Stirring device for processing tea oil

A stirring device and camellia oil technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of long heating time, low production efficiency, slow scraping speed, tea oil stirring speed, etc. , to achieve the effects of large stirring force area, preventing gas loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

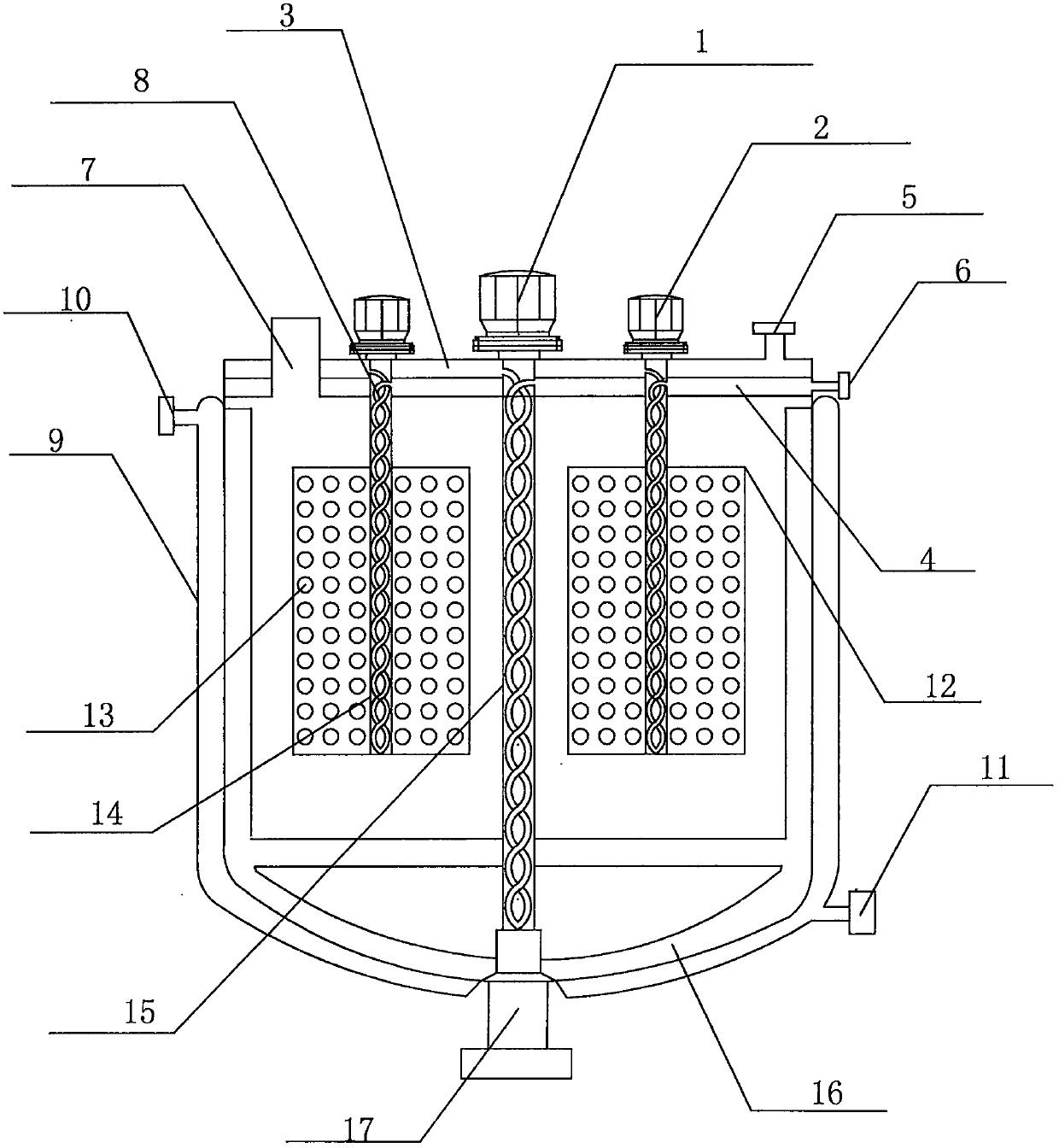

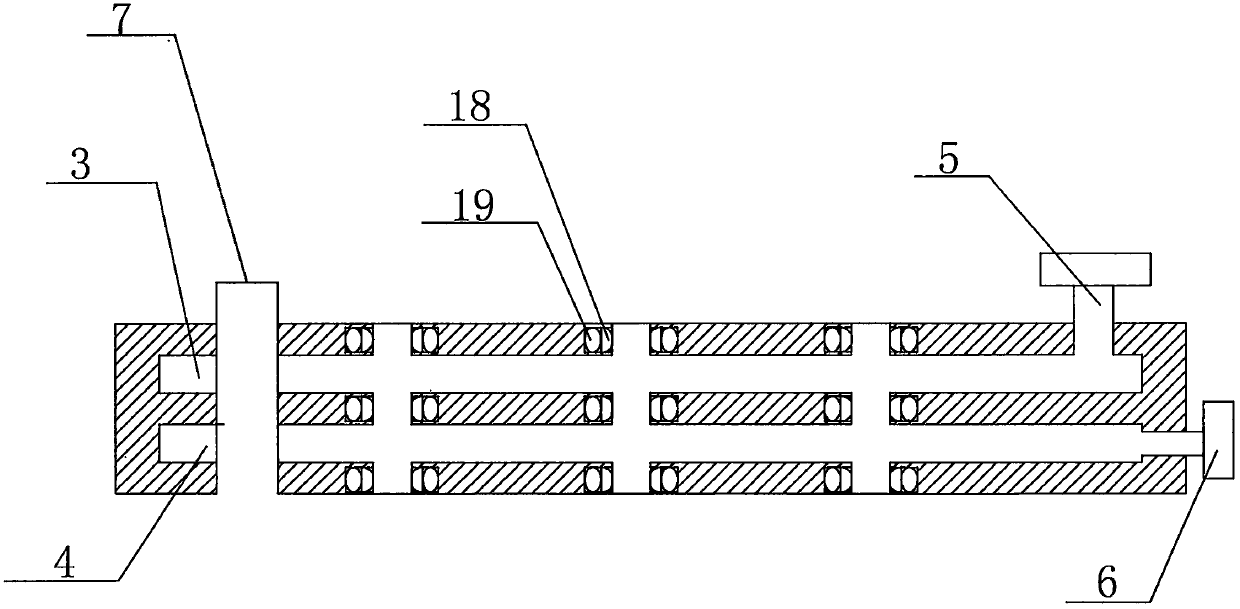

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0015] like Figures 1 to 2 A stirring device for processing camellia oil is shown, including a reaction cylinder and a cylinder cover matching it. An oil inlet 7 is arranged on the periphery of the cylinder cover, and the bottom of the reaction cylinder adopts an arc structure. An oil outlet 17 is arranged at the center, and a casing 9 is arranged outside the reaction cylinder. A heating chamber is left between the casing 9 and the reaction cylinder. A liquid inlet 11 connected to the heating chamber is arranged below the casing 9. A liquid outlet 10 communicating with the heating chamber is provided above the body 9 to realize heating of the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com