Household gas-liquid delivery device for rapidly preparing ozone water, and ozone water preparation device

A technology of gas-liquid transfer, ozone water, applied in the direction of mixers with rotating stirring devices, chemical instruments and methods, dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

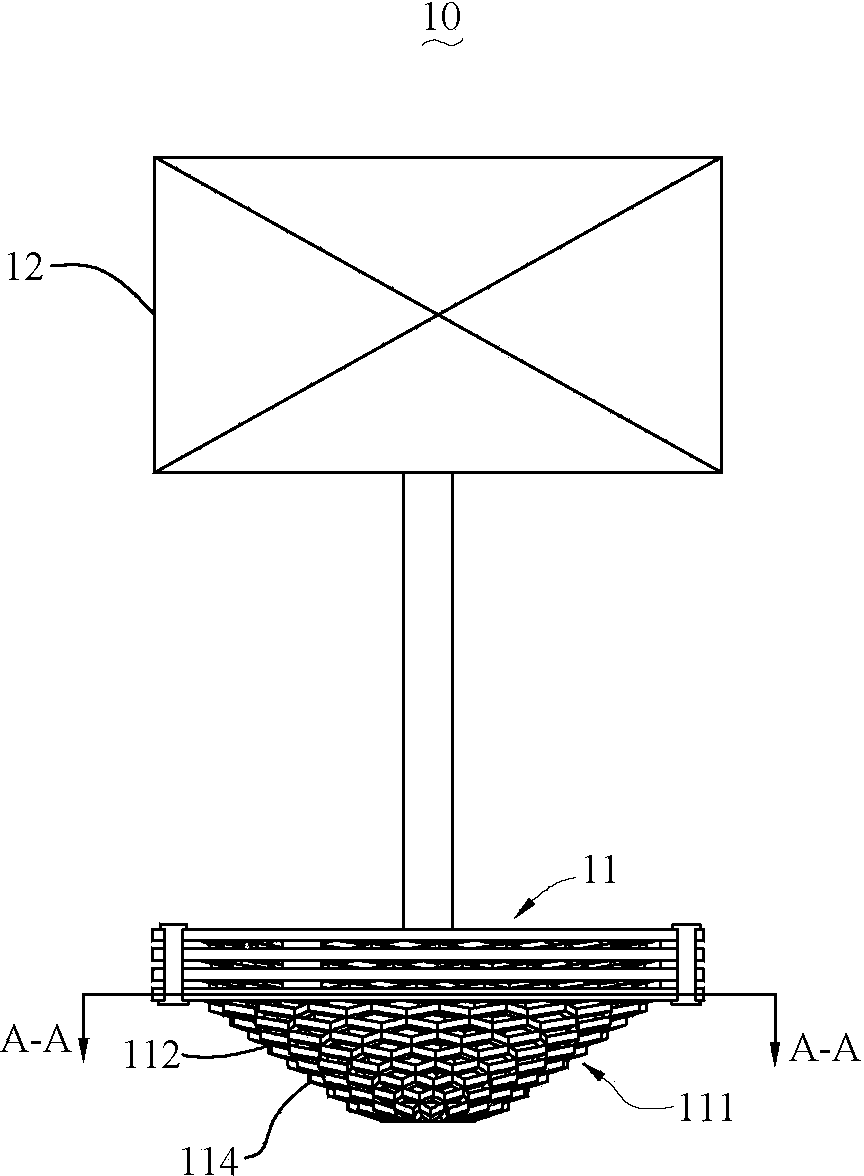

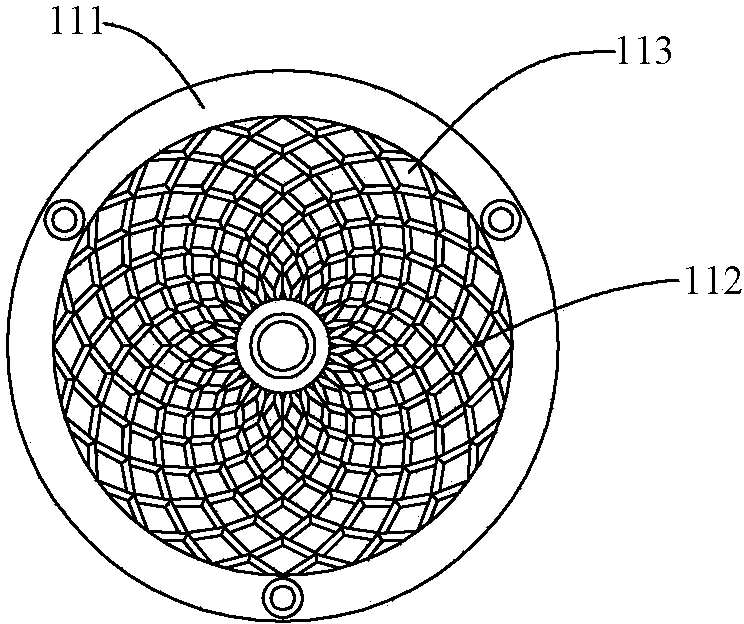

[0043] see figure 1 As shown, the present invention is the first embodiment of the gas-liquid transfer device for the rapid preparation of ozone water at home. 11 fast rotating rotating power part 12 . The rotating power part 12 is connected to the centrifugal gas-liquid mixing part 11 through the rotating shaft; the centrifugal gas-liquid mixing part 11 stirs the water to flow quickly to generate turbulent flow, drags the ozone gas into the water to generate bubbles; the centrifugal gas-liquid mixing part 11 includes micronized air bubbles A plurality of dividing ribs 112 .

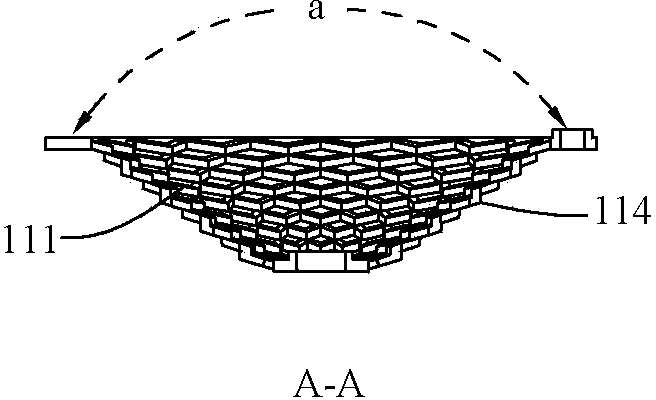

[0044] see figure 2 , the umbrella inner taper a of the inverted umbrella-shaped centrifugal gas-liquid mixing element 11 is 15-175 degrees. If the inner taper a of the umbrella is less than 15 degrees, the centrifugal gas-liquid mixing member 11 will have less agitation force on the water and cannot form a larger area of turbulent flow, which is not conducive to ozone entering the water; if the t...

Embodiment approach 2

[0058] see Figure 5 As shown in the second embodiment of the gas-liquid transfer device for the rapid preparation of ozone water at home, the difference between the gas-liquid transfer device 20 for the rapid preparation of ozone water at home and the gas-liquid transfer device 10 for the rapid preparation of ozone water at home is: The centrifugal gas-liquid mixing unit 11 also includes a support member 21 on which the dividing net 111 is installed.

[0059] The support member 21 is provided with a hot-pressing boss 22, and the upper edge of the dividing net 111 is provided with a mounting hole, and the dividing net 111 is sleeved on the hot-pressing boss 22 through the mounting hole, so that the dividing net 111 is installed on the supporting member. superior. The support member 21 is an inverted umbrella-shaped support plate, and an air suction port (not shown in the figure) is opened on the support plate.

[0060] In the present invention, the support member 21 can be u...

Embodiment approach 3

[0065] see Figure 6 and Figure 7 Shown is the third embodiment of the gas-liquid transfer device for household rapid preparation of ozone water of the present invention, the inverted umbrella type centrifugal gas-liquid mixing part 11 of the gas-liquid transfer device 30 for household rapid preparation of ozone water includes a dividing net 31 and A plurality of dividing ribs 32 for miniaturizing air bubbles, and cutting edges are provided on the dividing ribs 32 . The dividing ribs 32 are distributed on the dividing net 31 in a staggered manner.

[0066] It can be understood that the dividing ribs can be arranged on the umbrella surface or in the dividing net.

[0067] It can be understood that the partition ribs can also be detachably installed on the partition net.

[0068] It can be understood that multiple partition holes may also be provided on the partition ribs to enhance the effect of miniaturizing the air bubbles. Then this non-essential change of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com