Preparation of PET/nano silver wire transparent conductive film after illumination sintering

A transparent conductive film, nano silver wire technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, nanotechnology for material and surface science, etc., can solve the problem of poor surface hydrophobicity and antistatic property of PET , poor conductivity and adhesion of nano-silver wire film, uneven distribution of nano-silver wire, etc., to achieve the effect of low cost, excellent adhesion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

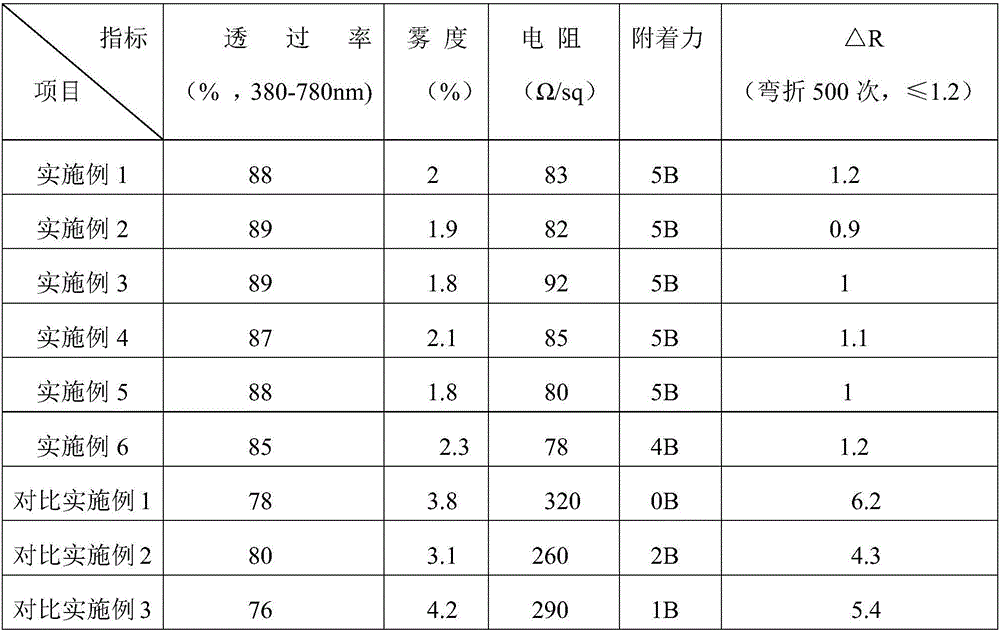

Examples

Embodiment 1

[0026] Step 1) Cleaning of impurities on the surface of the PET substrate: Clean the 188um optical-grade double-sided hardened PET substrate with a mixed solvent with an absolute ethanol / acetone volume ratio of 1, then rinse the residual mixed solvent on the PET surface with distilled water, and vacuum at 80°C After drying, a PET substrate with a clean surface is obtained;

[0027] Step 2) Preparation of transparent conductive film: Precisely coat 0.2 mg / ml nano-silver wire ethanol dispersion on the surface-clean PET substrate obtained in step 1) by micro-gravure coating machine , after drying at room temperature for 60 minutes, and then use CO 2 The laser is used as a laser source with an output power of 200W and a scanning speed of 0.5m / s for laser line scanning sintering to prepare a PET / nano-silver wire transparent conductive film with a thickness of 40nm.

Embodiment 2

[0029] Step 1) Cleaning of impurities on the surface of the PET substrate: Clean the 188um optical-grade double-sided hardened PET substrate with a mixed solvent with an absolute ethanol / acetone volume ratio of 1, then rinse the residual mixed solvent on the PET surface with distilled water, and vacuum at 80°C After drying, a PET substrate with a clean surface is obtained;

[0030] Step 2) Preparation of transparent conductive film: Precisely coat 0.6 mg / ml nano-silver wire ethanol dispersion on the clean surface PET substrate obtained in step 1) by micro-gravure coating machine , after drying at room temperature for 90 minutes, and then using CO 2 The laser is used as a laser source with an output power of 200W and a scanning speed of 0.5m / s for laser line scanning sintering to prepare a PET / nano-silver wire transparent conductive film with a thickness of 40nm.

Embodiment 3

[0032] Step 1) Cleaning of impurities on the surface of the PET substrate: Clean the 188um optical-grade double-sided hardened PET substrate with a mixed solvent with an absolute ethanol / acetone volume ratio of 1, then rinse the residual mixed solvent on the PET surface with distilled water, and vacuum at 80°C After drying, a PET substrate with a clean surface is obtained;

[0033] Step 2) Preparation of transparent conductive film: Precisely coat 1 mg / ml nano-silver wire ethanol dispersion on the surface-clean PET substrate obtained in step 1) by using a micro-gravure coating machine, After drying at room temperature for 120 min, use CO 2 The laser is used as a laser source with an output power of 200W and a scanning speed of 0.5m / s for laser line scanning sintering to prepare a PET / nano-silver wire transparent conductive film with a thickness of 40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com