Marine flat-bulb steel squirrel-cage type induction heating device and marine flat-bulb steel squirrel-cage type induction heating process

A technology of induction heating device and bulb flat steel, which is applied to the improvement of process efficiency, heat treatment furnaces, manufacturing tools, etc., can solve the problems of large temperature difference, increased internal stress, rapid temperature rise, etc., to improve uniformity and reduce localization. The effect of excessive temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

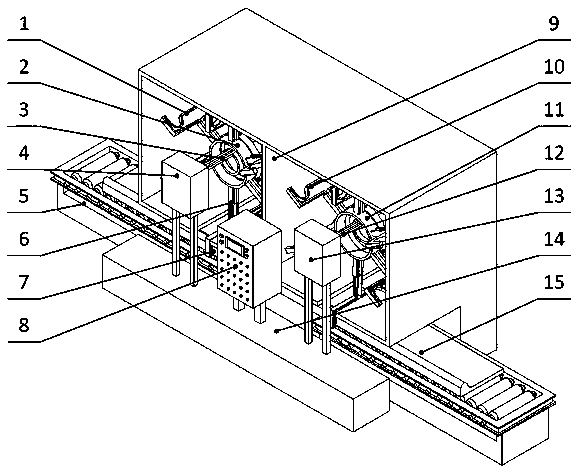

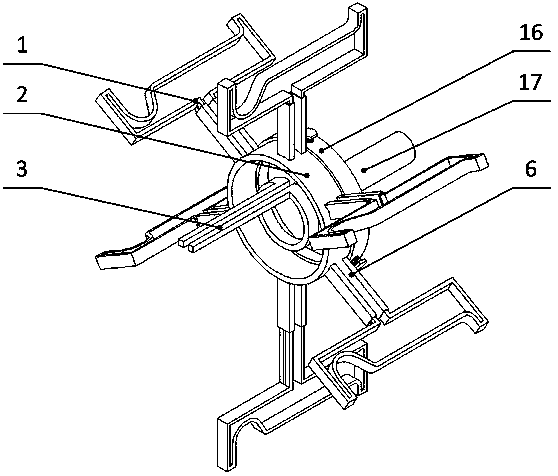

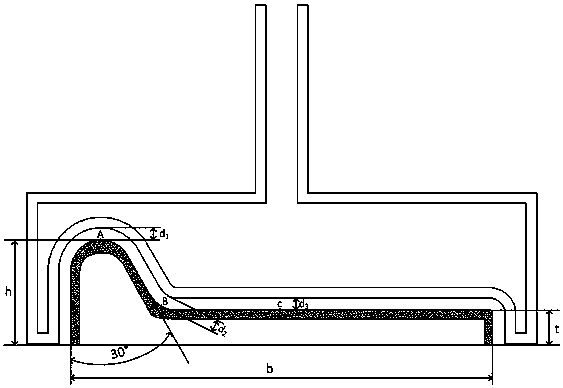

[0031] The invention discloses a squirrel-cage induction heating device and process for marine spherical flat steel. Specifically, it is a squirrel-cage induction heating device and process applied to special profiles. It adopts the method of preheating and heating twice, The roller conveyor belt is used to drive the marine bulb flat steel to move at a constant speed on the production line to realize continuous quenching, and to obtain a reasonable temperature distribution on the surface of the workpiece through heat conduction, and to obtain an ideal heating effect after secondary heating.

[0032] A marine spherical flat steel squirrel-cage induction heating device, including a heating box with an isolation plate 9 inside, a roller conveyor belt 5 located at the lower part of the heating box for transmitting the marine spherical flat steel 15, and a temperature measuring camera 7 arranged at the bottom of the heating box and the numerical control console 8; the heating box is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com