Steel strip continuous vertical quenching device and quenching method

A quenching device and vertical technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as steel strip bending, increase processing efficiency, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

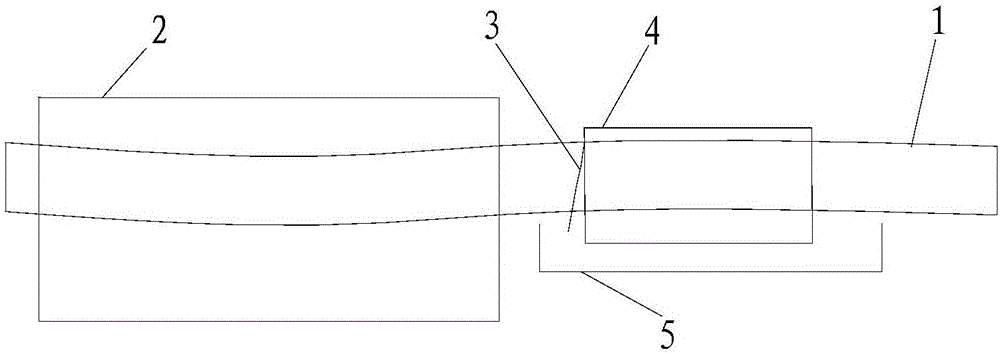

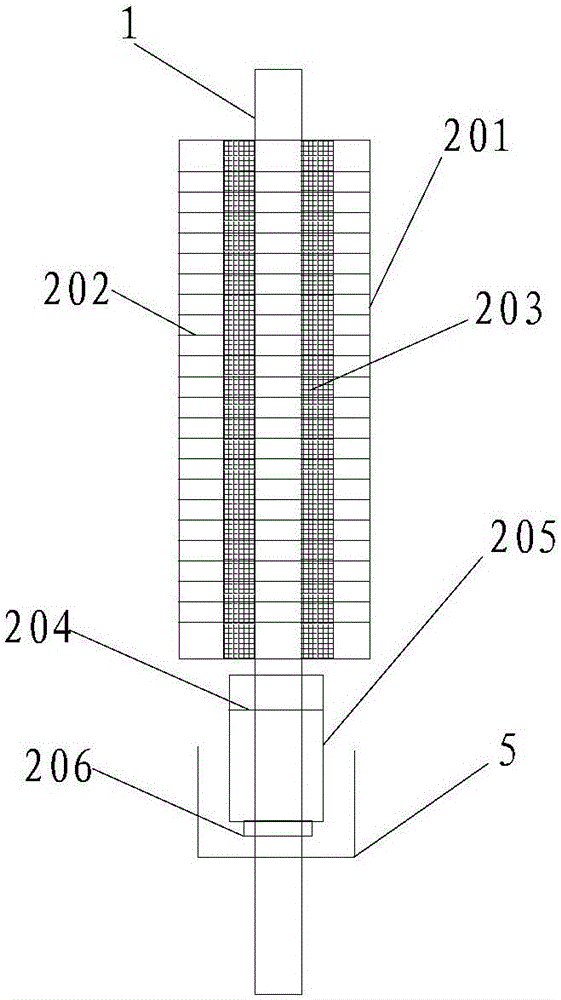

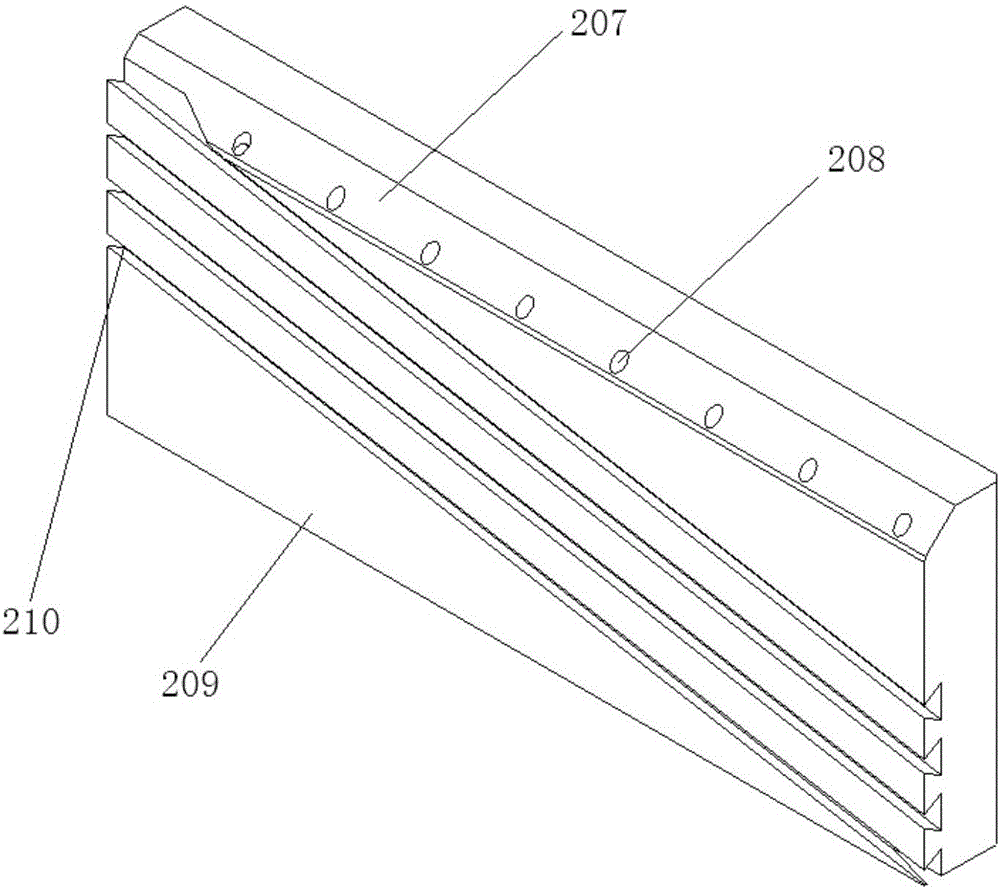

[0024] Such as figure 2 The shown continuous vertical quenching device for steel strips includes: a vertical quenching furnace 201; a vertical quenching oil tank 205 located below the vertical quenching furnace 201, which should maintain a sufficiently high quenching oil level 204 inside; The oil receiving tank 5 below the oil tank 205 has an outlet in the middle of the oil receiving tank 5, and the steel strip 1 after quenching enters the next process through the outlet. In addition, an annular rib is provided around the outlet to prevent the oil receiving tank from The quenching oil in 5 overflows from the outlet; the oil scraping base 206 that is arranged in the oil receiving groove 5 and is pressed on both sides of the steel strip 1, and the opposite side of the oil scraping base 206 is installed such as image 3 The wiper blade shown.

[0025] In this embodiment, a heating rod 202 is arranged in the vertical quenching furnace 201. The heating rod is a linear silicon-mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com