Lead bullion refining device and lead bullion refining method

A crude lead refining and crude lead technology, applied in the fields of instruments, optics, photography, etc., can solve the problems of inability to efficiently complete copper removal and arsenic, antimony and tin removal, and shorten the crude lead refining cycle, reduce energy consumption, and reduce construction. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

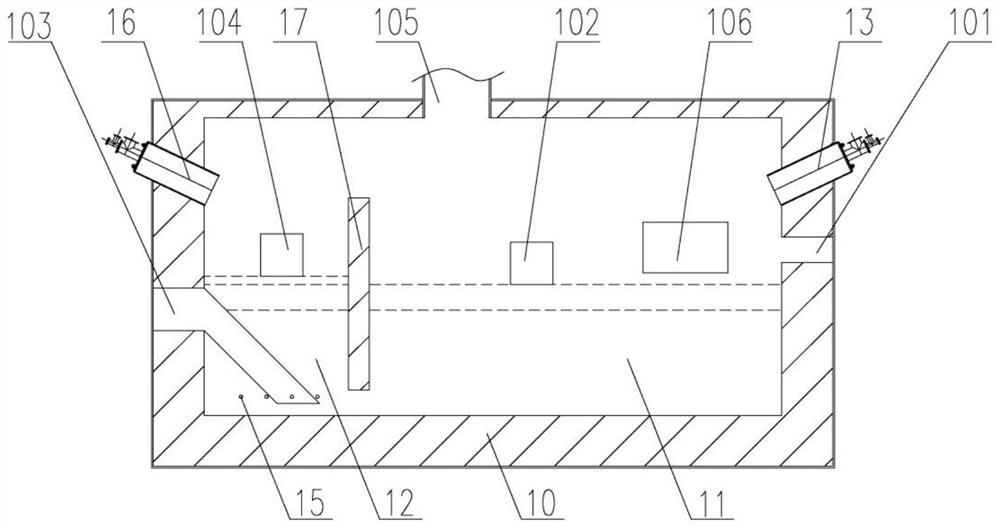

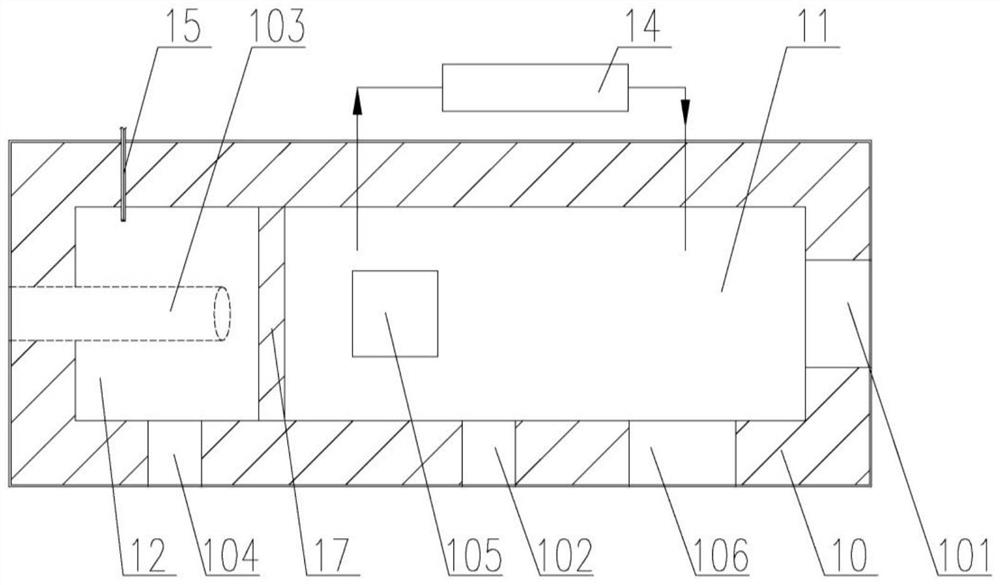

[0054] use figure 1 and 2 The crude lead refining device shown in the following crude lead refining and removing copper and arsenic, antimony and tin, crude lead is smelting crude lead, and the components are as follows (weight percentage): Pb, 95%; Cu, 1.50%; As, 0.6%; Sb, 1.5%; S, 0.20%; other elements 1.2%, the crude lead weight is 60t.

[0055] The crude lead refining device is a horizontal rectangular refining furnace, and the furnace cavity is divided into two areas by a partition wall, which are the copper removal area (the first refining area) and the arsenic, antimony and tin removal area (the second refining area). The length ratio is 3:1. The copper removal area is connected with the lower molten pool of the arsenic, antimony and tin area for the circulation of crude lead in the copper removal area and the arsenic, antimony and tin area; the upper molten pool is separated by a partition wall, and the flue gas area is connected. The copper removal area is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com