Method for deep desulfurization of molten steel refining, device and application for molten steel refining

A technology for deep desulfurization and molten steel, which is applied in the field of equipment for deep desulfurization and molten steel refining, can solve the problems of low stirring effect of argon gas-enhanced molten pool and the desulfurization kinetic conditions need to be further improved, so as to improve the thermodynamics of desulfurization. and kinetic conditions, low-cost and high-efficiency removal, and the effect of shortening smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

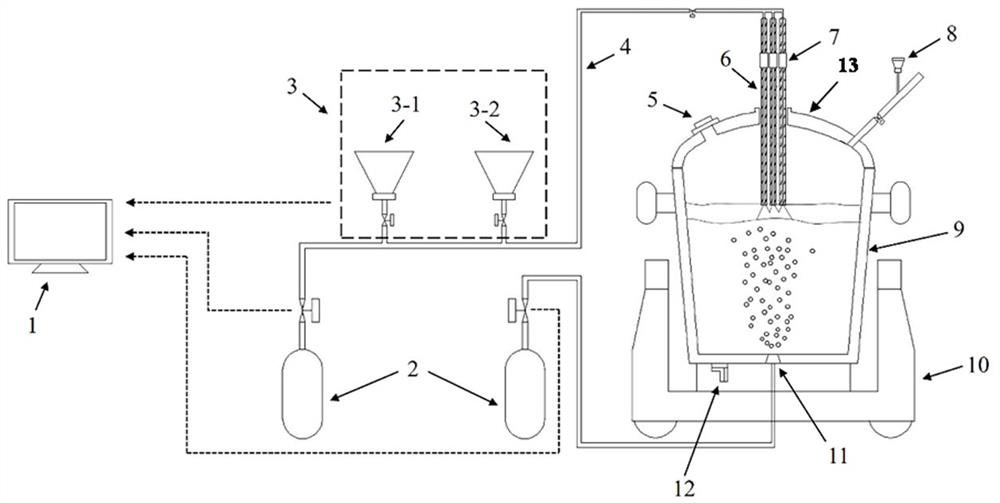

[0078] The molten steel refining deep desulfurization process in this embodiment adopts such as figure 1 The shown device for refining molten steel is carried out, and the specific process is as follows:

[0079] ①Converter tapping, in the process of tapping the molten steel to be refined to the ladle, the bottom blowing argon gas is started after the ladle sees flow, and the flow rate of the bottom blowing argon gas is 1.2NL / (min·t); 1 / 4 of the total mass of the molten steel to be refined is tapped into the ladle, and then active lime is added. The amount of active lime added is 3.2 kg / t.

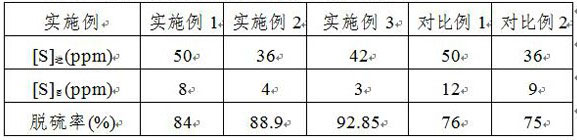

[0080] ② When LF enters the station, the sulfur content of molten steel to be refined (initial sulfur content) [S] 进 After all the molten steel to be refined is tapped into the ladle, the ladle containing the molten steel to be refined is sent to the LF station (refining station), and after entering the LF station, adjust the bottom blowing argon The gas flow rate is 4NL / (min·t).

[008...

Embodiment 2

[0087] The molten steel refining deep desulfurization process in this embodiment adopts such as figure 1 The shown device for refining molten steel is carried out, and the specific process is as follows:

[0088] ①Converter tapping, in the process of tapping the molten steel to be refined to the ladle, the bottom blowing of argon is started after the ladle sees flow, and the flow rate of the bottom blowing argon is 2NL / (min·t); 1 / 4 of the total mass of the molten steel to be refined is tapped into the ladle, and then active lime is added. The amount of active lime added is 3.8 kg / t.

[0089] ② When LF enters the station, the sulfur content of molten steel to be refined (initial sulfur content) [S] 进 is 36ppm; after all the molten steel to be refined is tapped into the ladle, the ladle containing the molten steel to be refined is sent to the LF station (refining station), and after entering the LF station, adjust the bottom blowing argon The gas flow rate is 6NL / (min·t).

[...

Embodiment 3

[0096] ①Converter tapping, in the process of tapping the molten steel to be refined to the ladle, the bottom blowing of argon is started after the ladle sees flow, and the flow rate of the bottom blowing argon is 2NL / (min·t); 1 / 4 of the total mass of the molten steel to be refined is tapped into the ladle, and then active lime is added, and the amount of active lime added is 4.0 kg / t.

[0097] ② When LF enters the station, the sulfur content of molten steel to be refined (initial sulfur content) [S] 进 After all the molten steel to be refined is tapped into the ladle, the ladle containing the molten steel to be refined is sent to the LF station (refining station), and after entering the LF station, adjust the bottom blowing argon The gas flow rate is 7NL / (min·t).

[0098] ③Preliminary stage of slag removal: Open the top-blowing argon valve, and top-blown argon into the ladle. Argon plasma slag formed by argon gas for 3 minutes, then adjust the flow rate of top-blown argon to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com