Aluminum-calcium deoxidation and desulphurization slag remover for metallurgy

An aluminum-calcium and slag agent technology, applied in the field of metallurgical refining, can solve the problems of reducing the service life of the furnace lining, high burning loss of deoxidizing materials, increasing the production cost, etc., to reduce the temperature drop of molten steel, ensure the service life, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Example 1 Aluminum calcium deoxidation desulfurization slag accelerator A for metallurgy:

[0021] The parts by weight containing each component are calcium carbide 1

[0022] Aluminum-calcium alloy + aluminum-calcium slag 14

[0023] Silicon-calcium alloy + silicon-calcium slag 2

[0024] lime 2

[0025] Aluminum + AD powder 1.

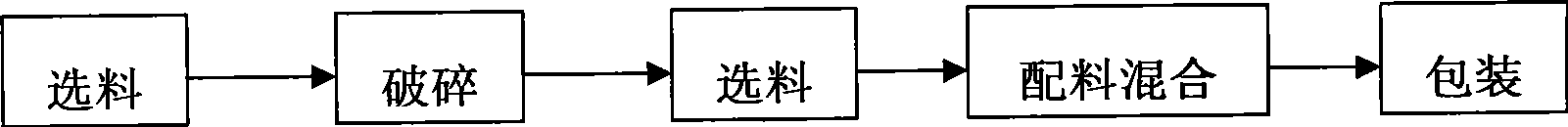

[0026] It is made through the processes of material selection, crushing, drying, and ingredient mixing.

example 2

[0027] Example 2 Aluminum-calcium deoxidation and desulfurization slag accelerator B for metallurgy:

[0028] The parts by weight containing each component are calcium carbide 1

[0029] Aluminum-calcium alloy + aluminum-calcium slag 10

[0030] Calcium silicon alloy + calcium calcium slag 4

[0031] lime 2

[0032] Aluminum + AD powder 3.

[0033] It is made through the processes of material selection, crushing, drying, and ingredient mixing.

example 3

[0034] Example 3 Aluminum-calcium deoxidation and desulfurization slag accelerator C for metallurgy:

[0035] The parts by weight containing each component are calcium carbide 1

[0036] Aluminum-calcium alloy+aluminum-calcium slag 6

[0037] Calcium silicon alloy + calcium calcium slag 6

[0038] lime or limestone 3

[0039] Aluminum + AD powder 4.

[0040] It is made through the processes of material selection, crushing, drying, and ingredient mixing.

[0041] Apply the above products A, B, and C on the LF furnace, and the implementation steps are as follows:

[0042] Smelting → Tapping → Adding aluminum-calcium deoxidation, desulfurization and slag accelerator for metallurgy at the refining position → Continuous casting, the data obtained are as follows:

[0043] Average amount added to tapping Desulfurization rate Deoxidation inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com