Electrode rotation double-station electric arc heating vacuum treatment device and using method thereof

A vacuum processing device and arc heating technology, applied in the field of steel refining, can solve the problems of seldom used and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

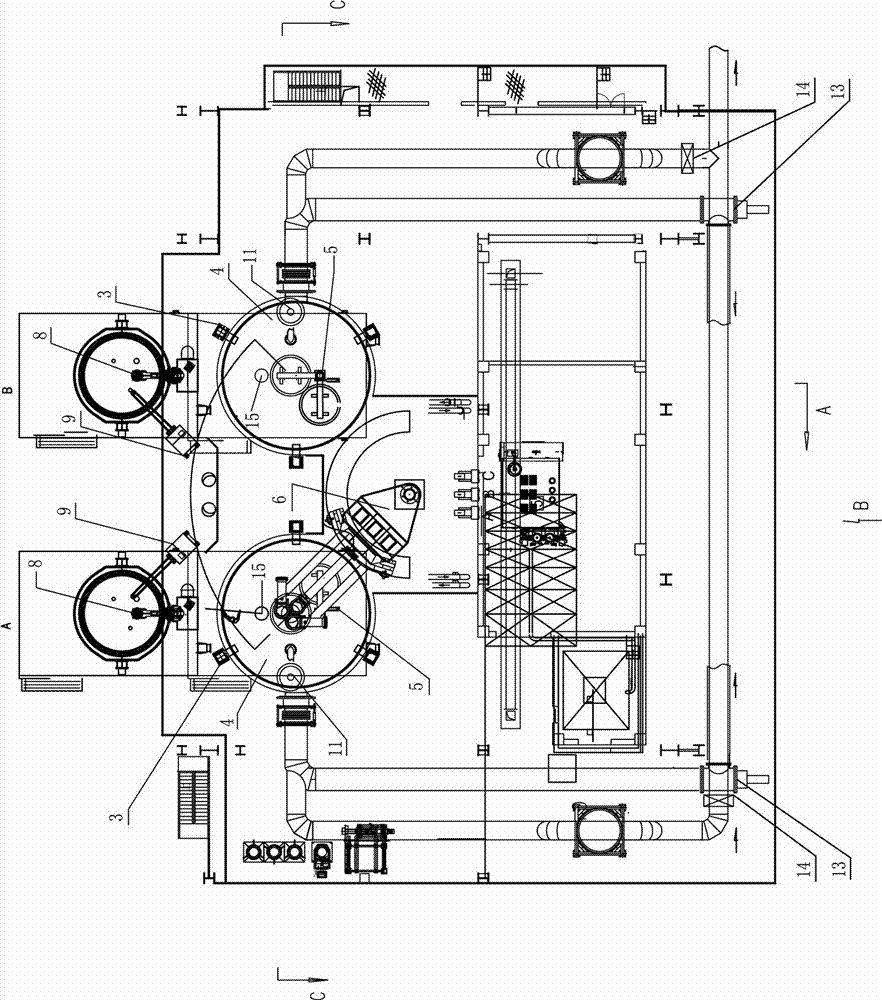

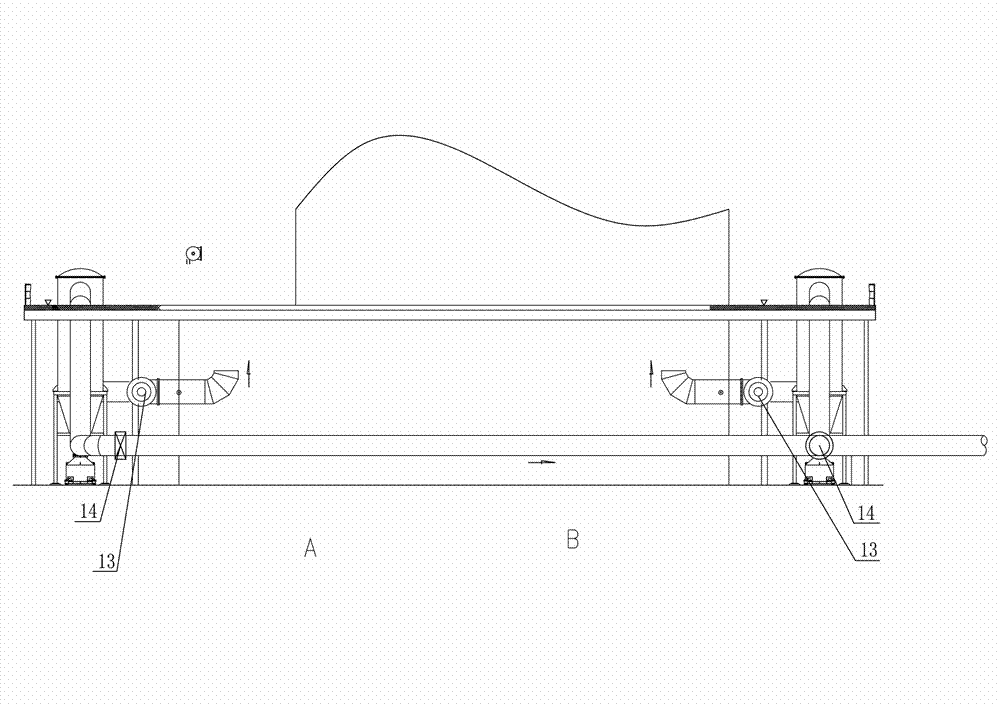

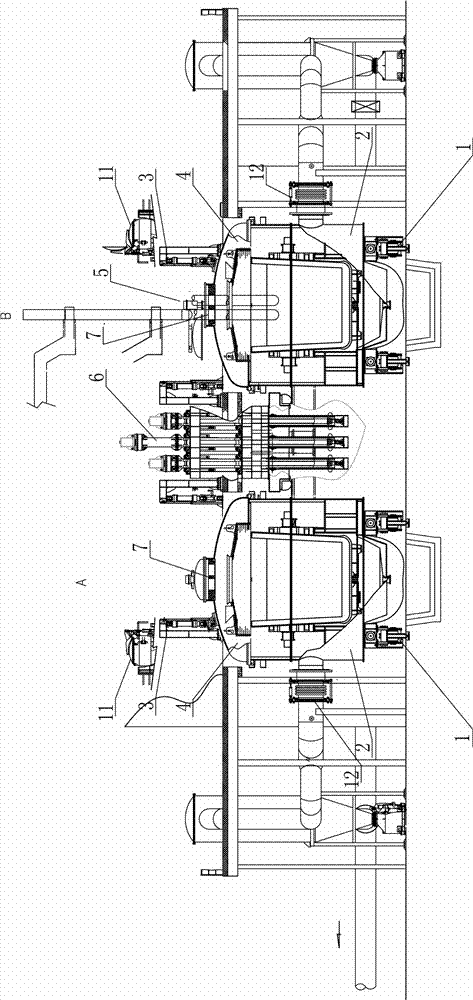

[0101] An electrode rotating dual-station arc heating vacuum processing device, including a processing station A and a processing station B, each processing station includes a vacuum tank car 1, a vacuum tank 2, a lifting device 3, a vacuum tank cover 4, a jacking Device 5, electrode rotation device 6, casting material small furnace cover 7, radiation thermometer 8, wire feeder 9, ash removal device 10, feeding fine-tuning device 11, suction pipe locking device 12, dust removal pipe sealing cut-off valve 13, suction Gas pipeline sealing cut-off valve 14 and observation window 15, such as figure 1 As shown in the figure, the specific structure is:

[0102] The vacuum tank 2 is arranged on the vacuum tank truck 1;

[0103] Vacuum tank cover 4 is covered on the top of vacuum tank 2;

[0104] There are at least three lifting devices 3. The lifting device 3 is evenly arranged around the vacuum tank cover 4. The vacuum tank cover 4 is suspended under the lifting device 3. The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com