Method for preparing industrial silicon refining slag agent by using silica fume as raw material

A technology of micro-silica fume and industrial silicon, which is applied in chemical instruments and methods, silicon compounds, climate sustainability, etc., can solve the problems of lower metal silicon yield, lower refining efficiency, and slow slagging rate, etc., and achieve improvement High-temperature viscosity characteristics, reducing oxidation loss, and promoting the effect of slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

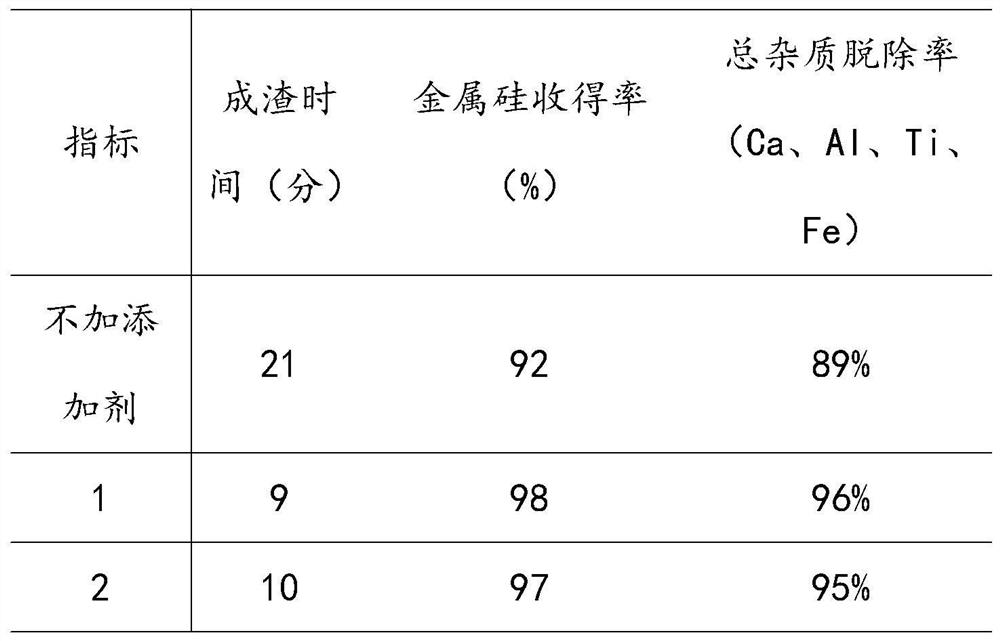

[0017] The invention provides a method for preparing an industrial silicon refining slag agent by using microsilica powder as a raw material. The technical problems solved by the additive of the present invention are: accelerating slag formation, improving industrial silicon refining efficiency, adjusting industrial silicon refining temperature, and improving metal silicon yield.

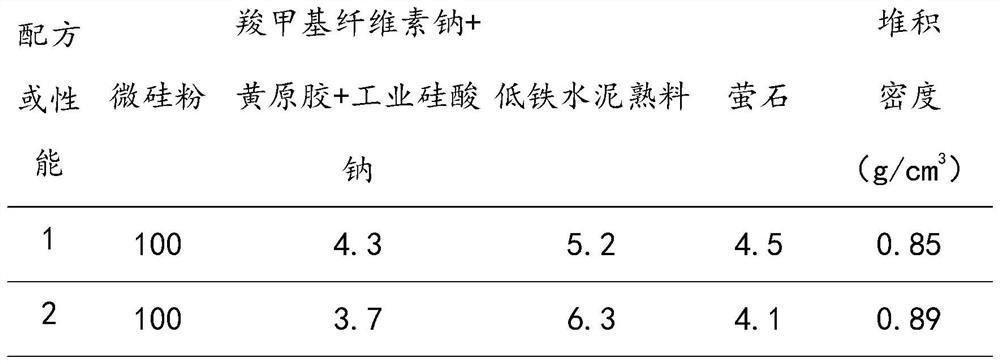

[0018] Specifically, the present invention is realized by adding appropriate combination of additives and a small amount of industrial / mineral raw materials to microsilica, and then processing. First, weigh a certain mass of microsilica powder, add 0.8-1.2 times the weight of water and a combination of 2%-7% by weight of microsilica powder to obtain a mixture, the combination is composed of sodium carboxymethyl cellulose, xanthan gum, At least one or two kinds of sodium silicate are composed, and sodium carboxymethyl cellulose <4%, xanthan gum <3%, sodium silicate <6%, and at the same time adding mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com