A rapid decarburization method of rh

A decarburization and rapid technology, applied in the field of steelmaking, to achieve efficient and rapid decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

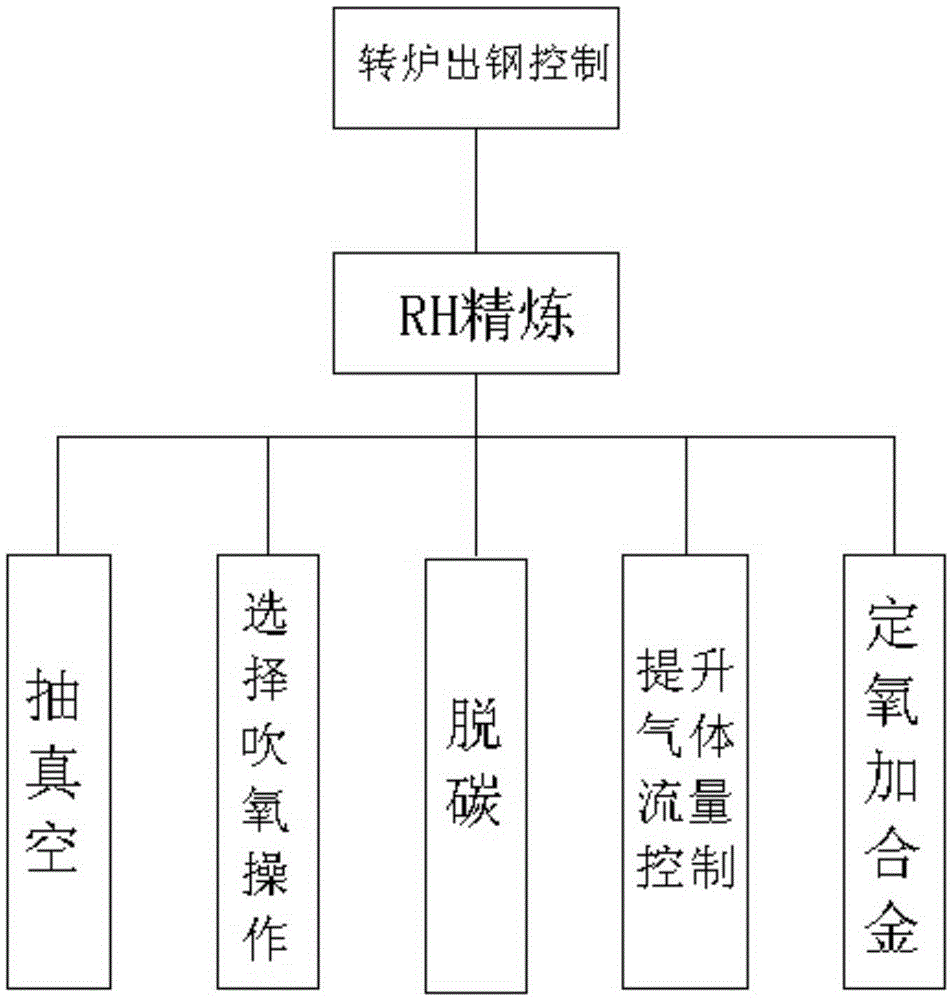

[0038] The process of the RH rapid decarbonization method provided by the present invention is:

[0039] The converter end point control, the converter tapping end temperature is controlled at 1680℃; calculated by mass percentage, the converter tapping end C content is controlled at 0.030%, and the oxygen content is controlled at 558ppm by mass per million; the converter enters RH after tapping. For refining, the temperature of molten steel entering the station is controlled at 1623℃; to ensure that oxygen blowing is not required during the RH refining process; the lifting gas flow control during the refining process is: 0~3min after the start of vacuum, the lifting gas flow should be kept at 180m 3 / h; 3~9min after the start of vacuuming, the lifting gas flow is kept at 150m 3 / h; 9~16min after the start of vacuuming, the lifting gas flow rate is maintained at 210m 3 / h; 16min-breaking after the vacuuming starts, and the lifting gas flow rate is maintained at 150m 3 / h; 12 to 14 m...

Embodiment 2

[0042] The process of the RH rapid decarbonization method provided by the present invention is:

[0043] The converter end point control, the converter tapping end temperature is controlled at 1680℃; calculated by mass percentage, the converter tapping end point C content is controlled at 0.030%, by mass per million, the oxygen content is controlled at 606ppm; after the converter tapping, it enters RH For refining, the temperature of molten steel entering the station is controlled at 1620℃; to ensure that no oxygen blowing operation is required during the RH refining process; the lifting gas flow control during the refining process is: 0~3min after the start of vacuuming, and the lifting gas flow should be kept at 180m 3 / h; 3~9min after the start of vacuuming, the lifting gas flow is kept at 150m 3 / h; 9~16min after the start of vacuuming, the lifting gas flow rate is maintained at 210m 3 / h; 16min-breaking after the vacuuming starts, and the lifting gas flow rate is maintained at...

Embodiment 3

[0046] The process of the RH rapid decarbonization method provided by the present invention is:

[0047] The converter end point control, the converter tapping end temperature is controlled at 1700℃; calculated by mass percentage, the converter tapping end point C content is controlled at 0.035%, and the oxygen content is controlled at 558ppm by mass percentage; after the converter tapping, it enters RH For refining, the temperature of molten steel entering the station is controlled at 1623℃; to ensure that oxygen blowing is not required during the RH refining process; the lifting gas flow control during the refining process is: 0~3min after the start of vacuuming, and the lifting gas flow should be kept at 175m 3 / h; 3~9min after the start of vacuuming, the lifting gas flow rate is maintained at 145m 3 / h; 9~16min after the start of vacuuming, the lifting gas flow rate is maintained at 215m 3 / h; 16min-breaking after the vacuuming starts, and the lifting gas flow rate is maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com