Polyfluoro-rubber chemical-reagent-resistance special anti-corrosive coating

A chemical-resistant and anti-corrosion coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as high cost and corrosion, and achieve high acid resistance and strong permeability resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

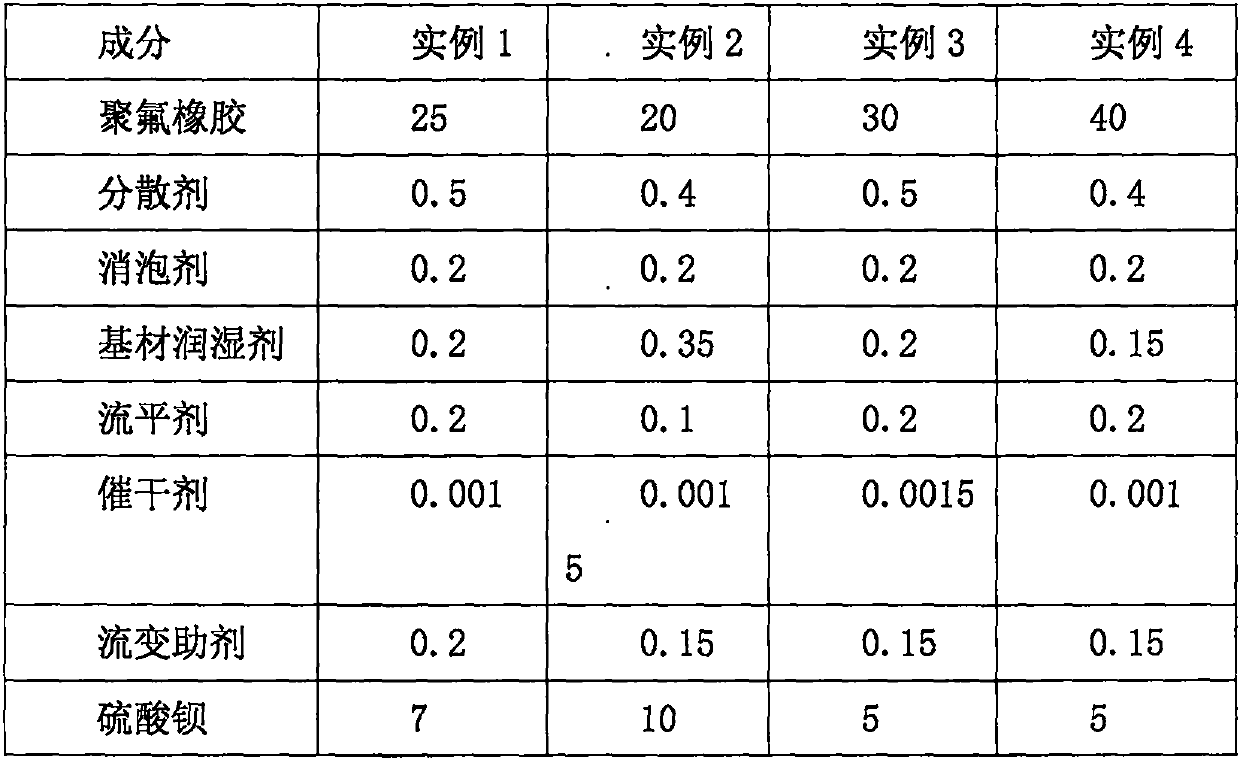

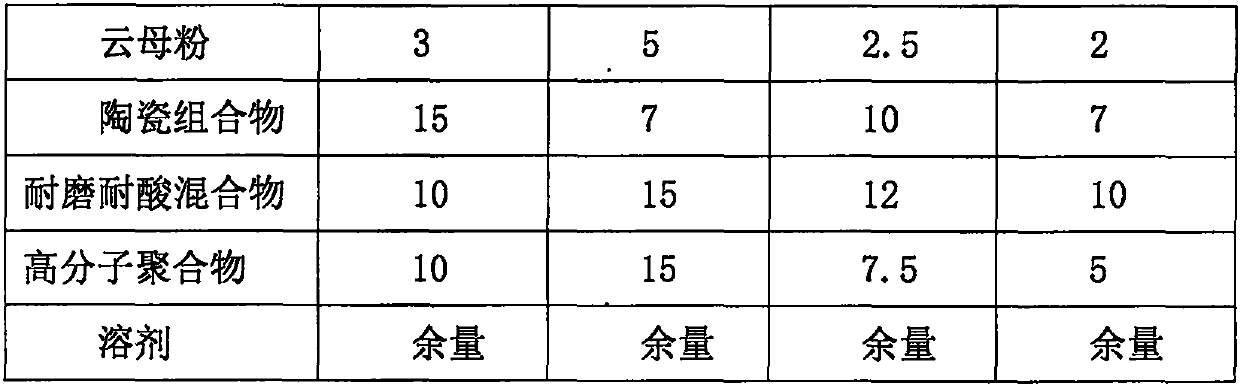

Examples

Embodiment Construction

[0033]

[0034]

[0035] 2 Preparation of component B of a special chemical-resistant anti-corrosion coating made of polyfluororubber

[0036] (1) Add special fluororubber to the constant temperature reaction kettle;

[0037] (2) Add 2 / 3 of the mixed solvent into the mixing tank, keep the temperature at 80°C and stir evenly at a stirring speed of 200-350rpm to form a uniform mixture;

[0038] (3) Transfer the mixture formed in step (2) to a mixing tank, slowly add N3390 isocyanate curing agent and stir at a stirring speed of 200-350rpm to form a uniform mixture, which is the curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com