The method of shortening the slag melting time of ladle refining furnace by frequency conversion ultrasonic wave

A frequency conversion ultrasonic and ultrasonic technology, applied in the field of ladle refining, can solve the problems of shortening the ladle refining furnace slag slag time, low production efficiency, slow slag slagging speed, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method of frequency conversion ultrasonic to shorten the slag melting time of ladle refining furnace includes the following specific contents:

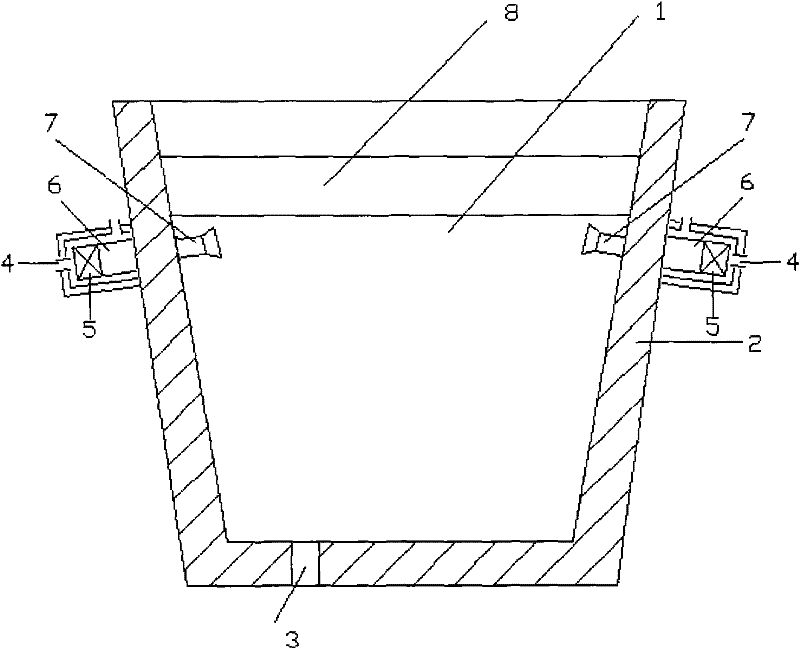

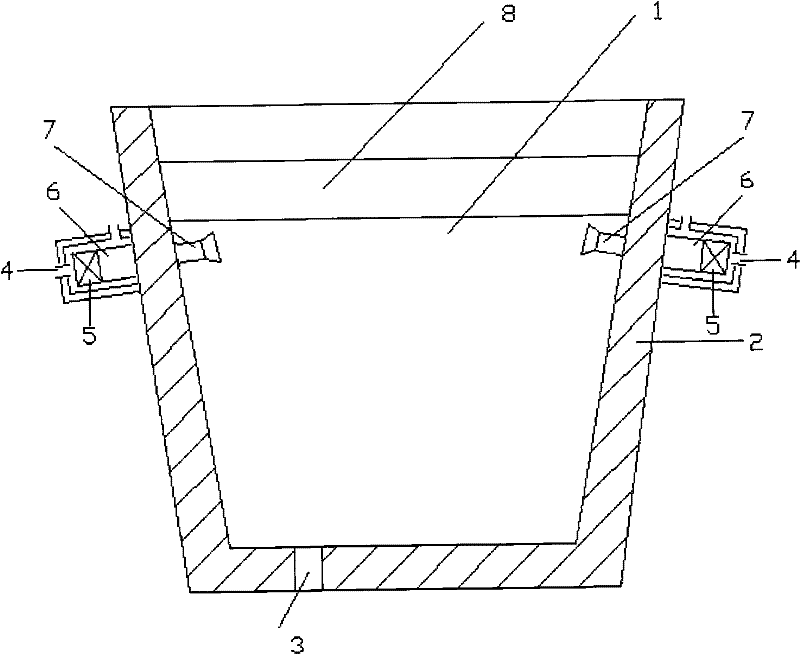

[0014] As shown in the figure, after the converter or the electric furnace is tapped, the molten steel 1 is poured into the ladle 2, and the ladle 2 is placed in the refining station. At the opening of the bottom-blown air-permeable brick 3, start to blow argon and stir, add synthetic slag 7 and Deoxidize the material and turn on the ultrasonic generator at the same time. The ultrasonic generator adopts frequency conversion water-cooled magnetostrictive transducer 5, and three frequency conversion water-cooled magnetostrictive transducers are installed at the position of the slag line on the side wall of the ladle. A horn 6 with mechanical vibration displacement amplification is installed in the transducer, and cooling water 4 is passed through. A tool head 8 matched with the variable frequency water-cooled magnetostrictive tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com