Small-thickness glass reinforced plastic chimney

A glass fiber reinforced plastic chimney and chimney technology, applied in the field of chimneys, can solve the problem of no large-scale thermal power plant FRP chimney engineering examples, etc., and achieve the effects of easy construction and quality control, long service life, and good hoop mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of FRP chimney of the present invention comprises the following steps:

[0069] (a) provide inner lining functional layer;

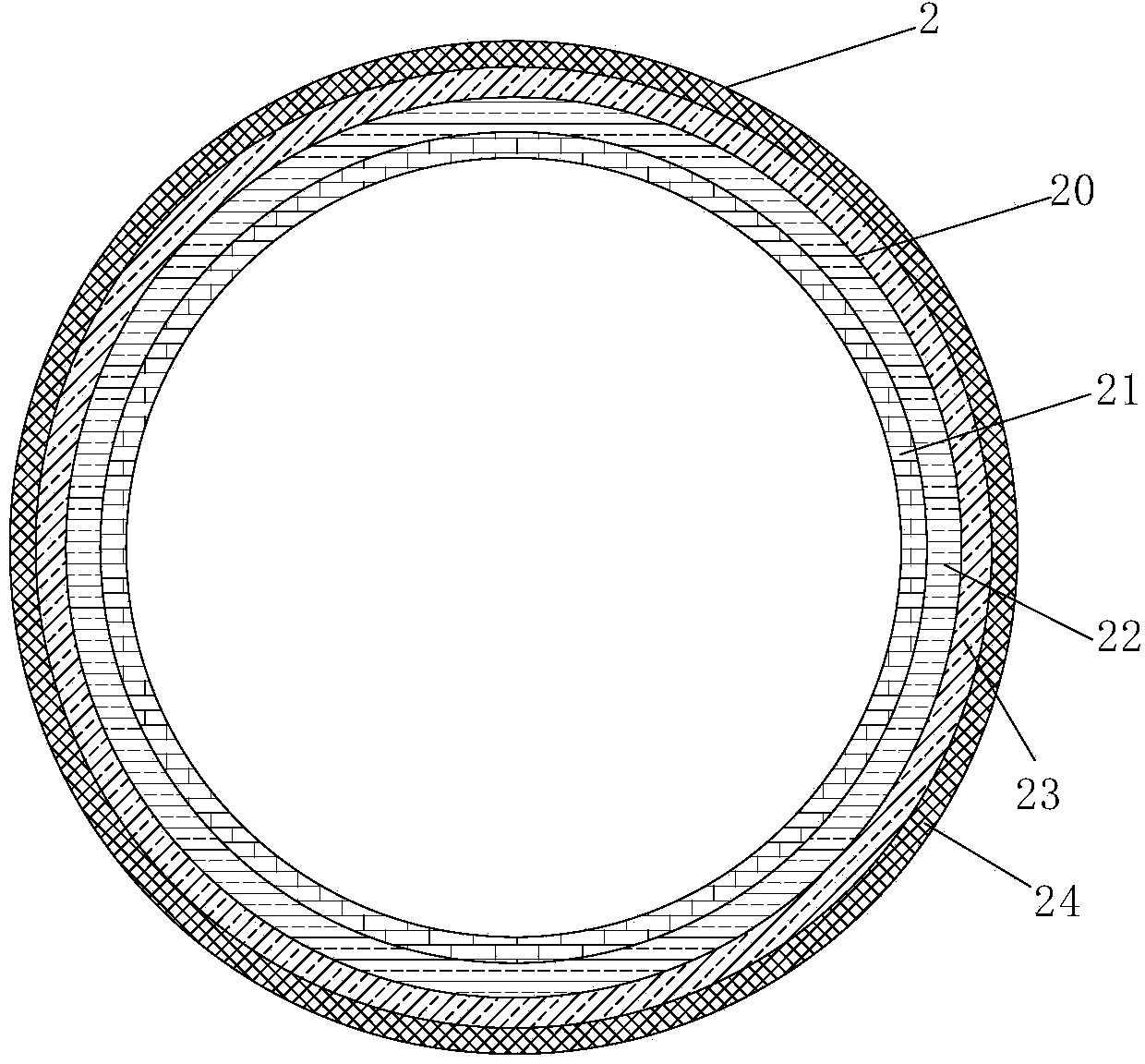

[0070] (b) laying the intermediate structural layer on the inner lining functional layer, and optionally

[0071] (c) laying the outer protective layer on the intermediate structural layer to obtain the glass fiber reinforced plastic chimney;

[0072] or include the following steps:

[0073] (a) providing an inner liner functional layer, an intermediate structural layer, and an optional outer protective layer;

[0074] (b) Assembling the inner lining functional layer, intermediate structural layer, and optional outer protective layer into the FRP chimney.

[0075] The fiberglass chimney of the present invention has one or more of the following features:

[0076] (1) The hoop tensile strength is greater than 235MPa, the modulus is greater than 19.0GPa, the axial tensile strength is greater than 110MPa, and the modulus is ...

Embodiment 1

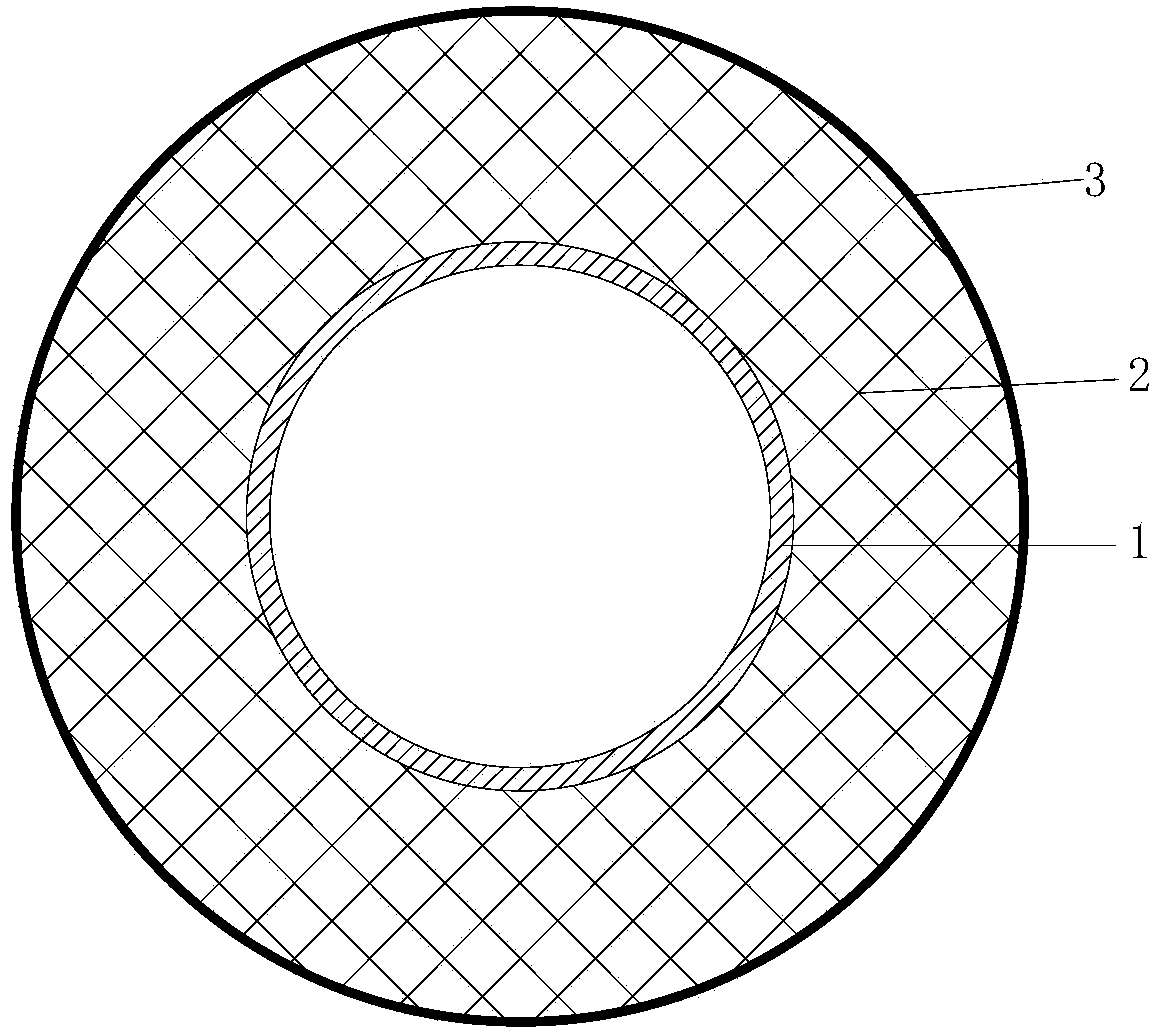

[0171] The fiberglass chimney of this embodiment includes an inner lining functional layer, an intermediate structural layer and an outer protective layer, with a diameter of 7.2 meters.

[0172] Wherein, the lining functional layer includes a surface felt layer and a sprayed yarn layer from the inside to the outside, with a thickness of 1.2 mm.

[0173] The middle structural layer is composed of 4 structural sub-layers 1 from inside to outside, 2 additional structural single layers and 1 outermost structural single layer. The structure is S1-S1-F1-F2-S1-S1-Y1, with a total thickness of 14.2mm .

[0174] The outer protective layer is a gel coat layer with a thickness of 0.25mm.

Embodiment 2

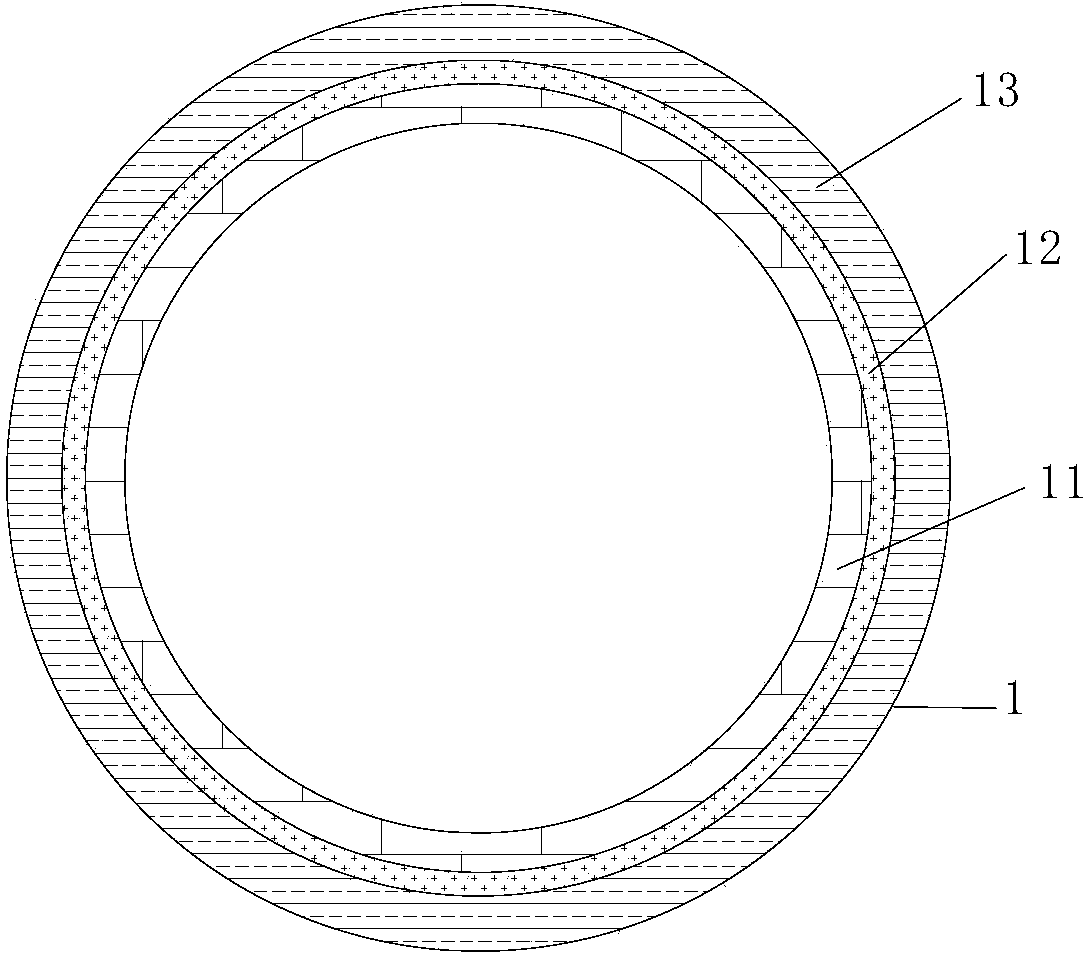

[0176] The fiberglass chimney of this embodiment includes an inner lining functional layer, an intermediate structural layer and an outer protective layer, with a diameter of 7.2 meters.

[0177] Among them, the lining functional layer is composed of carbon fiber felt layer, surface felt layer and jet yarn layer from inside to outside, with a thickness of 1.5mm.

[0178] The structure of the middle structure layer from inside to outside is S1-S1-F1-S1-S2-F1-F2-S1-S4, and the total thickness of the middle structure layer is 16.5mm.

[0179] The outer protective layer is a gel coat layer with a thickness of 0.25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com