Erosion-resistant CAS-OB refining device for dipping cover

The technology of refining device and dipping hood is applied in the field of CAS-OB refining device and CAS-OB refining device whose dipping hood is resistant to erosion. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

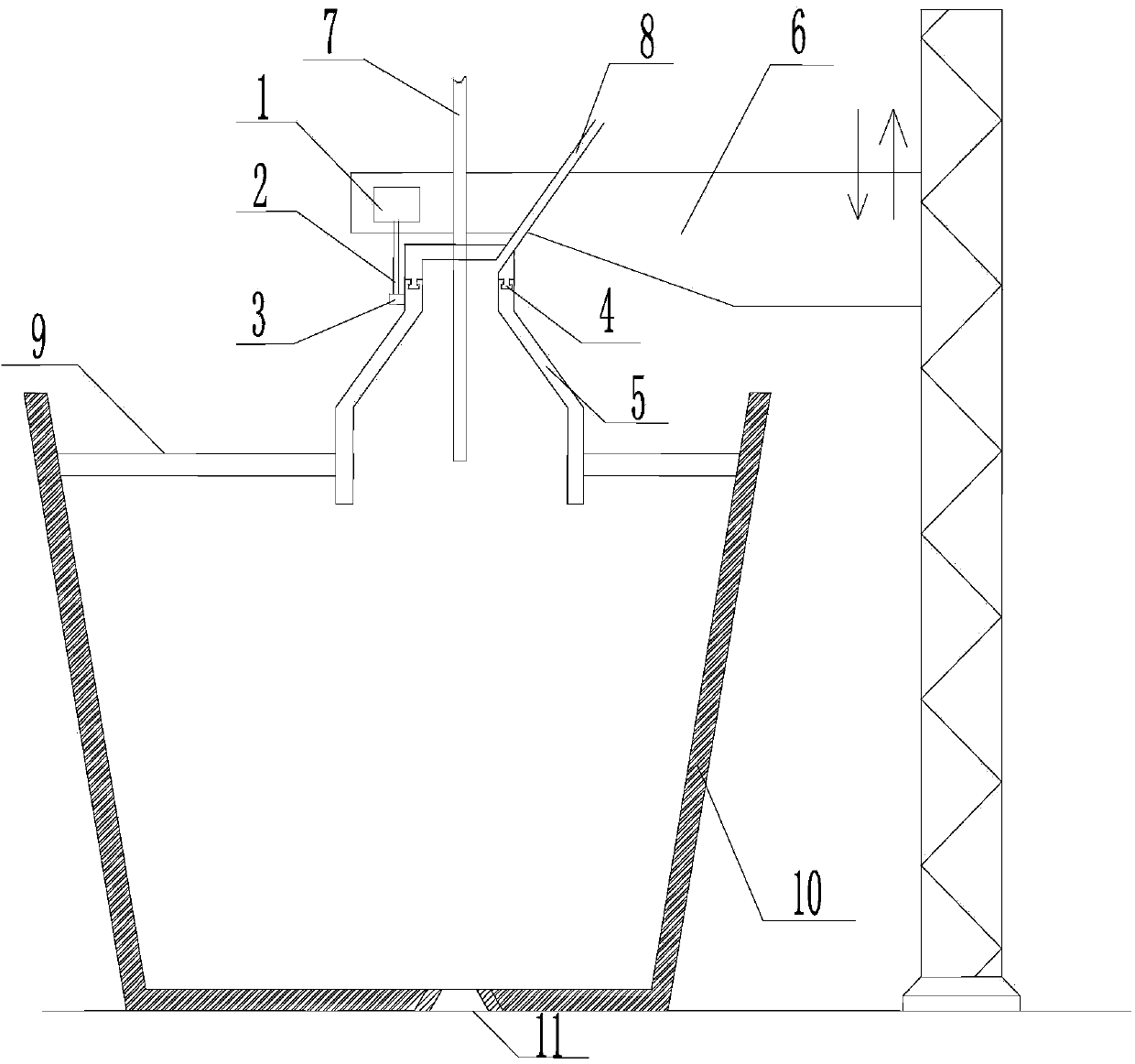

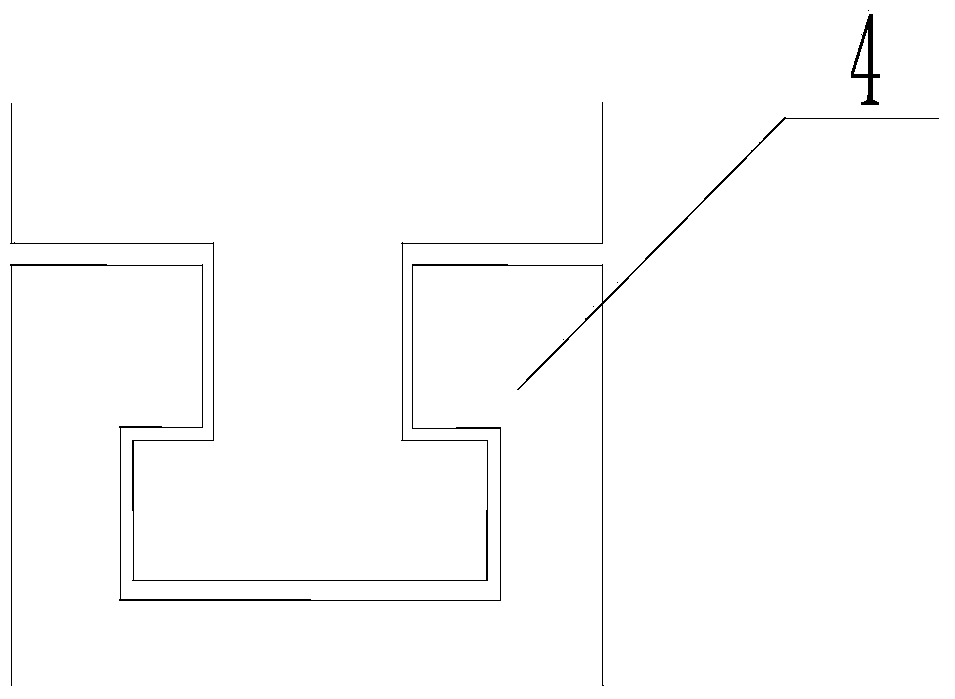

[0015] Such as figure 1 , figure 2 As shown, a CAS-OB refining device with corrosion resistance of the dipping cover is composed of a motor 1, a transmission shaft 2, a gear 3, a concave-convex connection button 4, a dipping cover 5, a dipping cover lifting device 6, an oxygen lance 7, an alloy material chute 8, Slag 9, ladle 10 and perforated brick 11 are composed. The upper part of the dipping cover 5 is a fixed part and the lower part is a rotating part. The joints of the upper part and the lower part are engraved with concave-convex connecting buckles 4, and the dipping cover 5 on the concave-convex connecting buckle 4 is non-rotatable. , the lower part of the dipping cover 5 is rotatable, the fixed part and the rotating part are connected by a concave-convex connection buckle 4, the motor 1 is fixed on the dipping cover lifting device 6, the motor 1 is connected to a transmission shaft 2, and the motor 1 and the transmission shaft 2 follow the dipping cover Ascending an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com