Motor

A printed circuit board and open part technology, applied in the field of small motors, can solve the problems of stator molded motors with many processes, difficult stator molded motors, and high defective products, so as to prevent bad phenomena, simplify assembly, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

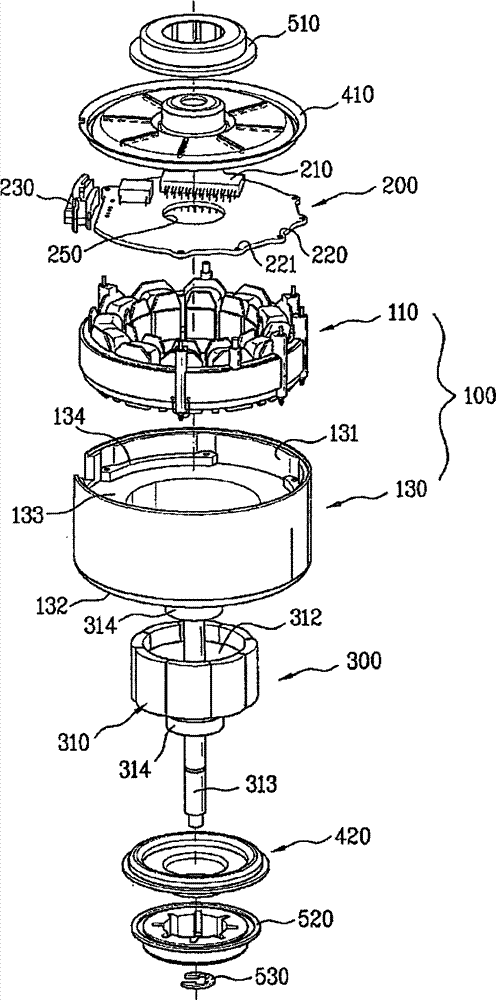

[0052] figure 1 It is an exploded perspective view of the motor of the present invention.

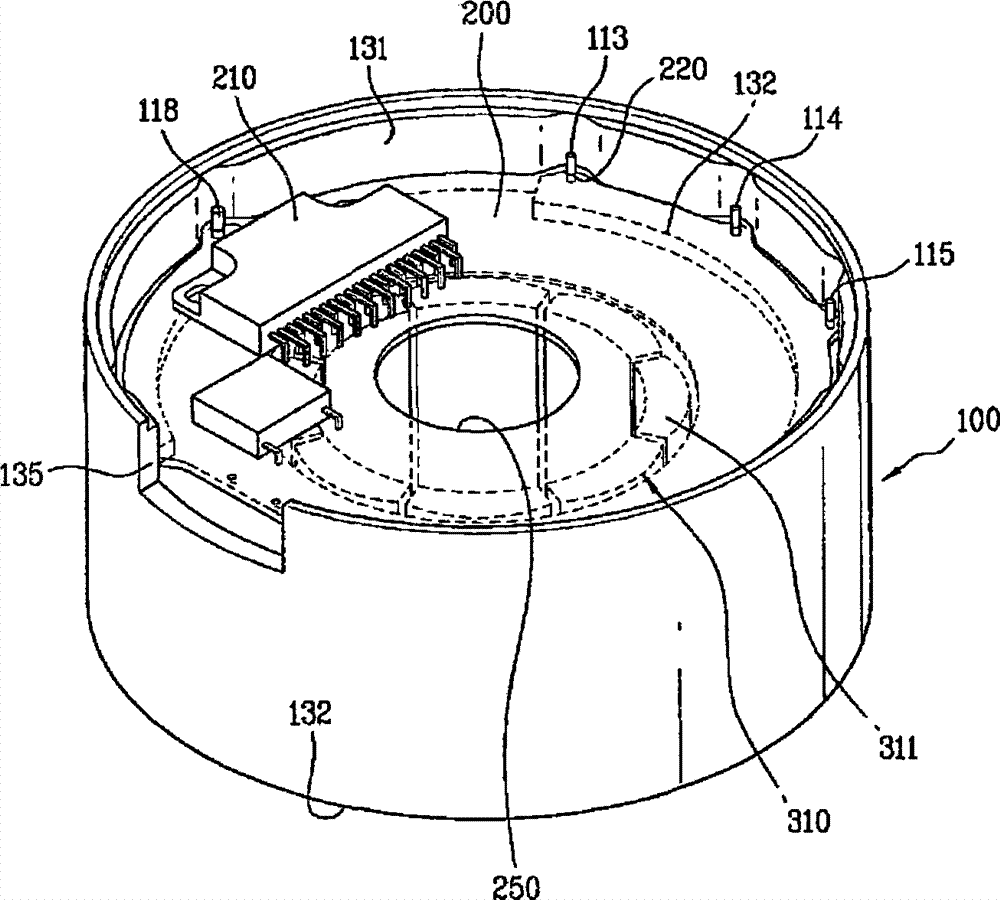

[0053] Such as figure 1 As shown, the motor of the present invention includes a stator assembly 100 , a rotor assembly 300 and a printed circuit board 200 . That is, the rotor assembly 300 rotates relative to the stator assembly 100 ; the printed circuit board controls the rotation of the rotor assembly 300 .

[0054] The stator assembly 100 includes a stator 110 and a molding part 130; the material selected for the molding part is an insulating resin material, preferably formed by molding BMC (Bulk Molding compound).

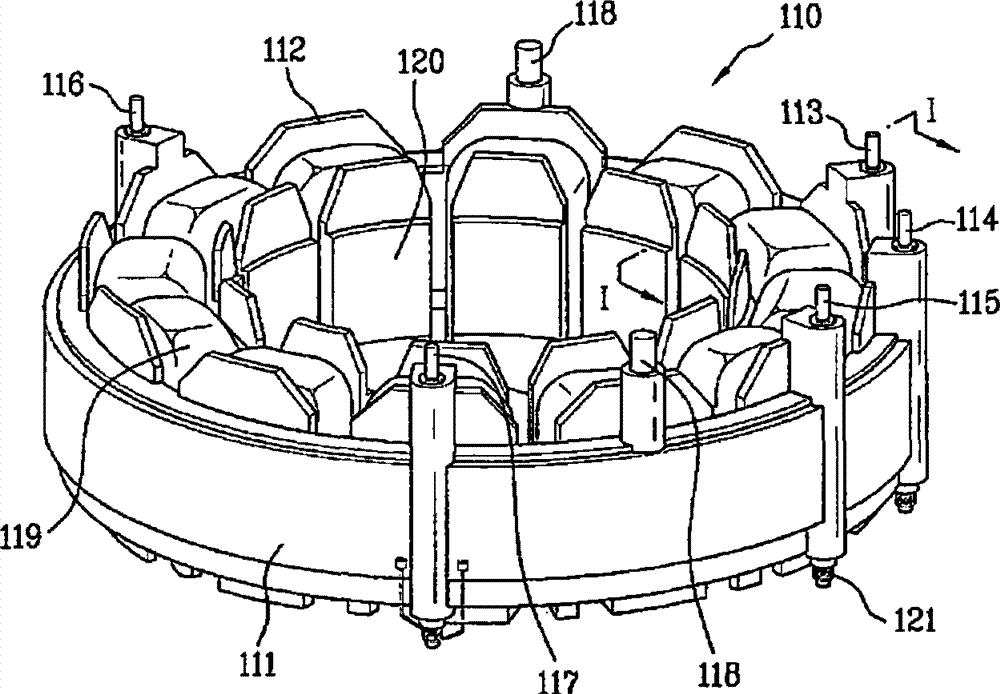

[0055] Such as figure 2 As shown, the stator 110 includes a stator core 111, an insulator 112 and a stator coil 119 (hereinafter referred to as "coil").

[0056] The stator core 111 is generally formed by stacking stator magnetic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com