Press-twisting forming method of aluminum alloy disc-shaped workpiece

A forming method and technology of aluminum alloy, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor circumferential mechanical properties of aluminum alloy materials, etc., and achieve the effect of simple structure, convenient operation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

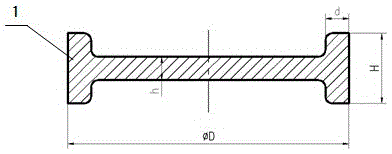

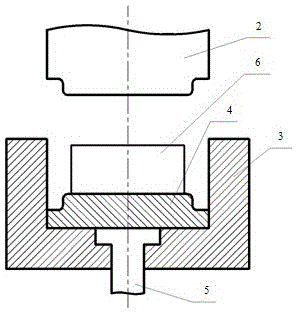

[0033] Such as figure 1 , 2 As shown, for No. Ⅰ disc-shaped workpiece 1, its alloy grade is 7075 aluminum alloy, the outer diameter of the workpiece is D=100-200mm, the height H=10-50mm, d=5-30mm, h=8-20mm, according to the workpiece According to the shape and characteristics of the 7075 aluminum alloy material, the process characteristics of the 7075 aluminum alloy material and the final part The size of the specification, the extrusion rod of φ75mm is used as the No. 1 blank 6, and the height of the blank is 30-100mm. Both the mold and the blank are heated to 360-480°C and kept warm for 1 hour, and then molded and twisted on the twist forming machine. The molding pressure is 500-5,000 tons, the torsional torque is 10,000-200,000 N. 5 revolutions, when the pressure is twisted until the disc-shaped workpiece reaches the limit size, then twist 2 to 5 circles, finally release the pressure and eject the workpiece from the mold, after air cooling, turn and remove the flash of th...

Embodiment 2

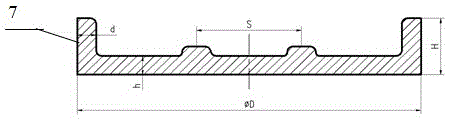

[0037] Such as image 3 , 4 As shown, for No. Ⅱ disc-shaped workpiece 7, its alloy grade is 7A04 aluminum alloy, the outer diameter of the workpiece D=120-300mm, the height H=10-50mm, d=5-30mm, h=8-20mm, s= 50 ~ 100mm, according to the shape and characteristics of the workpiece, design and process No. Ⅱ upper mold 8, No. Ⅱ lower mold mold cover 9, No. Ⅱ lower mold core 10 and No. Ⅱ ejector core rod 11, according to 7A04 aluminum alloy material The technological characteristics of the process and the specifications of the final piece, the ingot of φ80mm is used as the No. Ⅱ blank 12, and the height of the blank is 20-80mm. Both the mold and the blank are heated to 360-480°C and kept warm for 1 hour, and then molded and twisted on the twist forming machine. The molding pressure is 500-5,000 tons, the torsional torque is 10,000-200,000 N. 5 revolutions, when the pressure is twisted until the disc-shaped workpiece reaches the limit size, then twist 2 to 5 circles, finally releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com