A kind of lf furnace dynamic bottom blowing co2-ar refining method and device

A co2-ar, dynamic technology, applied in the field of steelmaking, can solve the problems of easy nitrogen absorption of molten steel, limited Ar blowing strength, and difficulty in rapid deep desulfurization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

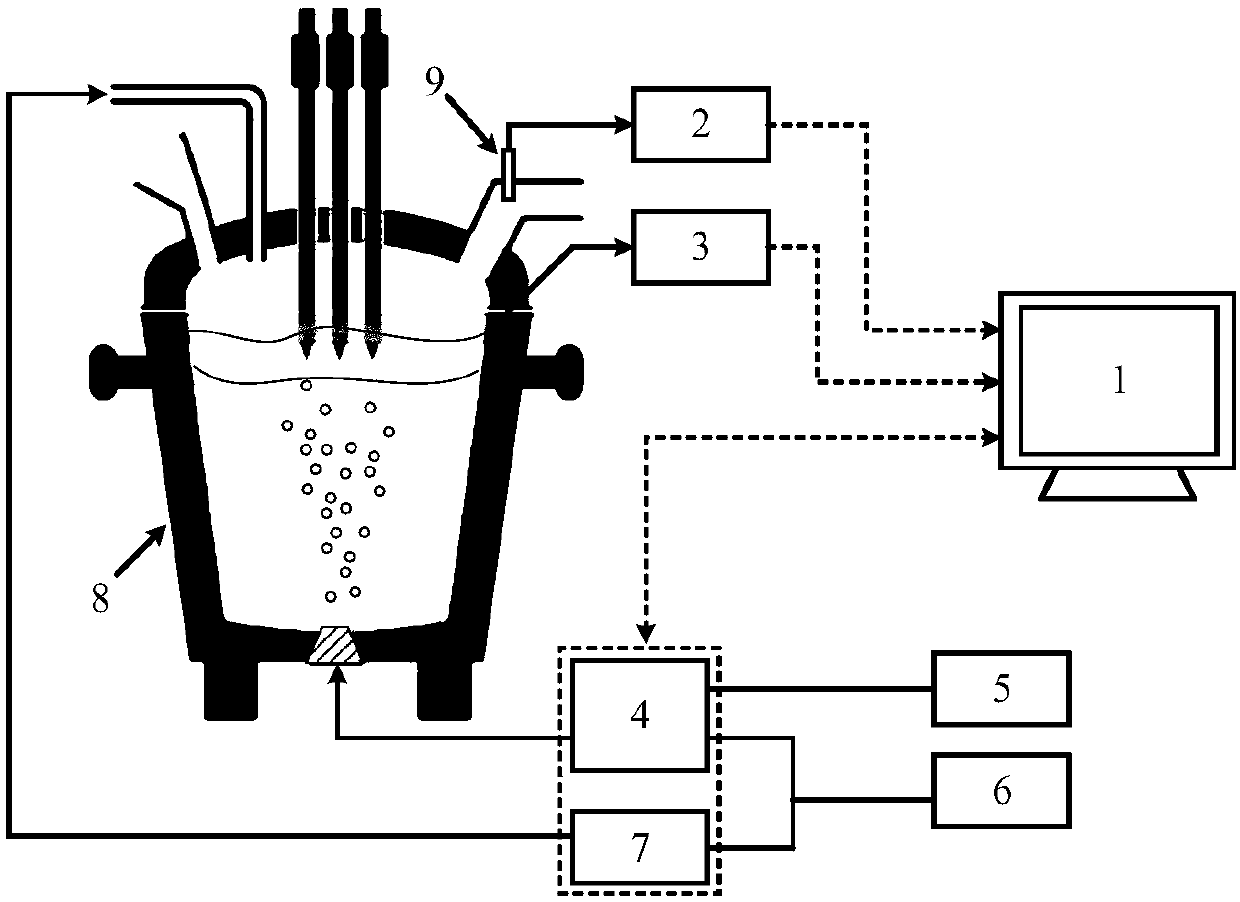

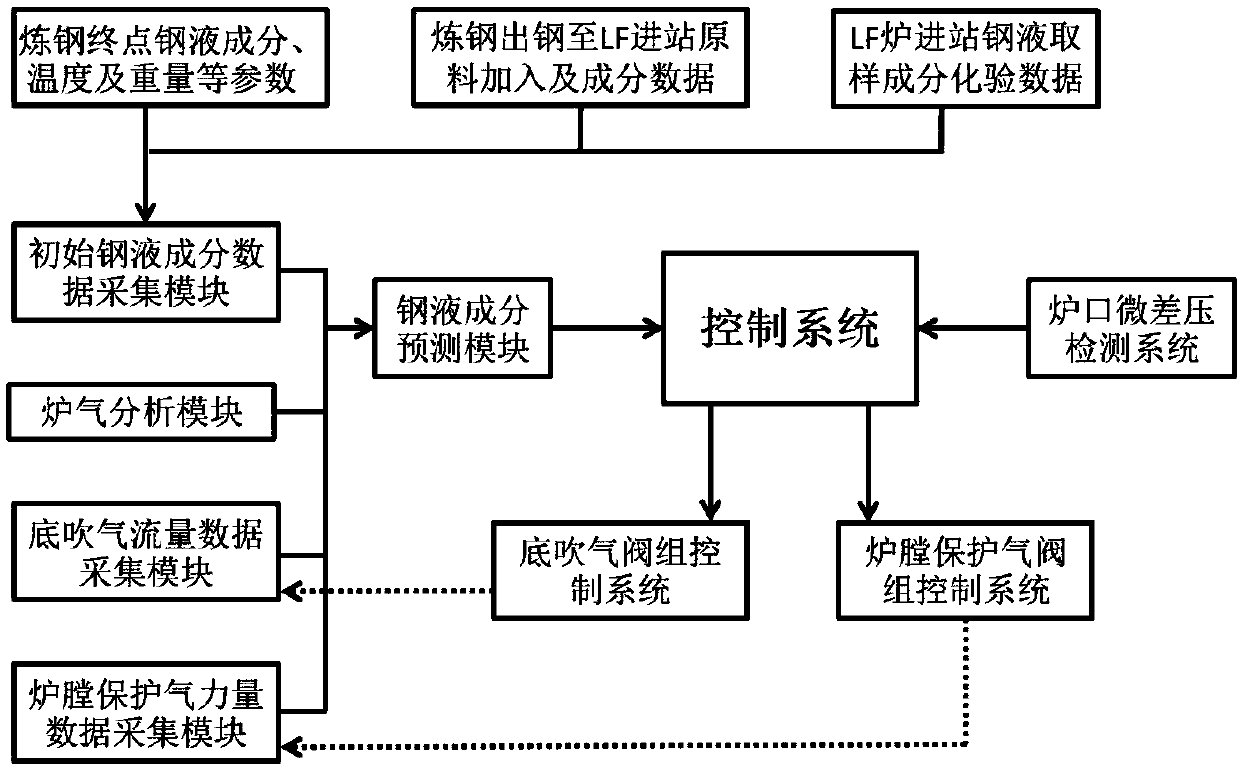

Method used

Image

Examples

example 1

[0026] Example 1: The present invention is applied to a 90t LF furnace, and the bottom blowing gas is CO 2 Mixed gas with Ar, the initial smelting furnace is a 90t electric arc furnace, the carbon content of the final tapping is 0.10%, 200kg of recarburizer is added during the tapping process, and 100kg of aluminum ingots are added.

[0027] 1): The molten steel composition data acquisition module obtains the composition data of the electric arc furnace tapping molten steel and the quality and composition data of the smelting materials added to the ladle between tapping and LF furnace entering the station, and calculates the carbon content of the LF furnace refining entering station as 0.45%.

[0028] 2): Preliminary slag removal stage: the control system controls the action of the furnace protection gas control valve group according to the micro pressure difference data at the furnace mouth, and adjusts the furnace protection gas flow rate 0-10Nm online 3 / h, to ensure that ...

example 2

[0036] Example 2: The present invention is applied to a 150t LF furnace, and the bottom blowing gas is CO 2 Mixed gas with Ar, the initial smelting furnace is a 150t converter, and the carbon content of the final tapping is 0.06%. During the tapping process, 300kg of recarburizer, 100kg of aluminum ingot, and 100kg of ferrosilicon are added.

[0037] 1): The molten steel composition data acquisition module obtains the composition data of the electric arc furnace tapping molten steel and the quality and composition data of the smelting materials added to the ladle between tapping and LF furnace entering the station, and calculates the carbon content of the LF furnace refining entering station as 0.35%.

[0038] 2): Preliminary slag removal stage: the control system controls the action of the furnace protection gas control valve group according to the micro pressure difference data at the furnace mouth, and online regulates the furnace protection gas flow rate 0-15Nm 3 / h, to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com