Preparation method of cylindrical controlled fragments

A cylindrical and fragmented technology, applied in the direction of offensive equipment, weapon accessories, warheads, etc., can solve the problems of poor penetration effect, achieve the effect of improving performance, extending shelf life, and enhancing penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

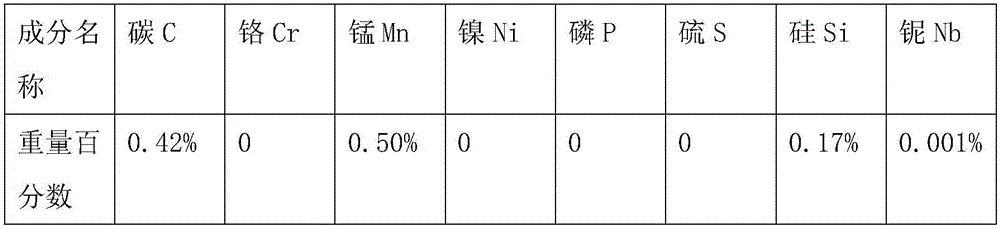

[0032] A method for preparing cylindrical prefabricated fragments, the steps are as follows:

[0033] S1 material selection: choose medium carbon steel wire with a hardness of 45-55HRC, a tensile strength of 1670MPa, and a diameter of 2mm;

[0034] S2 wire drawing: put the medium carbon steel wire in step S1 into a metal wire drawing machine for wire drawing, and draw the medium carbon steel wire with a diameter of 2 mm into a cylindrical steel wire with a diameter equal to the diameter of the finished product;

[0035] S3 die breaking: the ion spiral die breaking machine dies the cylindrical steel wire in step S2 into a cylindrical blank with the same length;

[0036] S4 screening: select and screen the cylindrical blanks in the step S3, and screen out the blanks with a size deviation of more than ±0.1mm;

[0037] S5 nickel-plating: use the barrel plating method to cover all the cylindrical blanks sieved in step S4 with a nickel layer to obtain cylindrical prefabricated frag...

Embodiment 2

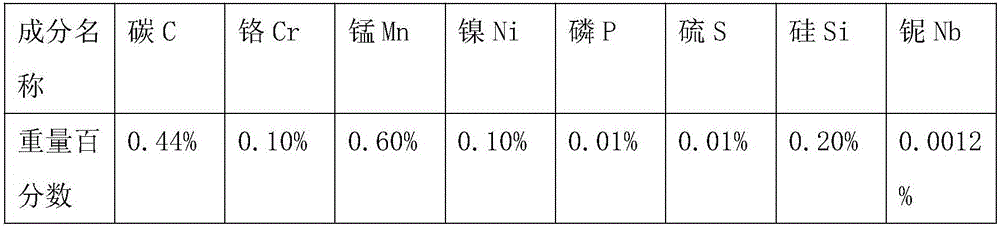

[0045] A method for preparing cylindrical prefabricated fragments, the steps are as follows:

[0046] S1 material selection: choose medium-carbon steel wire with a hardness of 50HRC, a tensile strength of 1670MPa, and a diameter of 2mm;

[0047] S2 wire drawing: put the medium carbon steel wire in step S1 into a metal wire drawing machine for wire drawing, and draw the medium carbon steel wire with a diameter of 2 mm into a cylindrical steel wire with a diameter equal to the diameter of the finished product;

[0048] S3 die breaking: the ion spiral die breaking machine dies the cylindrical steel wire in step S2 into a cylindrical blank with the same length;

[0049] S4 screening: select and screen the cylindrical blanks in the step S3, and screen out the blanks with a size deviation of more than ±0.1mm;

[0050] S5 nickel-plating: use the barrel plating method to cover all the cylindrical blanks sieved in step S4 with a nickel layer to obtain cylindrical prefabricated fragmen...

Embodiment 3

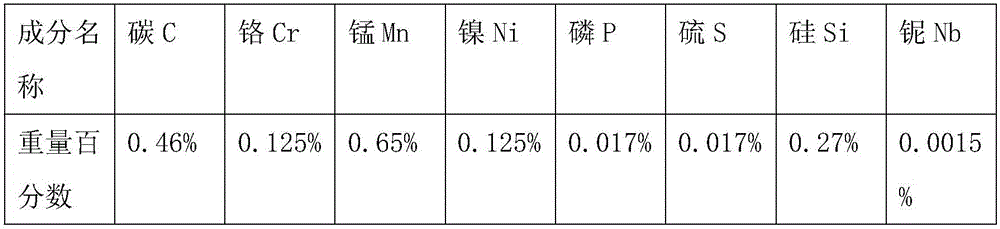

[0058] A method for preparing cylindrical prefabricated fragments, the steps are as follows:

[0059] S1 material selection: choose medium carbon steel wire with a hardness of 45HRC, a tensile strength of 1770MPa, and a diameter of 2mm;

[0060] S2 wire drawing: put the medium carbon steel wire in step S1 into a metal wire drawing machine for wire drawing, and draw the medium carbon steel wire with a diameter of 2 mm into a cylindrical steel wire with a diameter equal to the diameter of the finished product;

[0061] S3 die breaking: the ion spiral die breaking machine dies the cylindrical steel wire in step S2 into a cylindrical blank with the same length;

[0062] S4 screening: select and screen the cylindrical blanks in the step S3, and screen out the blanks with a size deviation of more than ±0.1mm;

[0063] S5 nickel-plating: use the barrel plating method to cover all the cylindrical blanks sieved in step S4 with a nickel layer to obtain cylindrical prefabricated fragmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com