RH efficient deep decarburization control method based on plasma jet

A technology of plasma and control method, which is applied in the field of RH high-efficiency deep decarburization control of plasma spraying, which can solve the problems of deoxidized alloy consumption, easy peroxidation of molten steel, and low utilization rate, so as to shorten the refining rhythm and reduce inclusions , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

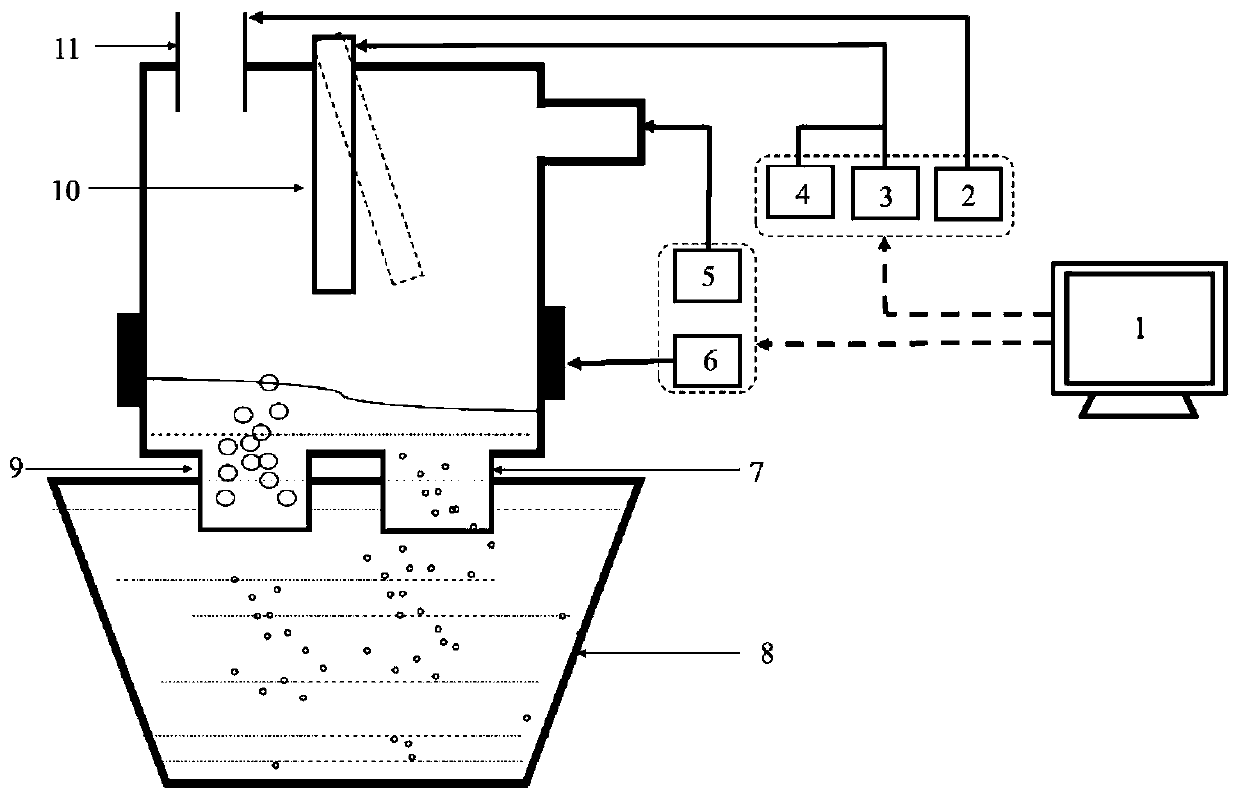

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention is applied in the 210tRH refining process, the lifting gas is Ar, and the deoxidation alloy adopts aluminum particles. Specific steps are as follows:

[0028] 1) When the RH ladle enters the station, the composition and temperature of the molten steel are measured and the conditions of the molten steel are uploaded to the control system, and the lifting gas of 120Nm is turned on at the same time 3 / h, turn on the mechanical pump to vacuum; initial carbon content [%C] 0 =300×10 -6 .

[0029] 2) Efficient decarburization period: the control system is based on the initial carbon content of molten steel [%C] 0 , efficient decarburization time t 1 , O 2 Utilization μ 1 and other data information to calculate and use the top blowing gas control valve group to online control the top blowing O 2 The flow is Q 1 , spray O to the molten steel surface in the vacuum chamber through the top-blown gas plasma spray gun 2 Plasma, while turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com