The process of smelting precipitation hardening steel by vacuum decarburization furnace

A technology of vacuum decarburization and precipitation hardening, applied in the field of steelmaking, can solve the problems of long refining and smelting cycle, high cost and inability to guarantee, and achieve the effect of shortening refining cycle, reducing dosage and reducing control cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

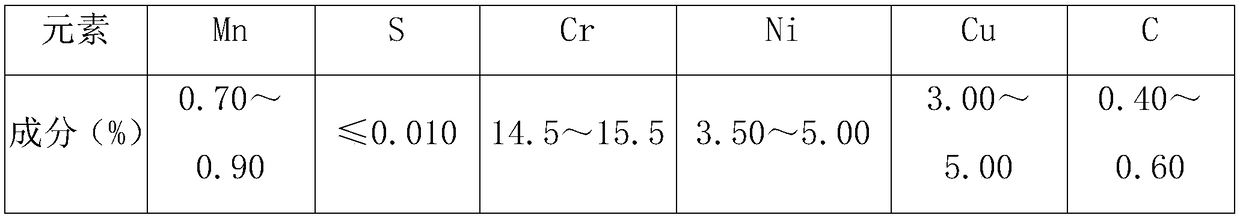

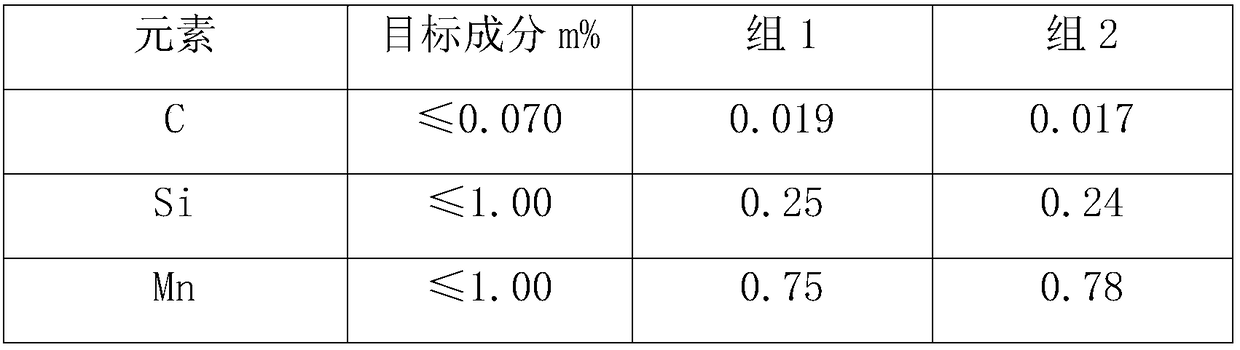

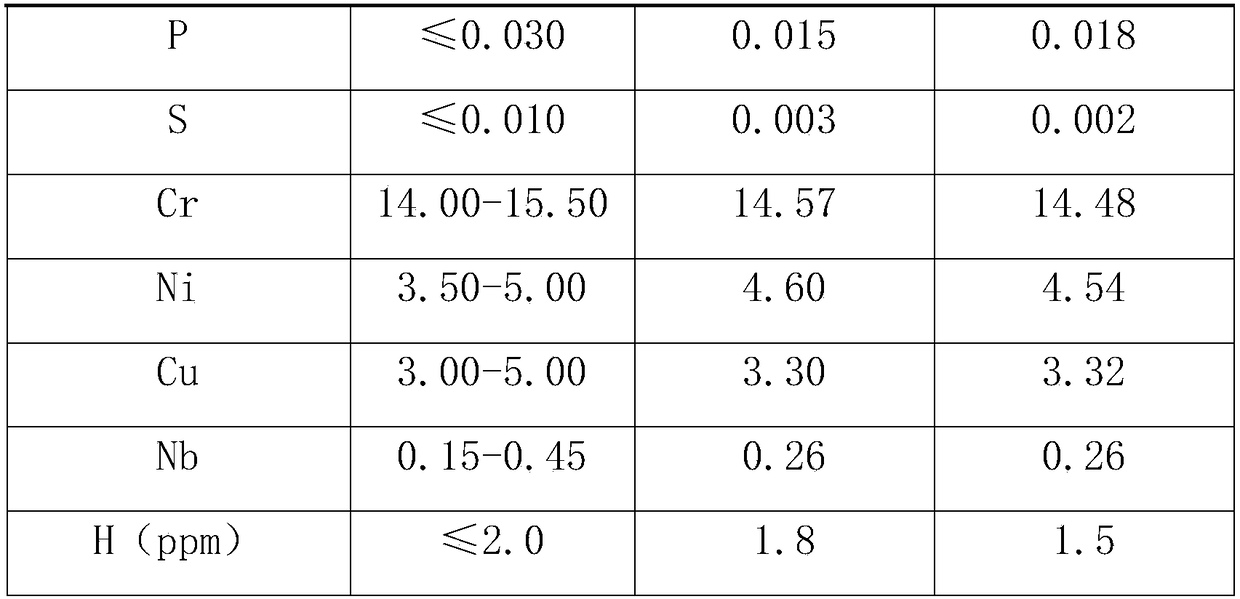

[0026] Embodiment: The present invention adopts the process route of 60tEAF / 10tIF-60tLF-60tVOD-IC, the composition is as follows: [C]≤0.07%, [Si]≤1.0%, [Mn]≤1.0%, [P]≤0.030%, [S]≤0.010%, [Ni]: 3.50-5.00%, [Cr]: 14.0-15.5%, [Cu]: 3.00-5.00%, [Nb]: 0.15-0.45%, [H]≤2.0ppm; VOD: Vacuum Decarburization Furnace; VCD: Vacuum Oxygen Decarburization; Success Mark: The chemical elements completely meet the technical requirements, which means success, and the short smelting time is the characteristic of relatively common smelting methods. The process route is: 60tEAF / 10tIF-60tLF-60tVOD-IC. The raw materials for the production process of the invention are high-quality steel scrap, pig iron, sponge iron, carburizer, ferrochrome, copper plate, nickel plate and ferromanganese. During the micro-adjustment process of the LF furnace alloy, the medium-carbon ferromanganese is used to adjust the Mn content to reduce the production cost. The VOD furnace adopts ten steps of "preparation-calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com