Reciprocating heat accumulating type internal combustion engine using scavenging pump for auxiliary intake and exhaust

A scavenging pump, regenerative technology, applied in exhaust devices, combustion engines, fuel heat treatment devices, etc., can solve the problems of low efficiency in variable working conditions, low efficiency of gasoline engines, and many moving parts, and achieve low vibration and noise. , The engine pressure ratio is small, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with the accompanying drawings, the present invention will be further described by taking specific implementation as an example.

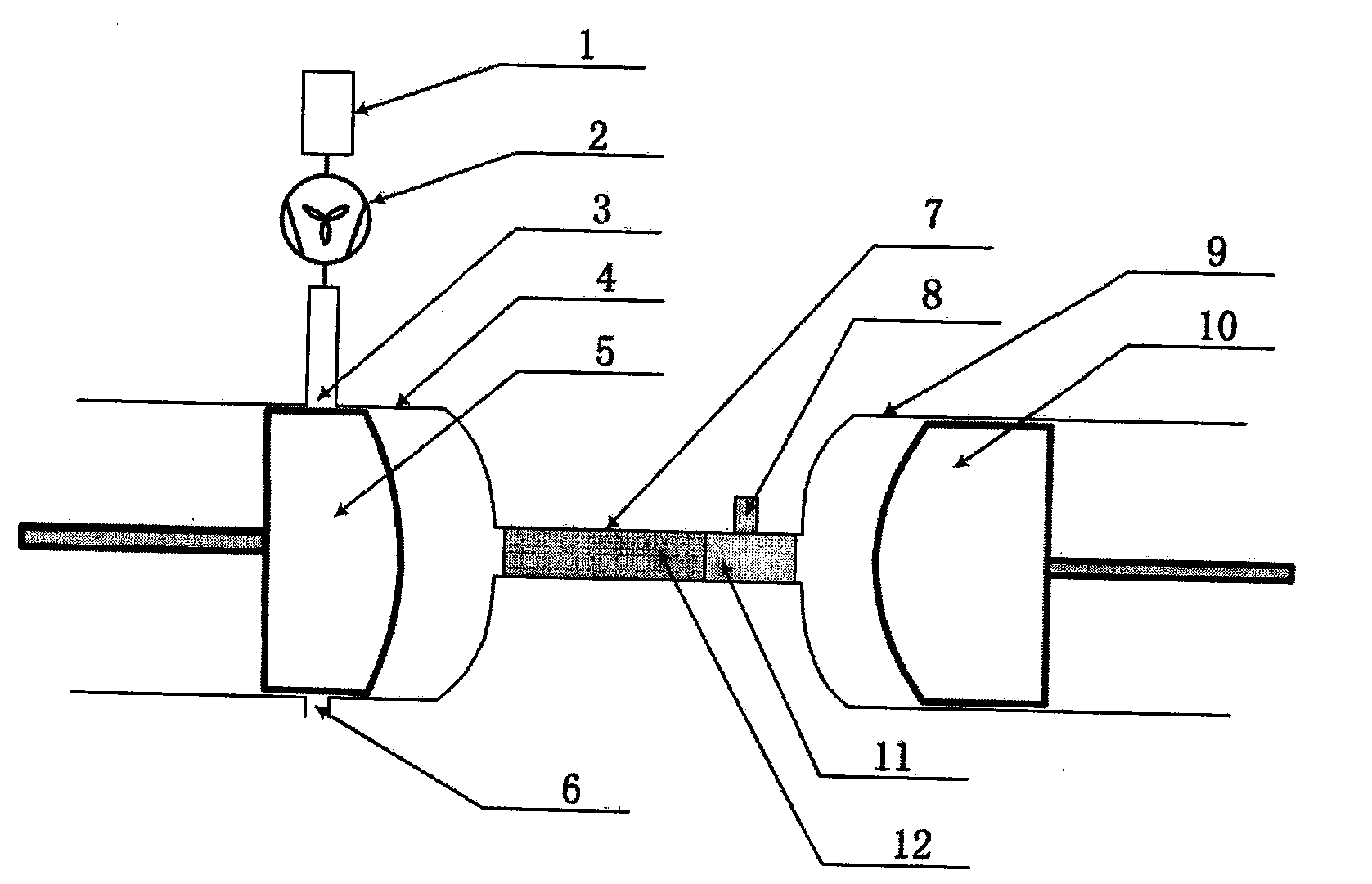

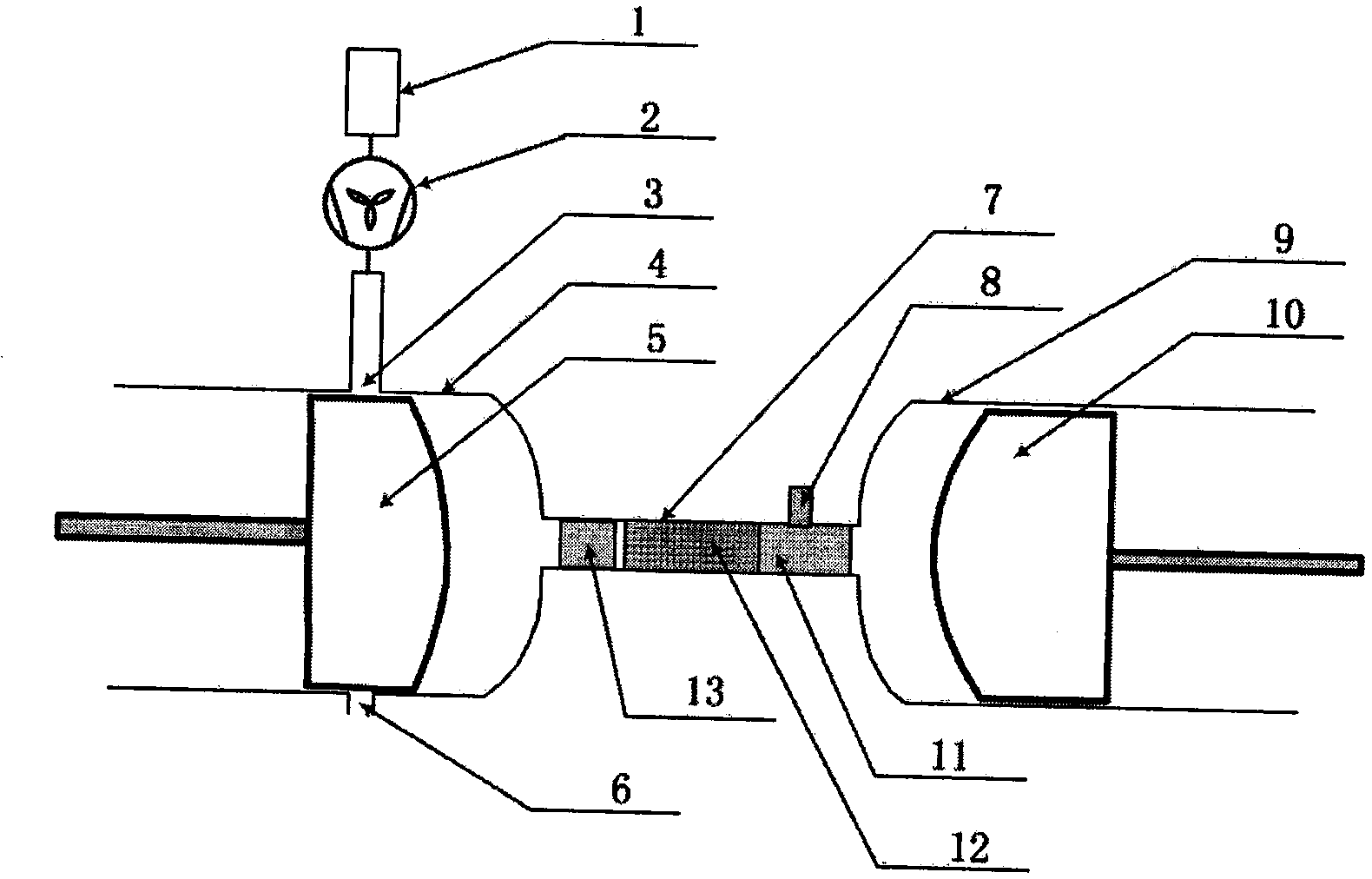

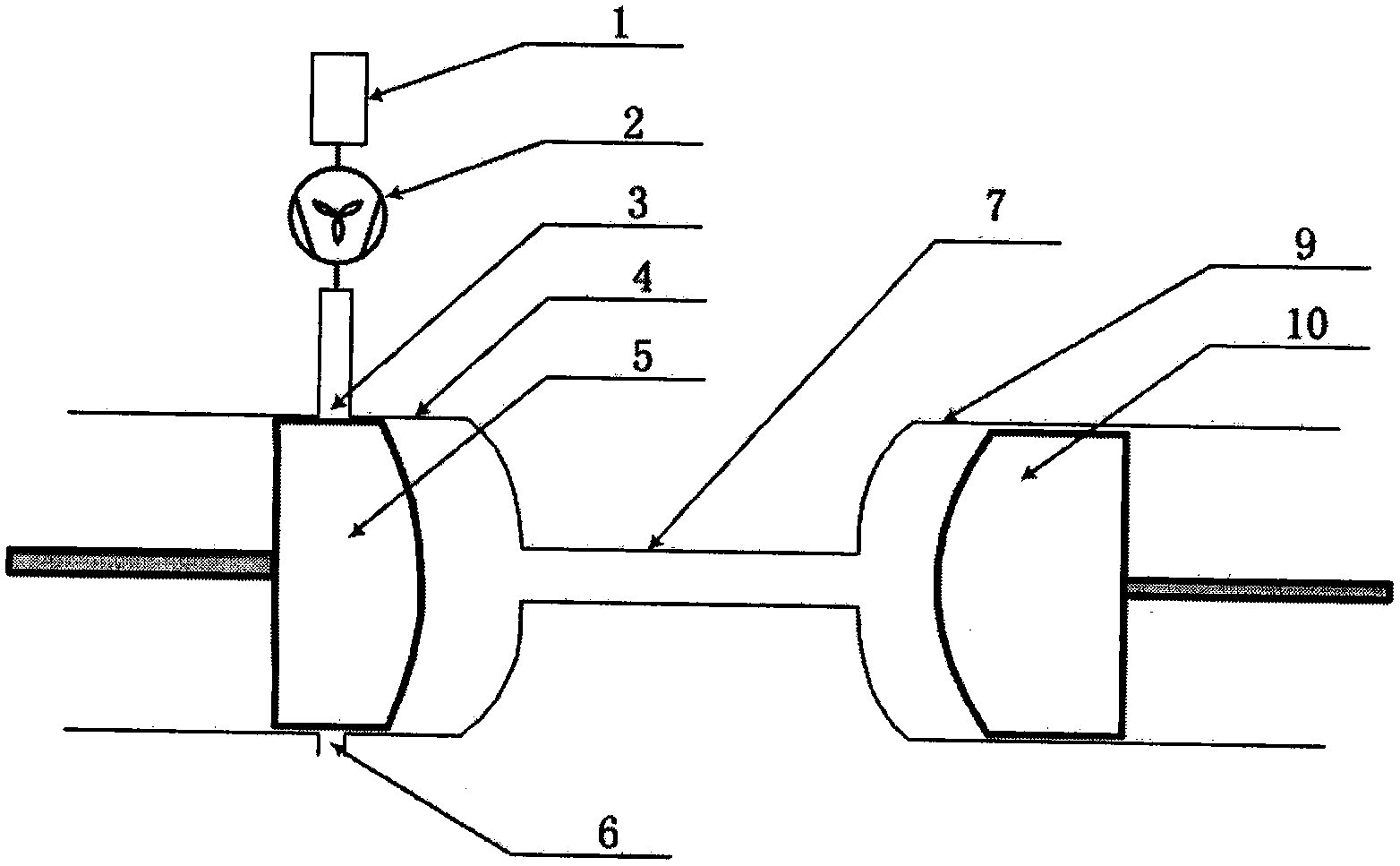

[0025] Such as figure 1 As shown, the reciprocating regenerative internal combustion engine mainly includes a scavenging pump 2 , a compression cylinder 4 , a connecting pipe 7 , a heat storage body 12 , a combustion chamber 11 and an expansion cylinder 9 . The connection mode of the scavenging pump 2, the compression cylinder 4, the connecting pipe 7 and the expansion cylinder 9 is as follows: image 3 shown. The compressed gas outlet of the compression cylinder 4 is connected to one end of the communication pipe 7 , and the other end of the communication pipe 7 is connected to the expansion cylinder 9 . The connection port between the communication pipe 7 and the expansion cylinder 9 is used as the intake and exhaust port of the expansion cylinder 9, that is, the gas entering and discharging of the expansion cylinder 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com