electrical connector socket

A technology of electrical connectors and electrical connection parts, which is applied in the direction of connection, parts of connection devices, circuits, etc., can solve the problems of reduced conductive quality, poor rigidity and elasticity of pure copper, oxidation, etc., and achieve the goal of reducing friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

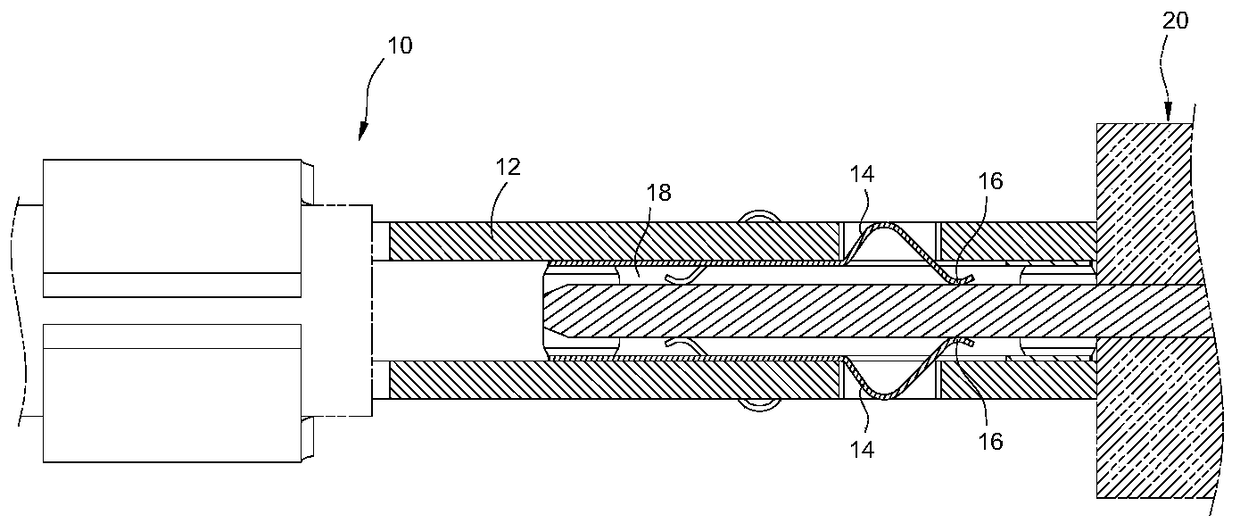

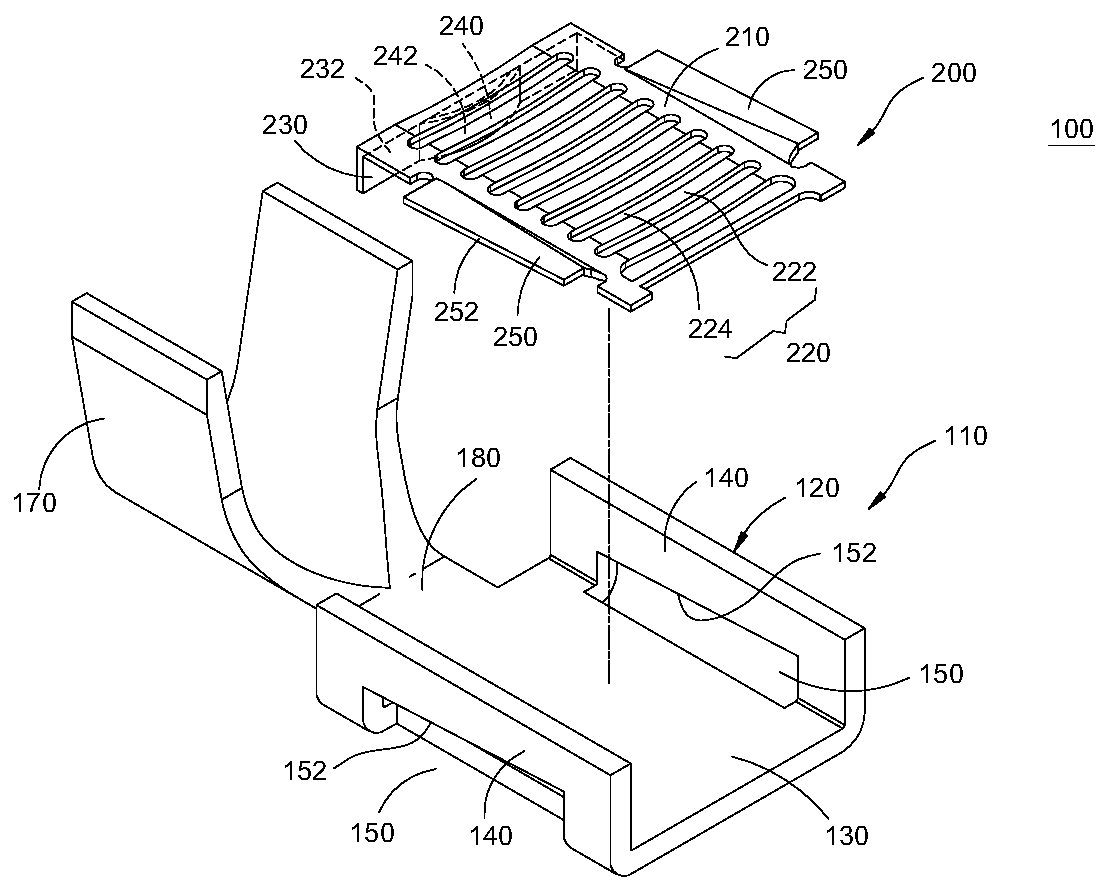

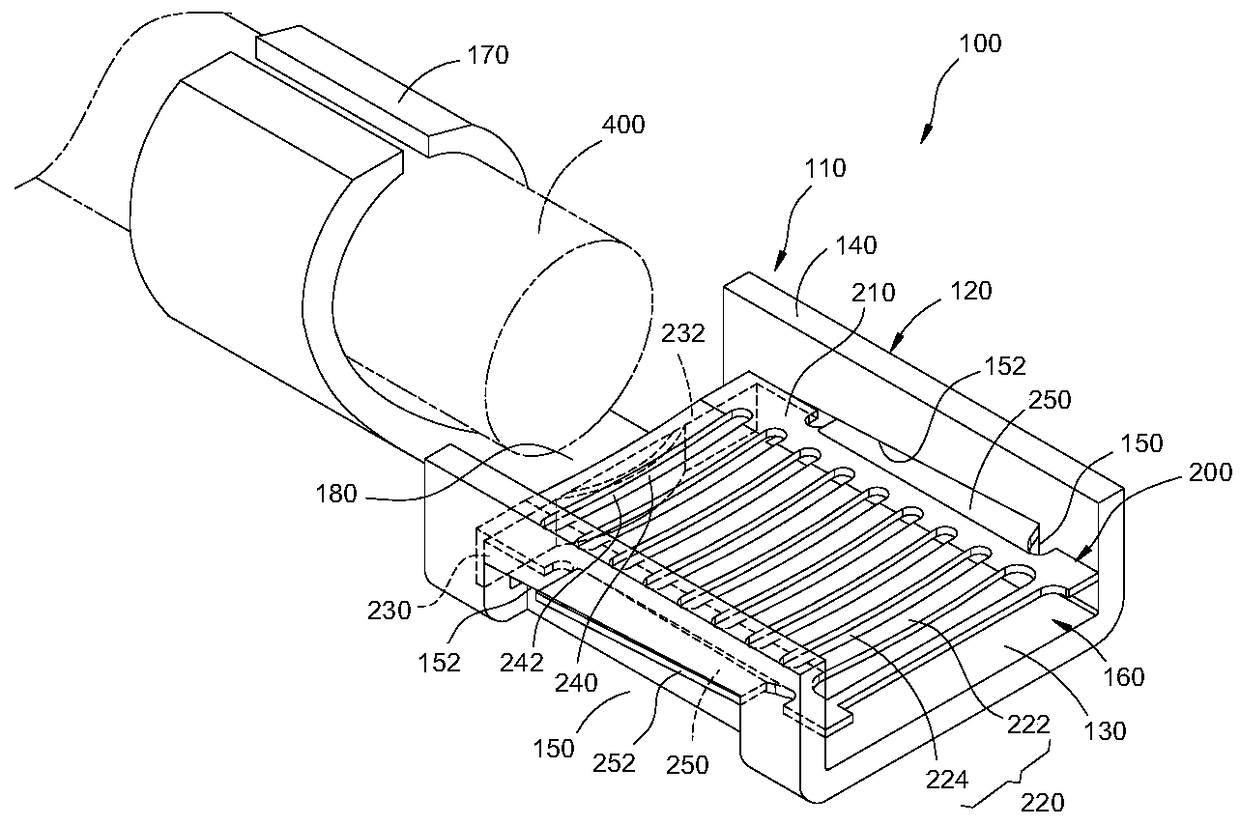

[0041] Such as Figure 2 to Figure 4 As shown, the present invention provides an electrical connector receptacle 100 for use with an electrical connector plug 300 , including a conductive member 110 and a pressed member 200 . The conductive element 110 has an electrical connection portion 120 . The electrical connection part 120 also has a bottom plate 130 and a pair of side plates 140 connected to the bottom plate 130 , wherein each side plate 140 is provided with a sliding slot 150 inclined relative to the bottom plate 130 . The pressing part 200 has a body 210 , a pressing part 220 disposed on the body 210 , and a top part 230 connected to the body 210 . Both sides of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com