Horizontal type rotary drum stirring, feeding and discharging device

A stirring device and drum technology, which is applied in the field of horizontal drum stirring and in-out devices, can solve the problems that materials cannot be fully contacted with air, affect fermentation quality, and uneven fermentation, so as to achieve smooth material level, improve fermentation efficiency, strong mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

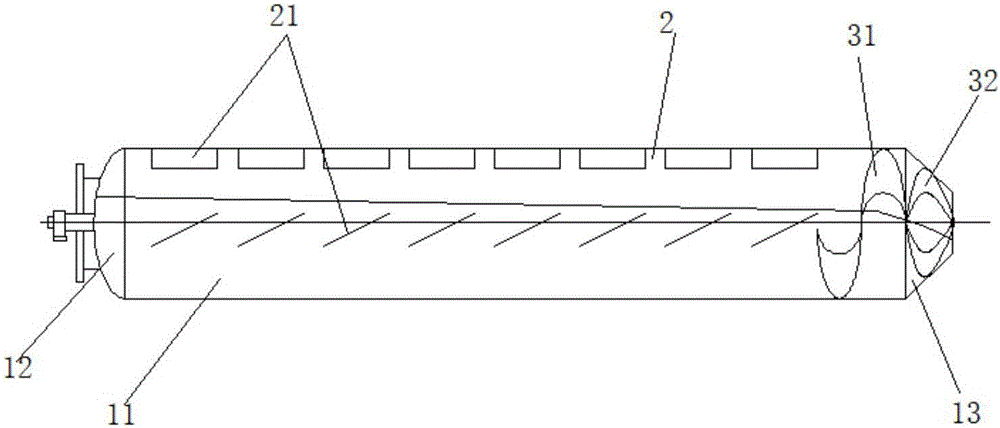

[0017] Such as figure 1 As shown, the utility model relates to a horizontal drum stirring and in-out device, including a drum body and a stirring device. The fermenter includes a columnar body 11, a left head 12 and a right head 13. Inside the cylinder, it is used to stir the materials in the tank; the stirring device is an intermittent blade 2, which is composed of sub-blades 21, which are arranged at equal distances in the axial direction and fixed on the inner wall of the drum, and the sub-blades 21 are rectangular. The size of each sub-blade 21 is the same, and its height is not higher than the radius of the section of the cylinder 11. Sub-blades 21 of different heights and widths can be customized according to the type of material. The sub-blades 21 are not less than three pieces, and the sub-blades 21 are 0 -90° angle, more preferably 10-25° angle, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com