Clean steel smelting system and method

A smelting method and technology for cleaning steel, applied in the field of metallurgy, can solve the problems of complex design of load-bearing structures, increased natural temperature drop of molten steel, and reduced yield of alloys, so as to suppress the formation of oxide inclusions, reduce load-bearing requirements, and reduce refining The effect of cycle sum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

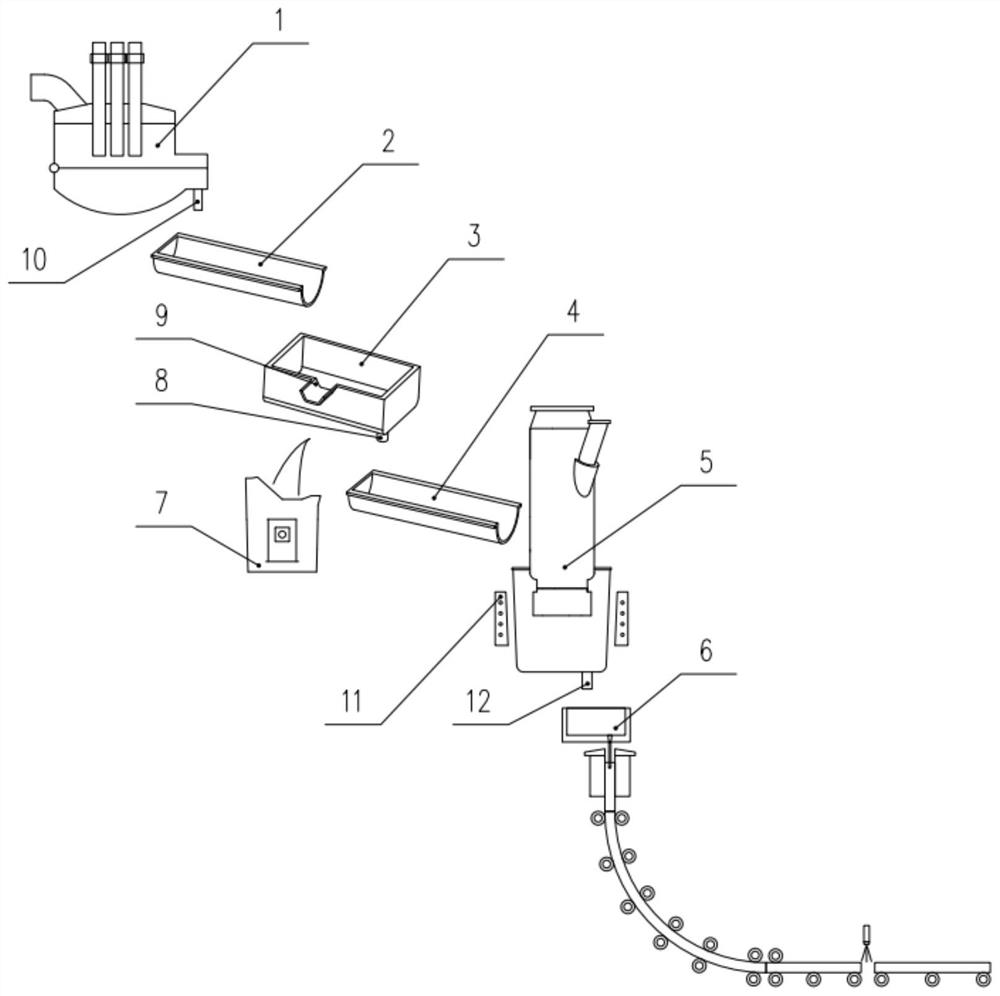

[0045] A clean steel smelting system, comprising a primary smelting furnace 1, a first diversion tank 2, a slag-steel separation device 3, a second diversion tank 4, a refining furnace 5, a continuous casting ladle 6 and a slag tank 7, wherein the refining furnace 5 Adopt induction heating vacuum refining furnace.

[0046] The first diversion tank 2 is connected to the primary smelting furnace 1 and the slag-steel separating device 3 , one end of which is located below the tapping hole 10 of the primary smelting furnace, and the other end is located above the slag-steel separating device 3 .

[0047] The second diversion groove 4 is connected to the slag-steel separation device 3 and the refining furnace 5 , one end of which is located below the tap hole 8 of the slag-steel separation device, and the other end is located above the refining furnace 5 .

[0048] When the primary smelting furnace 1 finishes smelting, the molten steel flows out from the tapping hole 10 of the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com