Injecting manual pasting mixing and forming technology for glass fiber reinforced plastics chamber cover die of wind turbine

A wind turbine canopy and hybrid molding technology, which is applied in the field of glass fiber reinforced plastic wind turbine canopy mold injection hand lay-up hybrid molding process, can solve the problems of difficult product quality control, poor product performance stability, low labor intensity of workers, etc., to save material consumption. , The effect of stable product quality and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

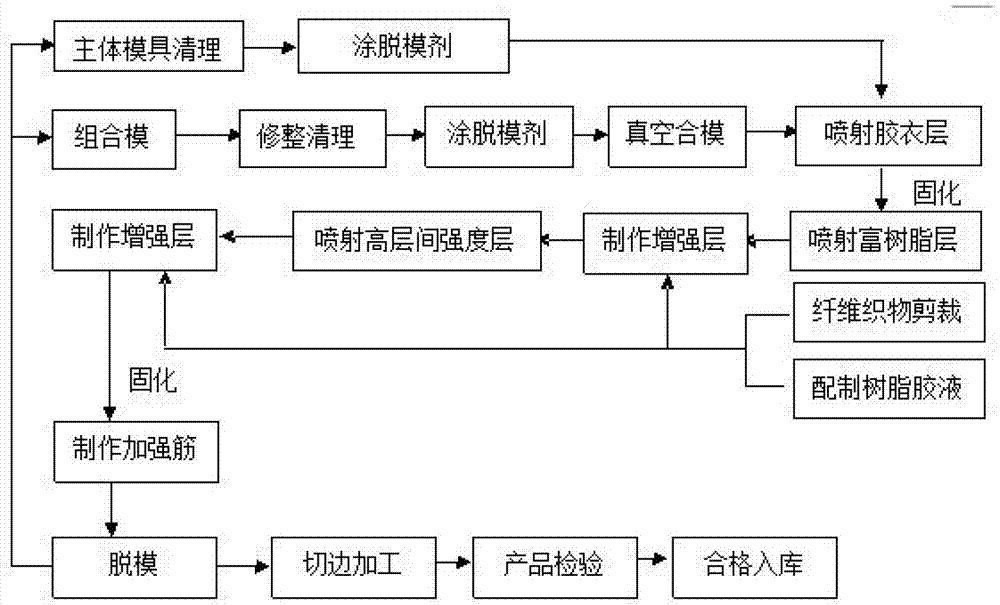

[0021] figure 1 It is a process flow chart of the present invention, as shown in the figure: the glass fiber reinforced plastic wind turbine cabin cover mold injection hand lay-up hybrid molding process of the present embodiment includes the following steps:

[0022] a. Mold treatment: Coat the surface of the cleaned original mold with a release agent and cure it; in order to ensure a better release effect, cellulose acetate, PVA and wax can be used in combination, first brush cellulose acetate, then brush PVA , and finally waxing; if the surface of the mold is completely covered by the easy-to-polish gel coat, PMR can also be used as a release material, so that the surface quality of the release is better;

[0023] b. Spray gel coat layer; special gel coat for mold is used to ensure high mold surface hardness, good wear resistance, heat resistance, fire resistance, ultraviolet resistance, etc. Pigments can be added to the gel coat, which has the characteristics of strong aest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com