Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

A wet-process phosphoric acid and mixing system technology, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor mixing effect and low uniformity, achieve high uniformity, improve mixing effect, and reduce fluid stagnation The effect of flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

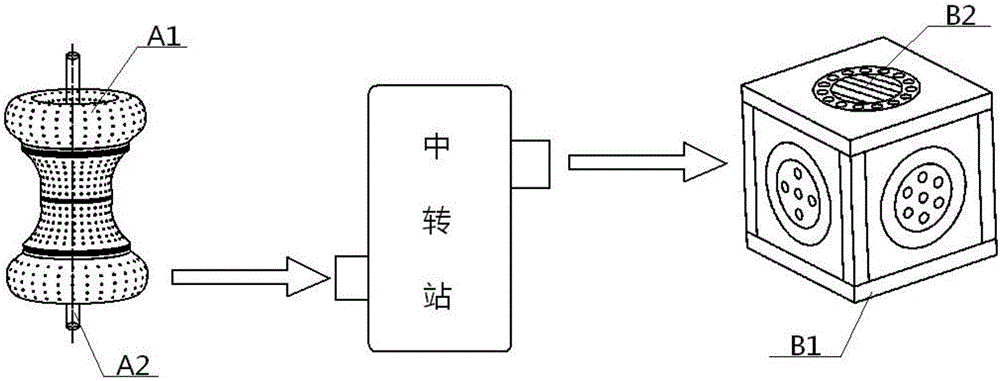

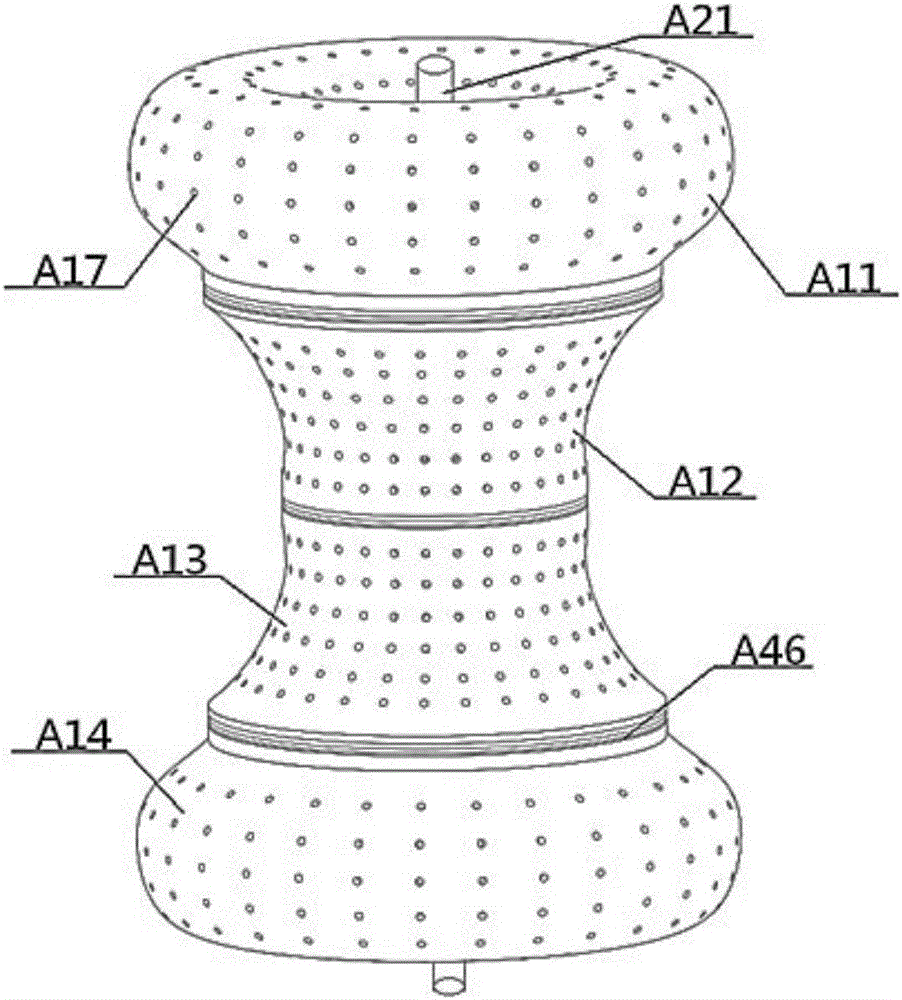

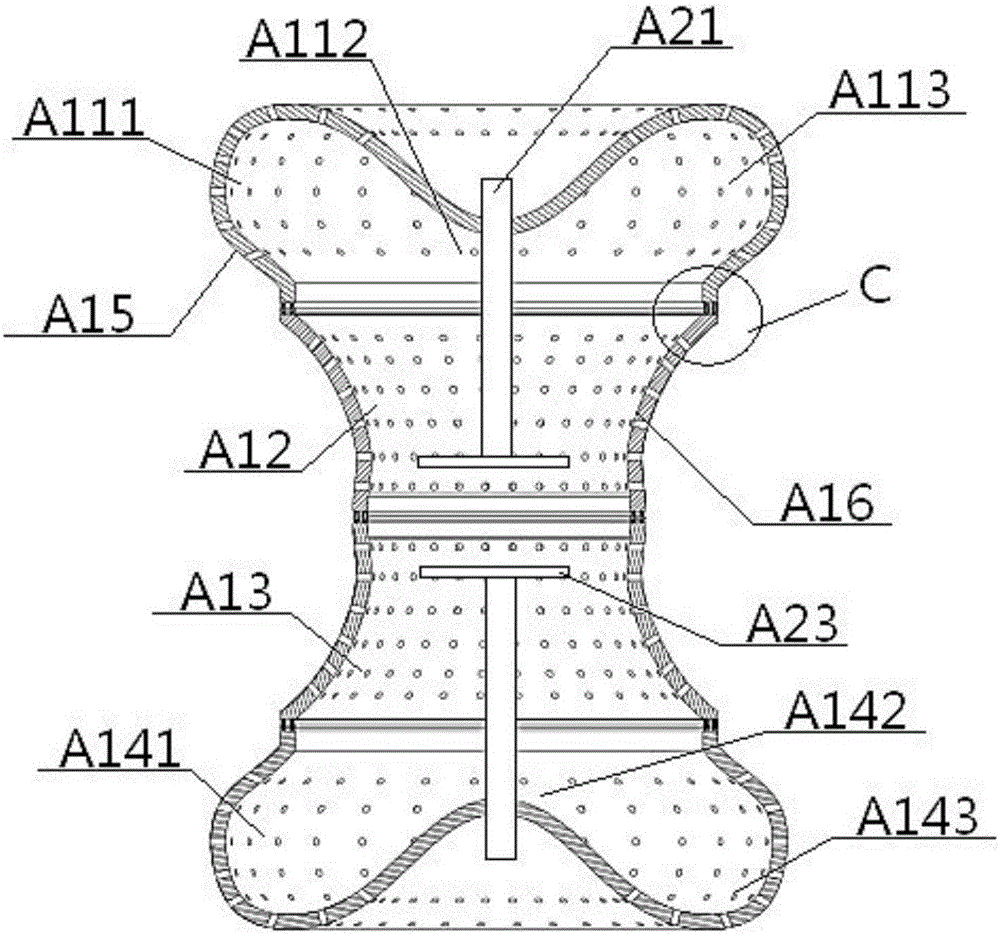

[0124] see Figure 1 to Figure 14 , during use, first put the raw materials to be mixed into the A-type outer container A1, the raw materials can be a combination of powder and liquid, or a combination of liquid and liquid (only the types of raw materials are limited, not limited to two kinds of raw materials) ), then start the top outer container A11, upper middle outer container A12, middle lower outer container A13, and bottom outer container A14 to rotate, and at the same time start the A-type agitator A2 to rotate to stir and mix the mixture to obtain a primary mixture, and then The primary mixture is put into the B-type outer container B1 through the transfer station for secondary stirring and mixing. At this time, new liquid or powder raw materials can be added according to the application requirements, and then the rotating pipe seat B4 is started to flow into the B-type outer container B1. The swirling airflow is ejected, and at the same time, the B-type agitator B2 i...

Embodiment 2

[0126] Basic content is the same as embodiment 1, the difference is:

[0127] When the A-type mixing device or the B-type mixing device is stirring and mixing, a heating element can be installed in the two to heat the mixed raw materials, so that the mixing is under a certain temperature condition. The specific heating element type selection, The layout design depends on the mixing temperature required by the application.

Embodiment 3

[0129] Basic content is the same as embodiment 1, the difference is:

[0130] When the A-type mixing device is stirring and mixing, it can inject swirling airflow to its inside through the air inlet pipe A17 provided on the A-type outer container A1 to enhance the mixing effect. All the air intake equipment disclosed can also be the air guide column B5 structure adopted in the B-type mixing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com