Oily-pen-resistant waterborne woodware varnish and preparation method thereof

A pen water-based, clear topcoat technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc. Anti-graffiti, excellent resistance to various chemical media, good scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

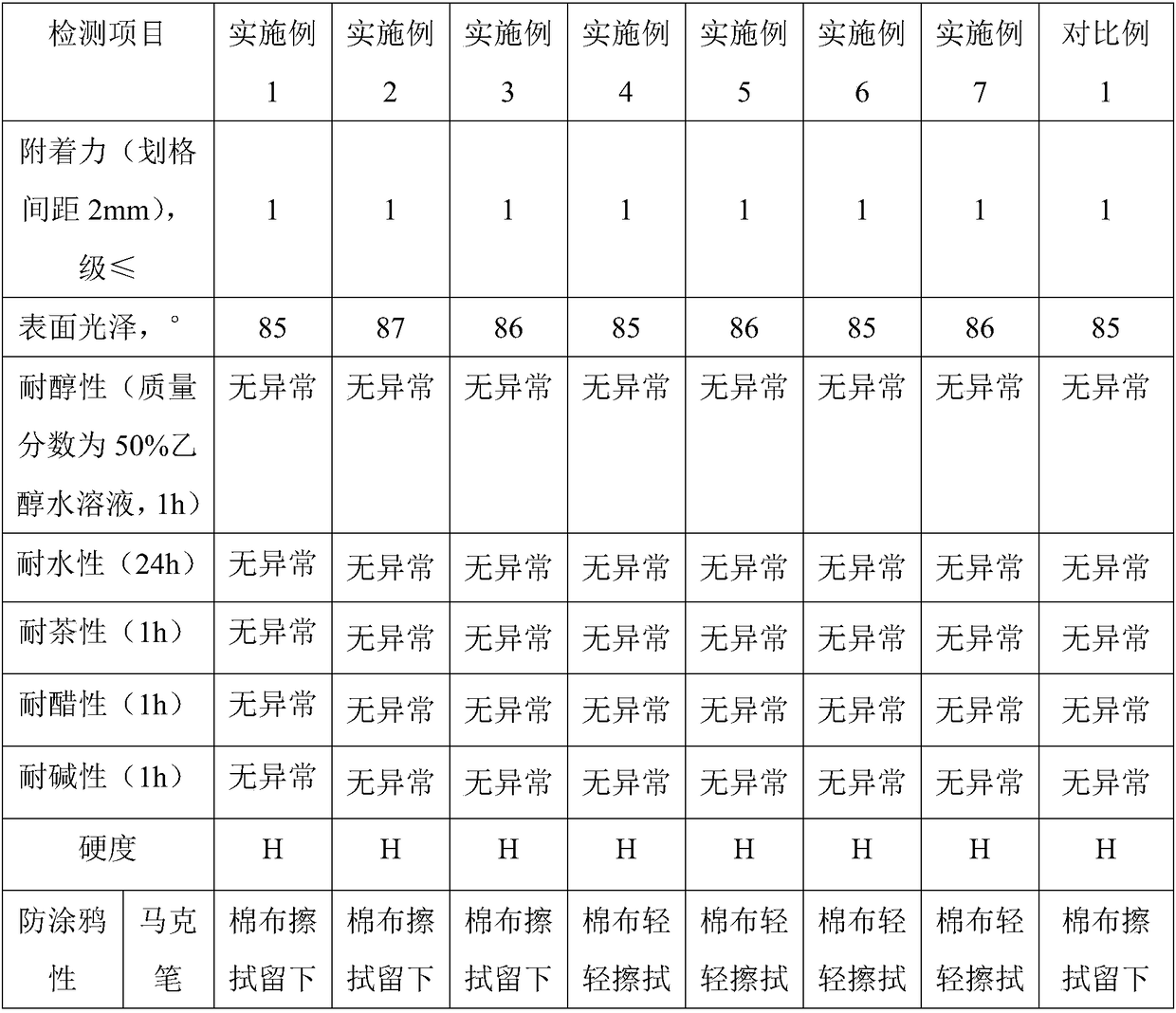

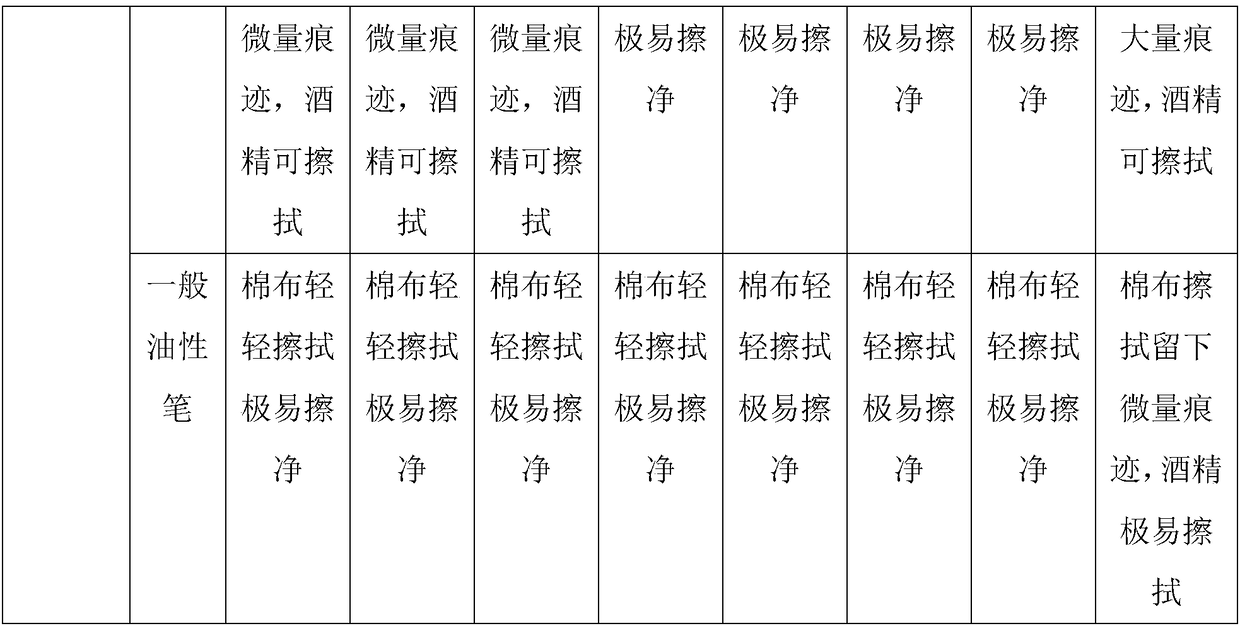

Examples

Embodiment 1

[0040] A preparation method of oil-resistant pen water-based wood varnish, comprising the following steps:

[0041] 1) Add 60kg of water-based hydroxyacrylic resin (model 2755) into the disperser, and start stirring;

[0042] 2) Add 0.1kg pH regulator, 0.2kg water-based defoamer (model BYK-054), 0.2kg water-based wetting agent (model SP-994), 0.2kg water-based leveling agent (model TEGO450), 4kg film-forming agent in sequence Additive (model DPM), 6kg nano additive (ASY-703), 6kg anti-graffiti additive (model protect5100N), 1kg wear-resistant additive (model W-18), 0.1kg fungicide and 22.1kg water, fully stir Uniform, get A component;

[0043] 3) Before spraying the construction process, put 15kg of curing agent (model 2655) into component A, stir evenly, let stand for 30 minutes, then spray the board and place it at room temperature.

Embodiment 2

[0045] A preparation method of oil-resistant pen water-based wood varnish, comprising the following steps:

[0046] 1) Add 65kg of water-based hydroxyacrylic resin (model 2755) into the disperser, and start stirring;

[0047] 2) Add 0.1kg pH regulator, 0.2kg water-based defoamer (model BYK-054), 0.2kg water-based wetting agent (model SP-994), 0.2kg water-based leveling agent (model TEGO450), 4kg film-forming agent in sequence Additive (model DPM), 6kg nano additive (ASY-703), 6kg anti-graffiti additive (model protect5100N), 1kg wear-resistant additive (model W-18), 0.1kg fungicide and 17.1kg water, fully stir Uniform, get A component;

[0048] 3) Before spraying the construction process, put 16kg of curing agent (model 2655) into component A, stir evenly, stand still for 30 minutes, then spray the board and place it at room temperature.

Embodiment 3

[0050] A preparation method of oil-resistant pen water-based wood varnish, comprising the following steps:

[0051] 1) Add 70kg of water-based hydroxyacrylic resin (model 2755) into the disperser and start stirring;

[0052]2) Add 0.1kg pH regulator, 0.2kg water-based defoamer (model BYK-054), 0.2kg water-based wetting agent (model SP-994), 0.2kg water-based leveling agent (model TEGO450), 4kg film-forming agent in sequence Auxiliary (model DPM), 6kg nano-auxiliary (ASY-703), 6kg anti-graffiti additive (model protect5100N), 1kg wear-resistant additive (model W-18), 0.1kg fungicide and 12.1kg water, fully stir Uniform, get A component;

[0053] 3) Before spraying the construction process, put 17kg of curing agent (model 2655) into component A, stir evenly, let stand for 30 minutes, then spray the board and place it at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com