jacquard stockings, which can solve problems such as not being able to meet the requirements of fabrics, and achieve the effects of light and thin texture, lower production costs, and clear layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with specific drawings.

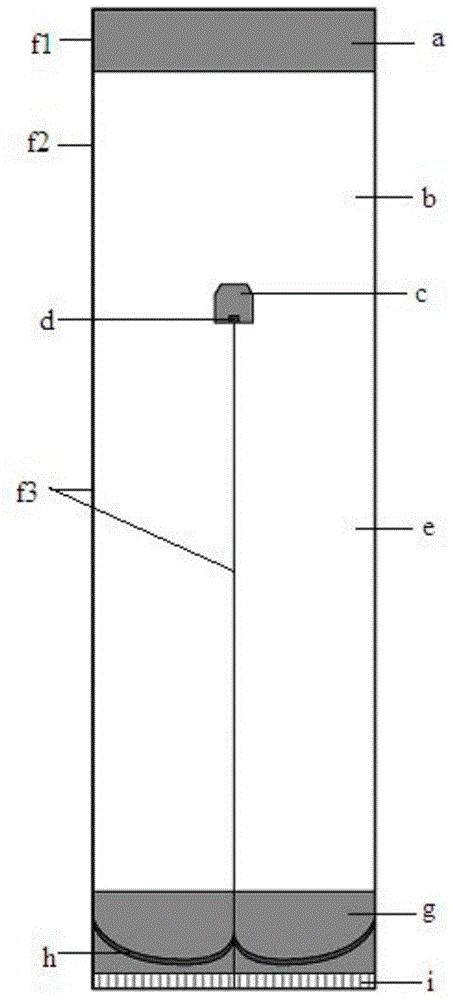

[0067] Such as figure 2 As shown, the warp-knitted seamless bottomless jacquard stockings of the present invention include a trouser waist a, a trouser body b, a sock tube e, a crotch c, a sock toe g and a sock bottom dividing part i, the trouser waist a, trousers The body part b and the sock part e respectively consist of two front and rear pieces, the side seam f1 of the trousers body is formed between the front and rear pieces of the trouser waist part a, and the side seam f1 is formed by the front and rear pieces of the trouser body part b. Seam f2, the side seam f3 of the sock is formed by the seam between the front and rear panels of the sock part e, the crotch seam d is formed by thick stitching at the middle seam of the crotch part c, and the front end of the toe part g is formed by thick stitching Toe seam h. The trouser waist part a adopts thick weave; the trouser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com