High-strength light fabric used in fencing clothes and processing method thereof

A processing technology and light-weight technology, applied in clothing, clothing, applications, etc., can solve the problems of personal injury, failure to meet the penetration resistance standard of the second-level fencing suit, etc., and achieve the effect of strong penetration resistance, good texture and light fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] A high-strength and light-weight fabric for fencing clothing, the fabric composition includes polyester and polypropylene, and the polyester includes glossy polyester and dull polyester. The ratio of polyester and polypropylene is: polyester 85-97%, polypropylene 3-15%.

[0009] The processing technology of the high-strength light-weight fabric for fencing clothes of the present invention includes wire drawing, twisting, weaving and printing and dyeing, specifically as follows:

[0010] A) Wire drawing --- It is required to control the ambient temperature at 8-25°C, the wire drawing pressure at 6-8kg, and the elongation at break of the wire drawing at 9-11 points;

[0011] B) twisting --- control the twist at 70-100 degrees;

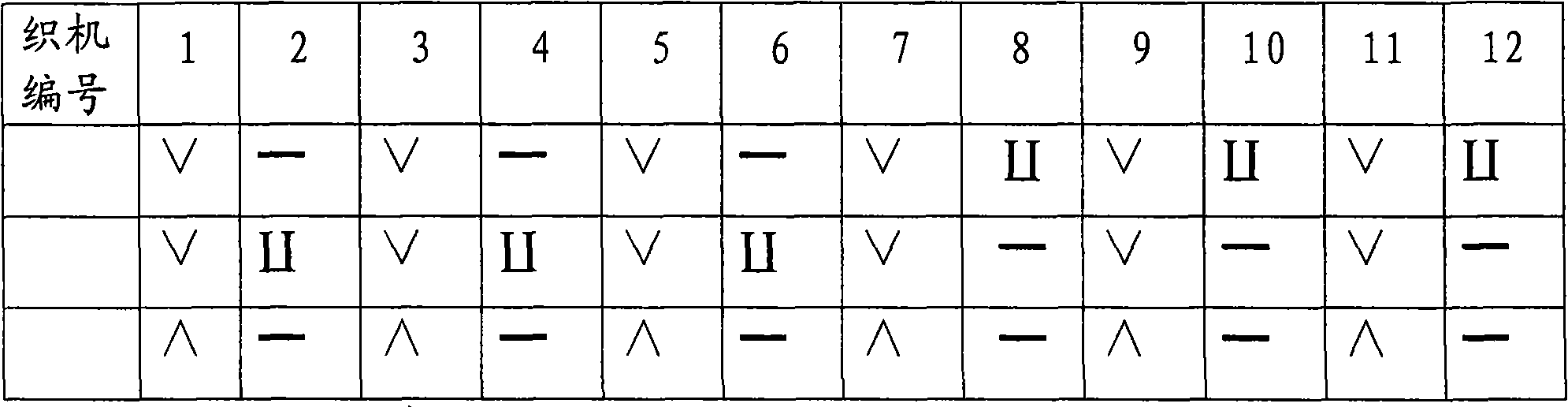

[0012] C) Weaving --- weaving with a large circular machine, using honeycomb weaving when weaving; the weaving diagram is as follows

[0013]

[0014] Note: ∨---indicates that the needle is coiled, and the upper needle is 1 pass, and the lowe...

Embodiment 2

[0022] A high-strength and light-weight fabric for fencing clothing as in Example 1, the difference is that the yarn count is controlled at 100-800 during weaving, and different counts are used according to the type of need to achieve different anti-puncture performance requirements. For example, only 100, 150, 200, 250, 300 pieces are needed for ordinary type; 200, 250, 300 pieces are used for competition suit 350N; 350, 400, 450, 500, 550, 600, 650 700, 750, 800 sticks.

[0023] Note: This is not limited to the above example counts, and counts of 110, 120, etc. can also be used, and according to different styles, the warp and weft counts can also be different during weaving to meet the weaving requirements of different styles. Realize the change of fabric style.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com