Multifunctional enzyme vinegar

A multi-functional and fermentative technology, applied in the preparation of vinegar, microorganisms, biochemical equipment and methods, etc., can solve the problems of pollution, waste of energy, and few types of microorganisms, and achieve rich sources of raw materials, reduce labor intensity, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

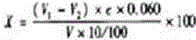

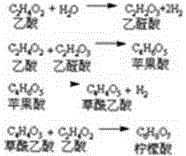

Method used

Image

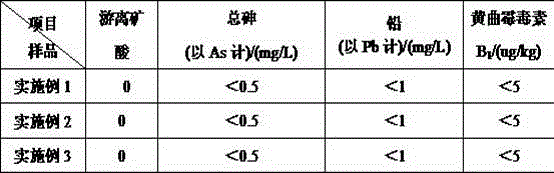

Examples

Embodiment 1

[0053] 1) Put 1000 kg of starchy raw wheat, 800 kg of broken rice, 500 kg of rice bran, and 500 kg of sweet potato into a tablet machine and squeeze them into flakes for later use; the fruit raw materials are 1000 kg of apples, 500 kg of grapes, and 800 kg of mangoes. 1, 400 kg of bananas, pitted, peeled, cleaned and cut into small pieces for later use; 1000 kg of spinach and 500 kg of vegetable raw materials, celery, cleaned and cut into small pieces for later use;

[0054] 2) Put the processed fruit raw materials and vegetable raw materials into the screw press to squeeze out the fruit and vegetable juice, and keep the juice and residue for later use;

[0055] 3) Add the fruit and vegetable juices and residues treated in step 2) to the starchy raw materials treated in step 1), stir evenly, put them into a bio-fermentation machine, add 80 kg of Aspergillus niger, 80 kg of Aspergillus oryzae, and 1600 kg of Daqu , 400 kg of small koji, 480 kg of red koji, add 0.7 kg of nutrien...

Embodiment 2

[0061] 1) Put 500 kg of starchy raw materials sorghum, 1000 kg of barley, 500 kg of corn kernels, and 500 kg of cassava into a tablet machine and squeeze them into flakes for later use; put 500 kg of fruit raw materials papaya, 500 kg of pears, and 500 kg of pineapple 1. 500 kg of kiwi fruit, pitted, peeled, cleaned and cut into small pieces for later use; 800 kg of vegetable raw materials watercress, 900 kg of okra, and 800 kg of cauliflower were cleaned and cut into small pieces for later use;

[0062] 2) Put the processed fruit raw materials and vegetable raw materials into the screw press to squeeze out the fruit and vegetable juice, and keep the juice and residue for later use;

[0063] 3) Add the fruit and vegetable juice and slag treated in step 2) to the starchy raw material treated in step 1), stir evenly, put it into the bio-fermentation machine, add 100 kg of Aspergillus niger, 80 kg of Aspergillus oryzae, and 800 kg of Daqu , 800 kg of small koji, 400 kg of red koj...

Embodiment 3

[0069] 1) Put 500 kg of starchy raw materials of wheat, 800 kg of highland barley, 1000 kg of glutinous rice, and 500 kg of potatoes into a tablet machine and squeeze them into flakes for later use; 500 kg of plums, pitted, peeled, cleaned, and cut into small pieces for later use; 500 kg of bitter gourd, 800 kg of carrots, and 500 kg of lotus root, washed and cut into small pieces for later use;

[0070] 2) Put the fruit raw material and vegetable raw material processed in step 1) into a screw press machine and extrude the fruit and vegetable juice, and keep the juice and dregs for later use;

[0071] 3) Add the fruit and vegetable juice and slag treated in step 2) to the starchy raw material treated in step 1), stir evenly, put it into the bio-fermentation machine, add 160 kg of Aspergillus niger, 160 kg of Aspergillus oryzae, and 1200 kg of Daqu , Xiaoqu 400 kg, Hongqu 640kg, add 0.6 kg of nutrient salt at the same time, stir evenly, keep the tank pressure at 100 kPa, temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com