Method for refining palladium from alkaline strip liquor

A stripping liquid, alkaline technology, applied in the field of precious metal refining, can solve the problems of long refining cycle, low yield, unfriendly environment, etc., and achieve the effect of shortening refining cycle, high dissolution efficiency, and improving environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

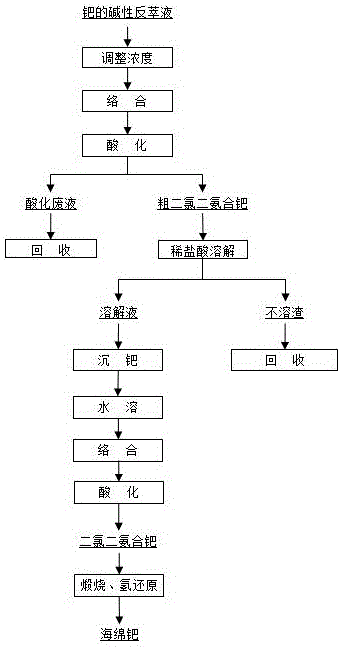

Method used

Image

Examples

Embodiment 1

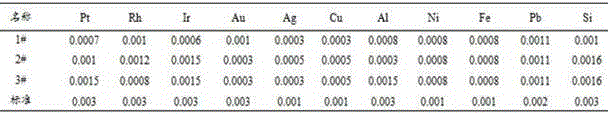

[0021] A method for refining palladium from alkaline stripping liquid, comprising the following steps: diisoamyl sulfide S 201 After extraction, adjust the palladium concentration to 80g / L in the alkaline ammonia-containing stripping solution produced by back-extraction with ammonia water, add ammonia water to adjust the pH=8, let stand for 4 hours, and filter out the insoluble matter. The filtrate was adjusted to pH = 1 with hydrochloric acid, filtered after standing for 3 hours, the filter residue was washed with 1% hydrochloric acid solution until the washing liquid was colorless, the filtrate was replaced with zinc powder, and the filter residue weighed 1352.5g. Slurry the washed filter residue with 6.8L of pure water for 1 hour at a solid-to-liquid ratio of 1:5, add 800ml of concentrated hydrochloric acid to it, adjust the acidity to 3mol / L, raise the temperature to 90°C under stirring, and keep the temperature for 1.5 hours The precipitate was completely dissolved, and a...

Embodiment 2

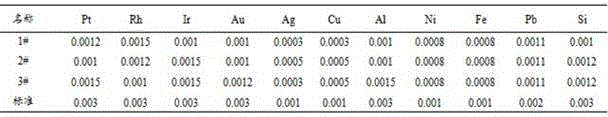

[0025] A method for refining palladium from alkaline stripping liquid, comprising the following steps: diisoamyl sulfide S 201 After extraction, adjust the concentration of palladium to 100g / L in the alkaline ammonia-containing stripping solution produced by back-extraction with ammonia water, add ammonia water to adjust the pH=10, then let it stand for 3 hours, and filter out a small amount of insoluble matter. The filtrate was adjusted to pH = 2 with hydrochloric acid, filtered after standing for 4 hours, the filter residue was washed with 5% hydrochloric acid solution until the washing liquid was colorless, the filtrate was replaced with zinc powder, and the filter residue weighed 139.35kg. Slurry the washed filter residue with 836L of pure water for 2 hours at a solid-to-liquid ratio of 1:6, add 90L of concentrated hydrochloric acid to it, adjust the acidity of the solution to 4mol / L, heat up to 100°C under stirring, and keep the temperature for 2 hours. The precipitate wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com