Patents

Literature

105results about How to "Strong penetration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

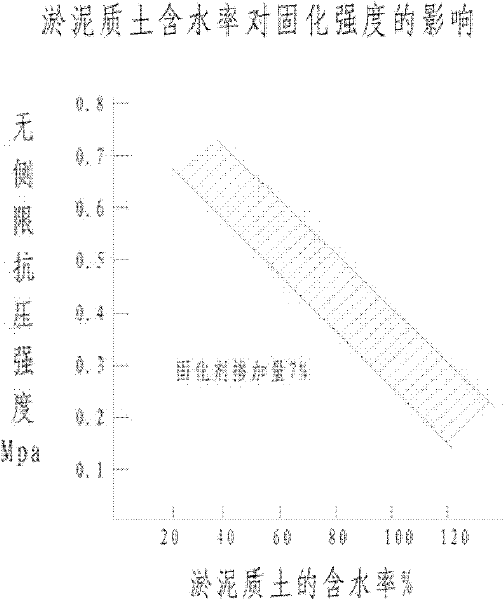

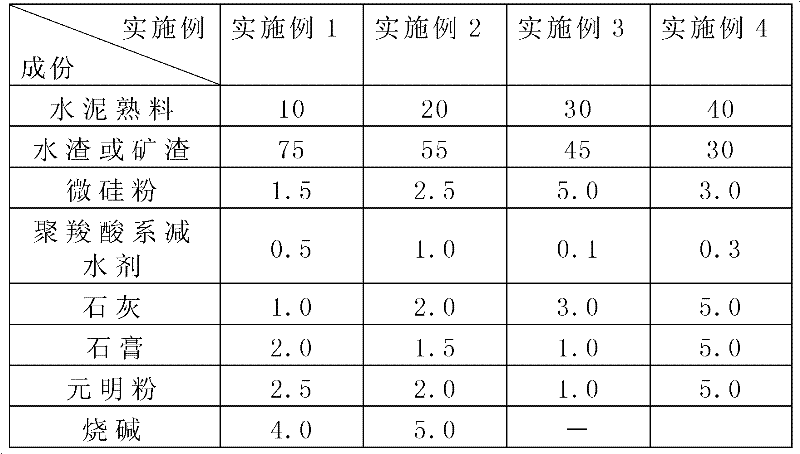

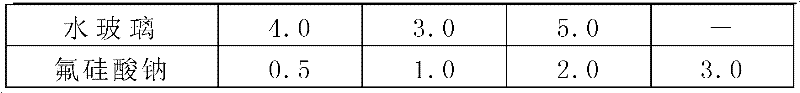

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

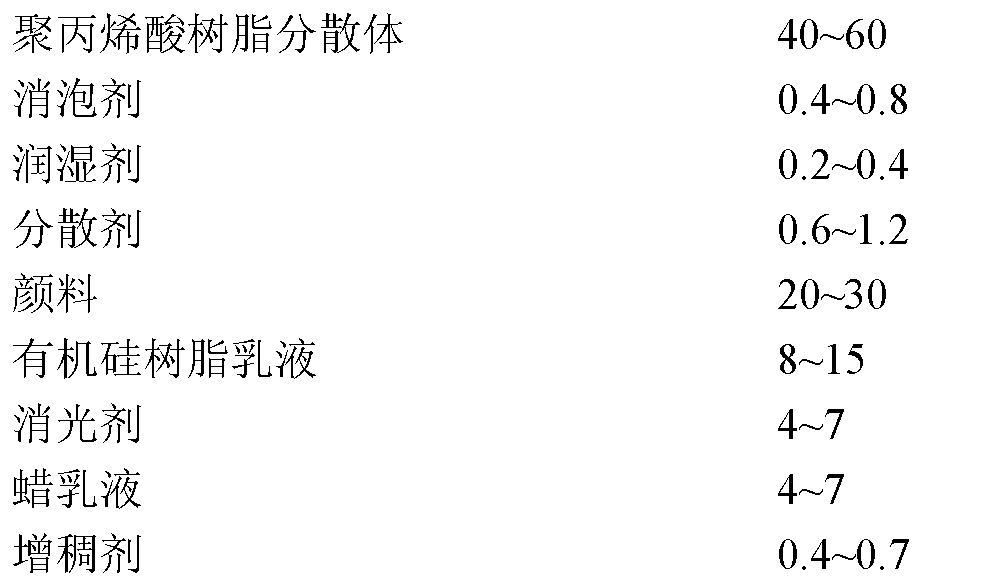

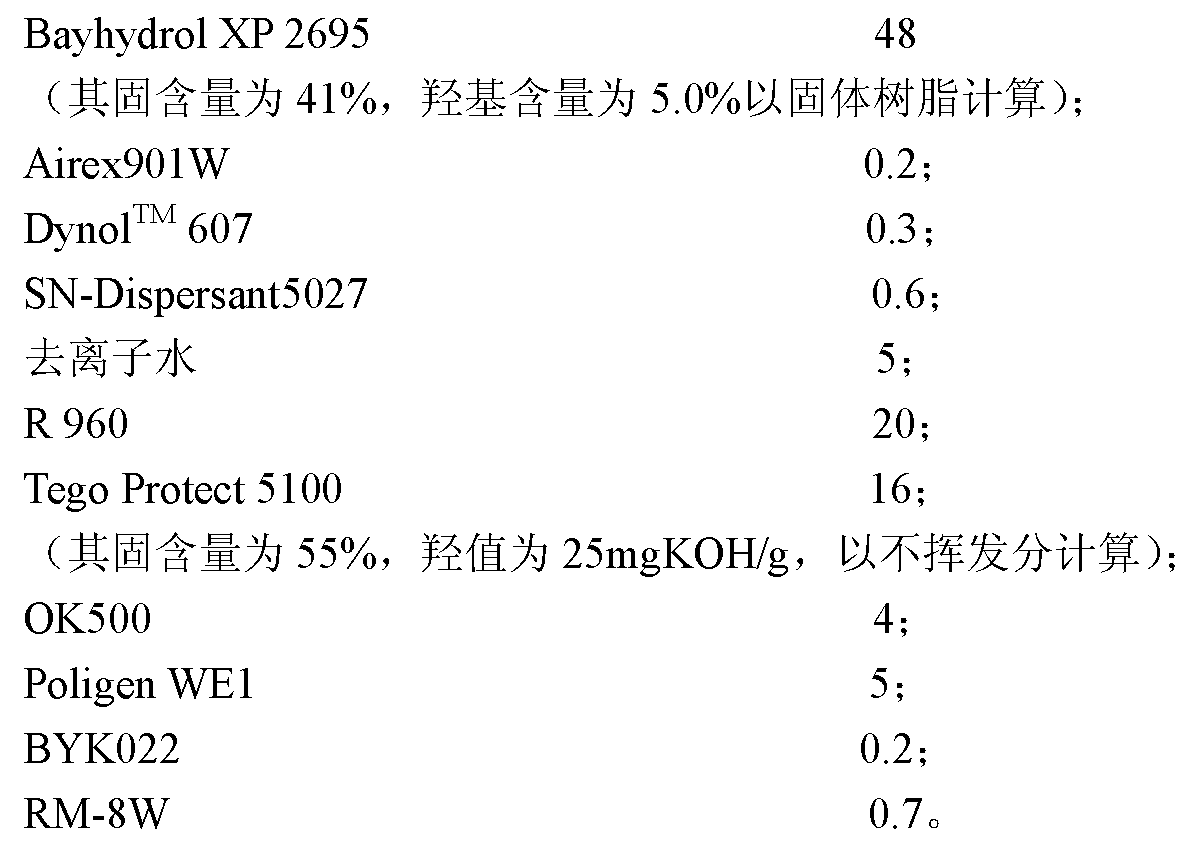

Dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance and preparation thereof

InactiveCN102516858AImprove scratch resistanceImprove friction resistancePolyurea/polyurethane coatingsWaxChemistry

The invention discloses a dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance, and a preparation method thereof. The dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance is prepared by using aqueous hydroxy-containing polyacrylic resin dispersion and fatty group polyisocyanate as main film forming substances, adding organosilicon resin emulsion, deionized water, antifoaming agent, wetting agent, dispersant, pigment, dulling agent, wax emulsion and thickening agent and carrying out high speed disperse. The paint has characteristics of high crosslinking density, low surface tension, strong permeability resistance, good scratch resistance, substantial scrawling resistance and pasting resistance, excellent performances of low VOC content, high hardness, good weatherability, brushing resistance and chemical resistance, and is suitable for application fields of municipal public facility, building paint and terrace paint coating, etc.

Owner:CENT SOUTH UNIV +1

Dispersive air brick and preparation method thereof

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

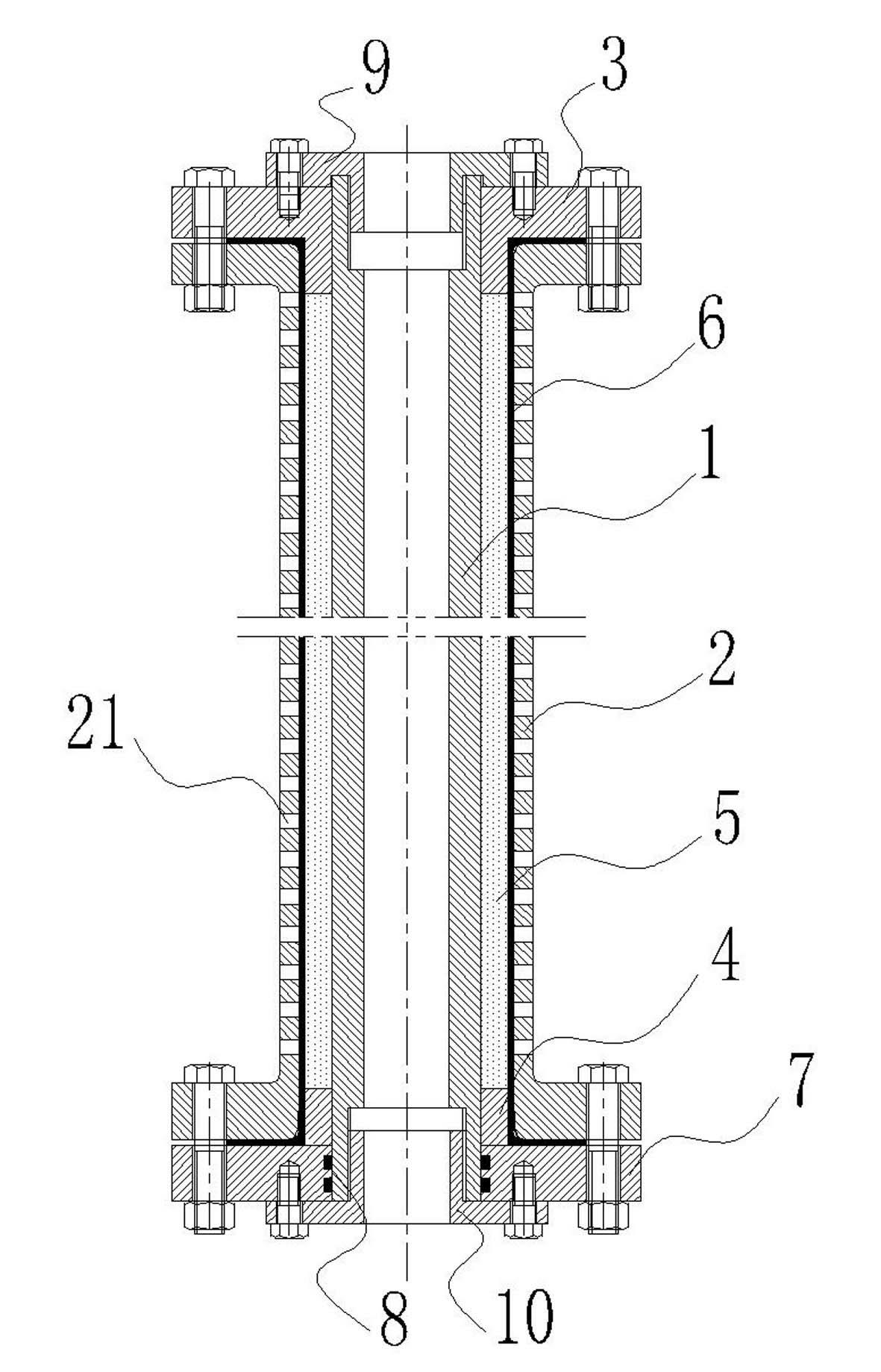

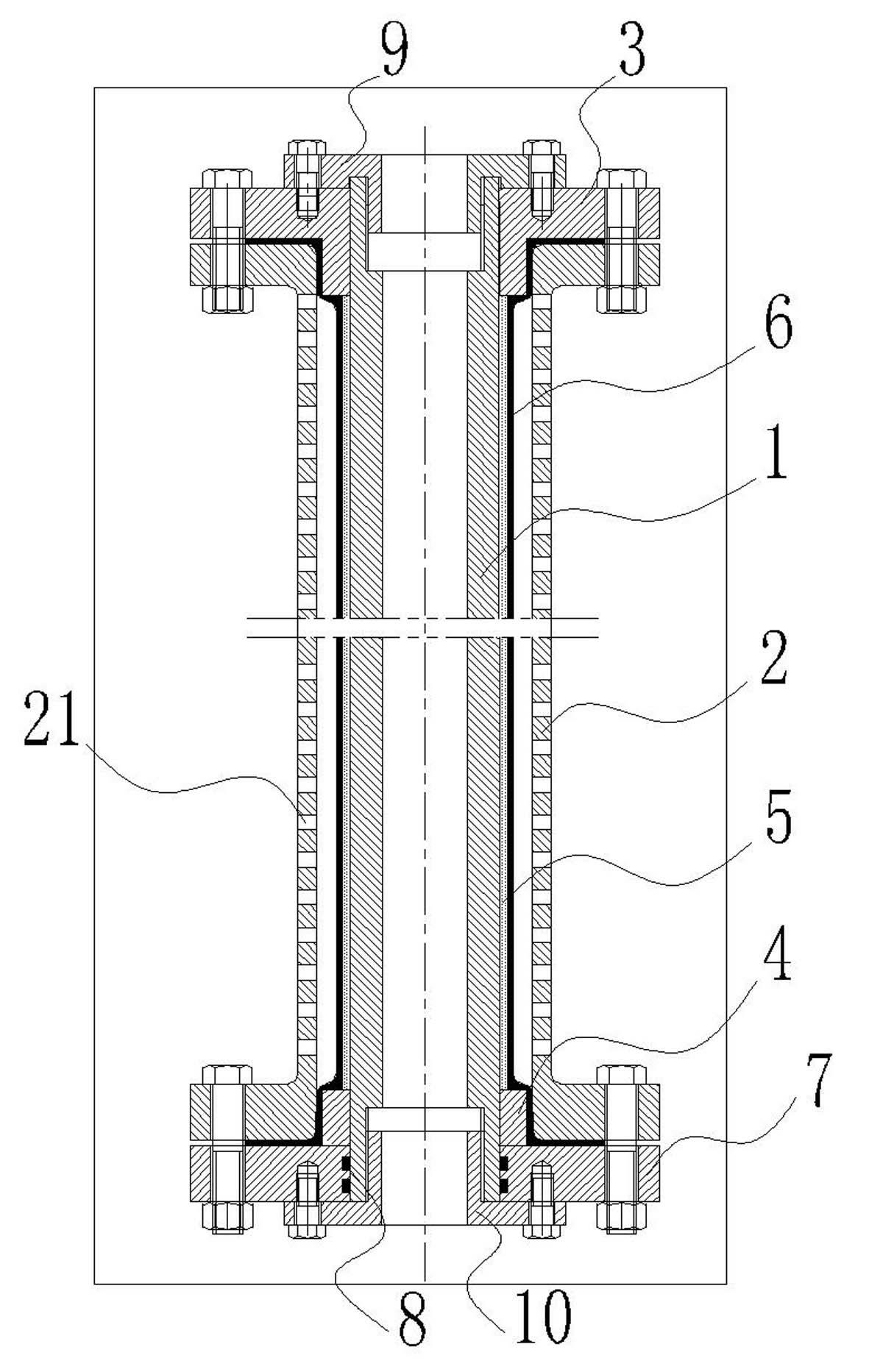

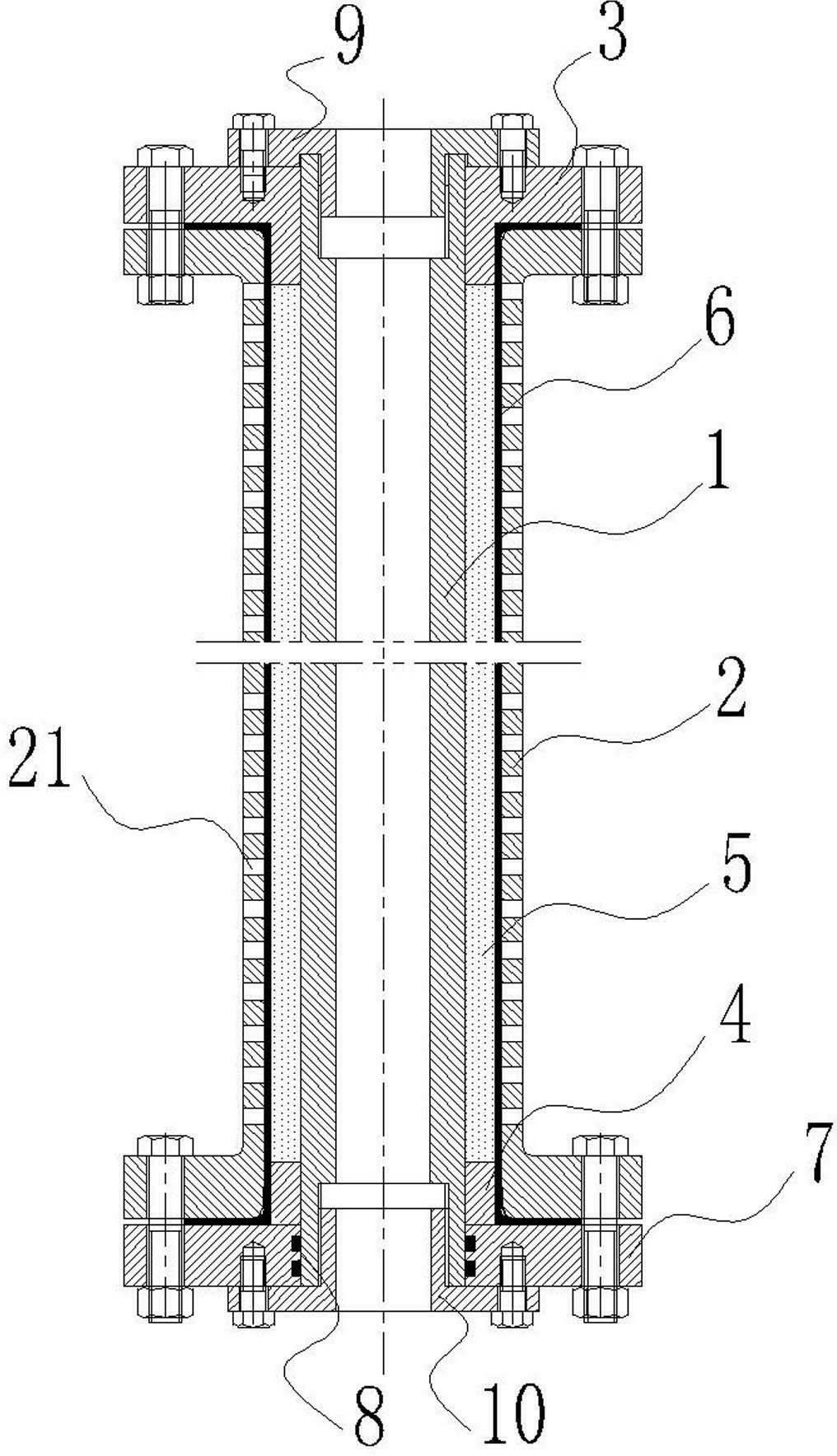

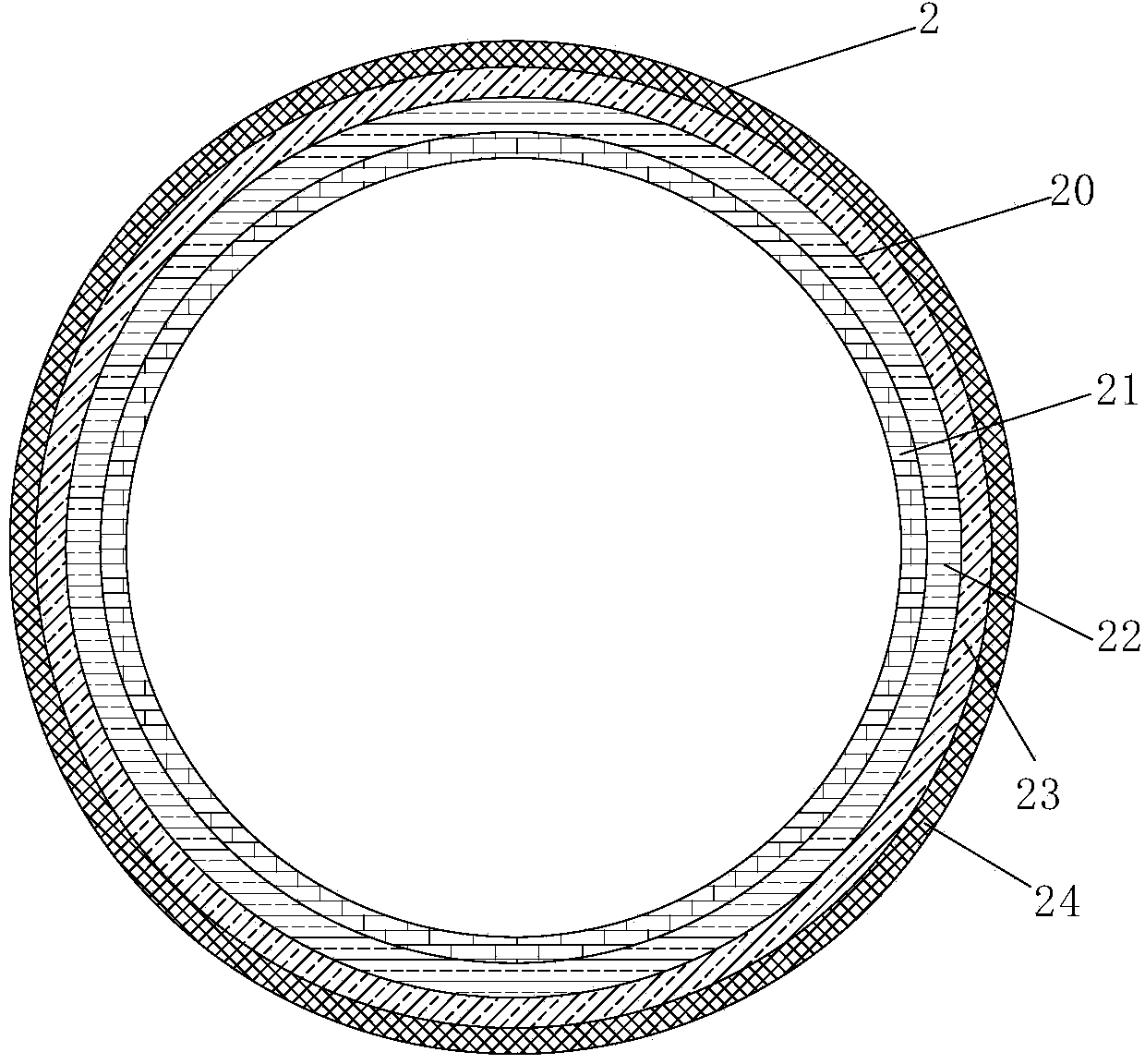

Polytetrafluoroethylene isostatic pressure molding device and pipeline lining method by aid of same

ActiveCN102632578AImprove product qualityHigh densityTubular articlesMoulding deviceComposite material

The invention discloses a lining molding device used on chemical equipment and a lining method, and provides a polytetrafluoroethylene isostatic pressure molding device and a lining method. The polytetrafluoroethylene isostatic pressure molding device is smart in conception and fine in performance, a pipe molded by the aid of the polytetrafluoroethylene isostatic pressure molding device is high in strength, and the polytetrafluoroethylene pipe can be tightly lined in a pipeline by the aid of the lining method, and the technical problems of low polytetrafluoroethylene lining density, poor tensile strength and permeation resistance and the like due to insufficient molding pressure of an existing polytetrafluoroethylene molded pipe of the prior are solved. The method includes integrally placing a mold below the liquid level of a high-pressure cabin of an isostatic pressure machine; pressurizing the high-pressure cabin to process pressure and leading a polytetrafluoroethylene blank to be in cold press molding; adopting an isostatic pressure process; sintering a blank part released from the mold, drawing down the blank part, and placing the blank part into the pipeline; realizing memory rebounding of a polytetrafluoroethylene pipe blank after heating; and leading the polytetrafluoroethylene pipe lining to be lined in the pipeline. The lining is fine in high-temperature resistance and high-pressure resistance, and full-vacuum service requirements under the condition with high temperature of 232 DEG C are met.

Owner:四达氟塑股份有限公司

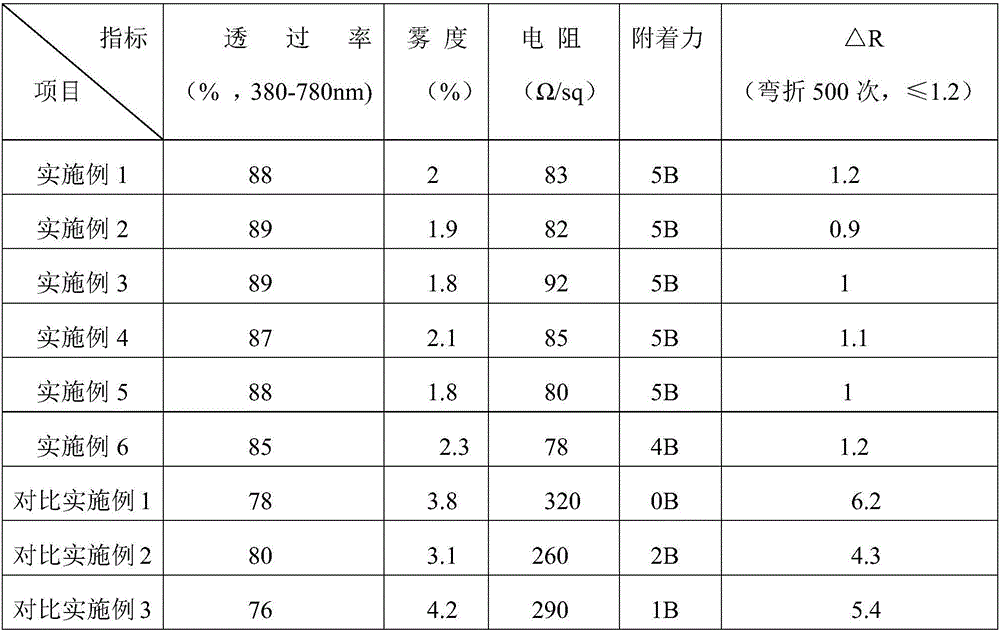

Preparation of PET/nano silver wire transparent conductive film after illumination sintering

ActiveCN106128564ATo achieve the purpose of conductionStrong penetration resistanceMaterial nanotechnologyConductive layers on insulating-supportsSurface cleaningLaser scanning

The invention relates to the technical field of flexible transparent conductive films, and specifically discloses the preparation of a PET / nano silver wire transparent conductive film after illumination sintering. The method comprises the steps of PET substrate surface cleaning and transparent conductive film preparing. The step of PET substrate surface cleaning comprises the steps that an optically coated PET substrate after double-side hardening layer processing is used; an acetone and ethanol mixed solvent is used to clean the PET substrate; and rinsing with distilled water and drying are carried out to acquire the PET substrate with clean surface. The step of transparent conductive film preparing comprises the steps that a nano silver wire ethanol dispersion with the concentration of 0.05 to 15mg / ml is uniformly and densely coated on the surface of the PET substrate after surface cleaning in a precise coating manner; and after drying at room temperature, the nano silver wire transparent conductive film is prepared through laser scanning and sintering. The transparent conductive film provided by the invention has the advantages of strong electric conductivity, excellent adhesion, good flexing resistance, simple operation, low cost and wide application prospect.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

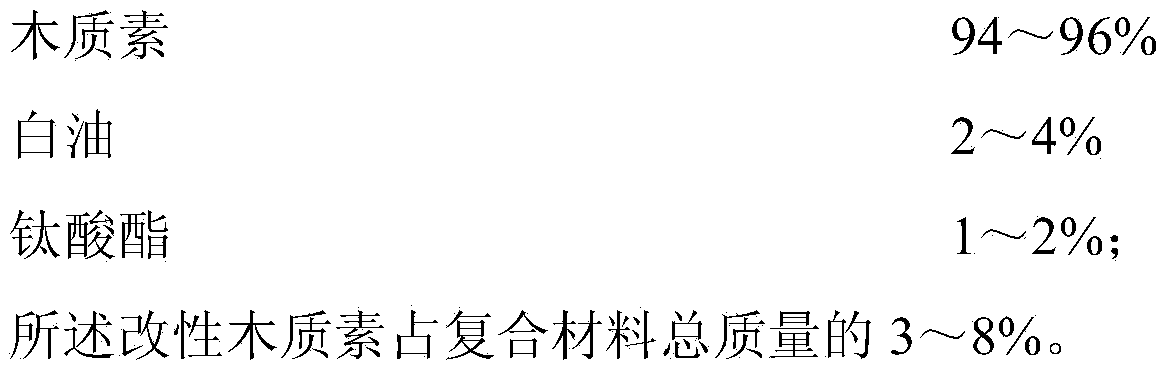

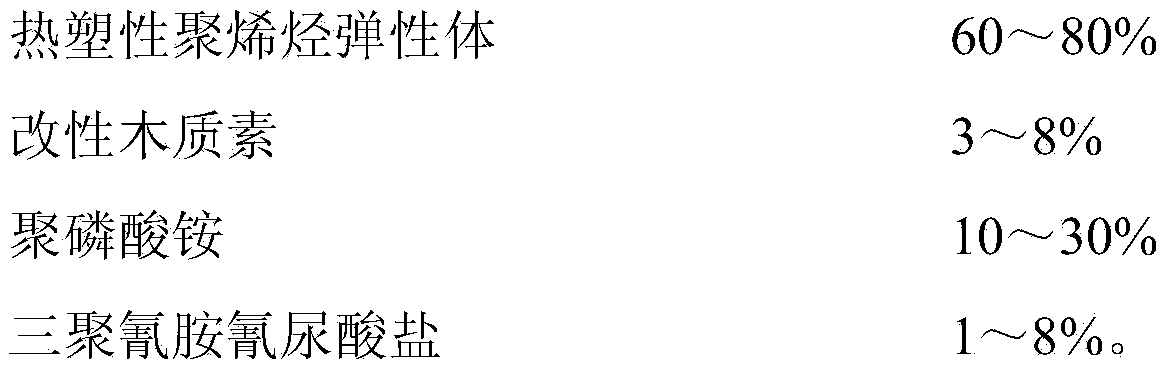

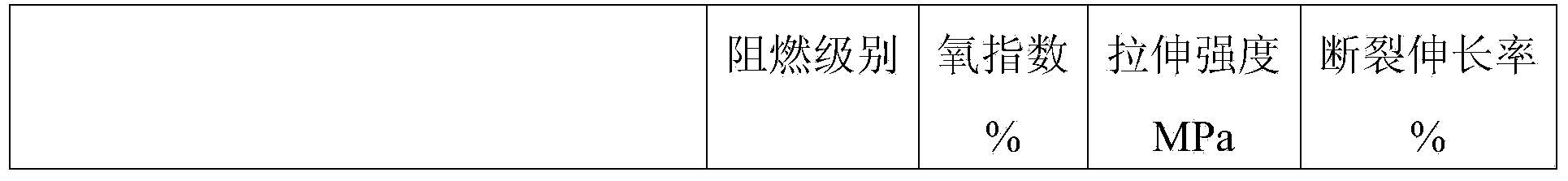

Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

InactiveCN103834107APromote environmental protectionHigh char formation ratePolyolefinAging resistance

The invention relates to a modified lignin intumescent flame retardant thermoplastic polyolefin (TPO) composite material as well as a preparation method and an application of the composite material. The composite material contains modified lignin, wherein the modified lignin consists of the following components in percentage by mass: 94-96% of lignin, 2-4% of white oil and 1-2% of titanate; and the modified lignin accounts for 3-8% in terms of total mass of the composite material. The prepared modified lignin intumescent flame retardant TPO composite material disclosed by the invention has the beneficial effects of being high in tensile strength at break, high in elongation at break, low in heating expansion amount, good in low temperature flexibility, good in penetration resistance and strong in chemical corrosion resistance; and the composite material is excellent in weather aging resistance, applicable to damp, hot and cold natural environments in a long term, and low in performance change.

Owner:DALIAN POLYTECHNIC UNIVERSITY

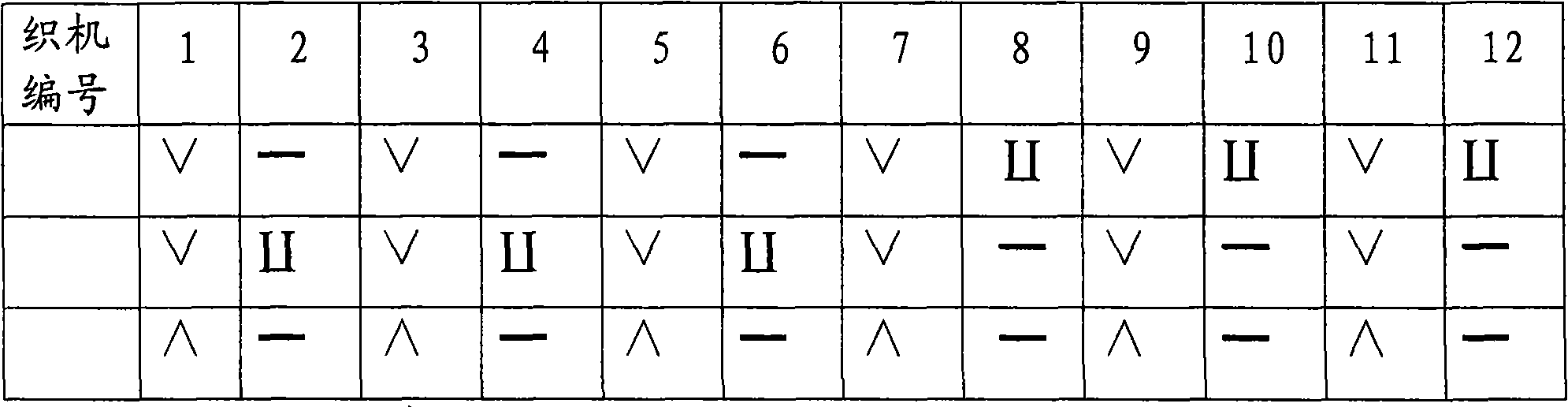

High-strength light fabric used in fencing clothes and processing method thereof

The invention relates to a high-strength light fabric used in fencing clothes, which is characterized by comprising terylene and polypropylene fibers, wherein the terylene consists of lustrous terylene and matt terylene. A processing method for the high-strength light fabric used in fencing clothes comprises the steps of wiredrawing, twisting, weaving, printing and dyeing, and is characterized in that the fabric is woven in honeycomb weaves. After being developed and produced, the fabric has the advantages that the breakdown resistance of the fabric is strong because of adopting the terylene and polypropylene fibers as main raw materials, for example, the fabric with 800N has the limit breakdown of over 3000N; the fabric is light as adopting the honeycomb weave, as the fabric with 800N has the unit weight of 630g / m<2>, and the fabric with 350N has the unit weight of 400g / m<2> (with the limit breakdown of 2978N). One finished jacket after being woven is lighter 500g than a conventional jacket; furthermore, the softness and the textile of products are much better than those of conventional products.

Owner:丹阳市斯鲍特体育用品有限公司

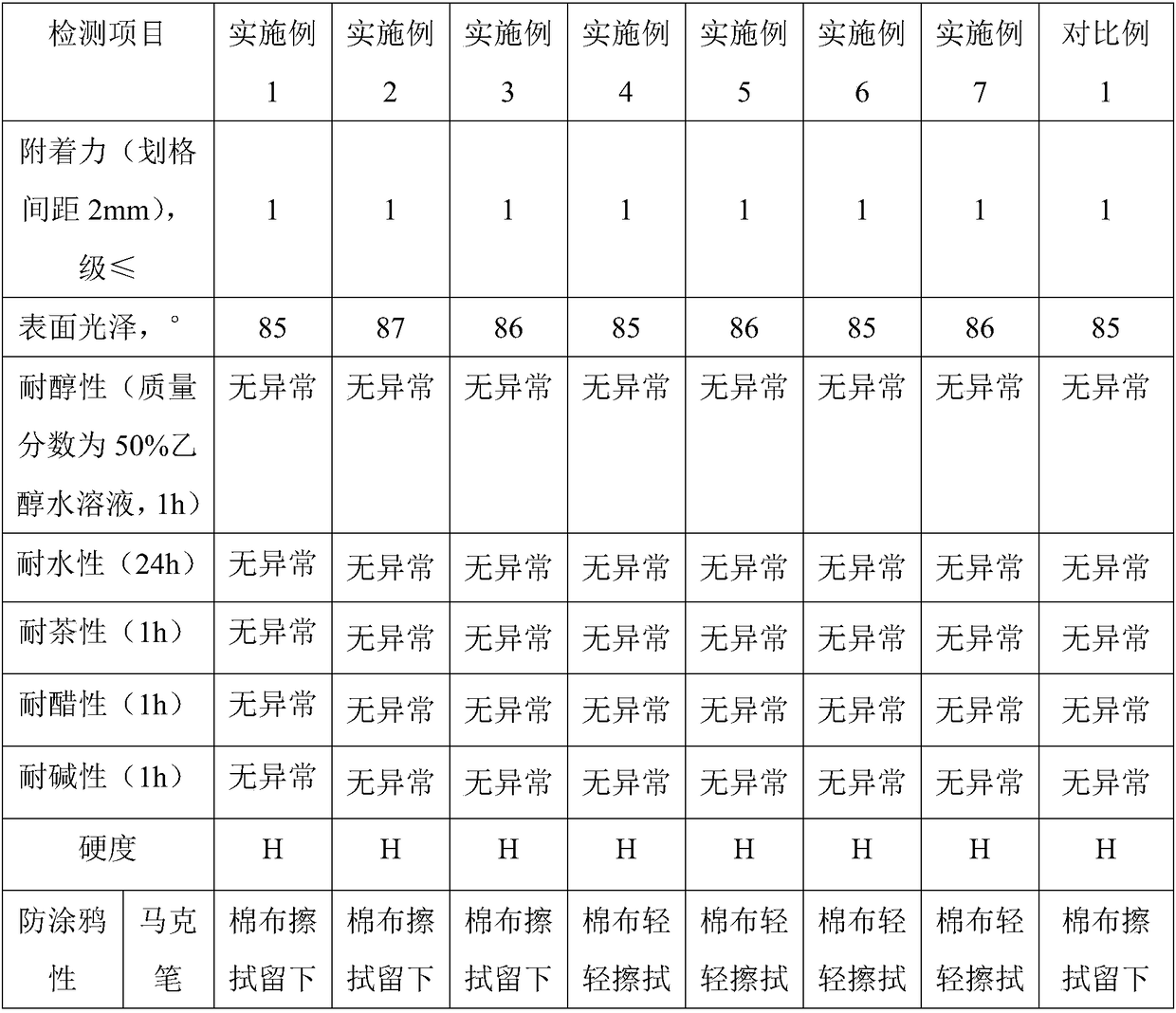

Oily-pen-resistant waterborne woodware varnish and preparation method thereof

InactiveCN108467670AIncrease crosslink densityImprove compactnessAntifouling/underwater paintsPaints with biocidesAcrylic resinWear resistant

The invention provides oily-pen-resistant waterborne woodware varnish and a preparation method thereof. The varnish comprises a component A and a component B, wherein the component A comprises, by weight, 60-80 parts of waterborne hydroxylated acrylic resin, 0.05-0.5 part of pH regulator, 0.1-0.5 part of waterborne defoaming agent, 0.1-0.5 part of waterborne wetting agent, 0.1-0.5 part of waterborne leveling agent, 1-5 parts of coalescing agents, 5-10 parts of nano additives, 5-10 parts of anti-doodling auxiliaries, 0.5-4 parts of wear-resistant auxiliaries, 0.05-2 parts of bactericide and 1-20 parts of water; the component B comprises, by weight, 15-30 parts of curing agent. The anti-doodling auxiliaries and the nano additives are added, so that the anti-doodling and anti-dirt propertiesof a coating are remarkably improved; the anti-doodling auxiliaries are preferably polydimethylsiloxane anti-doodling auxiliaries containing hydroxyl functional groups, and the anti-doodling auxiliaries contain hydroxyl and can participate in a curing reaction, so that the anti-doodling performance of paint film is further improved.

Owner:LANZHOU KETIAN ENVIRONMENTAL PROTECTION ENERGY SAVING TECH CO LTD +1

Wear-resistant smelting combined epoxy modified powder paint

InactiveCN1511906AHigh mechanical strengthStrong penetration resistancePowdery paintsEpoxy resin coatingsEpoxyWear resistant

The wear-resistant modified powder paint consists of E12 epoxy resin 50-70 wt%, curing agent of substituted cyanoguanidine 3-6 wt%, modifier of tetrafluoride 1-5 wt% and stuffing of SiO2+SiC accounting for the rest amount. The paint coating of the present invention has a abrasion loss less than 80 mg / 1000 g under the action of 5000 turns.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anti sea water smelting combined epoxy modified powder paint

InactiveCN1511904AHigh mechanical strengthStrong penetration resistancePowdery paintsEpoxy resin coatingsEpoxySalt solution

The sea water resisting modified powder paint consists of E12 epoxy resin 50-70 wt%, curing agent cyanoguanidine 3-6 wt%, modifier of superfine TiO2 powder 1-5 wt% and stuffing of CaCO3+BaSO4 accounting for the rest amount. The paint coating of the present invention can resist corrosion of saturated NaCl or KCl salt solution.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A60-level lightweight refractory deck composition

InactiveCN103172329AImprove thermal insulationHigh-strength thermal insulationExpanded clay aggregateNeoprene

The invention provides an A60-level lightweight refractory deck composition, comprising at least one component A and component B, wherein the mass ratio of the component A to the component B is (1 to 6) to (1 to 8); the component A is neoprene latex; the component B is prepared from ordinary silicon 42.5 cement, large ceramsite, small ceramsite, large vermiculite and small vermiculite; the grain size of the large ceramsite is 2-5mm; the grain size of the small ceramsite is 0.5-2mm; the grain size of the large vermiculite is 2-4mm; the grain size of the small vermiculite is 0.2-2mm; and the component B contains the ingredients by weight ratio of 50-55% of ordinary silicon 42.5 cement, 20-25% of large ceramsite, 5-10% of small ceramsite, 14-20% of large vermiculite and 5-10% of small vermiculite. The A60-level lightweight refractory deck composition has good lightness, compressive property, fracture resistance and shock resistance, and can effectively prevent sound transmission and heat conduction; and the fire resistance can achieve A-60 level.

Owner:湖北海风新材料股份有限公司

Treatment method for landfill leachate membrane treatment evaporated and concentrated liquor

InactiveCN108911324AFast curingStrong penetration resistanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSulfateTherapeutic effect

The invention discloses a treatment method for landfill leachate membrane treatment evaporated and concentrated liquor. The treatment method is characterized in that sulfate aluminum cement is adopted, and has high curing speed and strong permeability resistance in comparison with conventional silicate cement. Silicate cement, a heavy metal ion chelating agent and an additive are taken as curing agent main components, and can be effectively combined with pollutants such as organic substances and heavy metal in landfill leachate membrane treatment evaporated and concentrated liquor, so that thepollutants are cured in a curing body, and therefore, the harmless and stable purpose is achieved. The treatment method is simple in process, is high in practicability, is good in treatment effect, is taken as a deep treatment technology, makes up the defects of an existing landfill leachate membrane treatment evaporated and concentrated liquor treatment technology, and effectively solves the treatment problem of the landfill leachate membrane treatment evaporated and concentrated liquor.

Owner:武汉天源环保股份有限公司

Honeycomb ceramic heat storage body with low adsorption capability and preparation method thereof

The invention discloses a honeycomb ceramic heat storage body with low adsorption capability and a preparation method thereof. The honeycomb ceramic heat storage body with the low adsorption capability is sintered from the following components in parts by weight: 55 to 60 parts of white corundum powder, 8 to 10 parts of mullite, 10 to 15 parts of a-AL2O3 powder, 2 to 3 parts of SiO2 powder, 10 to15 parts of tricalcium phosphate, and 4 to 5 parts of high-temperature adhesive. The honeycomb ceramic heat storage body has high material compacting / low porosity, high high-temperature resistance / high chemical reaction heat, high impermeability, low adsorption capability, high desorption capability, low production cost, high energy-saving rate, low smoke emission temperature, and long service life.

Owner:醴陵友立特种陶瓷有限公司

Water-based high-temperature-resistant long-acting anticorrosive paint and preparation method thereof

InactiveCN110922855AImprove heat resistanceGood shieldingFireproof paintsAnti-corrosive paintsSilane couplingIsopropylene glycol

The invention discloses a water-based high-temperature-resistant long-acting anticorrosive paint and a preparation method thereof. The water-based high-temperature-resistant long-acting anticorrosivepaint comprises a component A and a component B, wherein the component A is prepared from the following raw materials: film-forming substance water-based novolac epoxy resin, carbon black, an antirustpigment, an extender pigment containing sericite powder, an anti-settling agent, deionized water, an epoxy silane coupling agent and other auxiliaries; the component B is prepared from the followingraw materials: a curing agent and propylene glycol monomethyl ether; and the mass ratio of the component A to the component B is (4-6): 1. The water-based novolac epoxy resin is used as a film-formingsubstance and is matched with the sericite powder, and excellent permeation resistance is provided for the coating by virtue of a scaly structure; and the epoxy silane coupling agent is added to improve the crosslinking degree and compactness of the coating, thereby greatly enhancing the heat resistance, chemical resistance, hardness and wear resistance of the coating and overcoming the defect that the existing water-based paint can not have high temperature resistance and long-acting corrosion resistance simultaneously.

Owner:无锡市太湖防腐材料有限公司

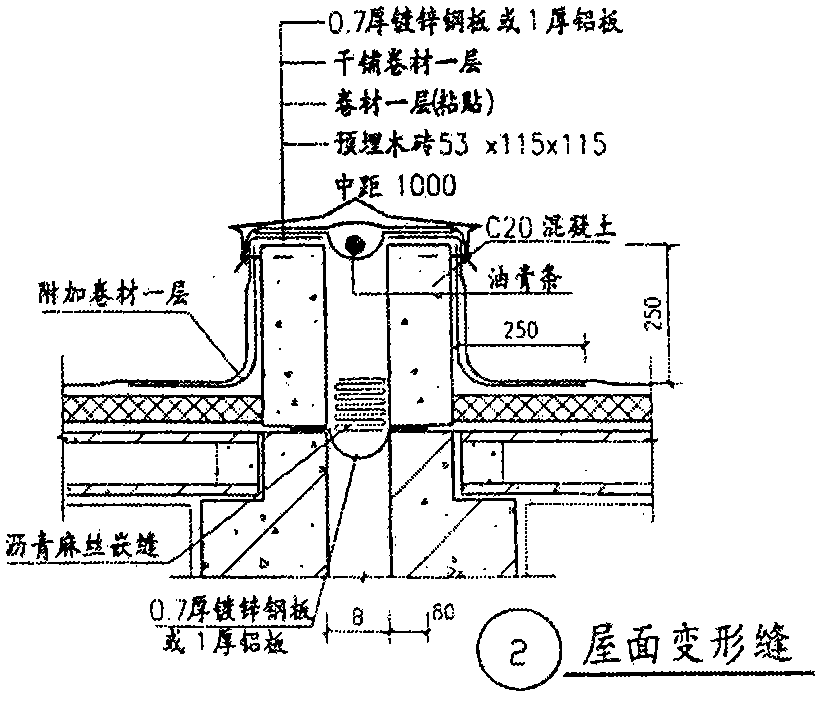

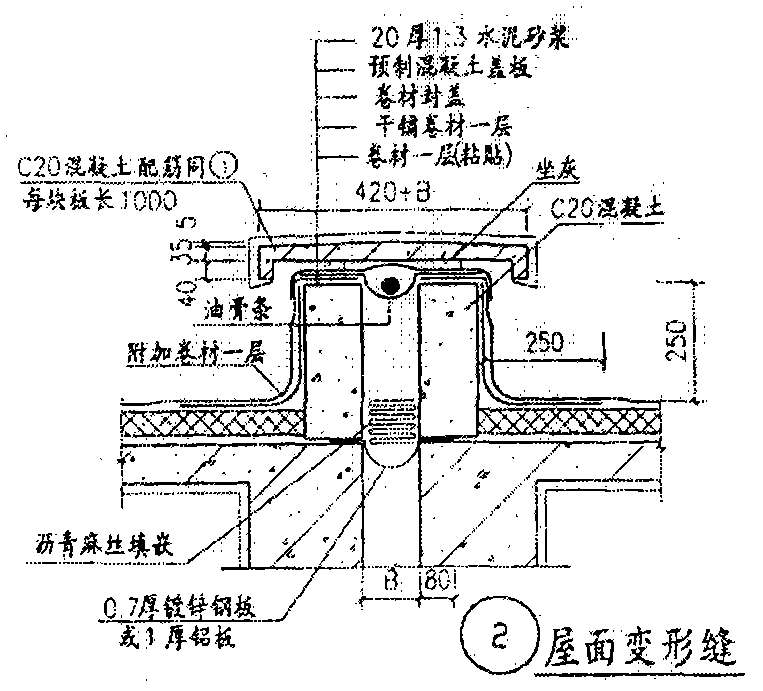

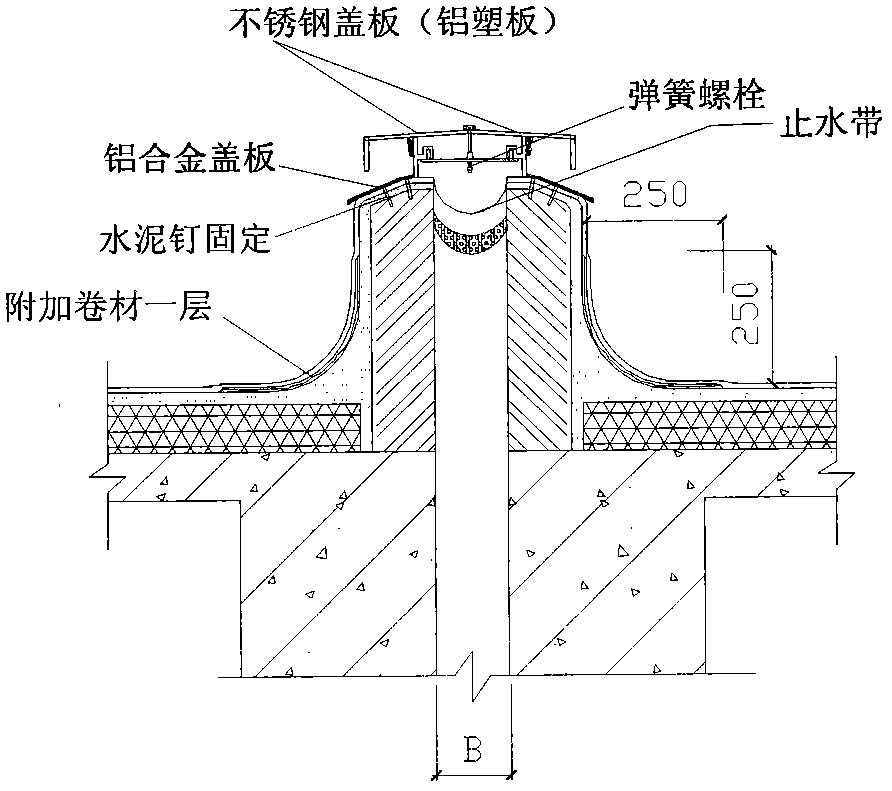

Treatment and construction method for connecting part of roof waterproof structure deformation joint and external wall

InactiveCN105649222AStrong penetration resistanceImprove sealingBuilding constructionsStructural engineeringRebar

The invention relates to a treatment and construction method for a connecting part of a roof waterproof structure deformation joint and an external wall. The method at least comprises the following technological processes of steel bar embedding at one side of a roof deformation joint, measuring and paying-off, formwork erecting (side formwork at one side), wall body and cover plate steel bar binding, base layer clearing, formwork erecting (side formwork at the other side), concrete casting, formwork dismounting, base layer clearing, wall body buildingat the other side, flashing position constructing, wall body deformation joint constructing, wall body painting, JS waterproof paint brushing, roof flushing position waterproof layer constructing, waterproof filling embedding, and waterproof paint coating and brushing on the surface. By using structural design innovation on the roof deformation joint and the wall body deformation joint, under the condition of ensuring the use function (upward, downward, leftward and rightward free deformation) of the deformation joints, the seepage phenomenon occurring in the positions of the roof deformation joint and the wall body deformation joint can be avoided; the durability of the deformation joints is high; and cracking and damage cannot easily occur.

Owner:ANHUI BAOXIANG CONSTR GRP +2

Functional crystallization master batch and preparation method thereof and waterproof material

InactiveCN102863170AImprove self-healing performanceImprove anti-re-pressure penetration functionNanotechnologyCalcium carbonateMethyl cellulose

The invention provides a functional crystallization master batch, a preparation method thereof and a waterproof material and belongs to the field of inorganic materials. The functional crystallization master batch is composed of a nanoscale calcium carbonate aluminum oxide composite powder body and chelated titanate. The preparation method includes preparing and mixing calcium carbonate powders and the nanoscale calcium carbonate aluminum oxide composite powder body. The waterproof material is composed of, by weight, 6-8% of the functional crystallization master batch, 4-6% of methyl cellulose thickening agents, 2-4% of anhydrous citric acids retarders, 25-35% of finely grinding quartz sands, and the balance cements. The functional crystallization master batch has excellent crystallization performance and usage performance, the preparation method is simple, low in production cost, safe in operation and suitable for industrial production, and the waterproof material has excellent impermeability pressure, compression strength and rupture strength.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Construction method of high-pressure airless spraying for desulfurated lining

InactiveCN102580908AImprove adhesionSimple and fast operationPretreated surfacesCoatingsGlass fiberSprayer

The invention discloses a construction method of high-pressure airless spraying for a desulfurated lining, which belongs to the technical field of corrosion prevention. The construction method of high-pressure airless spraying for the desulfurated lining disclosed by the invention comprises the following steps: 1 pre-processing the surface of the sprayed object before coating, including degreasing and removing rust, 2 executing bottom coating construction on the surface of the sprayed object, 3 carrying out pre-coating construction and partial glass fiber reinforced plastic reinforcing construction on the part which is difficultly sprayed on the surface of the sprayed object and the part on which a potential quality hazard easily appears, and 4 spraying vinyl ester resin chemical resistant glass flakes on the surface of a coating object by an airless sprayer. According to the construction method of high-pressure airless spraying for the desulfurated lining disclosed by the invention, the vinyl ester resin chemical resistant glass flakes are uniformly sprayed on the device by a high-pressure airless spraying technology so that a coating of an anti-corrosion layer is smooth and compact without chromatic aberration, and has good corrosion resistance and wide application range.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

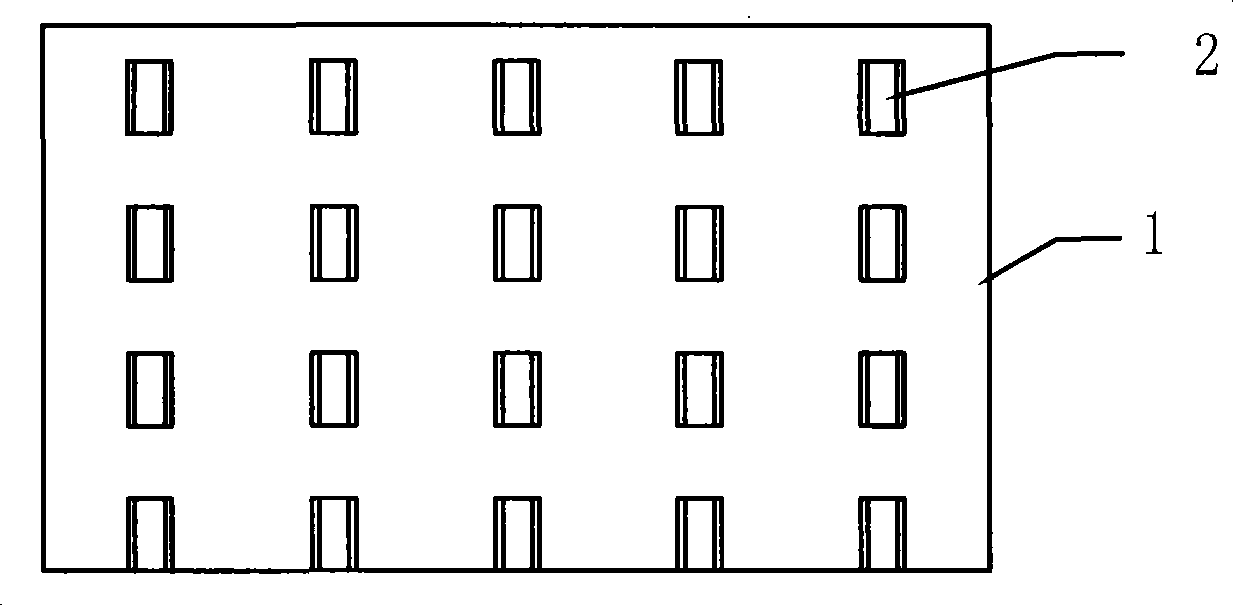

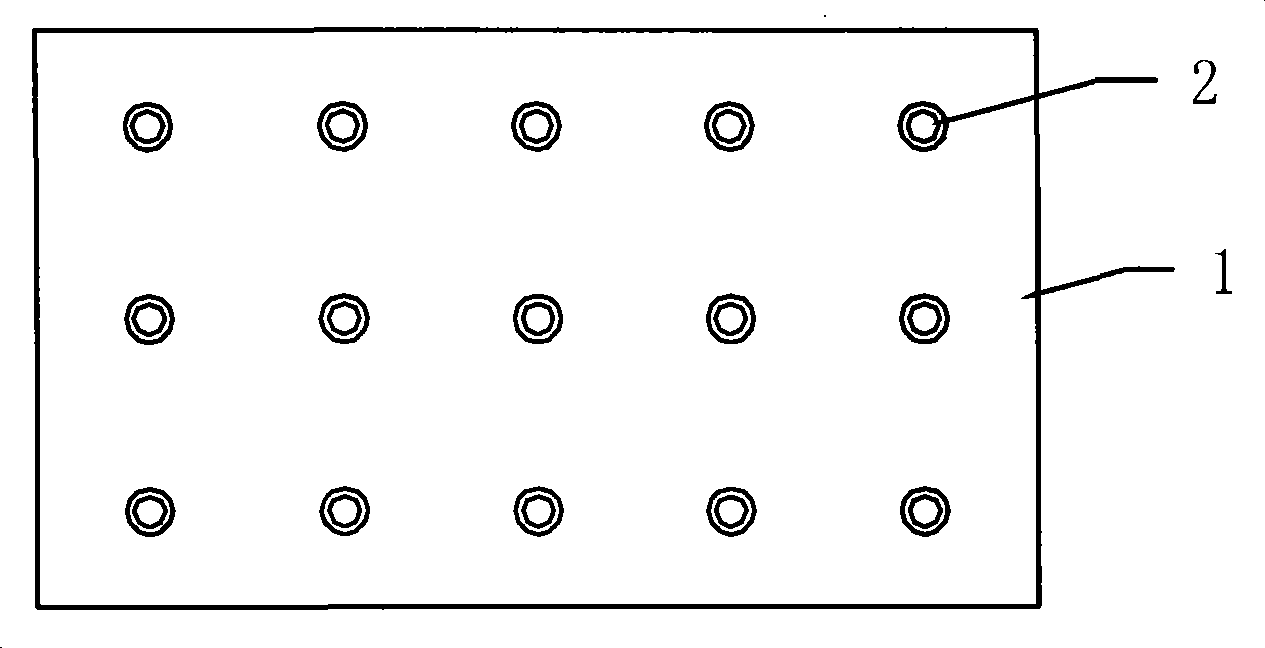

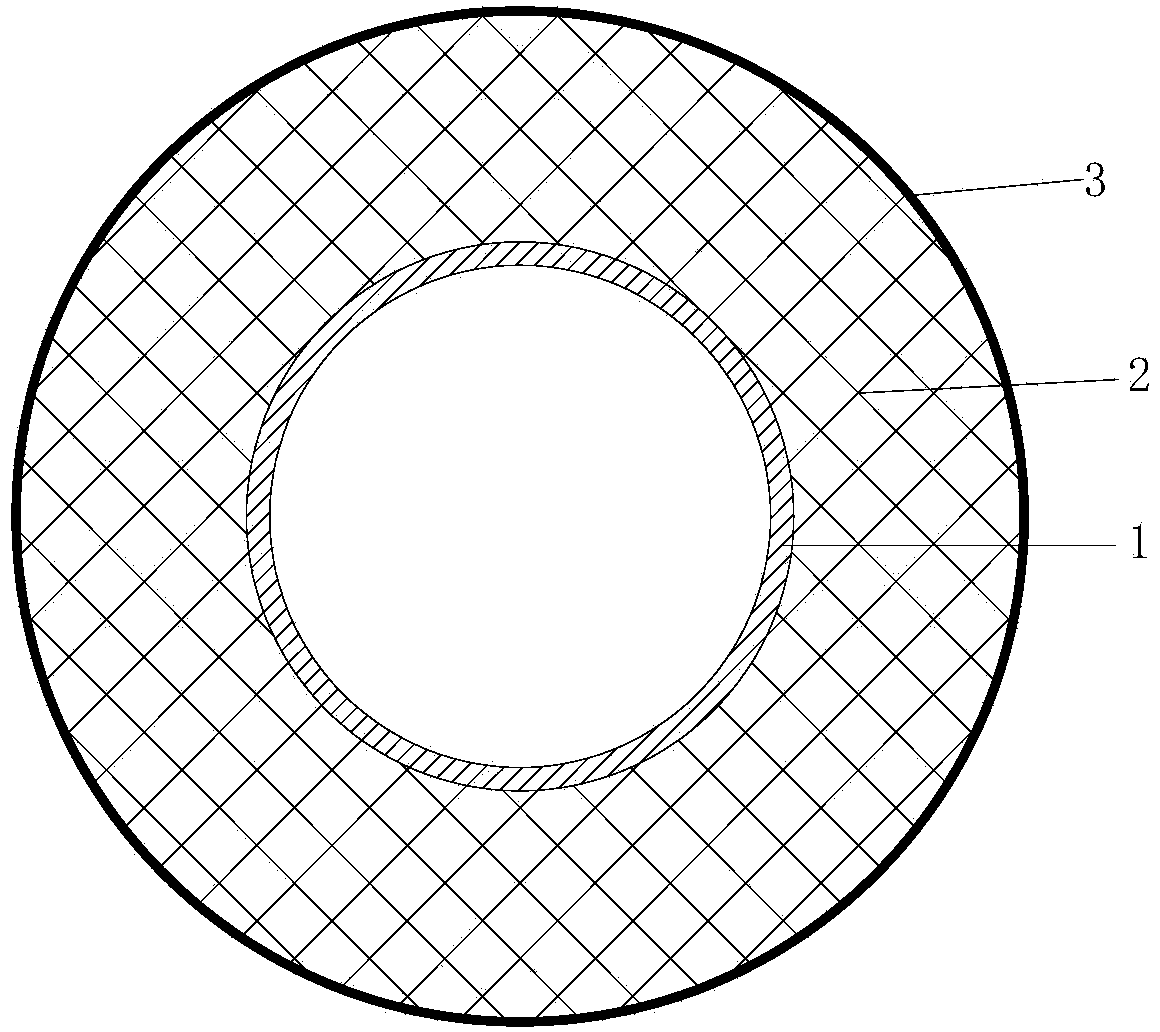

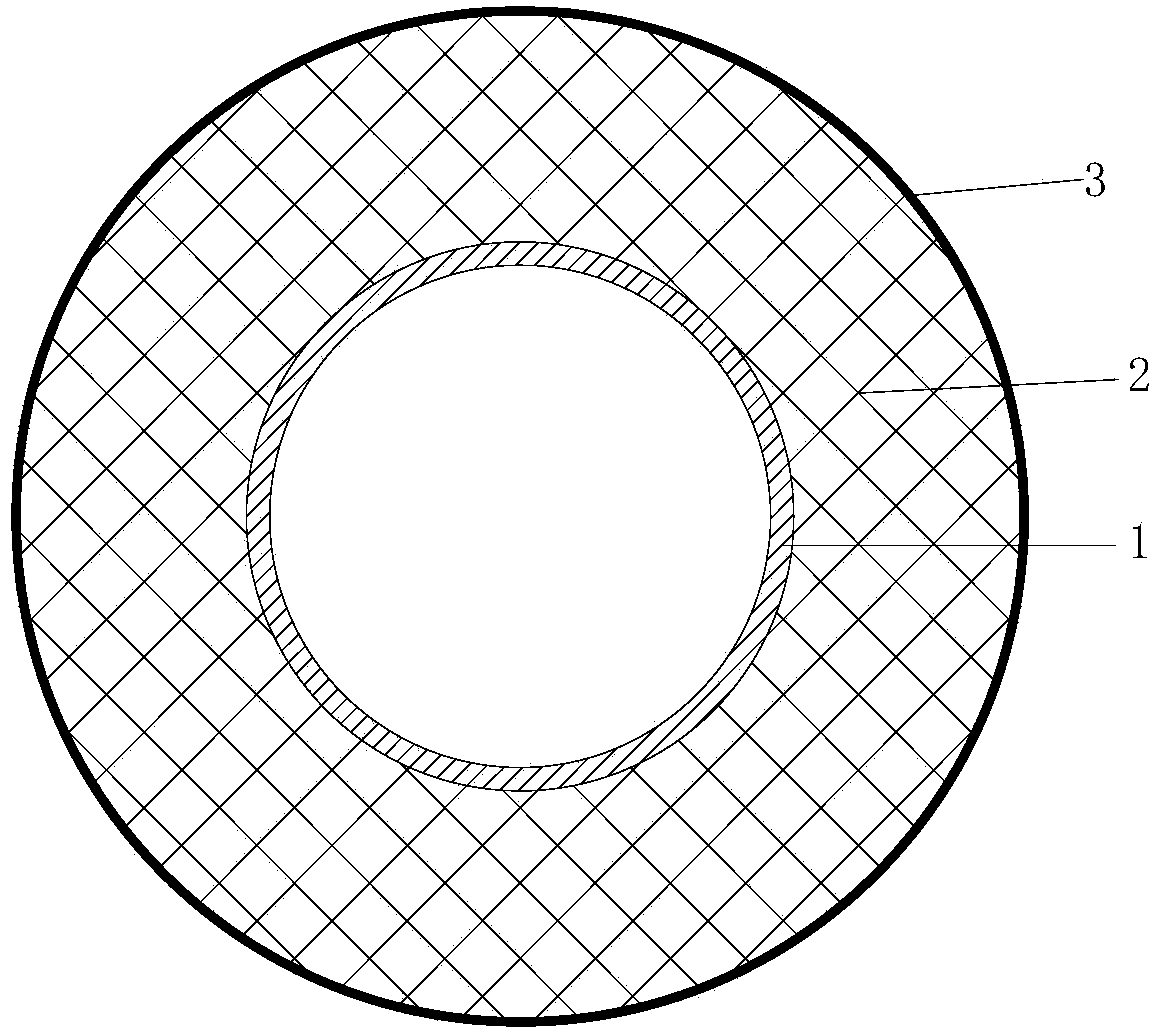

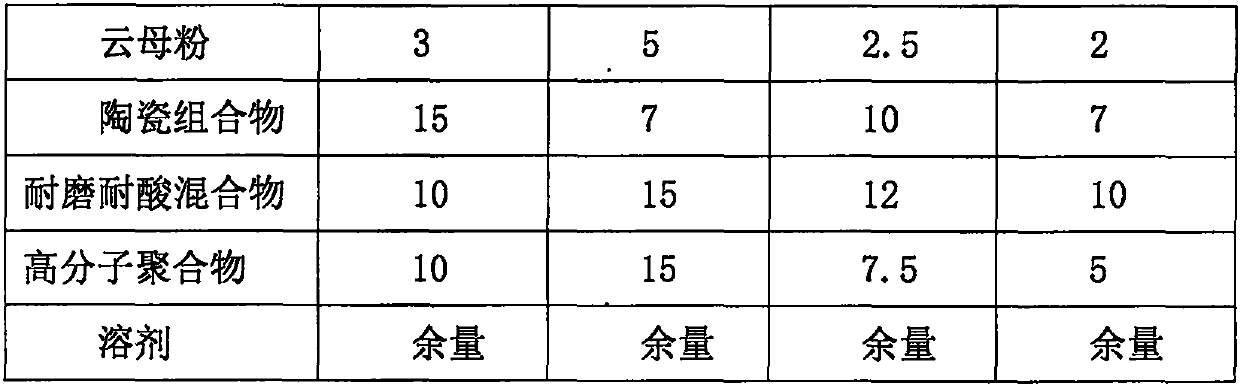

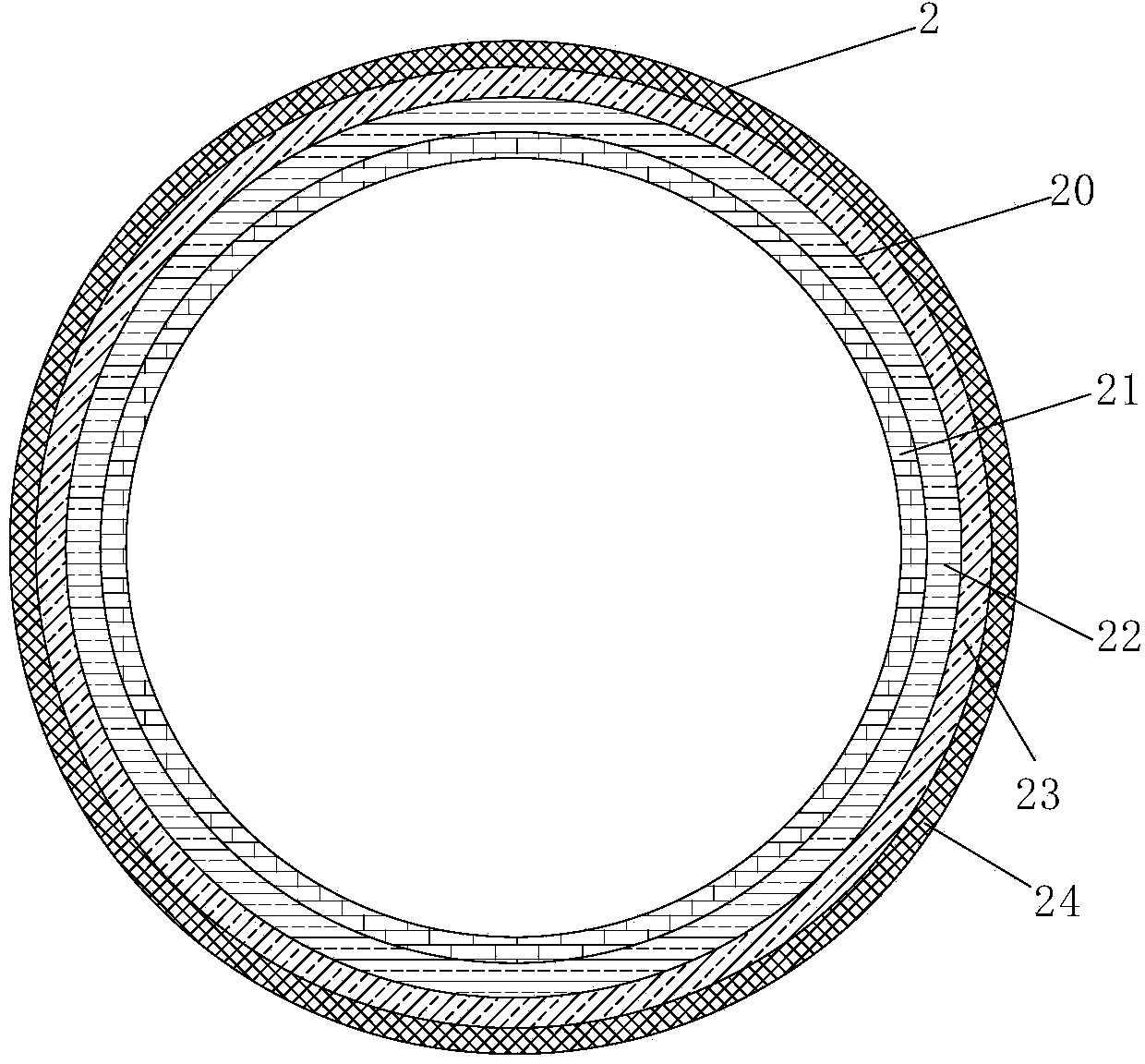

Plastic panel, concrete pipe coating plastic panel and plastic panel processing device

InactiveCN101451632AStrong anti-penetration abilityExtended service lifeCoatingsRigid pipesMoulding deviceEngineering

The invention relates to a plastic board for covering the inner wall of a concrete pipe, the concrete pipe that covers the plastic board and a device for processing the plastic board. The plastic board comprises a substrate and a plurality of fixing claws which are arranged on the surface of one side of the substrate. The width of the root of the fixing claws is less than that of the ends. The processing device comprises a plastic board forming device which comprises a forming roller, a compression roller, at least two pairs of annular molds, at least two stripping knives and a transport roller. The concrete pipe that is covered by the plastic board has stronger permeation resistance ability, longer service life and lower manufacturing cost. The processing device can extrude the plastics by an extruder between the forming roller and the compression roller, and the fixing claws of the board are extruded by the annular molds, and the fixing claws can separate from annular molds when the stripping knives separate the annular molds, and therefore, the processing of the plastic board is easier and the processing efficiency is higher.

Owner:侯兴福

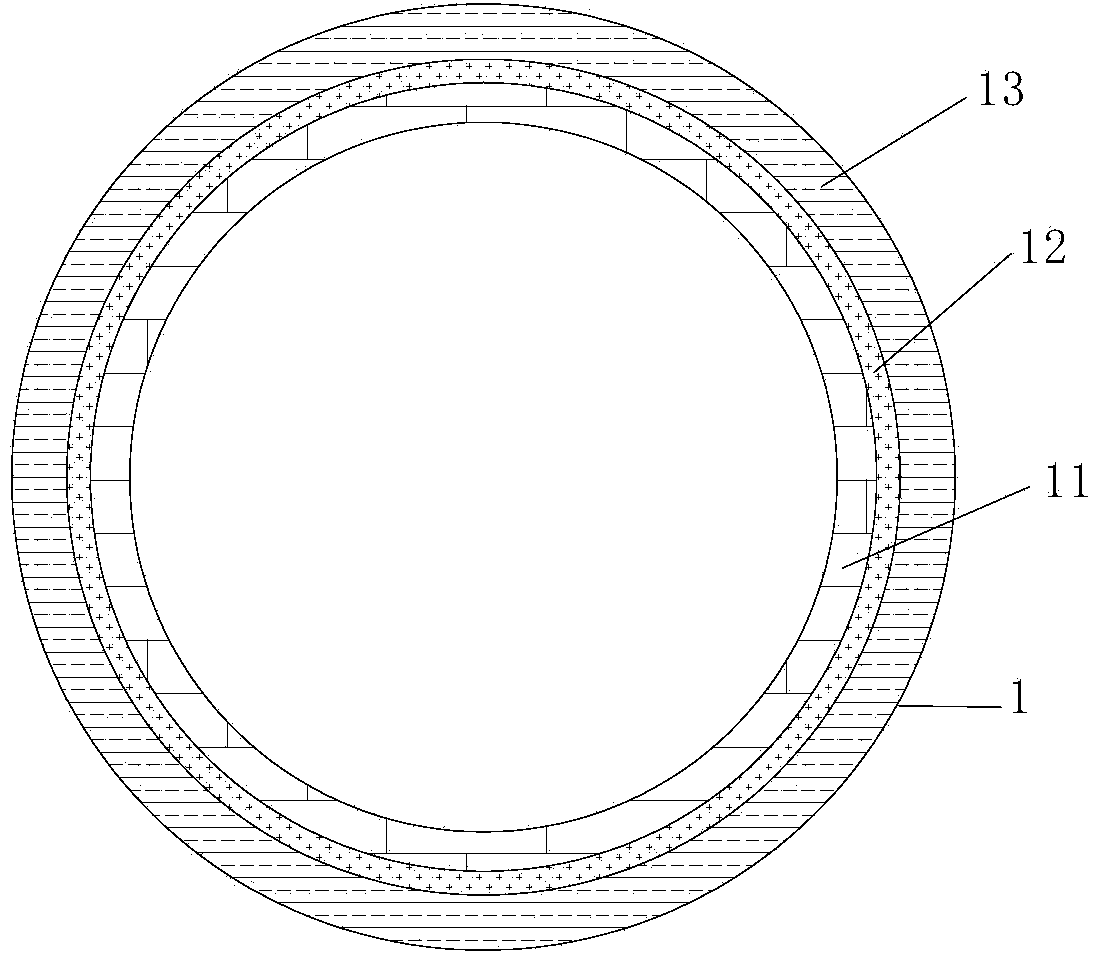

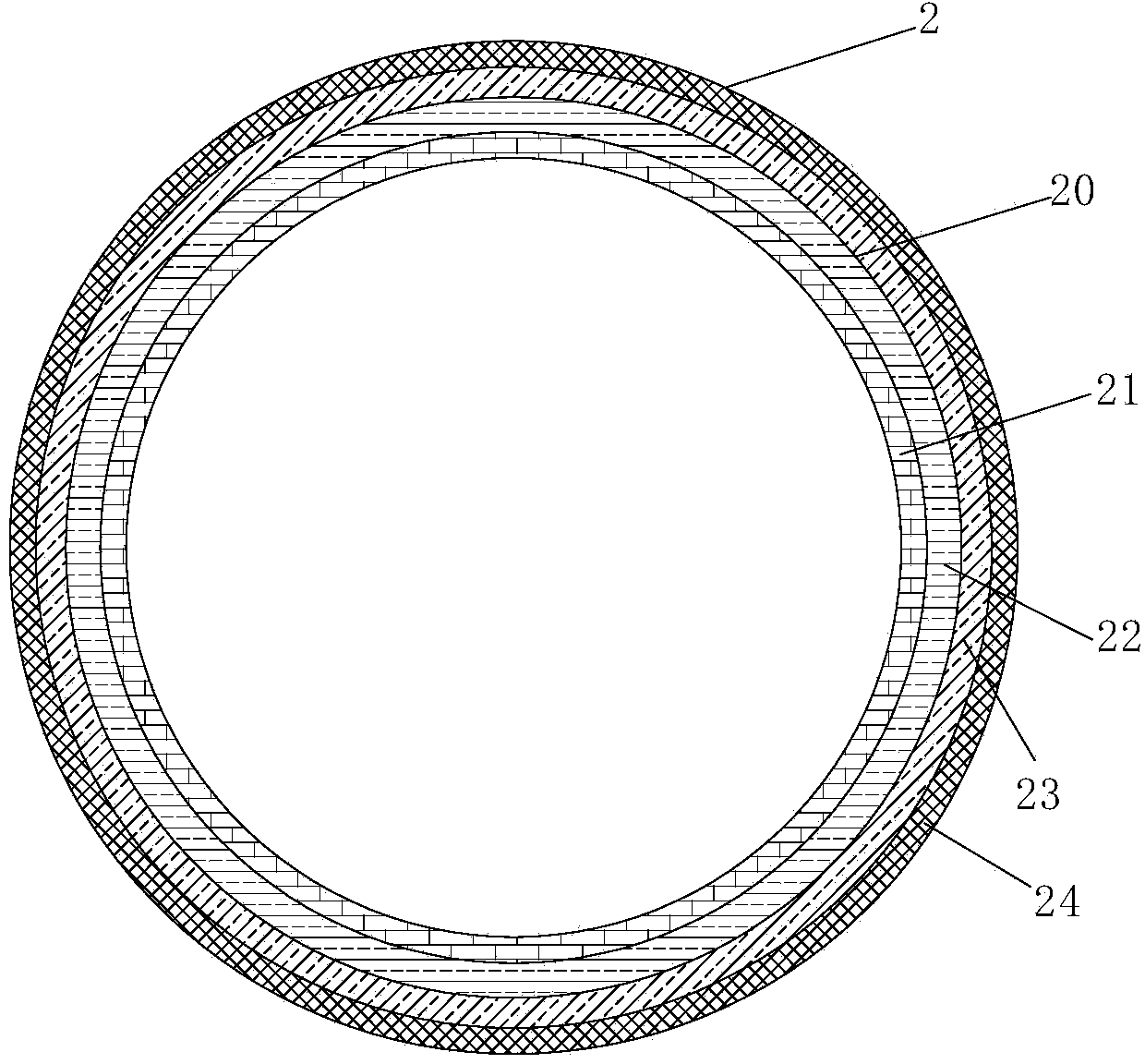

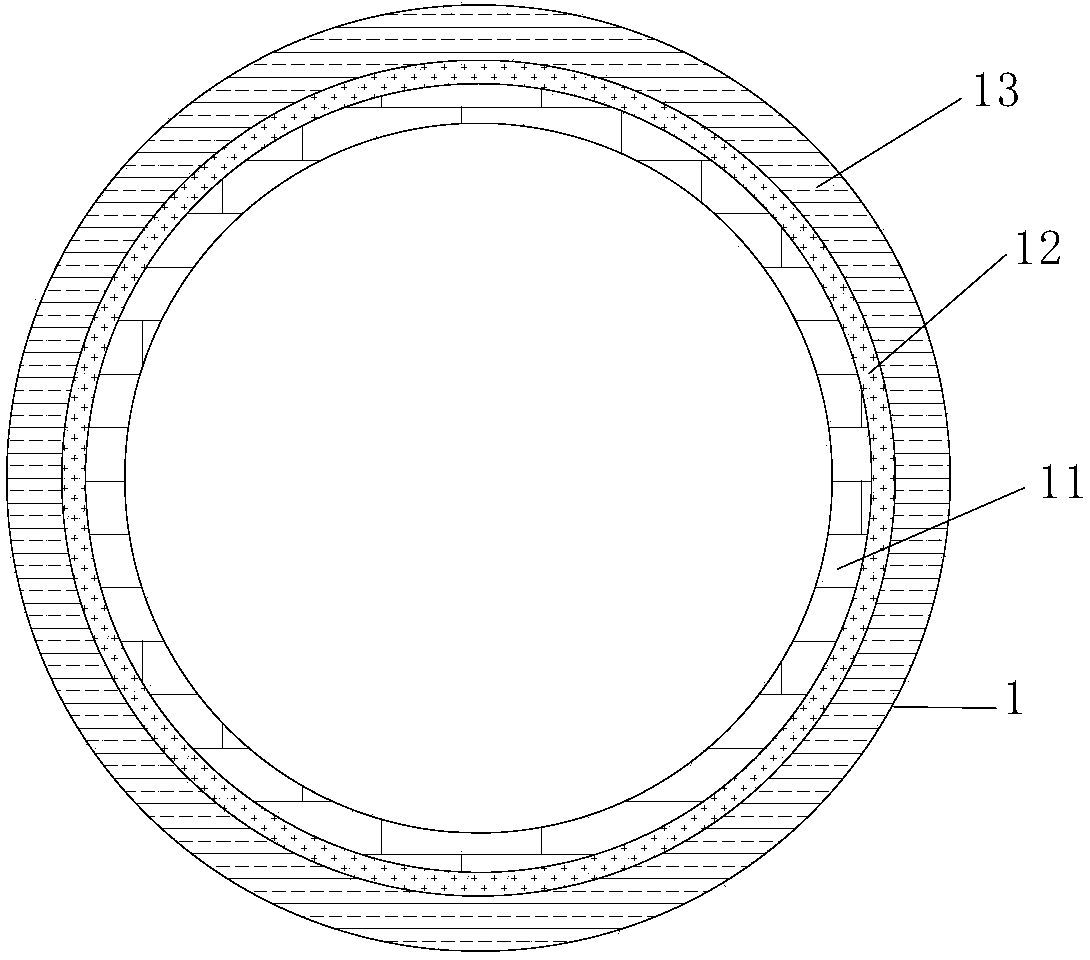

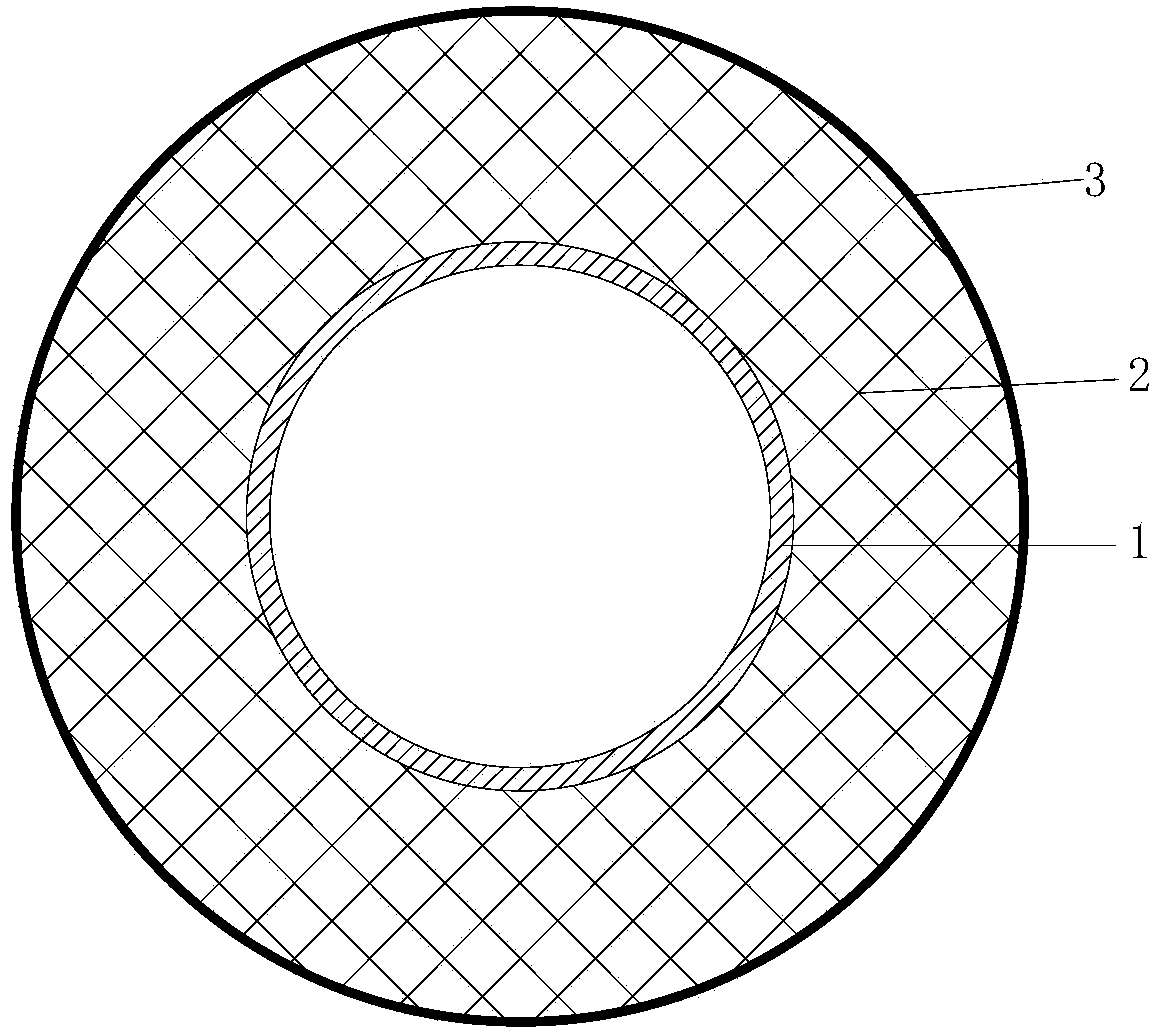

Novel-structured glass fiber reinforced plastic chimney

ActiveCN103526977AGood hoop mechanical propertiesGood axial mechanical propertiesTowersGlass fiberYarn

The invention relates to a novel-structured glass fiber reinforced plastic chimney. A cylinder wall comprises a lining function layer, a middle structural layer and an optional external protection layer, and the lining function layer comprises a surface felt layer and a jet yarn layer from interior to exterior of the cylinder wall; the middle structural layer comprises a plurality of structural sub-layers, each structural sub-layer structurally comprises structurally comprising a single structural layer A, a single structural layer B, a single structural layer C and a single structural layer D; the single structural layer A is a jet yarn layer or a one-way cloth layer; the single structural layer B does not exist or is a hoop winding layer; the single structural layer C is a jet yarn layer or a one-way cloth layer; the single structural layer D is the hoop winding layer; when the single structural layer is the jet yarn layer, the single structural layer C is the one-way cloth layer; or when the single structural layer A is the one-way cloth layer, the single structural layer C is the jet yarn layer; the external protection layer comprises a gel-coated layer. The novel-structural glass fiber reinforced plastic chimney is novel in structure, good in axial mechanical performance and loop mechanical performance, convenient to construct, convenient for control quality, long in service life and applicable to large thermal power plants.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

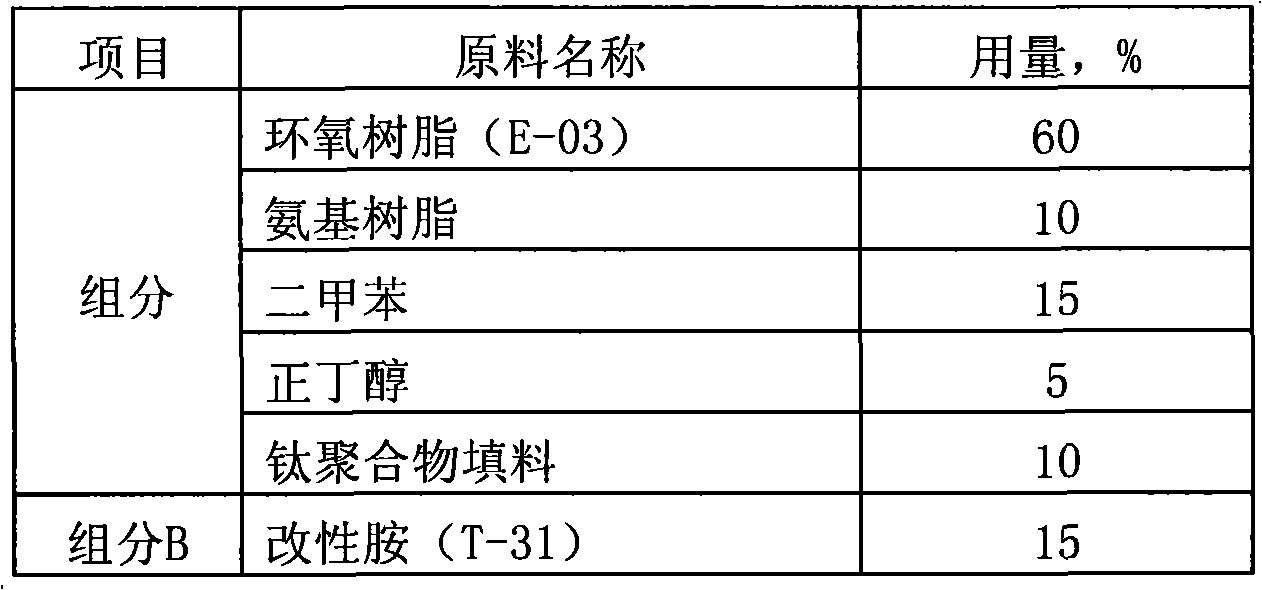

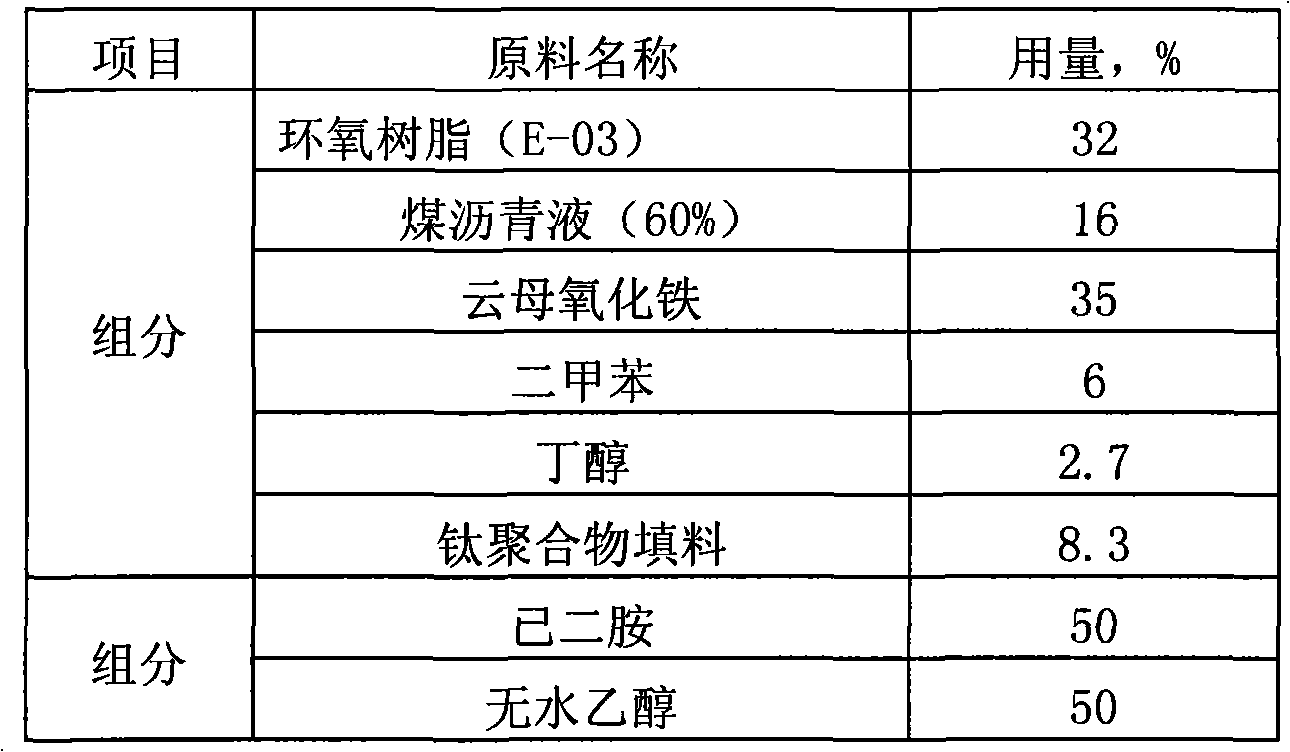

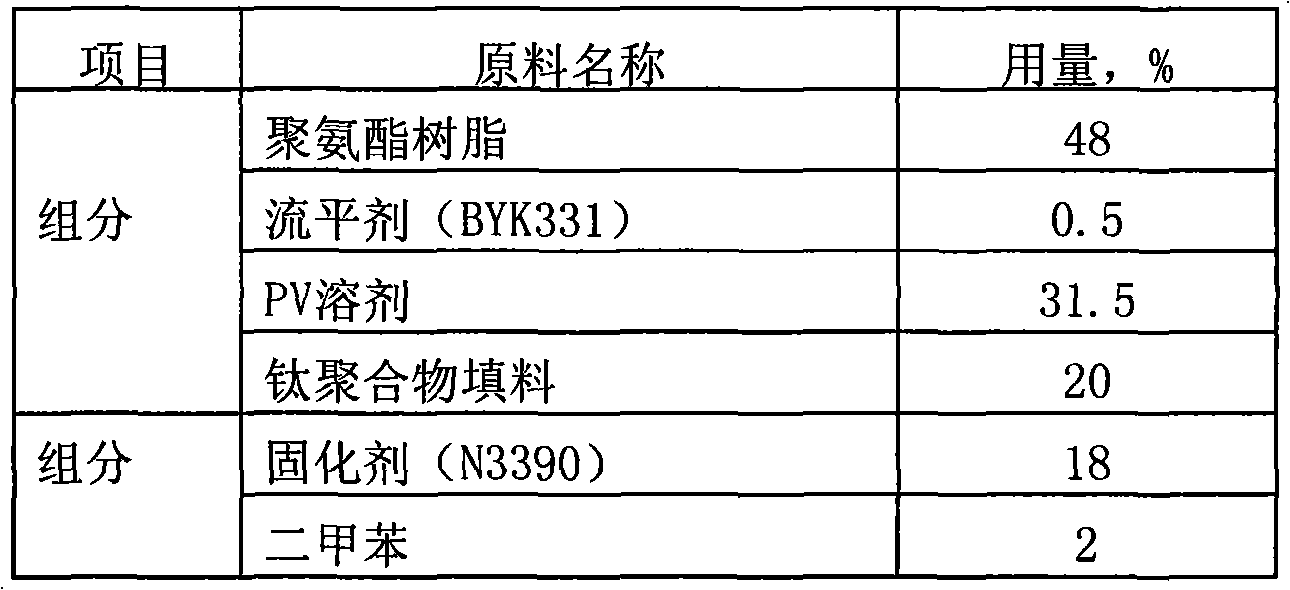

Method for producing titanium polymer resin anti-dirty corrosion-resistant oil pipe for oil field

InactiveCN101270845AIncrease resistanceStrong penetration resistanceCorrosion preventionPipe protection against corrosion/incrustationPolymer resinSpray coating

A preparation method for a titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field is disclosed. The preparation method for the titanium polymer resin, scale inhibition and anti-corrosion tube which is used in the oil field has the following procedures that the external and internal walls of the tube are coated with paint after the pre-treatment for the tube surface; the paint is produced that 7 percent to 20 percent titanium polymer fillings are added in the routine epoxy resin paint; the internal wall of the tube applies the high pressure, airless and stereo spray coating way; the external wall of the tube applies the stereo spray coating way with compressed air and three spray guns; the coating layers of the external and internal walls of the tube are adjusted and cured through an adjusting and curing furnace after the spray coating; the power of the furnace is 200KW, the temperature of the furnace is 50 degrees to 180 degrees and the curing time is 60 minutes; the tube rotates and moves forward in the adjusting and curing furnace; and the self-rotating speed of the tube is 30r / min to 80r / min. The preparation method solves the scaling and corrosion problem of the underground tube in the oil field under complex industrial and mining conditions, which protects the tube, prolongs the using life of the tube and saves the oil extraction cost.

Owner:DAQING PETROLEUM ADMINISTRATION

Water-borne long-acting electrostatic-conductive anticorrosive coating and preparation method thereof

InactiveCN109385180ALarge specific surface areaAchieving static conductivityAnti-corrosive paintsEpoxy resin coatingsConductive coatingSolvent based

The invention relates to a water-borne long-acting electrostatic-conductive anticorrosive coating and a preparation method thereof. Single-walled carbon nanotubes and electrostatic-conductive mica powder are used as nano electrostatic-conductive fillers; the specific surface area of the single-walled carbon nanotubes is high; the single-walled carbon nanotubes are embedded into a material matrix to form a three-dimensional nanotube network, the structure of the material can be greatly strengthened, the color of a coating layer can be maintained, and the mechanical properties can be enhanced, so that the product has uniform electrostatic conductivity and high specific conductance, is not affected by humidity and has permanent electrostatic conductive properties. A scaly structure of the electrostatic-conductive mica powder is horizontally arrayed in the coating layer, and has good shielding property and excellent anti-penetration ability; the coating layer can isolate a corrosive mediumwell, and good anti-corrosion performance of the coating layer is achieved. The coating is superior to traditional electrostatic-conductive coatings in electrostatic conductivity and anti-corrosion performance, is safe and environmentally friendly, conforms to the green development direction, avoids the generation of toxic and harmful gases and VOCs in solvent-based coatings, is not flammable orexplosive, is simple to construct, can replace traditional solvent-based coatings and has broad application prospects.

Owner:无锡市太湖防腐材料有限公司

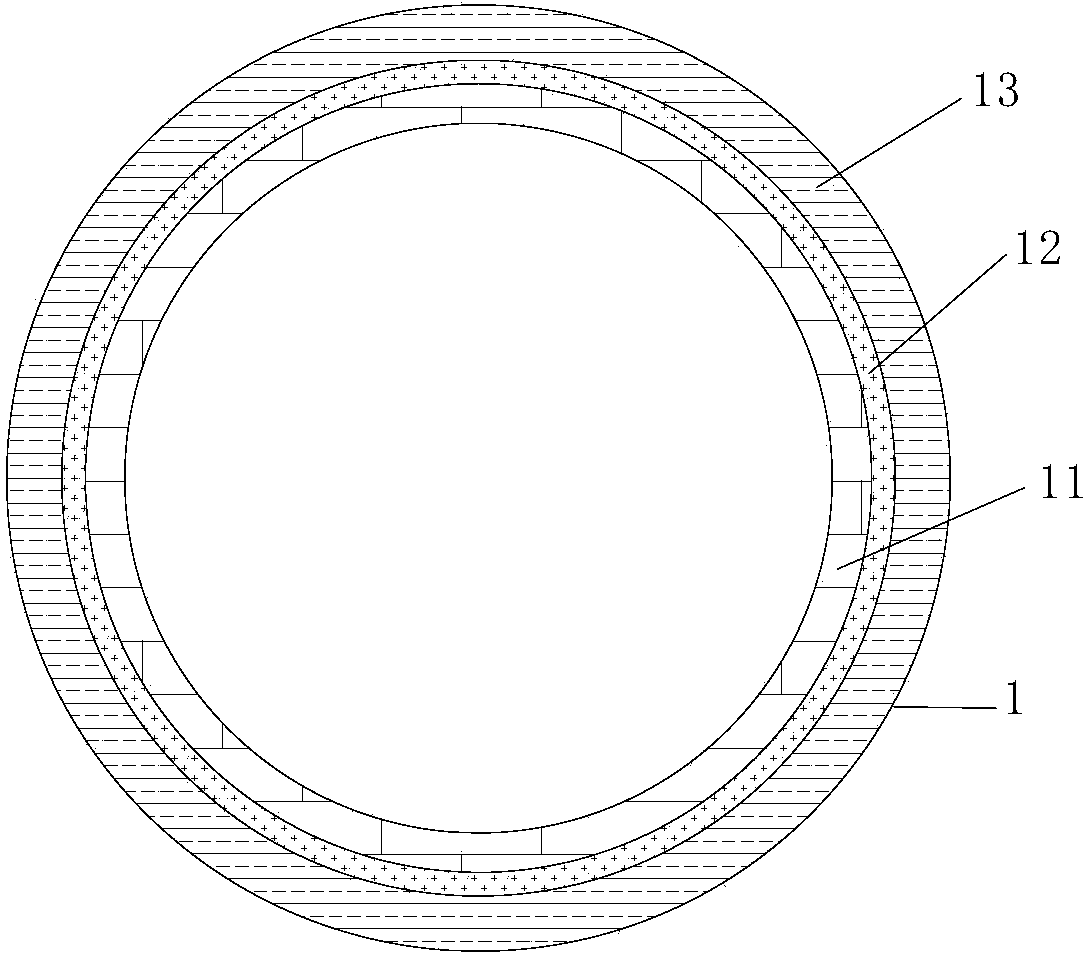

Glass fiber reinforced plastic chimney with excellent mechanical properties

ActiveCN103526976AGood hoop mechanical propertiesGood axial mechanical propertiesTowersGlass fiberYarn

The invention relates to a glass fiber reinforced plastic chimney with excellent mechanical properties. The chimney wall comprises an inner liner functional layer, a middle structural layer and an optional outer protection layer. The middle structural layer includes a plurality of structural sub layers; from the interior to exterior of the glass fiber reinforced plastic chimney, the structure of the structural sub layers includes a structural single layer A, a structural single layer B, a structural single layer C and a structural single layer D. The structural single layer A is a yarn injection layer or a unidirectional fabric layer; the structural single layer B is a non-directional or circumferential wrapping layer; the structural single layer C is a yarn injection layer or a unidirectional fabric layer; and the structural single layer D is a circumferential wrapping layer. When the structural single layer A is the yarn injection layer, the structural single layer C is the unidirectional fabric layer; when the structural single layer A is the unidirectional fabric layer, the structural single layer C is the yarn injection layer. The glass fiber reinforced plastic chimney has excellent axial mechanical properties and circumferential mechanical properties, construction and quality control are facilitated, service life is long, and the glass fiber reinforced plastic chimney is adaptable to large-scale power plants.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

Preparation method of wear-resistant corrosion-resistant coating

InactiveCN112143343ALess pollutionNo "three wastes" pollutionAnti-corrosive paintsPowdery paintsCarbon fibersNanoceramic

The invention relates to a preparation method of a wear-resistant corrosion-resistant coating, which comprises the following steps: (1) preparing the following raw materials in percentage by weight: 50-60% of resin, 23-40% of filler, 1-3% of leveling agent, 4-6% of curing agent, 2-3% of coupling agent and 3-5% of modifier; and (2) putting all the raw materials in the step (1) into an ultrafine powder ball mill, mixing and grinding until the particle size is 1200 meshes or above, thereby obtaining the wear-resistant and corrosion-resistant coating. According to the technical scheme, the carbonnano tubes selectively used in the coating have the characteristics of wear resistance, corrosion resistance, good stability and the like, the nano microlite has the characteristics of permeation resistance, good wear resistance and the like, and the nano sepiolite powder has the advantages of high adsorbability, high flame retardance, high temperature resistance, good wear resistance and the like; the carbon nanofibers have the advantages of wear resistance, corrosion resistance, high surface gloss and the like, and the nano ceramic powder has the advantages of wear resistance, high temperature resistance, corrosion resistance and the like.

Owner:广东科盛防腐科技有限公司 +1

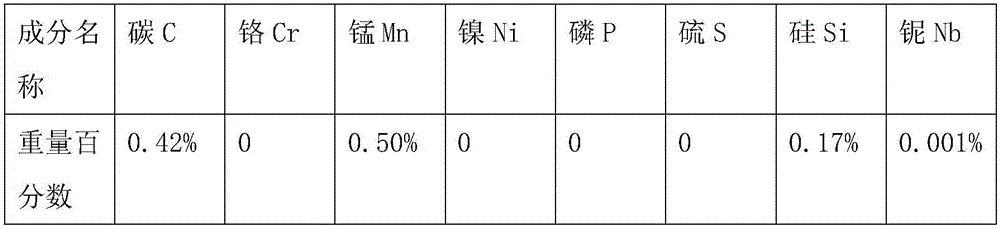

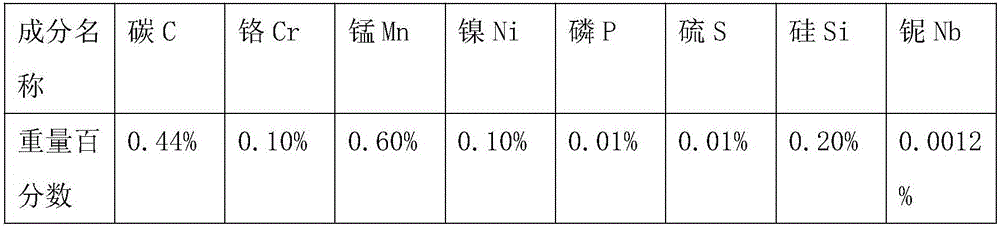

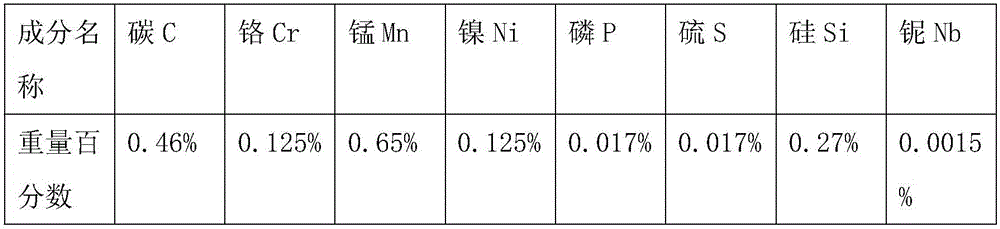

Preparation method of cylindrical controlled fragments

InactiveCN106288979AHigh strengthGuaranteed StrengthAmmunition projectilesProjectilesHardnessCarbon steel

The invention discloses a preparation method of cylindrical controlled fragments. The method includes the steps of material selection, wire drawing, die cutting, screening, nickel plating, detecting and warehousing. According to the method, a medium-carbon steel wire with the hardness of 45-55 HRC, the tensile strength of 1670-1770 MPa and the diameter of 2 mm is selected as the raw material; the cylindrical controlled fragments can deflect or turn over irregularly in the moving process under the action of gravity, air resistance and wind force and have high penetration capability on armored steel plates; when penetrating the human body, high-speed cylindrical controlled fragments can turn over continuously in the tissue of the human body under the resistance of the tissue, irregular cavities with the diameter several times or a dozen times or even dozens of times the bullet diameter are formed in the human body, and the killability of the cylindrical controlled fragments is 4-7 times that of common flaky fragments.

Owner:盐城德讯科技有限公司

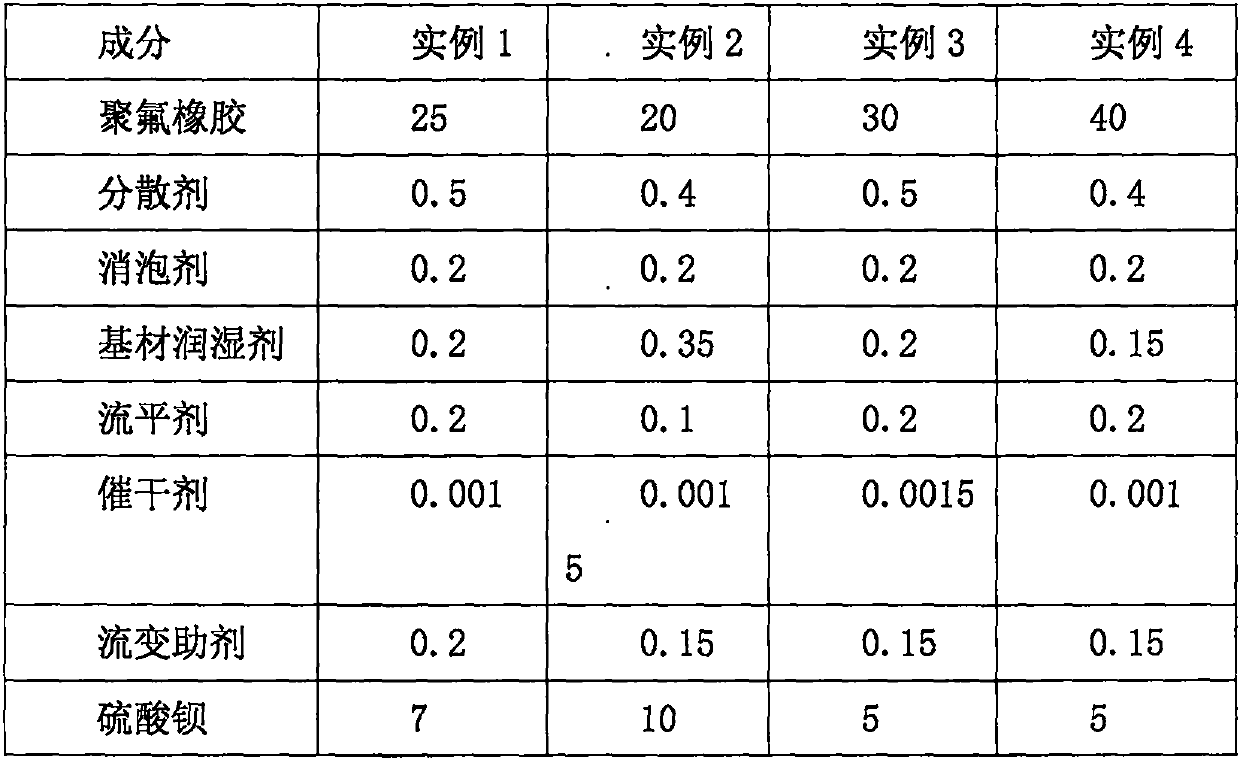

Polyfluoro-rubber chemical-reagent-resistance special anti-corrosive coating

InactiveCN110172281AImprove acid resistanceStrong penetration resistanceAntifouling/underwater paintsPaints with biocidesSolventDefoaming Agents

The invention discloses a polyfluoro-rubber chemical-reagent-resistance special anti-corrosive coating, and belongs to the technical field of special coatings. The coating belongs to a bi-component system and is prepared from, by mass, 20-40 parts of polyfluoro-rubber, 0-1 part of a dispersing agent, 0-0.5 part of a wetting agent, 0-0.5 part of a defoaming agent, 0-0.5 part of a flatting agent, 0-2 parts of a rheological auxiliary agent, 2-15 parts of a macromolecular polymer, 2-15 parts of a ceramic compound, 1-5 parts of mica powder, 3-10 parts of wearproof and acid-proof powder, 1-10 partsof barium sulfate, 20-40 parts of a curing agent and the balance solvent. According to the coating, construction technologies such as spray-coating, brush-coating and roller-coating can be adopted, apaint film is compact, full, high in flexibility and wear resistance, and resistant to various chemical solvents, and the coating can be used in an environment of 250 DEG C or below for a long term.

Owner:北京隆源纳欣科技有限公司

Small-thickness glass reinforced plastic chimney

ActiveCN103541579AGood hoop mechanical propertiesGood axial mechanical propertiesTowersYarnEngineering

The invention relates to a small-thickness glass reinforced plastic chimney. The chimney shaft wall comprises a lining functional layer, a middle structural layer and an optional outer protective layer, wherein the middle structural layer comprises a plurality of structural sub-layers from the inside to the outside of the glass reinforced plastic chimney. Each structural sub-layer consists of a structural single layer A, a structural single layer B, a structural single layer C and a structural single layer D, wherein the structural single layer A is a jet yarn layer or a unidirectional cloth layer. The structural single layer B does not exist or is an annular winding layer. The structural single layer C is a jet yarn layer or a unidirectional cloth layer. The structural single layer D is an annular winding layer. In addition, when the structural single layer A is the jet yarn layer, the structural single layer C is the unidirectional cloth layer; or when the structural single layer A is the unidirectional cloth layer, the structural single layer C is the jet yarn layer, and the thickness t of the middle structural layer is larger than or equal to 8 but smaller than 18mm. The small-thickness glass reinforced plastic chimney has good axial mechanical property and annular mechanical property, facilitates construction and quality control and is long in service life and suitable for a large thermal power plant.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

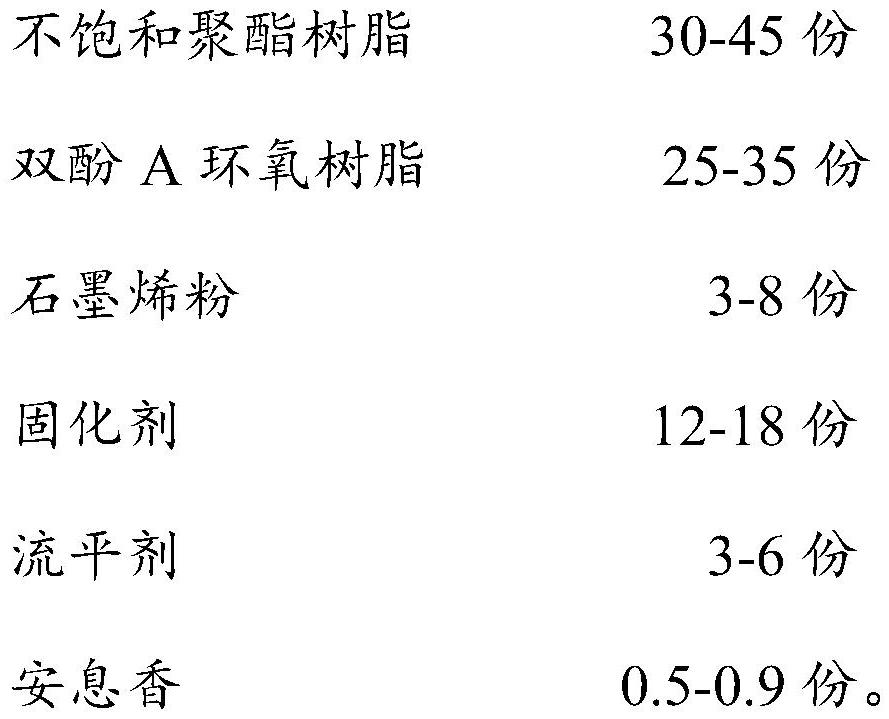

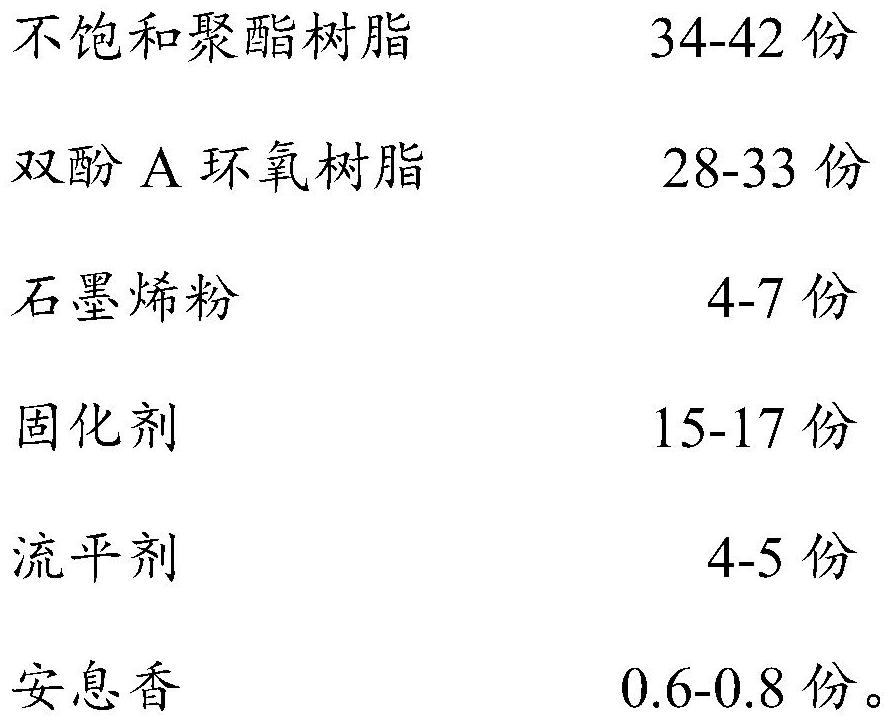

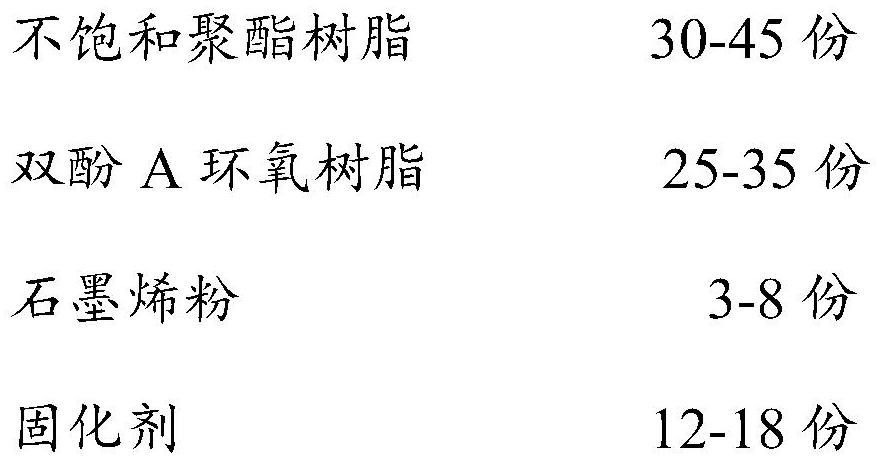

Powder coating material for metal corrosion prevention, preparation method and application method thereof

InactiveCN111793418AImprove compactnessStrong penetration resistanceLiquid surface applicatorsAnti-corrosive paintsBenzoinCorrosion prevention

The invention discloses a powder coating material for metal corrosion prevention, a preparation method and an application method of the powder coating material. The powder coating material is preparedfrom the following raw materials in parts by weight: 30 to 45 parts of unsaturated polyester resin, 25 to 35 parts of bisphenol A epoxy resin, 3 to 8 parts of graphene powder, 12 to 18 parts of a curing agent, 3 to 6 parts of a leveling agent and 0.5 to 0.9 part of benzoin. The powder coating material is applied to a metal plate, a compact coating layer is formed after the powder coating materialis cured, the compactness is high, the permeation resistance is high, corrosion prevention can be conducted on metal, the service life of the metal is greatly prolonged, the adhesive property is excellent, and the impact resistance is good.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

A kind of anti-riot helmet and preparation method thereof

InactiveCN107296318BReduce weightStrong penetration resistanceFibre typesOrganic non-macromolecular adhesiveAdhesiveAlloy

The invention discloses an antiriot helmet and a preparing method thereof. The antiriot helmet comprises an inner helmet body and an outer helmet body arranged on the inner helmet body in a sleeving mode. The inner helmet body and the outer helmet body are attached together through an adhesive. The outer helmet body is prepared through injection molding after melting of PC / ABS alloy aggregates. The inner helmet body is prepared through molding of multiple layers of aramid fiber fabric layers dipped with modified phenolic resin. The antiriot helmet effectively resists the attacks of bullets, edge tools, clubs, non-explosive projectiles and chemical liquid and effectively protects the head, face and neck of a human body.

Owner:FUJIAN QUANZHOU HAIBIN PROTECTIVE ARMANMENTS CO LTD

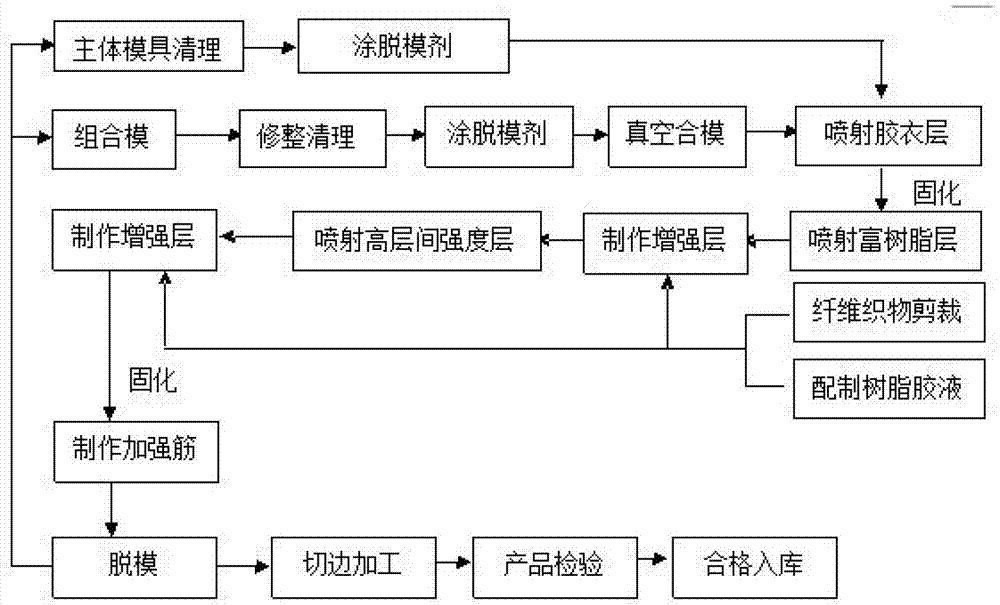

Injecting manual pasting mixing and forming technology for glass fiber reinforced plastics chamber cover die of wind turbine

The invention discloses an injecting manual pasting mixing and forming technology for a glass fiber reinforced plastics chamber cover die of a wind turbine. The technology comprises the steps of: processing a die, injecting a gel-coated layer, manufacturing a surface layer, manufacturing a reinforcing layer, reinforcing the die, and removing the die. According to the technology, the injecting step and the manual pasting step are combined to achieve formation, so that the surface water resistance and the interlaminar strength of a glass fiber reinforced plastics product can be improved; the usage cost of raw materials is reduced; the working strength of operators is reduced; the production efficiency is improved; the integrity of the internal function and external furnace of the chamber cover of the wind turbine is ensured, and the requirement on working in bad conditions can be met; and according to the technology, the production period is reduced, the mass production can be achieved, the stability of the product quality can be ensured, the stability of the product performance is high, about 8% of the materials can be saved, 10% of processing hours can be reduced, the production cost can be reduced, and an obvious economic benefit is provided.

Owner:CHONGQING HAIQING NEW MATERIAL

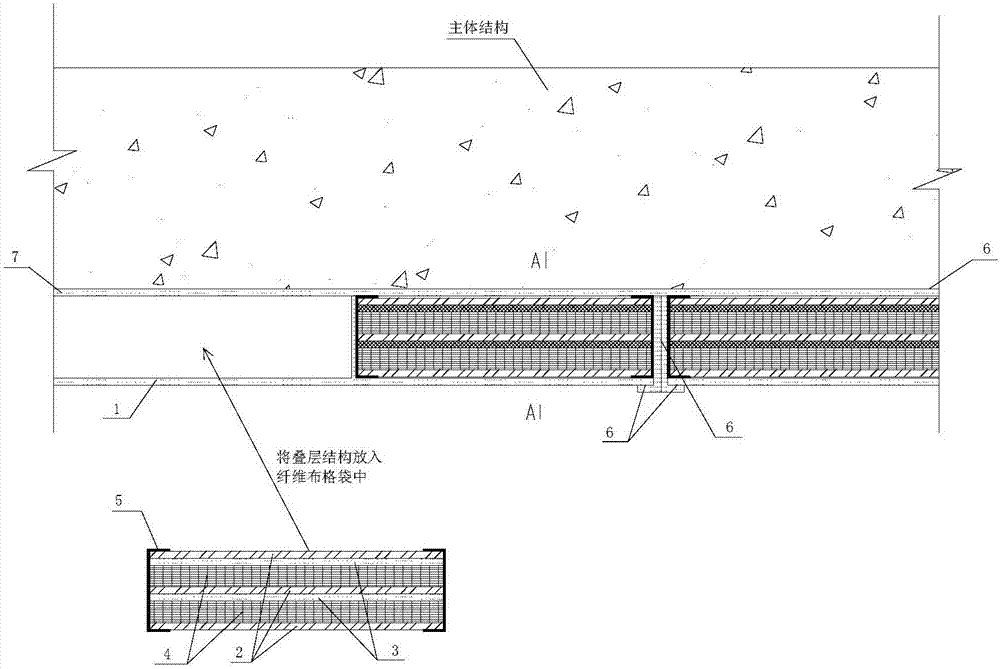

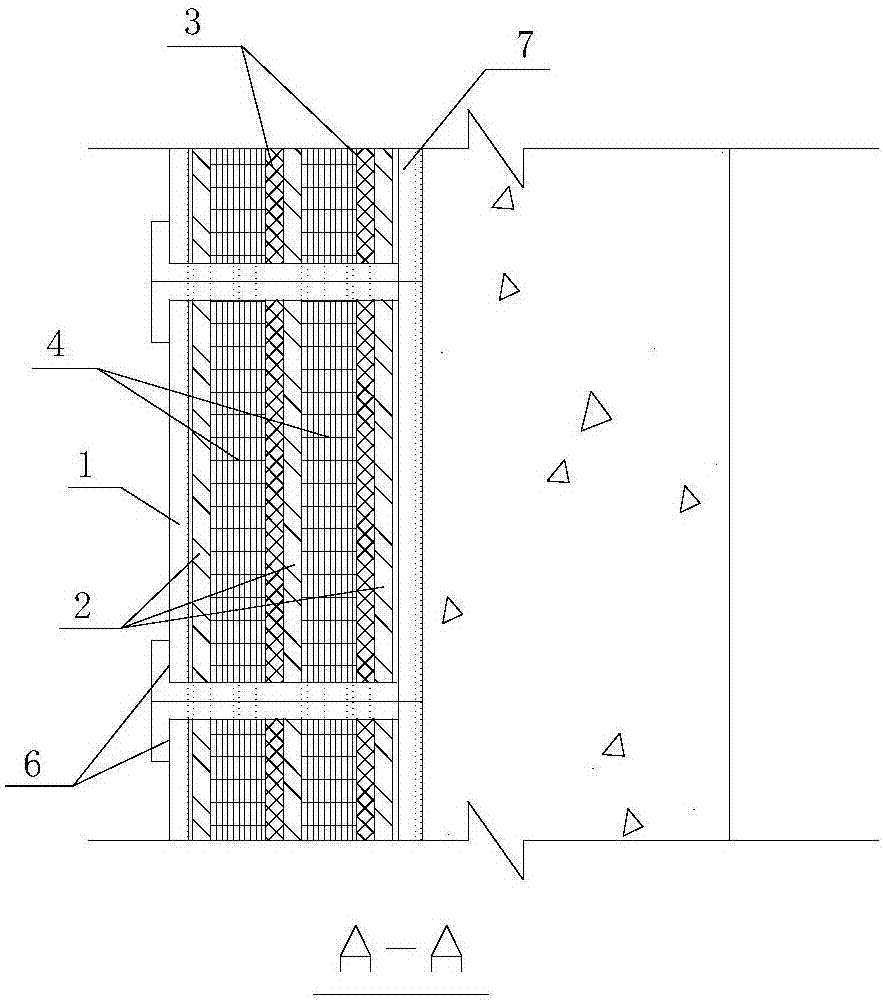

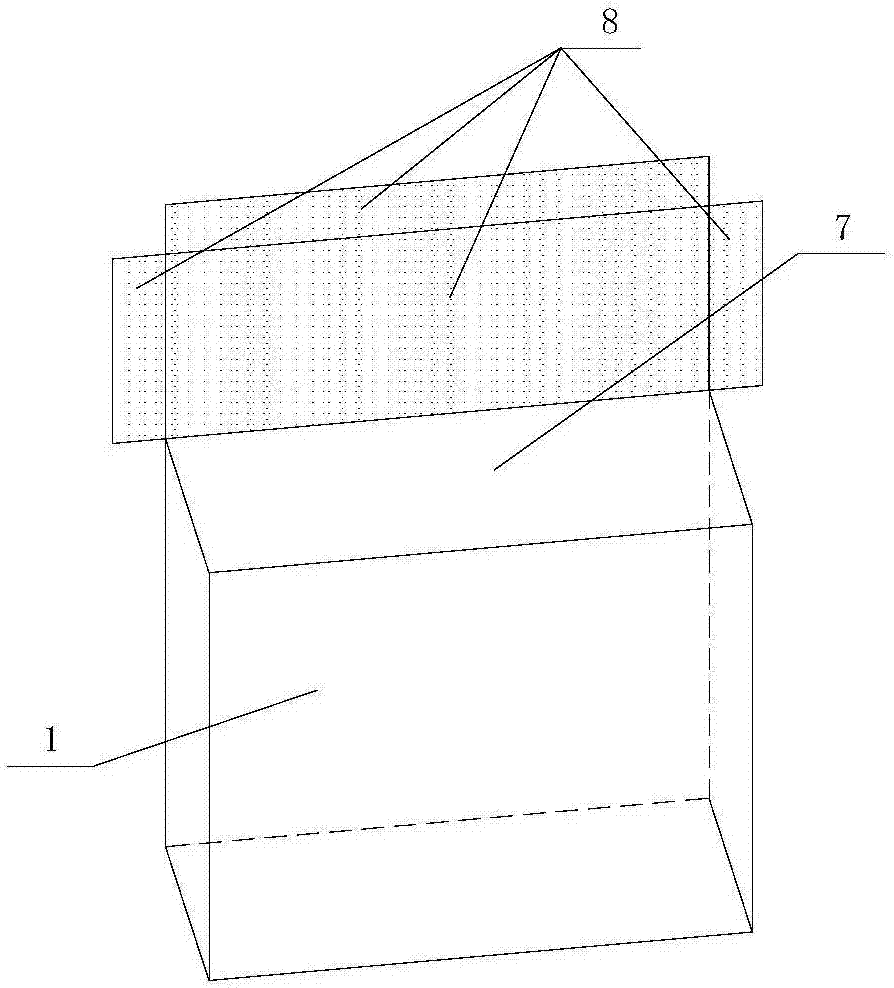

Lamination solid-liquid two-phase solution steel plate protective armor wrapped with high-performance fiber cloth

PendingCN107327043AIncrease Section ThicknessGood impact protectionBuilding repairsShock proofingFiberMissile

The invention provides a lamination solid-liquid two-phase solution steel plate protective armor wrapped with high-performance fiber cloth. The lamination solid-liquid two-phase solution steel plate protective armor wrapped with the high-performance fiber cloth comprises inner layer high-performance fiber cloth, steel plates, solid-liquid two-phase solution, engineering filler, edge-sealed plates, an adhesive agent and outer layer high-performance fiber cloth. Compared with adding the section thickness of a building main structure, the provided lamination solid-liquid two-phase solution steel plate protective armor wrapped with the high-performance fiber cloth has better missile-impact proofing and protecting effect, and excessive modification on the arrangement of the main structure is not required.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com