Method for manufacturing electronic product composite material shell through resin transfer molding process

A technology of resin transfer molding and electronic products, which is applied in the field of molding composite material shells to achieve the effects of high mechanical strength, high production efficiency and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

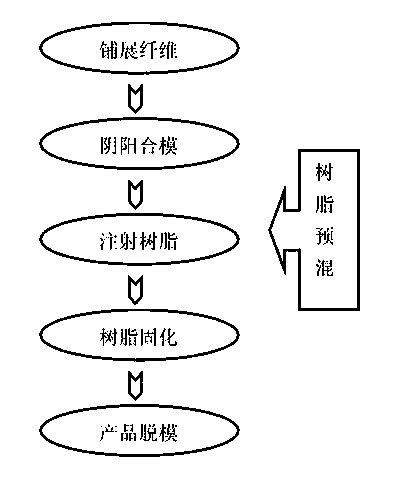

Method used

Image

Examples

Embodiment 1

[0018] To make a single-layer glass fiber composite electronic product casing, the manufacturing steps are:

[0019] First mix an appropriate amount of gel coat and accelerator, then mix with a certain amount of curing agent evenly, and then use a gel coat sprayer to spray a thin layer of the above premixed gel coat in the cavity of the female mold; after the gel coat is completely cured, you can Spread a layer of glass fiber cloth in the mold cavity;

[0020] At this time, the mold is closed, and the unsaturated polyester resin and curing agent automatically mixed by the equipment are injected into the mold cavity under a certain pressure;

[0021] Curing the resin at room temperature, demoulding, and taking out the composite material from the female mold cavity;

[0022] At this time, the main process steps have been completed, and then CNC is used to remove the overflow around the composite material, and the final spraying and printing processes are carried out to obtain t...

Embodiment 2

[0024] To make a single-layer Kevlar fiber composite electronic product casing, the manufacturing steps are as follows:

[0025] Spread a layer of Kevlar fiber cloth in the cavity of the female model; after closing the mold, the equipment will automatically mix epoxy resin and curing agent and inject it into the cavity of the mold under a certain pressure; The composite material is removed from the mold cavity.

[0026] After the main process is completed, the product can be post-processed, and the flash around the composite material is removed by laser engraving; the composite material is injected into the mold to form a buckle structure on the composite material; the composite material with a buckle structure is finally processed Spraying and printing process, you can get electronic product Kevlar composite shell.

Embodiment 3

[0028] To make a double-layer carbon fiber composite material electronic product casing, the manufacturing steps are as follows:

[0029] Spread two layers of carbon fiber cloth in the cavity of the female model; close the mold, vacuumize, press the equipment operation key, so that the bismaleimide resin and curing agent automatically mixed by the equipment are injected into the cavity of the mold; heat and cure the resin, De-mold and remove the composite from the female cavity.

[0030] After the main process is completed, use CNC to remove the overflow around the composite material; perform in-mold injection molding on the composite material, so that a buckle structure is formed on the composite material, and then the carbon fiber composite material with the buckle structure is finally sprayed and printed. Carbon fiber composite housings for electronics are available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com