Patents

Literature

35results about How to "Strong breakdown resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

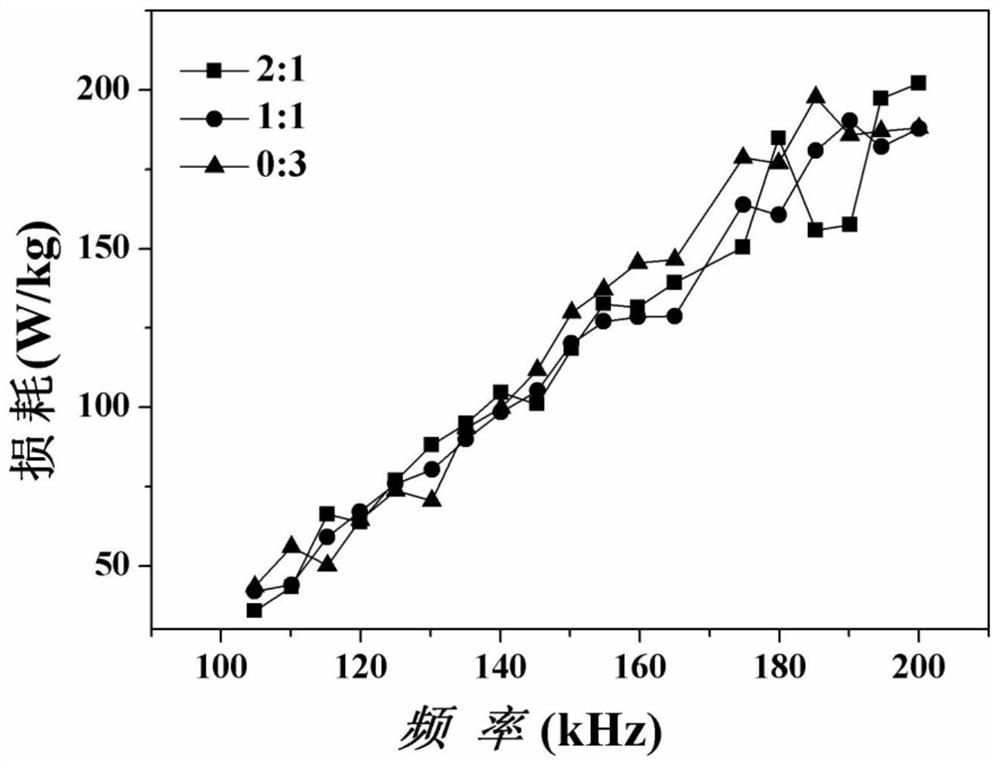

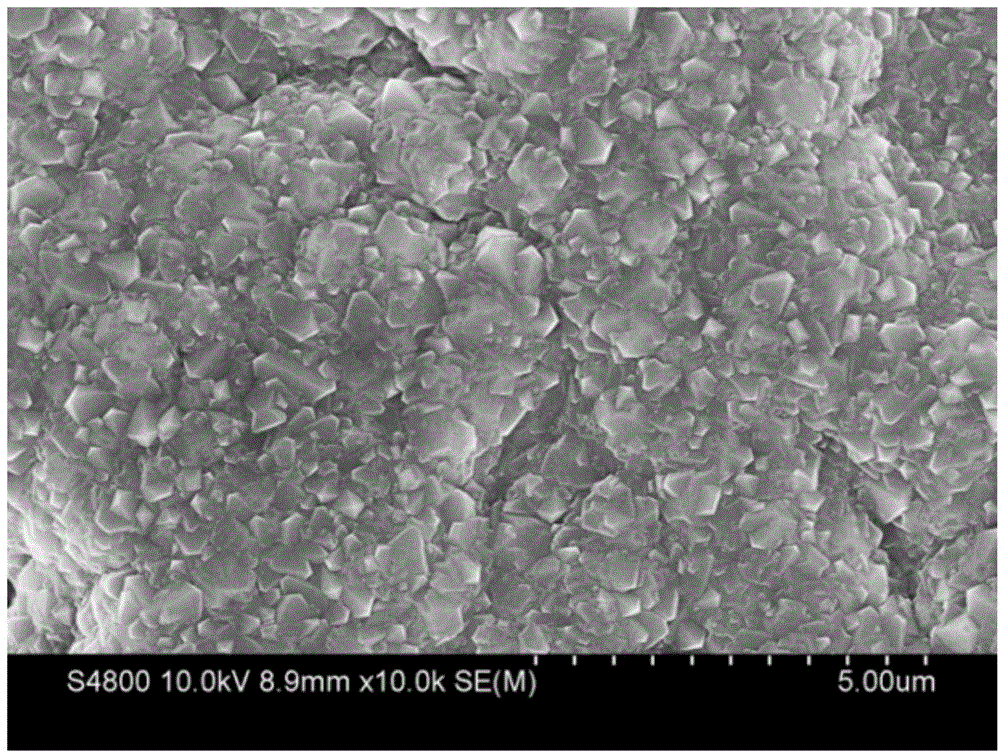

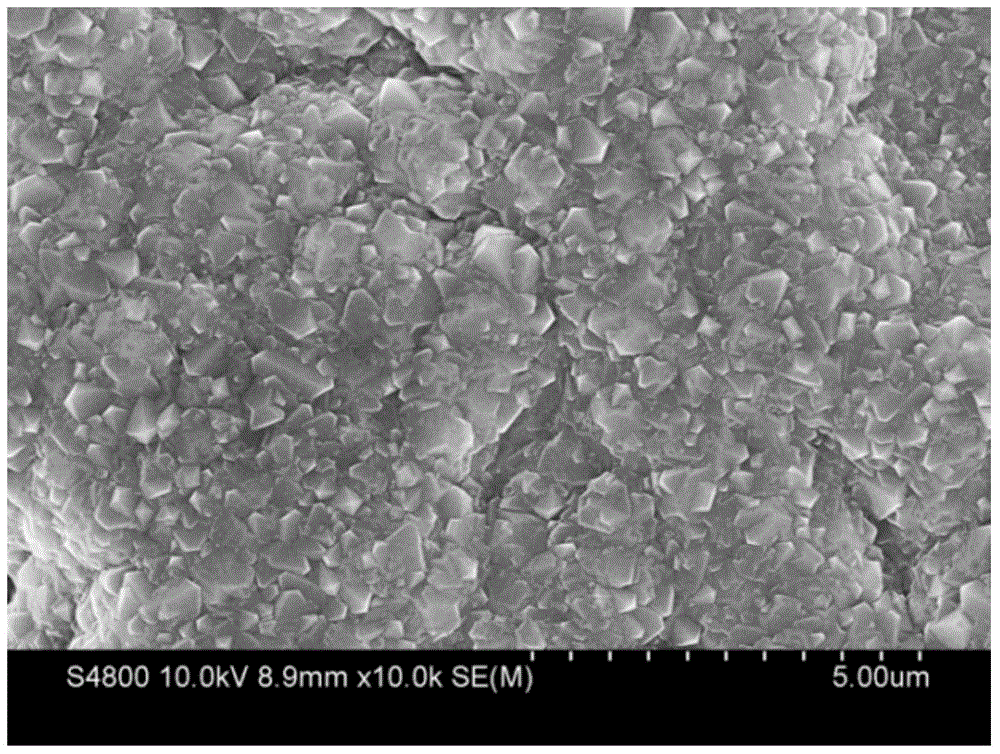

Magnetic powder core and preparation method thereof

ActiveCN109545537AImprove performanceHigh saturation flux densityInductances/transformers/magnets manufactureAfter treatmentIron powder

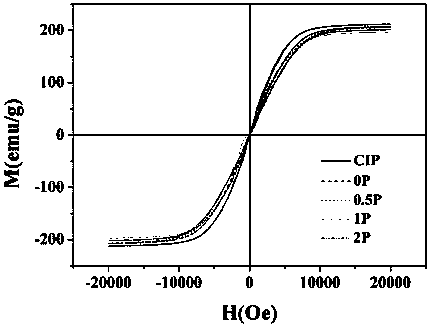

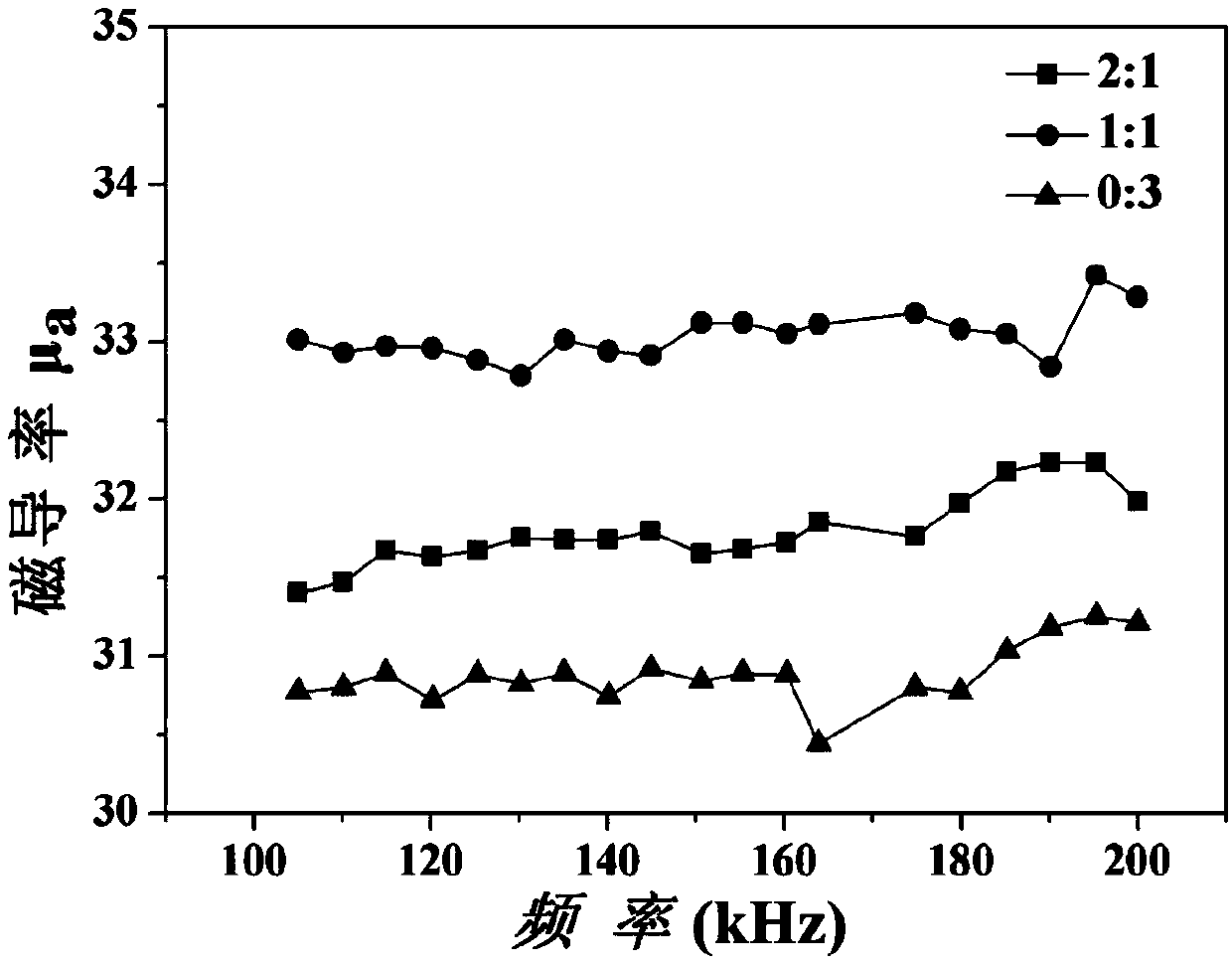

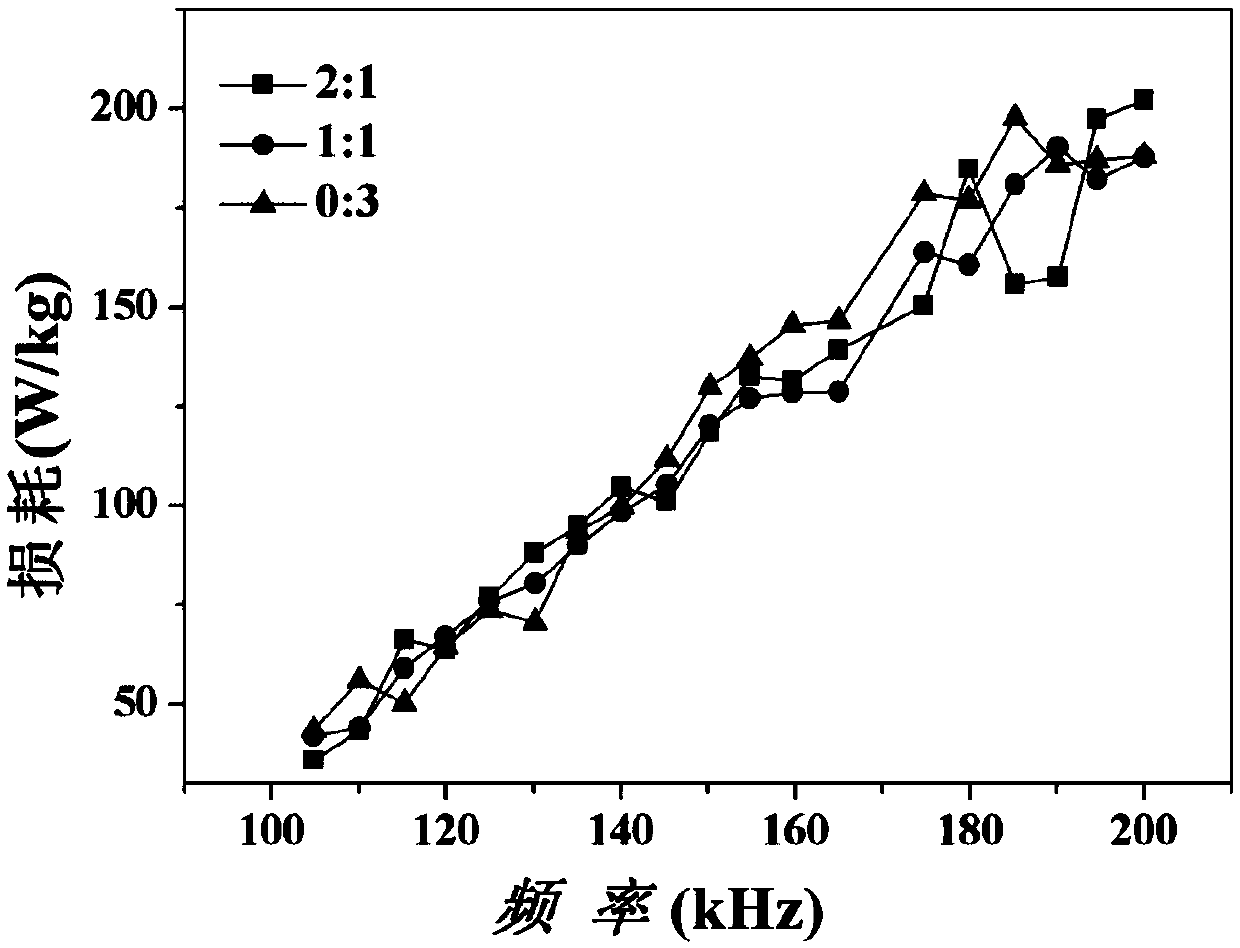

The invention provides a preparation method of magnetic powder cores. The preparation method comprises the steps: mixing carbonyl iron powder with a phosphating solution, and phosphating to obtain iron powder after treatment; drying the iron powder after treatment, sieving and then mixing and coating with an insulating coating agent to obtain powder after coating, wherein the insulating coating agent comprises organic resin, inorganic coating material, coupling agent and curing agent; and granulating, pressing and solidifying the coated powder to obtain a magnetic powder core. The preparationmethod of magnetic powder cores achieves the best performance of the magnetic powder core by selecting a specific insulating coating agent, and combines the remaining operations, thus having the magnetic properties such as higher saturation magnetic flux density and stable magnetic permeability, and having strong resistance to breakdown. The preparation method of magnetic powder cores is excellentin molding performance, can meet molding of the complex structure of one-piece inductors, and can satisfy the industrial requirement for mechanical properties. The preparation method of magnetic powder cores enables the insulating coating of the magnetic powder core to be more stable by combination of multi-element coatings, so that the prepared product has stronger working stability during the service life of the product.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC CO LTD

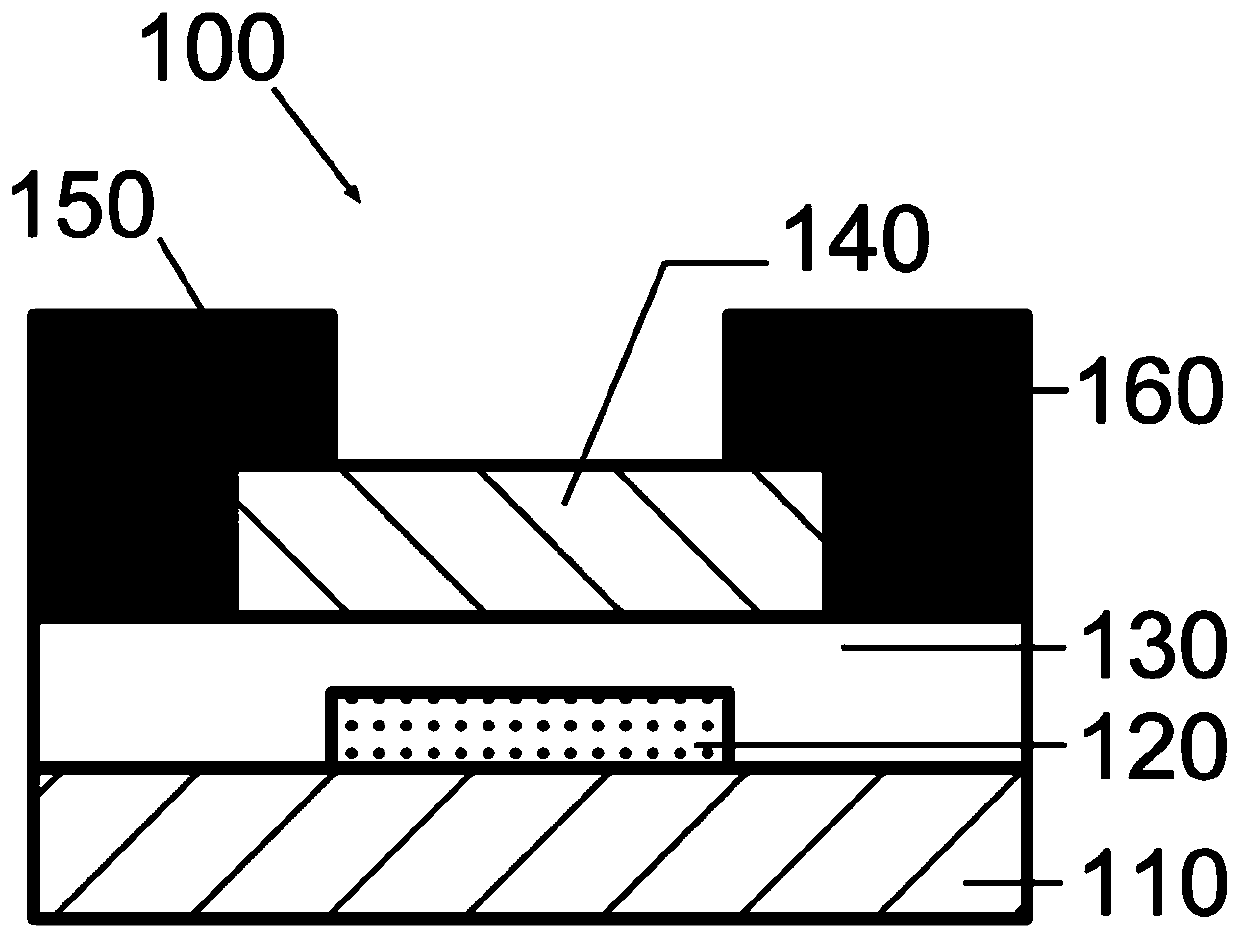

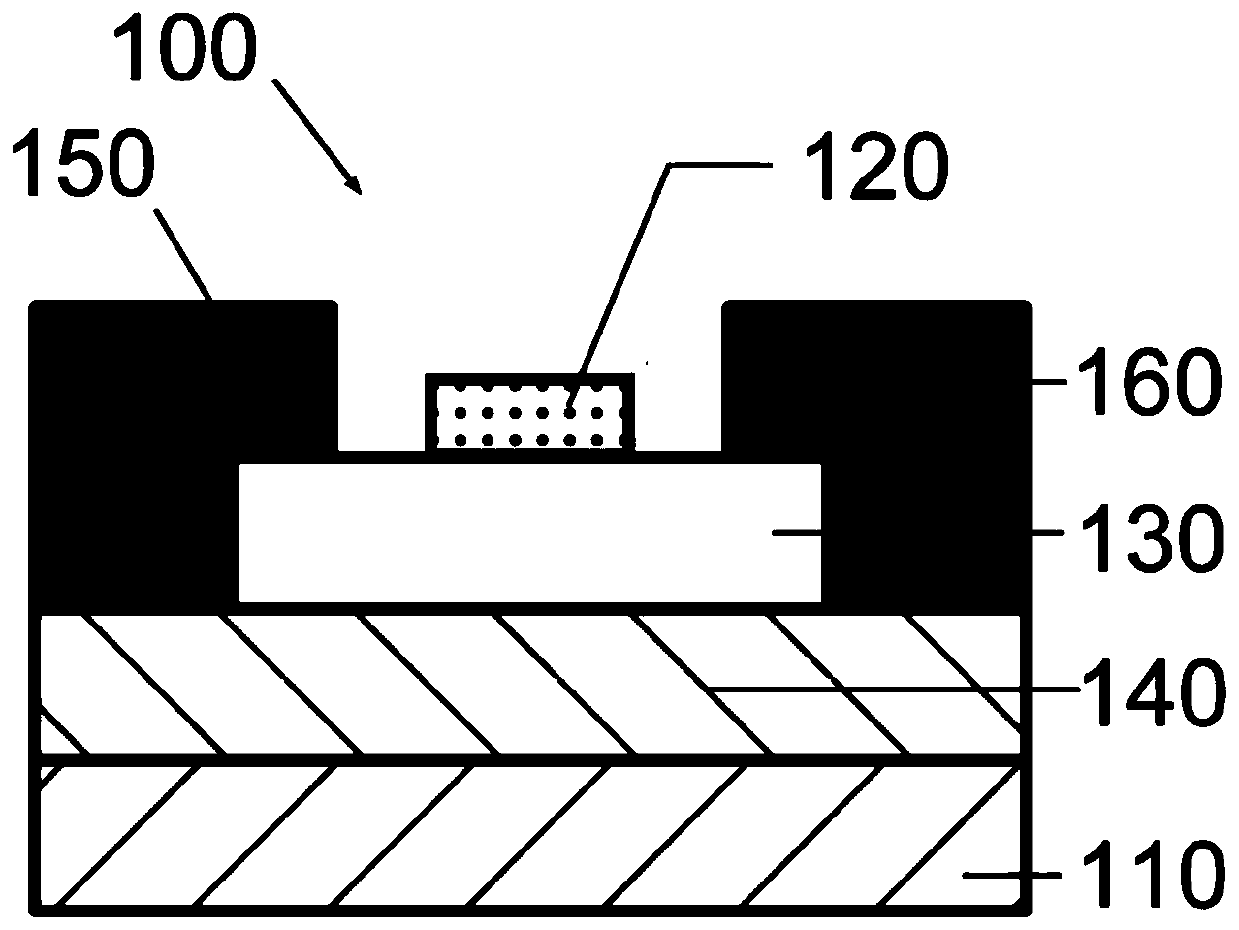

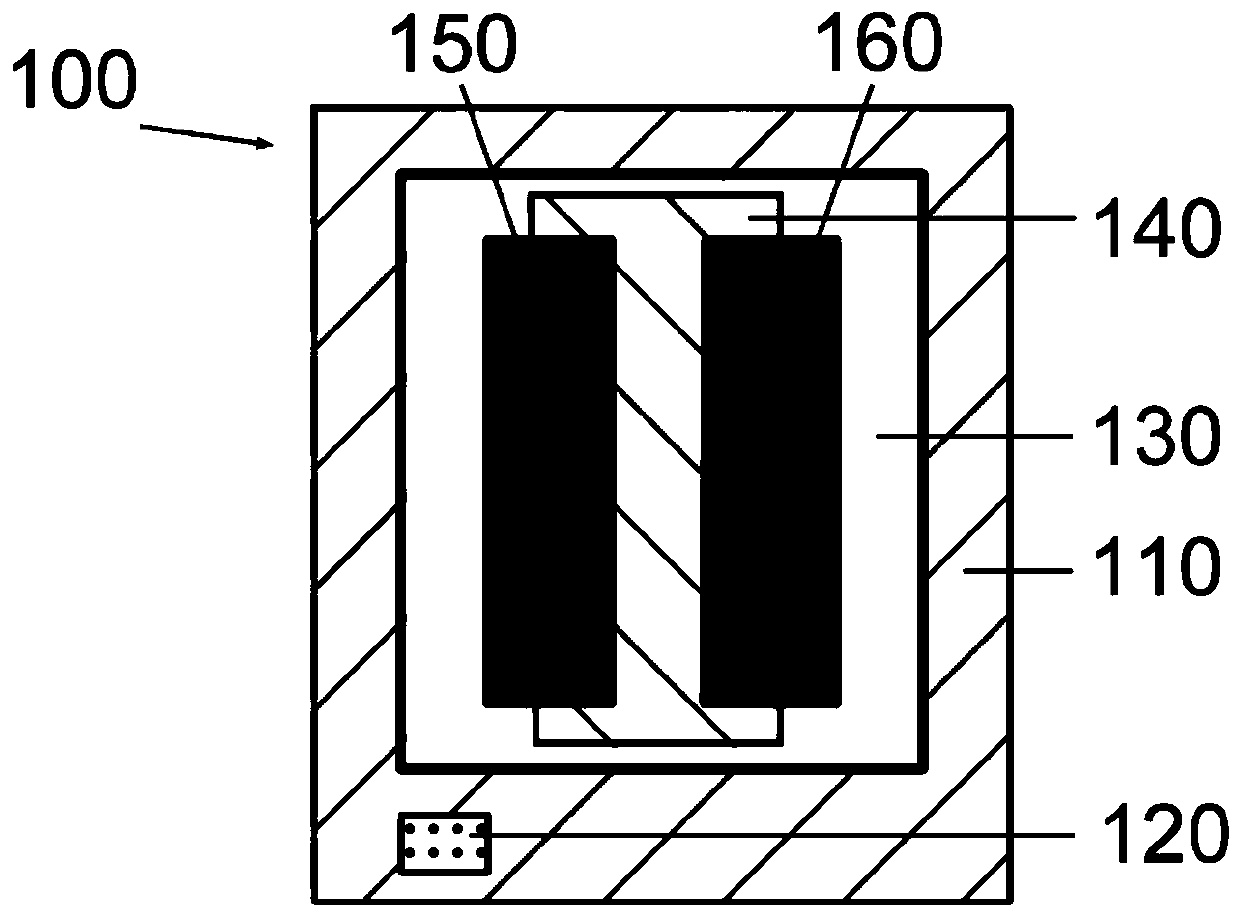

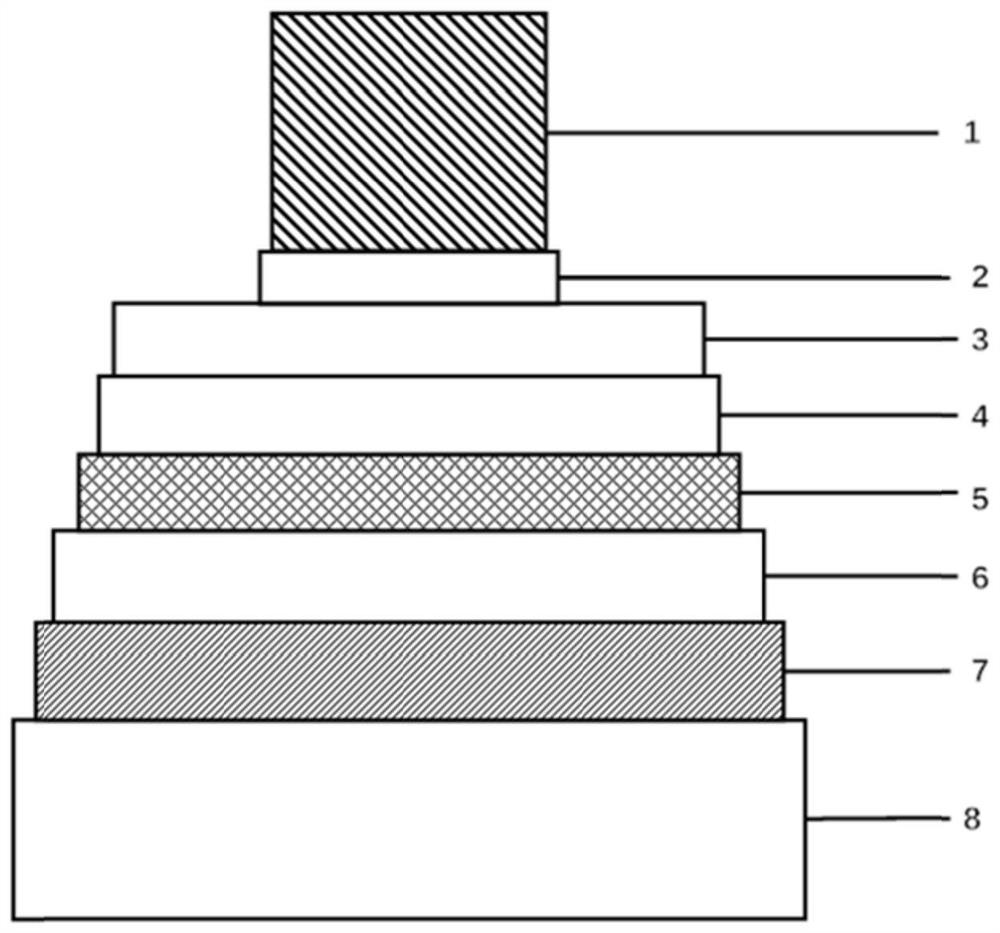

Deep-ultraviolet photoelectric detector of amorphous gallium oxide-based thin film transistor

InactiveCN109742180AIncrease the bandgapStrong breakdown resistanceSemiconductor devicesGate dielectricPhotovoltaic detectors

The invention discloses a deep-ultraviolet photoelectric detector of an amorphous gallium oxide-based thin film transistor. The deep-ultraviolet photoelectric detector comprises the thin film transistor, wherein the transistor comprises a substrate, a gate electrode, a gate dielectric layer, a channel layer, a source electrode and a drain electrode, the channel layer is an amorphous gallium oxide-based thin film, the thin film transistor is of a bottom gate structure, the gate electrode is arranged on the substrate, the gate dielectric layer covers the gate electrode, the channel covers an upper part of the gate dielectric layer, the source and the drain are respectively arranged at two ends of the channel layer, or the thin film transistor is of a top gate structure, the channel layer covers the substrate, the gate dielectric layer covers an upper part of the channel layer, the source electrode and the drain electrode are respectively arranged at two ends of the gate dielectric layer,and the gate electrode is arranged on the gate dielectric layer. The deep-ultraviolet photoelectric detector provided by the invention has the advantages of relatively high response and low power consumption under irradiation of deep ultraviolet light (320 nanometers), and moreover, the fabrication method is simple, large-area integration can be achieved, and the deep-ultraviolet photoelectric detector is compatible with a flexible substrate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

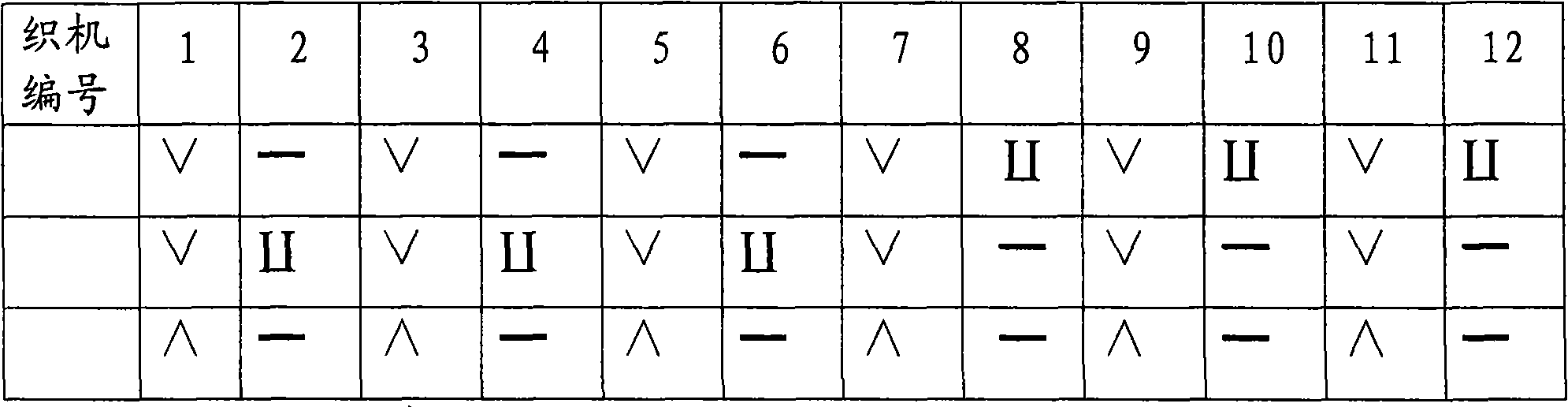

High-strength light fabric used in fencing clothes and processing method thereof

The invention relates to a high-strength light fabric used in fencing clothes, which is characterized by comprising terylene and polypropylene fibers, wherein the terylene consists of lustrous terylene and matt terylene. A processing method for the high-strength light fabric used in fencing clothes comprises the steps of wiredrawing, twisting, weaving, printing and dyeing, and is characterized in that the fabric is woven in honeycomb weaves. After being developed and produced, the fabric has the advantages that the breakdown resistance of the fabric is strong because of adopting the terylene and polypropylene fibers as main raw materials, for example, the fabric with 800N has the limit breakdown of over 3000N; the fabric is light as adopting the honeycomb weave, as the fabric with 800N has the unit weight of 630g / m<2>, and the fabric with 350N has the unit weight of 400g / m<2> (with the limit breakdown of 2978N). One finished jacket after being woven is lighter 500g than a conventional jacket; furthermore, the softness and the textile of products are much better than those of conventional products.

Owner:丹阳市斯鲍特体育用品有限公司

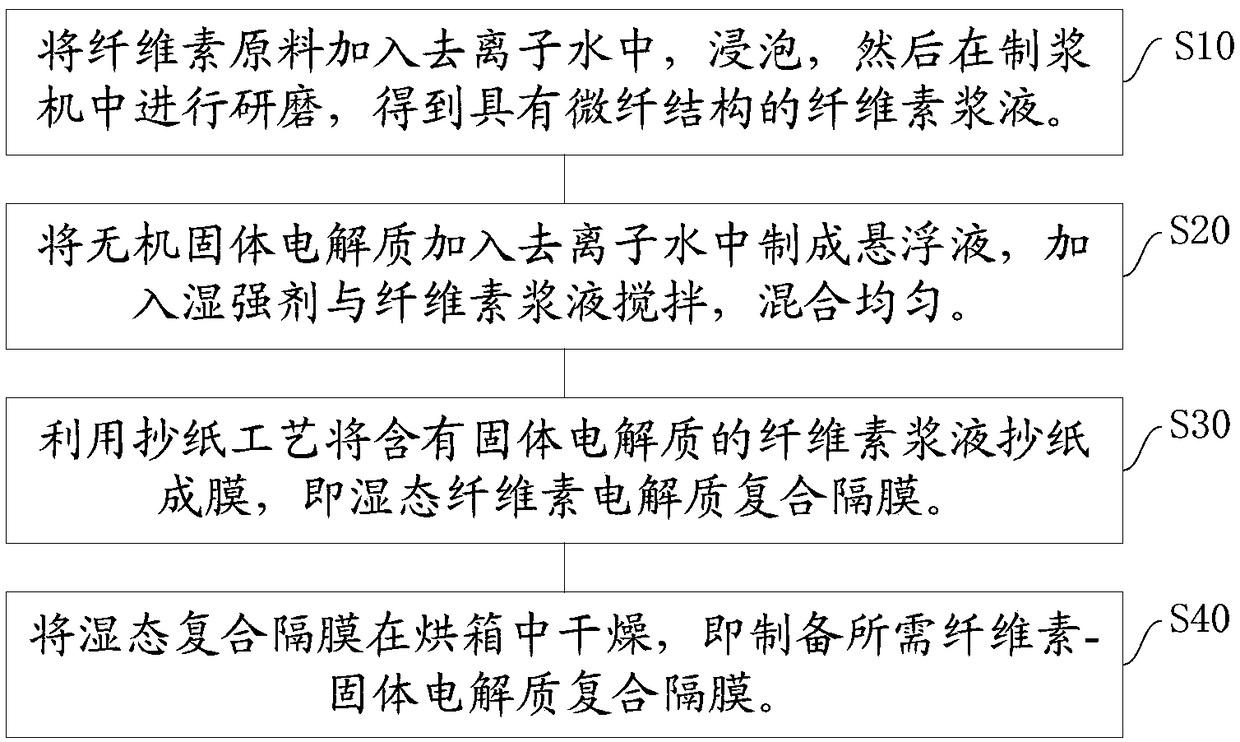

Inorganic solid electrolyte-cellulose composite diaphragm and preparation method thereof

InactiveCN108470875AEasy to manufactureUniform structure distributionCell component detailsPapermakingSlurry

The invention discloses an inorganic solid electrolyte-cellulose composite diaphragm and a preparation method thereof. The preparation method comprises the steps of S10, adding cellulose raw materialsinto deionized water to be immersed, and then performing grinding in a pulping machine to obtain a cellulose pulp solution with a micro-fiber structure; S20, adding an inorganic solid electrolyte into deionized water to prepare into a suspension liquid, then adding a wet strength agent and the cellulose pulp solution to be mixed uniformly; S30, performing papermaking and film forming on the cellulose pulp solution comprising the solid electrolyte by a papermaking process, namely, obtaining a wet cellulose electrolyte composite diaphragm; and S40, performing drying on the wet composite diaphragm in a drying oven to obtain the needed cellulose-solid electrolyte composite diaphragm. The prepared composite diaphragm is uniform in hole structural distribution, convenient to prepare, suitable for batch production, and high in heat resistance, high in wettability, high in ionic conductivity, high in breakdown resistance, and suitable for a lithium ion battery diaphragm; and meanwhile, the diaphragm is compounded with the inorganic solid electrolyte, so that an effect of the electrolyte can be played, and extra addition of an electrolyte solution is not needed.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

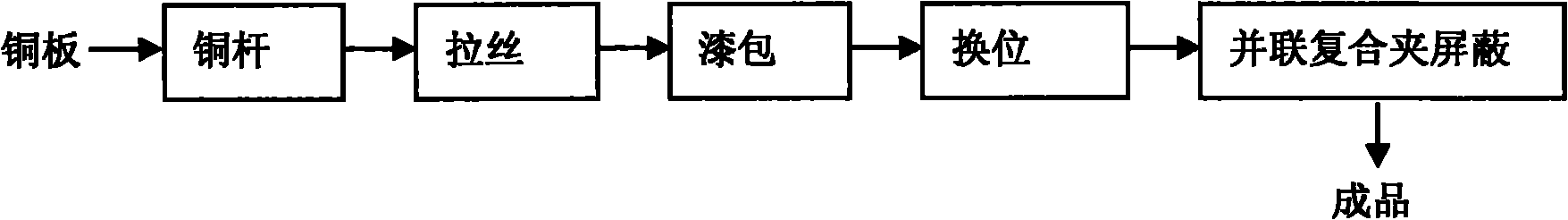

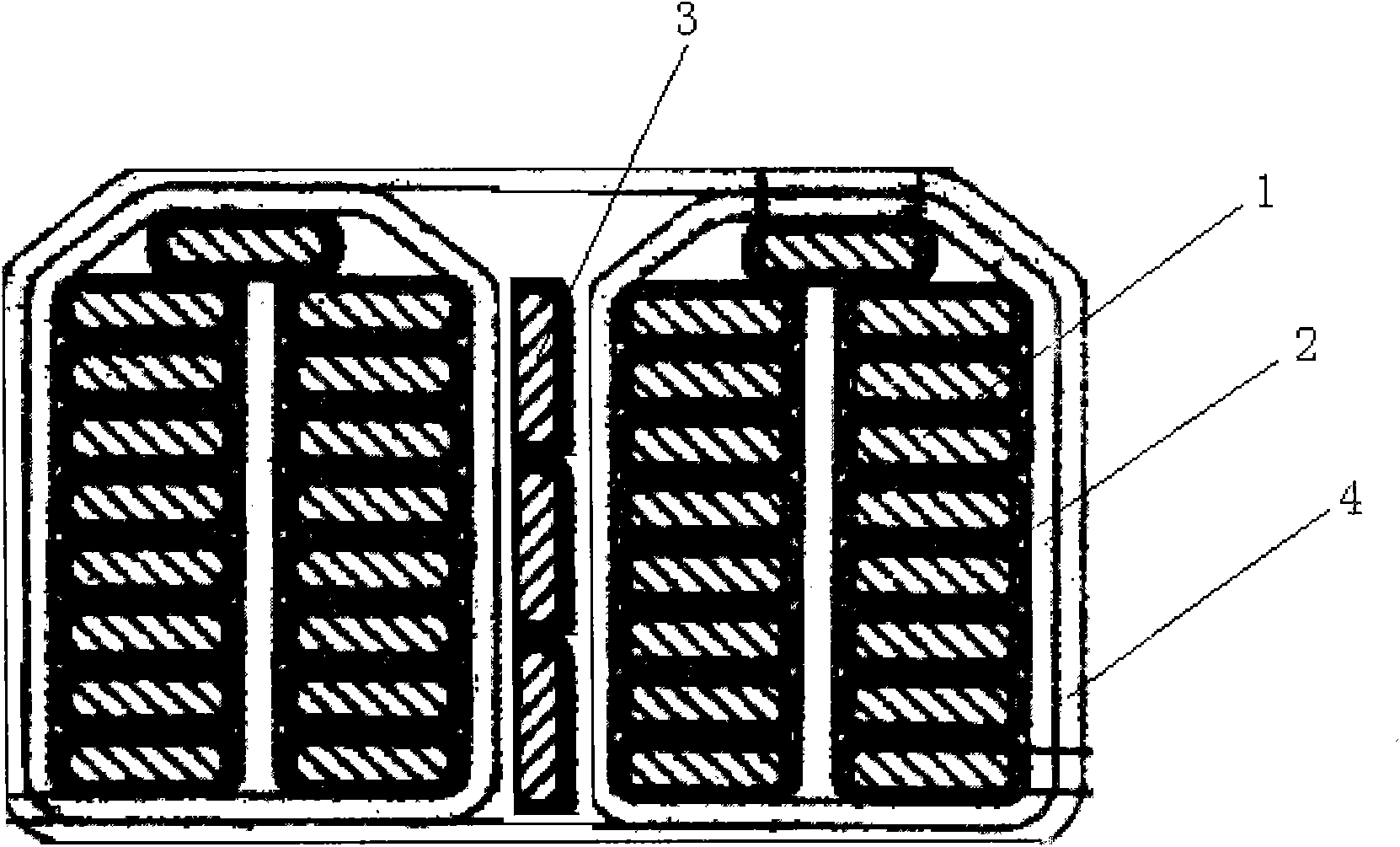

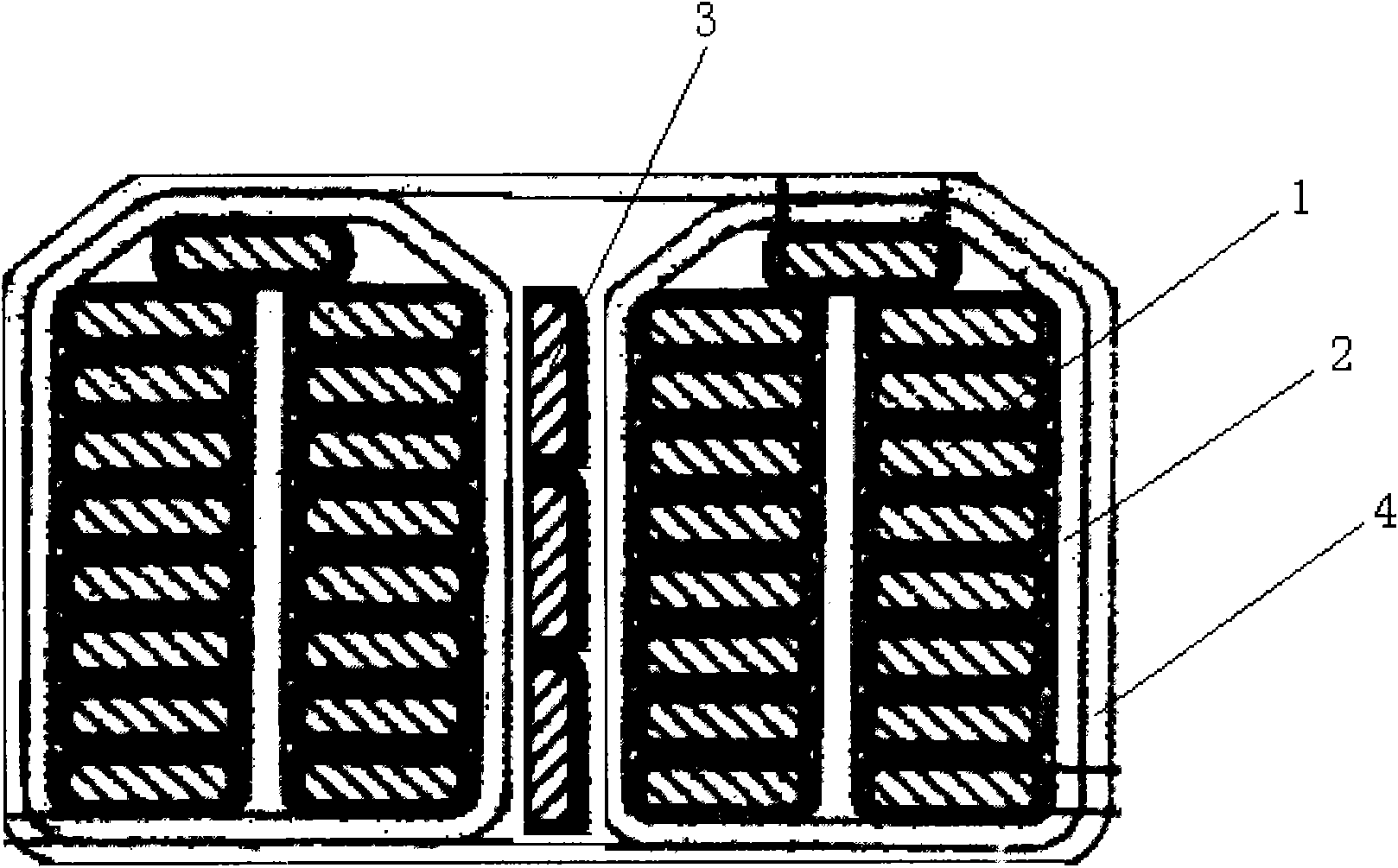

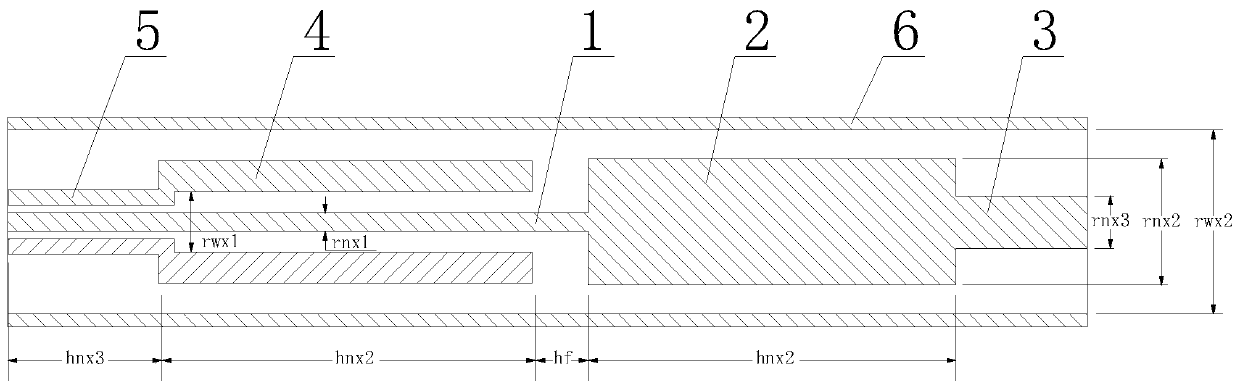

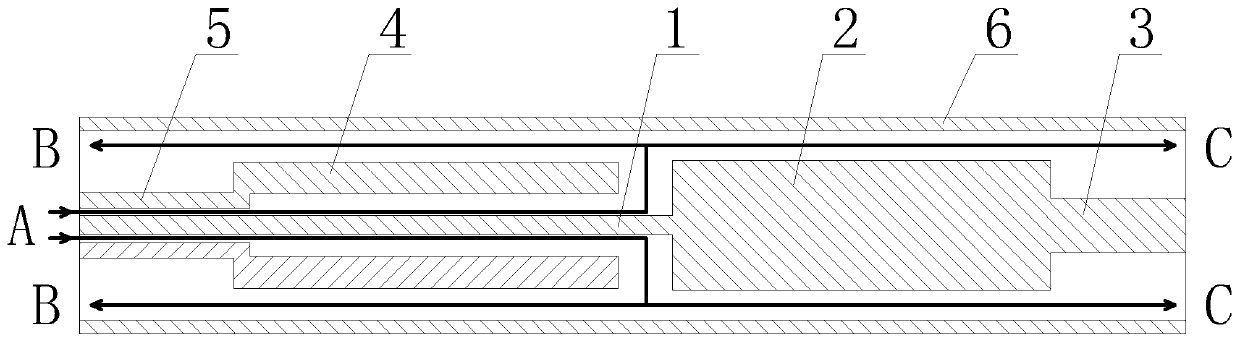

Shield conversion lead of parallel composite strip

InactiveCN101777401AIncrease the cross-sectional areaLarge voltage capacityTransformers/inductances coils/windings/connectionsFlat/ribbon cablesEngineeringCopper

The invention discloses a shield conversion lead of a parallel composite strip, comprising two groups of copper flat wires. An inner insulation paper layer is coated out of the single group of copper flat wires; two groups of copper flat wires are axially arranged in parallel; a shield wire is arranged between two groups of copper flat wires; and an outer insulation paper layer is coated outside the two groups of copper flat wires and the shield wire. In the invention, a group of enameled flat wires is adopted to replace the shield wire and directly clamped between two conversion leads to be integrated together with the outer insulation paper, thereby ensuring larger sectional area of the leads, increased the voltage capacity, better insulation effect and stronger puncture-resisting ability; besides, shield wires are arranged in the lead, thereby greatly reducing the difficulty degree in the coil winding process, simplifying the process and ensuring good effect of the shield wire.

Owner:刘松

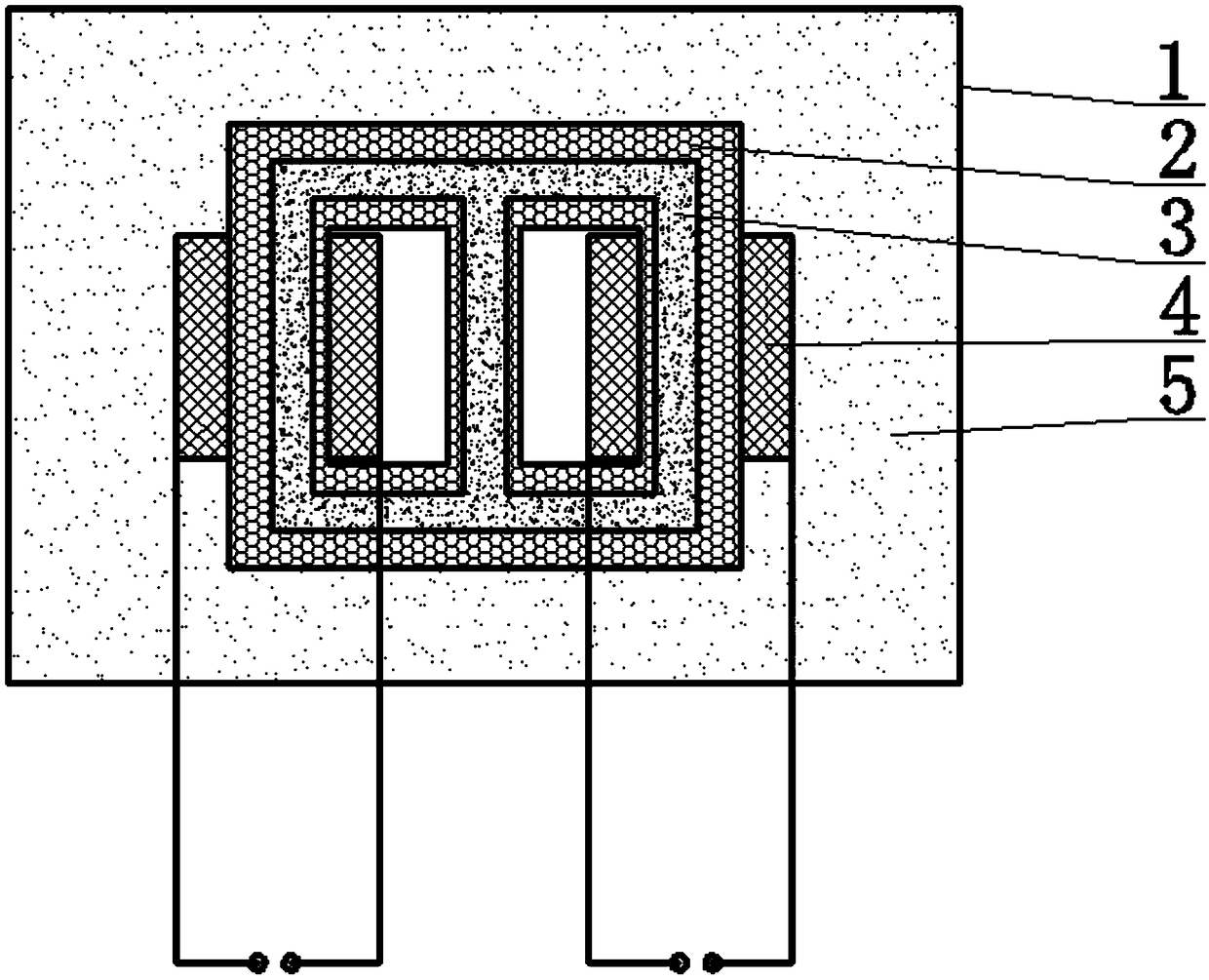

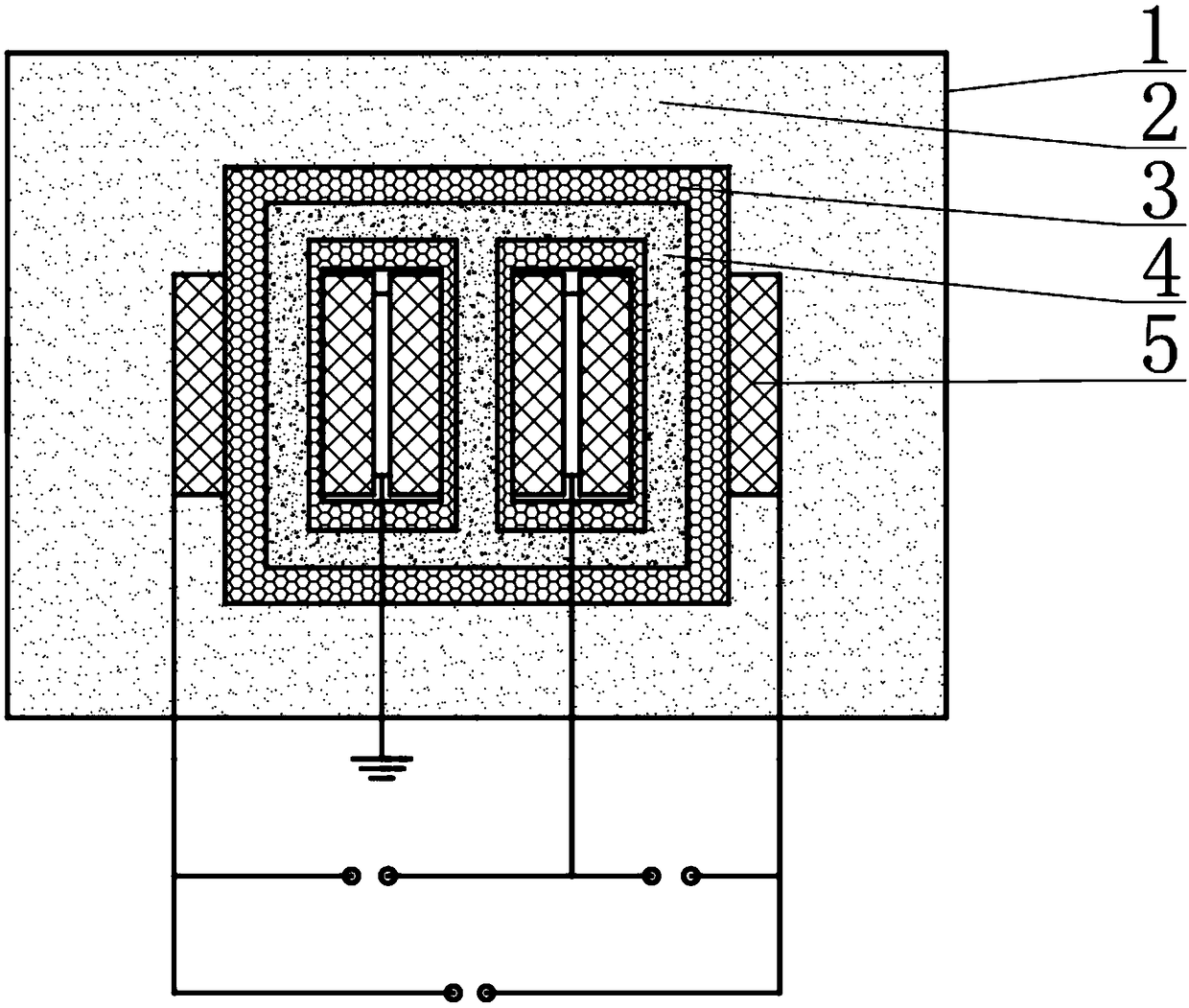

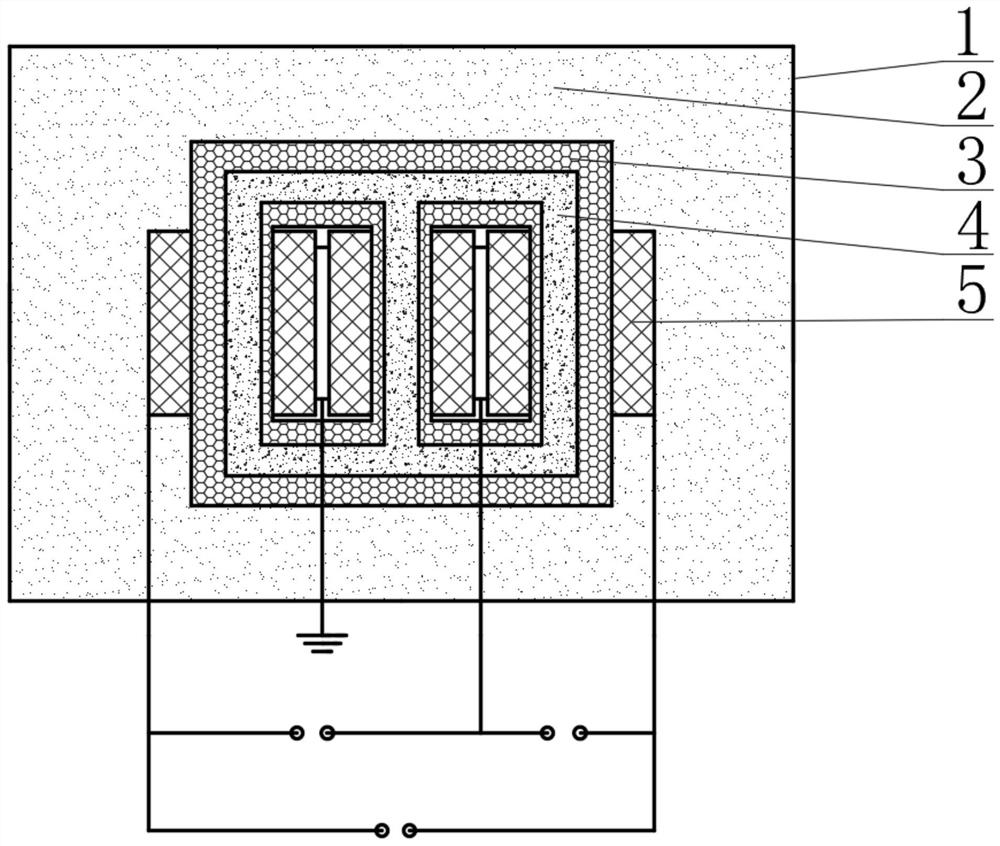

High-stability corrosion-resistant long-life communication transformer and manufacturing method thereof

ActiveCN109494065AReduce carbon contentImprove bindingTransformers/inductances casingsTransformers/inductances coils/windings/connectionsPolyesterPorosity

The invention discloses a high-stability corrosion-resistant long-life communication transformer and a manufacturing method thereof. The communication transformer comprises a framework, a winding, a magnetic core, a shielding cover and a packing material, and is characterized in that the framework is an alumina-based porous foam ceramic framework with a porosity of 20-30%; the winding adopts a purple copper wire with epoxy polyester insulating paint; the magnetic core is a molybdenum pomo magnetic core which is shaped like a Chinese character 'ri'; a self-circulation insulating heat transfer filler is filled in gaps between the shielding cover and other parts, and the self-circulation insulating heat transfer filler is a mixture of alumina-based porous foam ceramic and rosin; the shieldingcover is made of titanium-containing low-carbon steel with activated and passivated surface and is packaged in a totally-enclosed structure. The communication transformer has the advantages of smallloss, high conversion efficiency, good electromagnetic shielding property, good insulation property, corrosion resistance, oxidation resistance and long service life.

Owner:东莞市航其电子元件有限公司

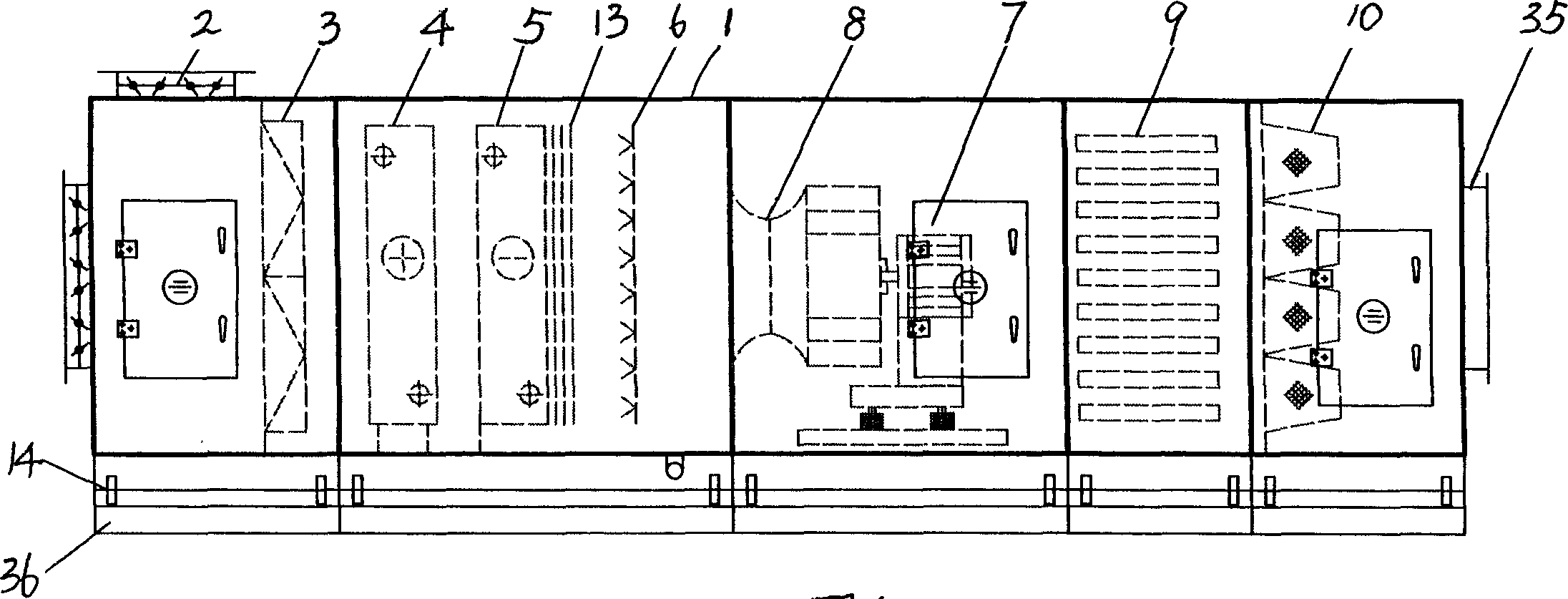

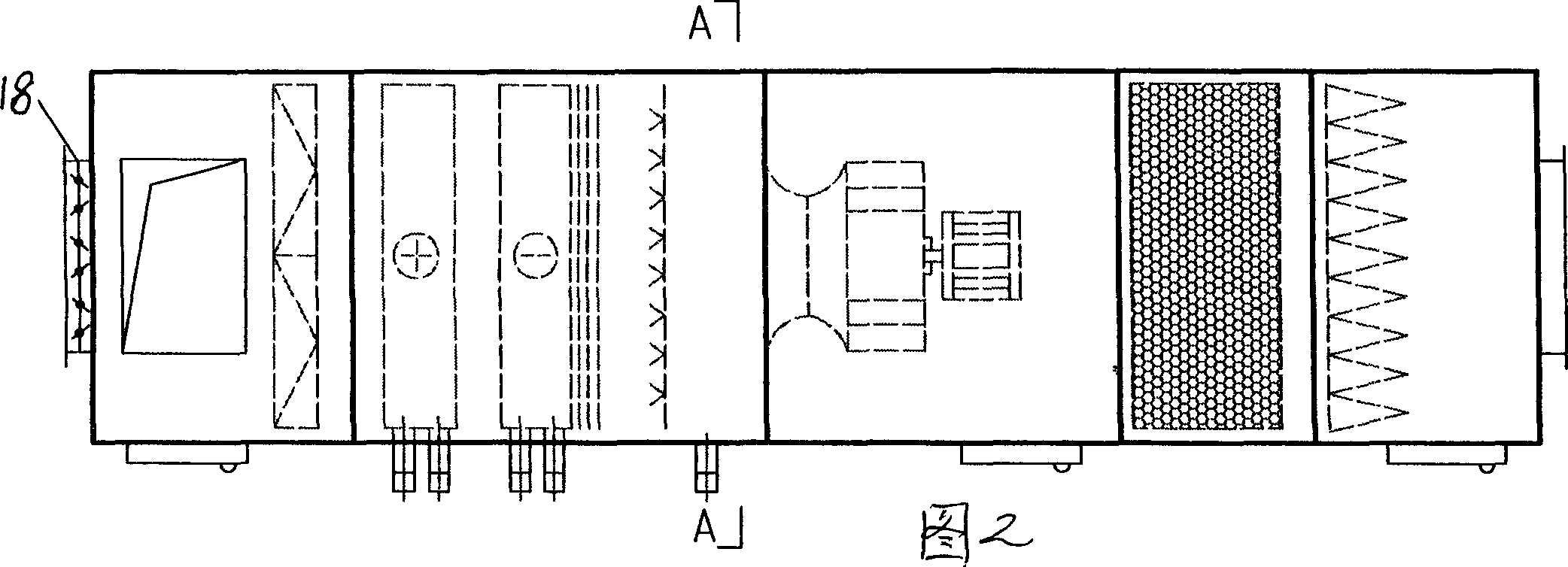

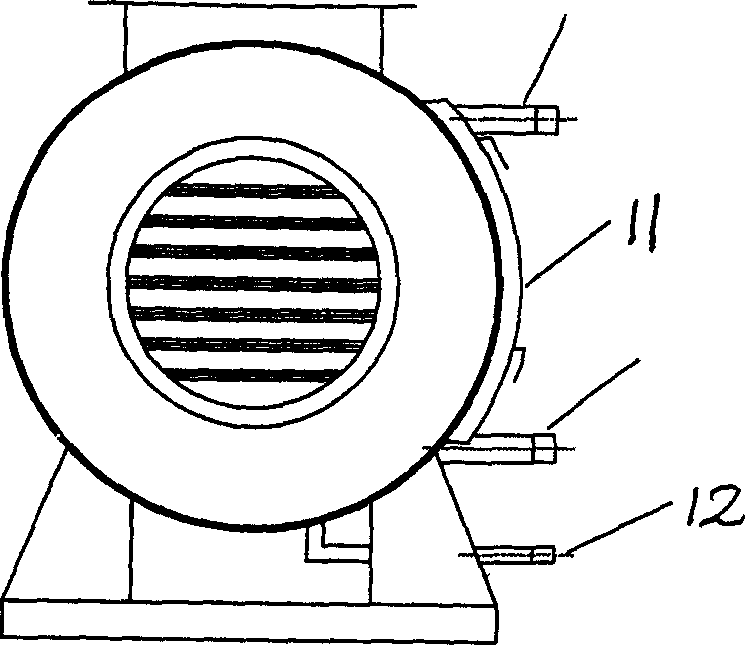

Drum type air treating machine set

InactiveCN1815095AIncrease airflowImproves airflow uniformityLighting and heating apparatusAir conditioning systemsElectric machineAir treatment

Present invention discloses a drum type air handling assembly. It includes cylinder shape horizontal shell, round multi-leaf damper, fan-shaped or tube type primary filter, round surface heater, primary filter surface air coolers, humidifier, circular arc shape service door, and condensate pipe. Said invention has reasonable structure and fine working performance.

Owner:JIANGSU FENGSHEN AIR CONDITIONING GRP

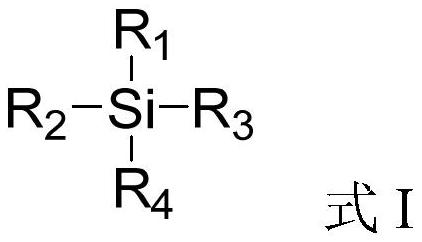

Composite flame-retardant cable material with excellent insulation performance and preparation method thereof

InactiveCN105175852AReduce injectionReduce aggregationPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses a composite flame-retardant cable material with an excellent insulation performance. The cable material is composed of the following components in parts by weight: 89 to 91 parts of high density polyethylene, 9 to 11 parts of polyolefin elastomer, 15 to 17 parts of decabromodiphenyl ether, 7 to 9 parts of antimony (III) trioxide, 2 to 3 parts of metallocene polyethylene, 2 to 3 parts of nano magnesium hydroxide, 4 to 5 parts of cyclohexane, 0.2 to 0.3 part of gamma-amino propyl triethoxysilane, 2 to 3 parts of dimethyl silicone oil, 0.6 to 0.8 part of promoter TMTD, 2 to 3 parts of bis(tetradecyl alcohol ester), 3 to 4 parts of chlorinated paraffin, 3 to 5 parts of zinc oxide, and 1 to 2 parts of calcium-zinc stabilizing agent. The formula is reasonable, high density polyethylene is compounded with polyethylene elastomer, the cable speed and insulation performance of the material are both improved, the fluidity of the produced material is good, and the material can be easily plasticized, does not contain any substance that does not meet the environment-friendly requirements, will not pollute the environment, and at the same time, has the advantages of high efficient low smoke flame retardant property, strong anti-puncture performance, and excellent comprehensive performance.

Owner:安徽吉安特种线缆制造有限公司

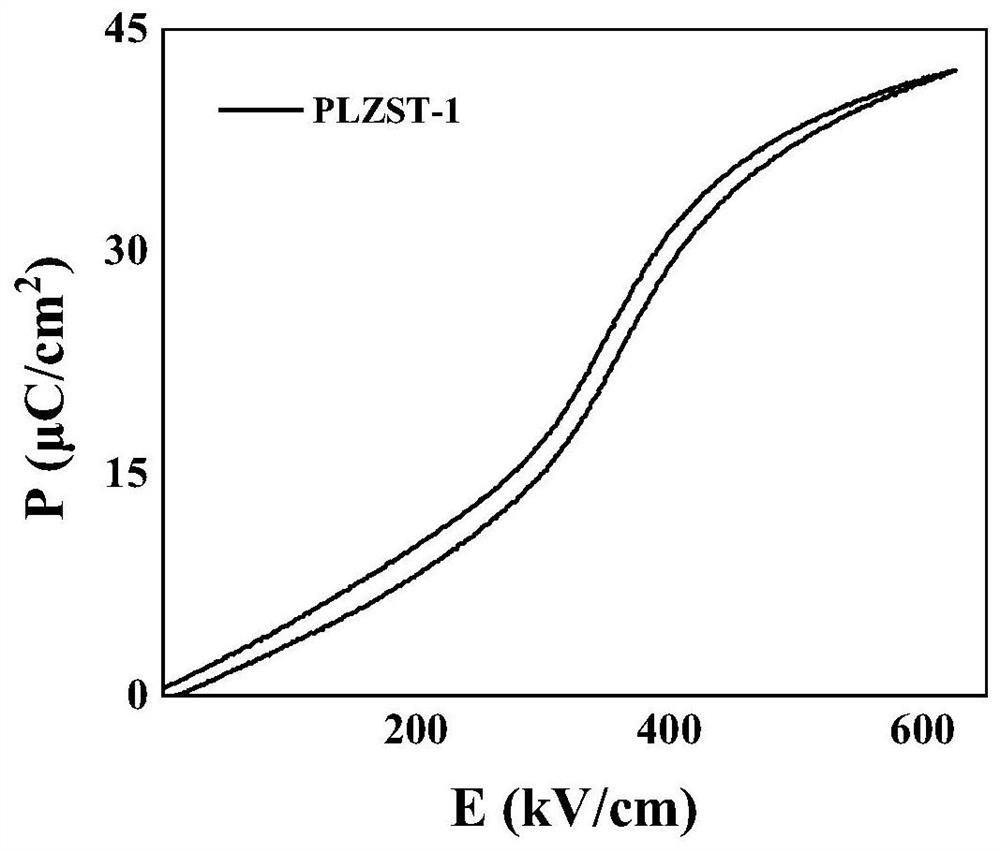

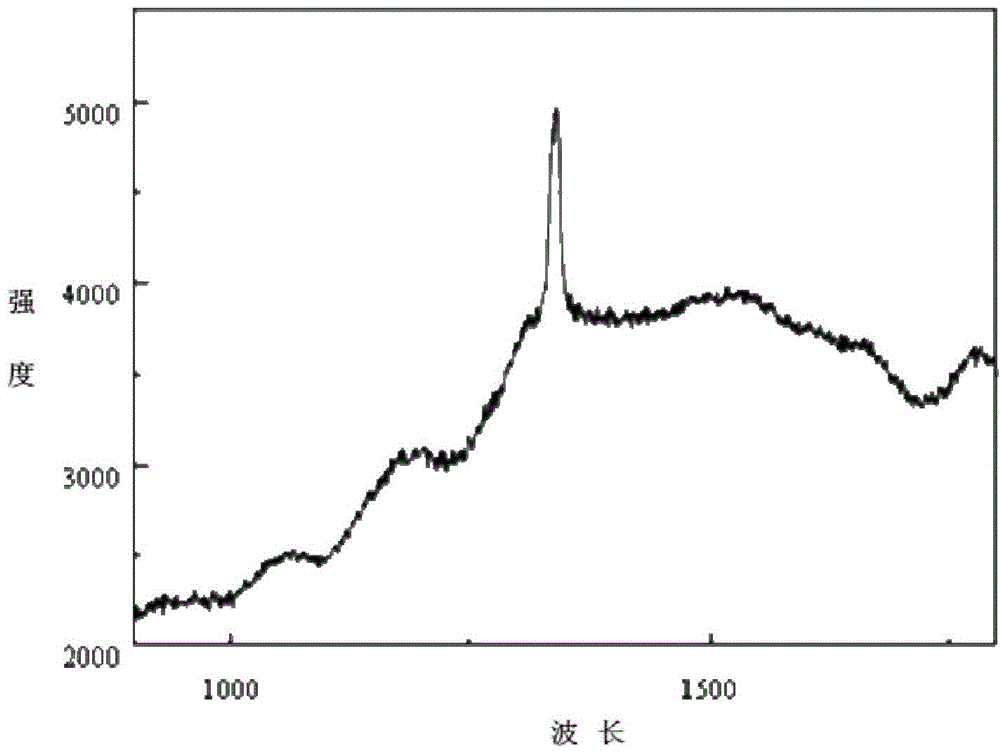

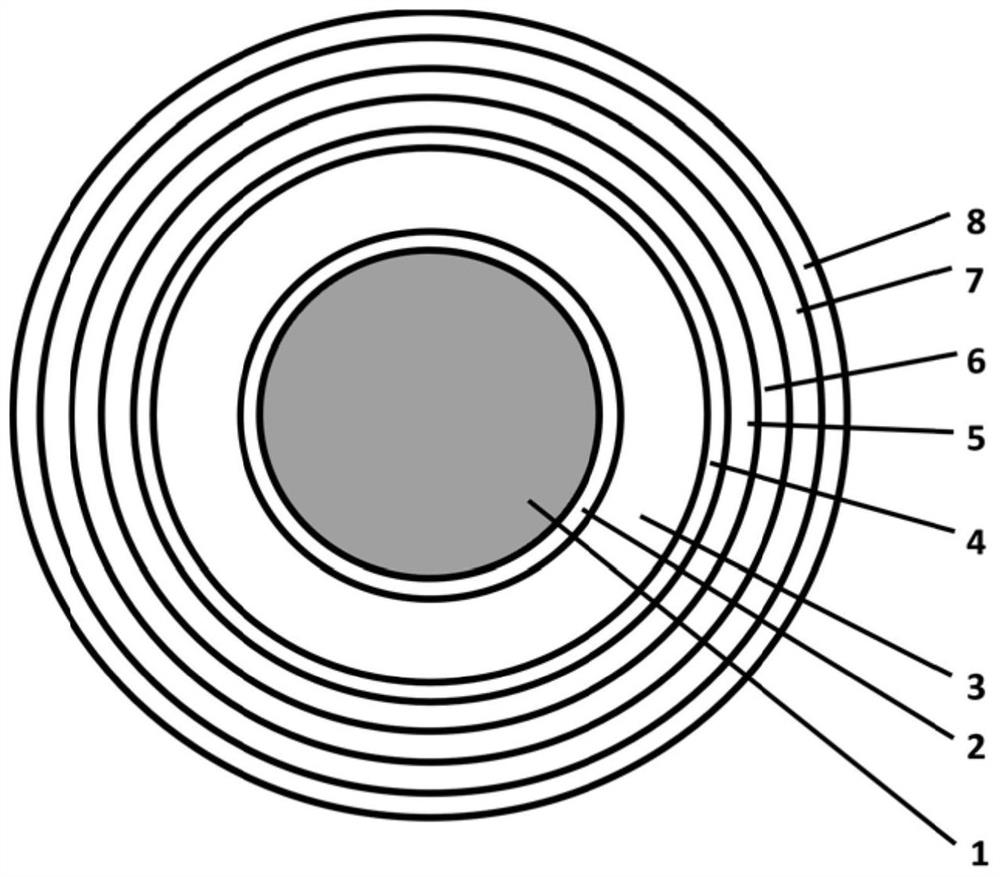

Antiferroelectric material and preparation method thereof, and capacitor containing antiferroelectric material

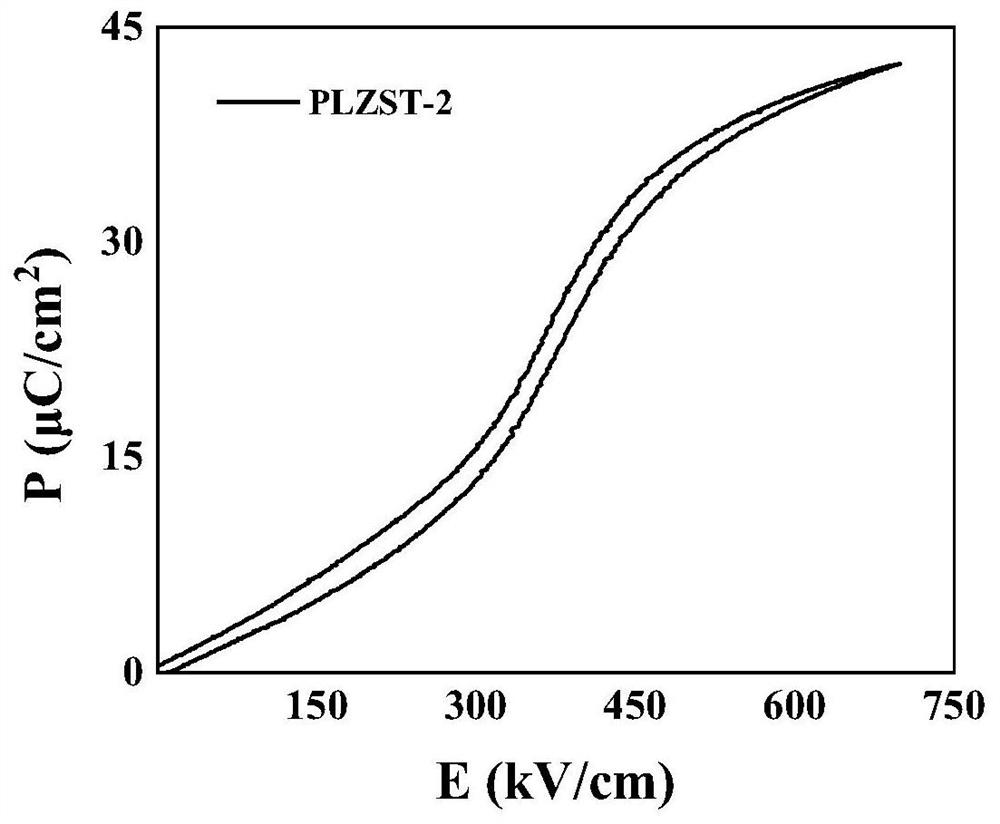

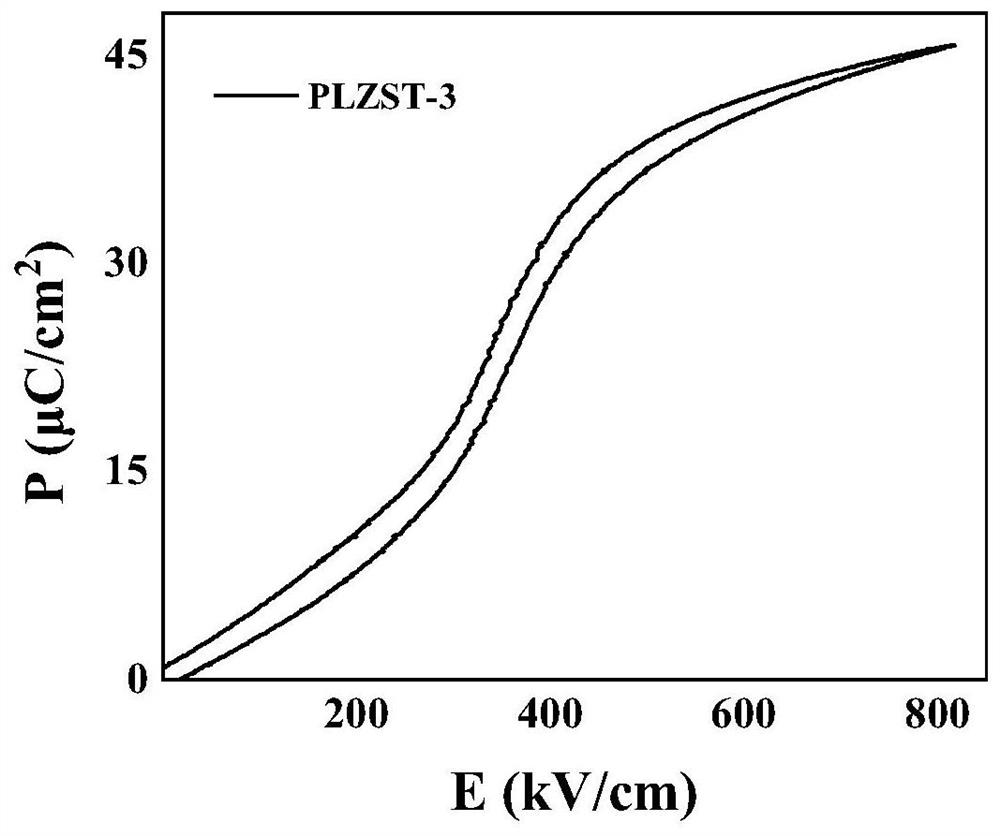

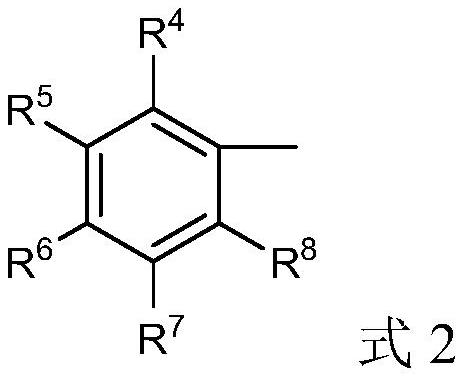

PendingCN111718194AStrong breakdown resistanceHigh energy storage densityThin/thick film capacitorFixed capacitor dielectricFilm capacitorHigh energy

The invention discloses an antiferroelectric material and a preparation method thereof, and a capacitor containing the antiferroelectric material. The antiferroelectric material includes an antiferroelectric body represented by a general formula (Pb<0.94>La<0.04>)(Zr<1-x-y>Sn<x>Ti<y>)O<3>, where x is greater than or equal to 0.3 and smaller than or equal to 0.5, and y is greater than or equal to 0.3 and smaller than or equal to 0.1. The antiferroelectric material can be used for manufacturing the energy storage capacitor. According to the lead lanthanum zirconate titanate stannate antiferroelectric thick-film capacitor prepared by a tape casting method disclosed by the invention, the ultrahigh energy storage efficiency of 90-95% can be achieved, and the capacitor also has relatively strongbreakdown resistance and high energy storage density, so a solid foundation is laid for researching and developing a dielectric energy storage capacitor with excellent energy storage performance; andthe capacitor has a very good application value.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Thermoplastic cable with modified polypropylene insulating layer

ActiveCN113571233AHigh volume resistivityStrong breakdown resistancePlastic/resin/waxes insulatorsClimate change adaptationThermoplasticPolymer science

The invention belongs to the electrical field, and relates to a thermoplastic cable with a modified polypropylene insulating layer. The cable comprises at least one conductor and at least one electrical insulation layer surrounding the conductor, wherein the electrical insulation layer is made of at least one silane grafted modified polypropylene material; the silane grafted modified polypropylene material comprises a structural unit derived from co-polypropylene and a structural unit derived from an alkenyl-containing silane monomer; and on the basis of the weight of the silane grafted modified polypropylene material, the content of a structural unit which is derived from an alkenyl-containing silane monomer and is in a grafted state in the silane grafted modified polypropylene material is 0.2-6 wt%. The cable provided by the invention has higher working temperature, and has the advantages of thinner electrical insulation layer thickness, better heat dissipation and lighter weight under the condition of ensuring the same voltage class and insulation level.

Owner:CHINA PETROLEUM & CHEM CORP +2

High-wear-resistance charge roller and processing technique thereof

The invention relates to the technical field of charge rollers, in particular to a high-wear-resistance charge roller and a processing technique thereof. The high-wear-resistance charge roller comprises a roller shaft, a foam conductive sponge layer sleeving the roller shaft, and a conductive nylon sleeve that sleeves the foam conductive sponge layer; the conductive nylon sleeve is made from the following materials according to parts by weight: 80-120 parts of PA12 resin, 25-45 parts of a filler, 10-20 parts of polyethylene, 6-10 parts of a wear-resistant modifier, 4-8 parts of a flexibilizer, 2-6 parts of a coupling agent, 1-5 parts of a lubricating agent, 1-3 parts of a flame retardant, and 1-2 parts of a conductive agent. The charge roller of the invention has the advantages that the charge roller is imparted good wear resistance, bright appearance and high quality by using the conductive nylon sleeve; the charge roller is high in stability and pollution resistance; the charge roller with high breakthrough resistance supports various drum cores in market. The charge roller of the invention is good in wear resistance and long in service life.

Owner:DONGGUAN WALTON RUBBER & PLASTIC NEW MATERIAL CO LTD

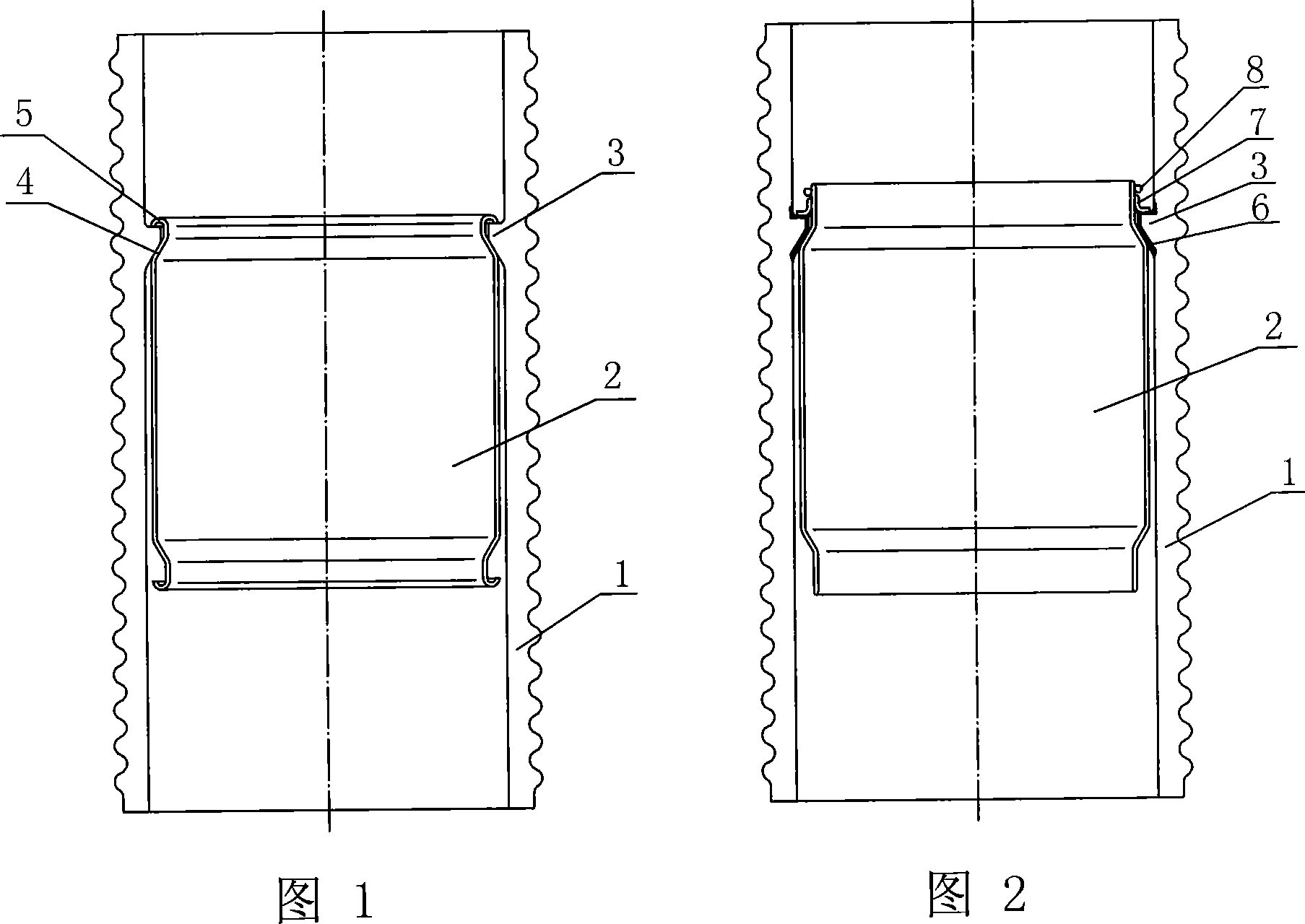

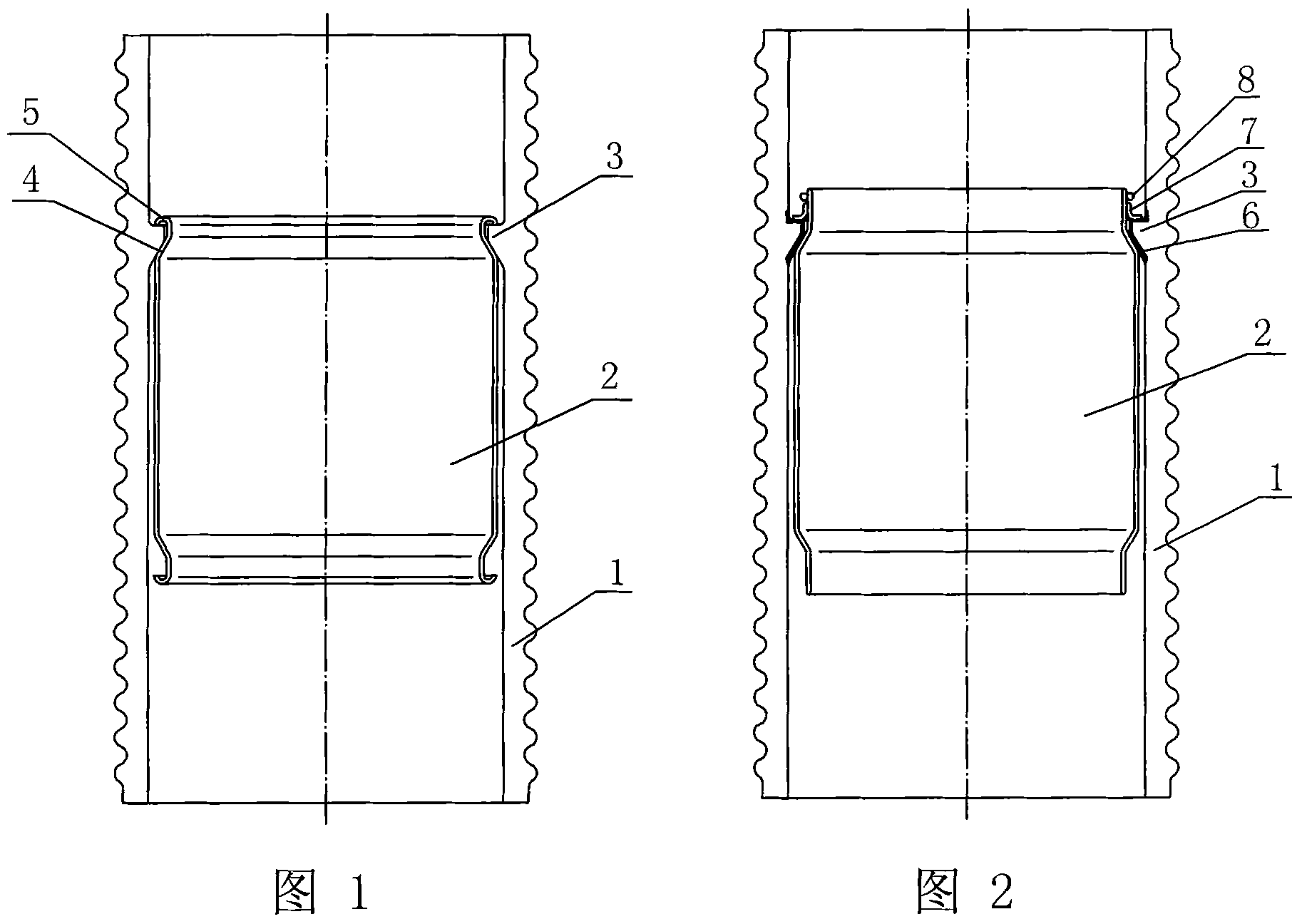

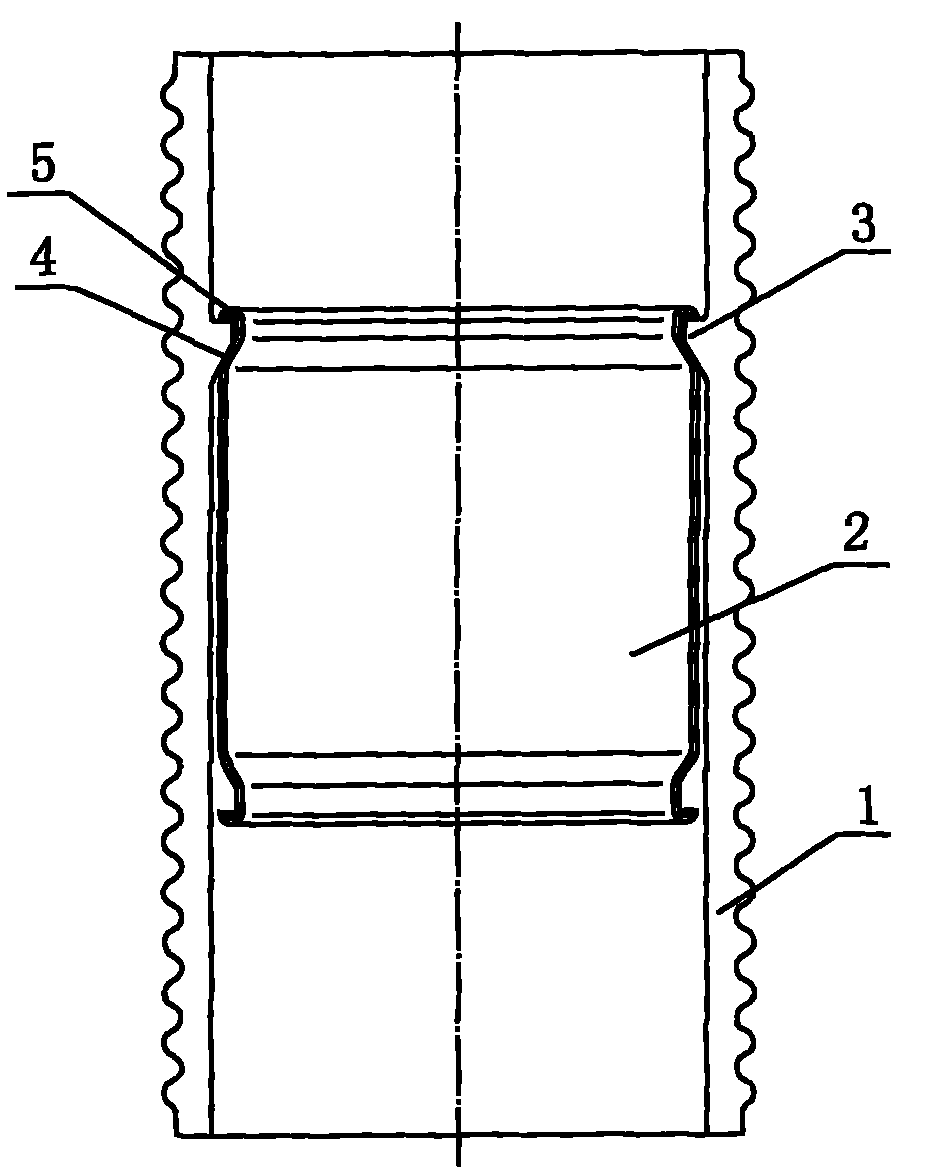

Vacuum arc-extinction porcelain shell component and its making technology

ActiveCN101236858AAvoid pollutionSolve sheddingHigh-tension/heavy-dress switchesAir-break switchesExtinctionEngineering

The invention relates to a vacuum arc extinguishing chamber ceramic shell component and a process for manufacturing the same, wherein the ceramic shell component comprises a ceramic shell and a shielding barrel; the inner wall of the ceramic shell is provided with a stiffener rib on which the shielding barrel is fixed; the edge of an upper opening of the shielding barrel is tightly pressed on the stiffener rib in a form of flanging structure, and the shape of the outer side surface of the upper opening part of the shielding barrel had better adapt to the stiffener rib. When the invention is manufactured, the shielding barrel is arranged in the ceramic shell, and the height of the edge of the upper opening of the shielding barrel is over the height of the stiffener rib of the ceramic shell; the shielding barrel is moved upward, so that the upper opening part of the shielding barrel correspondingly contact the lower part of the stiffener rib; the upper opening of the shielding barrel is forced to tightly press on the stiffener rib in the form of flanging structure. The ceramic component has the advantages of thoroughly avoiding the problem of the falling off of the shielding barrel, along with simple structure and reliable performance, and thoroughly avoids the problem of the dropout of the shielding barrel, and simple manufacturing process, convenient operation, low production cost, high production efficiency and production qualification rate and no environmental pollution due to the adoption of a tightly clamping and pressing structure instead of a welding structure.

Owner:山东晨鸿电气有限公司

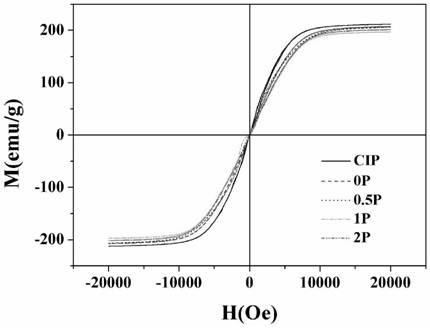

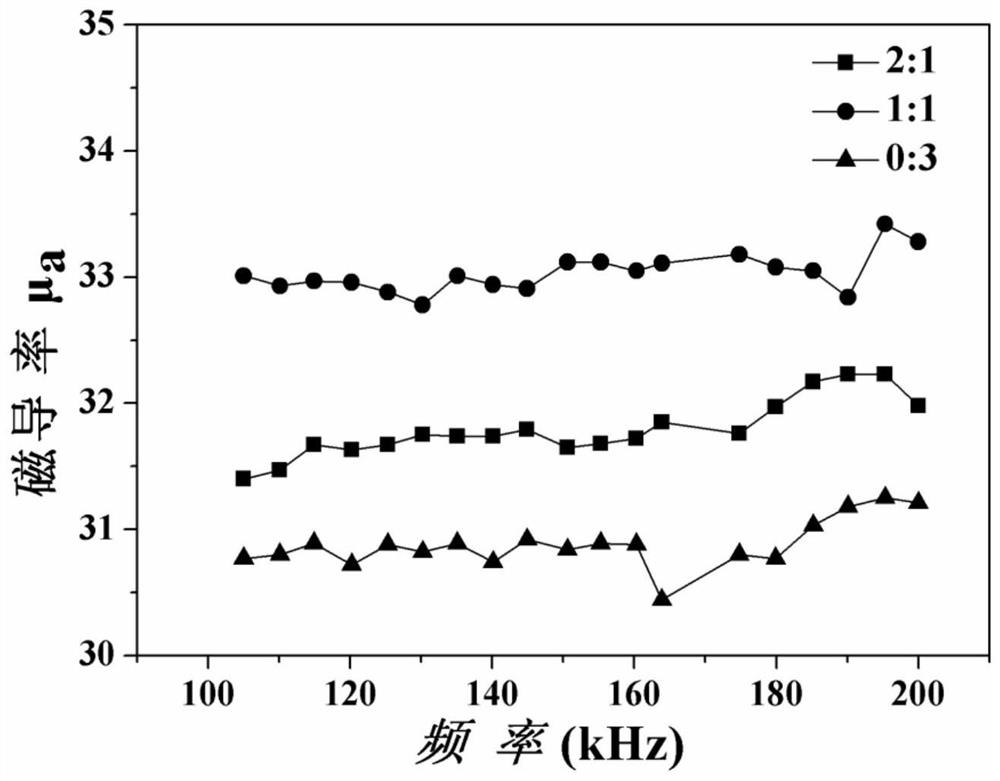

A kind of magnetic powder core and preparation method thereof

ActiveCN109545537BImprove performanceHigh saturation flux densityInductances/transformers/magnets manufactureIron powderPhysical chemistry

The invention provides a method for preparing a magnetic powder core, comprising: mixing carbonyl iron powder with a phosphating solution, and performing phosphating treatment to obtain treated iron powder; drying and sieving the treated iron powder and mixing with an insulating coating agent coating to obtain coated powder; the insulating coating agent includes organic resin, inorganic coating material, coupling agent and curing agent; the coated powder is granulated, pressed and solidified to obtain a magnetic powder core. In the present invention, by selecting a specific insulating coating agent and combining other operations, the magnetic powder core achieves the best comprehensive performance, which not only has high saturation magnetic flux density and stable magnetic permeability and other magnetic performance indicators, but also has breakdown resistance. Strong ability; and excellent molding performance, which meets the molding of complex structure of integrated inductor; mechanical properties can also meet industrial requirements. The present invention makes the insulating coating layer of the magnetic powder core more stable through multi-layer coating combination, and can make the working stability of the manufactured product stronger during the service life.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC CO LTD

High-stability high-reliability self-circulating three-winding autotransformer and manufacturing method thereof

ActiveCN109285681AEasy to oxidizeLarge iron lossInductances/transformers/magnets manufactureFixed transformersEpoxyPolyester

The invention discloses a high-stability high-reliability self-circulating three-winding autotransformer and a manufacturing method thereof. The three-winding autotransformer comprises a framework, windings, a magnetic core, a shielding cover and a packaging material and is characterized in that the framework is an alumina-based porous foamed ceramic framework with the porosity of 20-30%; the windings adopt red copper wires with 1140 epoxy polyester insulating varnish; the magnetic core is a B-shaped silicon steel sheet magnetic core; gaps between the shielding cover and other parts are filledwith self-circulating insulating heat transfer filler, and the self-circulating insulating heat transfer filler is a mixture of alumina-based porous foamed ceramic, non-vulcanized silica gel and gumrosin; the shielding cover is made of aluminum alloy and packaged by a full-closed structure. The autotransformer has the advantages of small loss, high conversion efficiency, good electromagnetic shielding performance, good insulation, high cost performance and long service life.

Owner:平顶山市恒锐电气制造有限公司

Surface-discharge ceramic substrate applied to optical pumping source and manufacturing method of surface-discharge ceramic substrate

ActiveCN104387117AExcellent dielectric propertiesStrong anti-particle erosion abilitySurface dischargeHot filament

The invention discloses a surface-discharge ceramic substrate applied to an optical pumping source. The surface-discharge ceramic substrate comprises a ceramic body and a diamond ablation-resistant coating deposited on the ceramic body, wherein the diamond ablation-resistant coating is deposited in only a region where surface discharge is generated on the surface of the ceramic body. The manufacturing method of the surface-discharge ceramic substrate comprises the following steps: preparing turbid liquid containing diamond powder; pretreating the ceramic body by using a hydrofluoric acid solution and then planting seed crystals for the ceramic body by using the turbid liquid; shielding the region, where no surface discharge is generated, of the ceramic body; depositing the diamond ablation-resistant coating on the surface of the ceramic body by means of hot filament chemical vapor deposition to obtain the surface-discharge ceramic substrate. The surface-discharge ceramic substrate disclosed by the invention is good in plasma ablation resistance, high in reutilization frequency and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

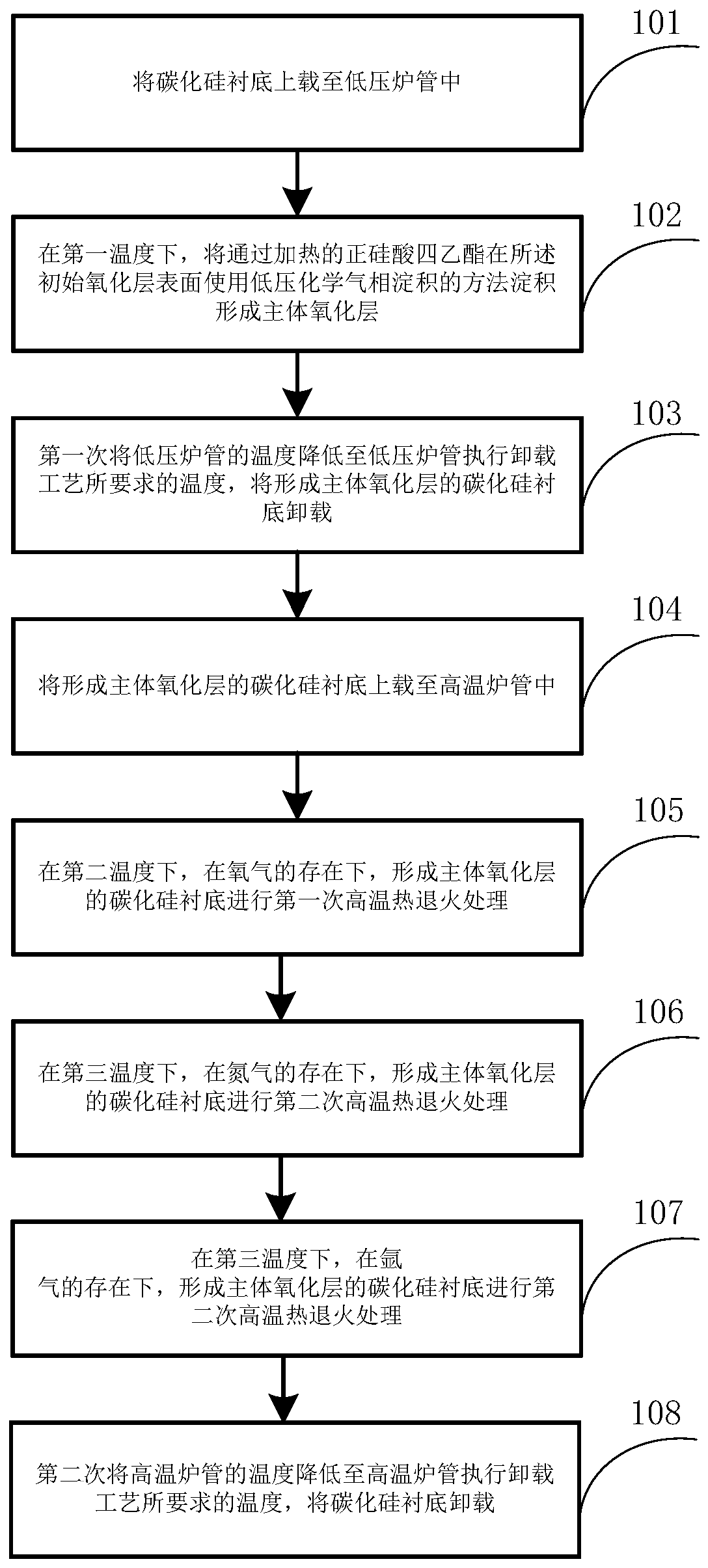

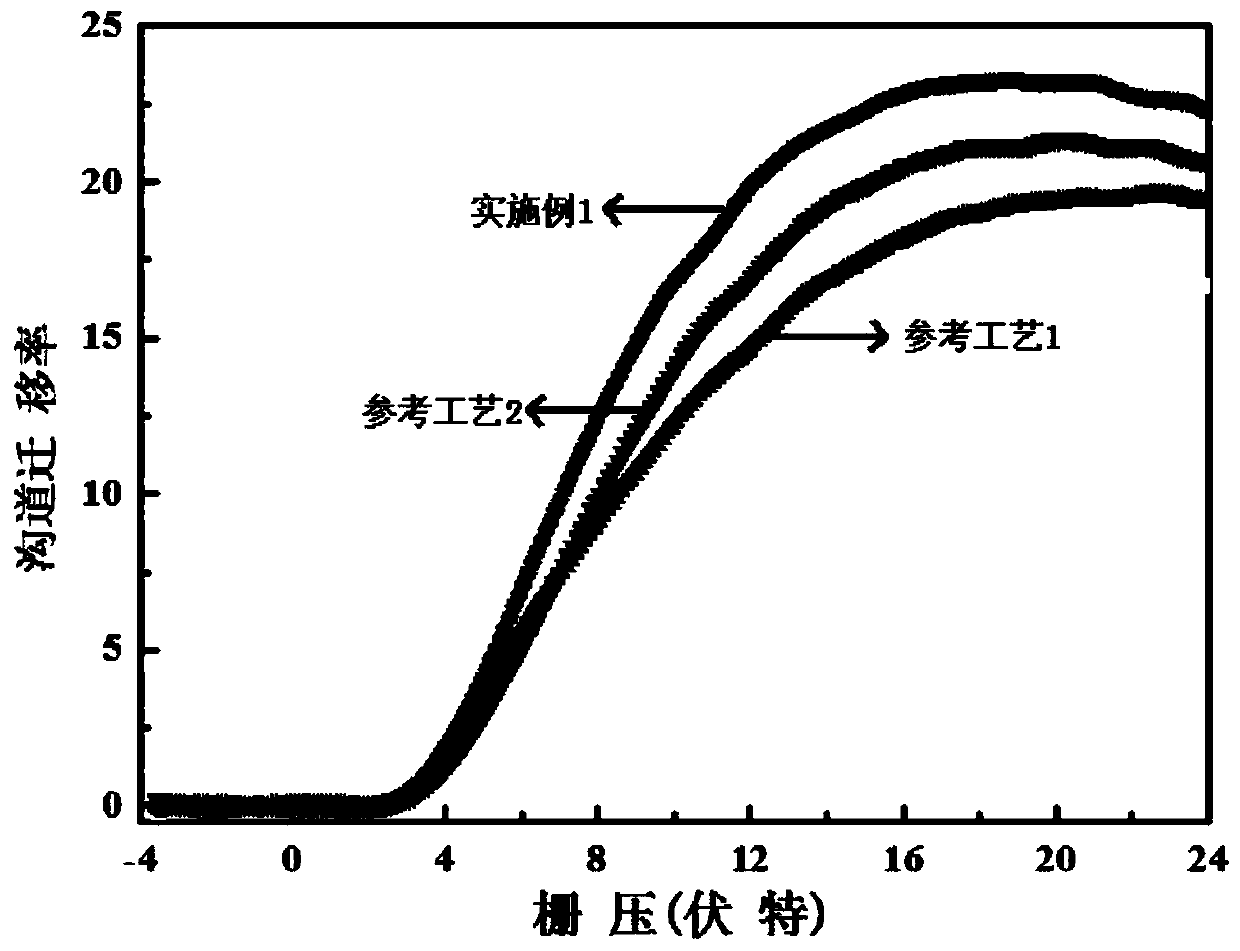

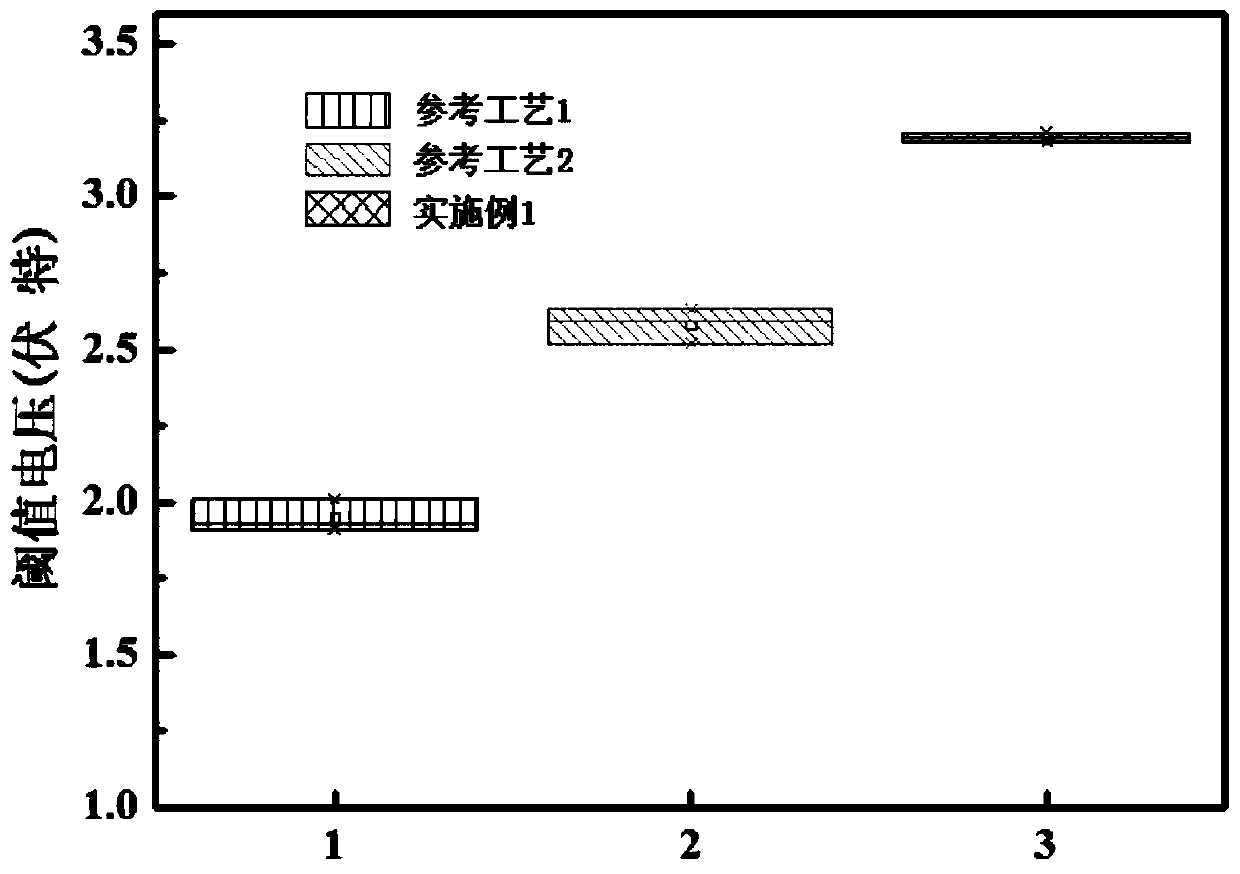

Method for manufacturing gate oxide layer on silicon carbide material

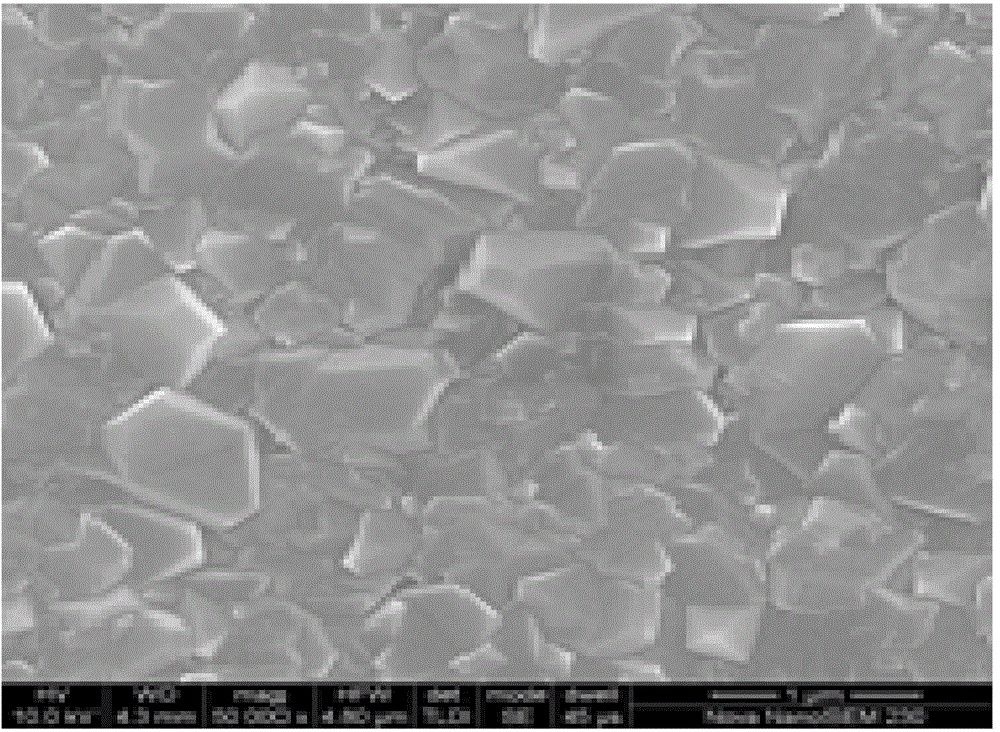

InactiveCN111048413AImprove channel mobilityRaise the threshold voltageSemiconductor/solid-state device manufacturingSemiconductor devicesTetraethyl orthosilicateCarbide silicon

The invention relates to a method for manufacturing a gate oxide layer on a silicon carbide material. The method comprises the steps: depositing silicon dioxide with a thickness of 50-70 nm on a surface of silicon carbide in a low-pressure environment through a method of thermal decomposition of tetraethyl orthosilicate; carrying out first high-temperature annealing on a silicon carbide substrateon which a main body oxide layer is formed in an oxygen environment; then carrying out secondary high-temperature annealing on the oxide layer in a nitrogen atmosphere; and finally, carrying out thirdhigh-temperature treatment on the silicon carbide substrate on which the oxide layer is formed in argon. According to the manufacturing method of the gate oxide layer on the silicon carbide material,the gate oxide layer is more compact, fixed oxide layer charges and interface trapped charges formed in an oxidation process are removed, an interface state of the gate oxide layer is reduced, and performance of the gate oxide layer is improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

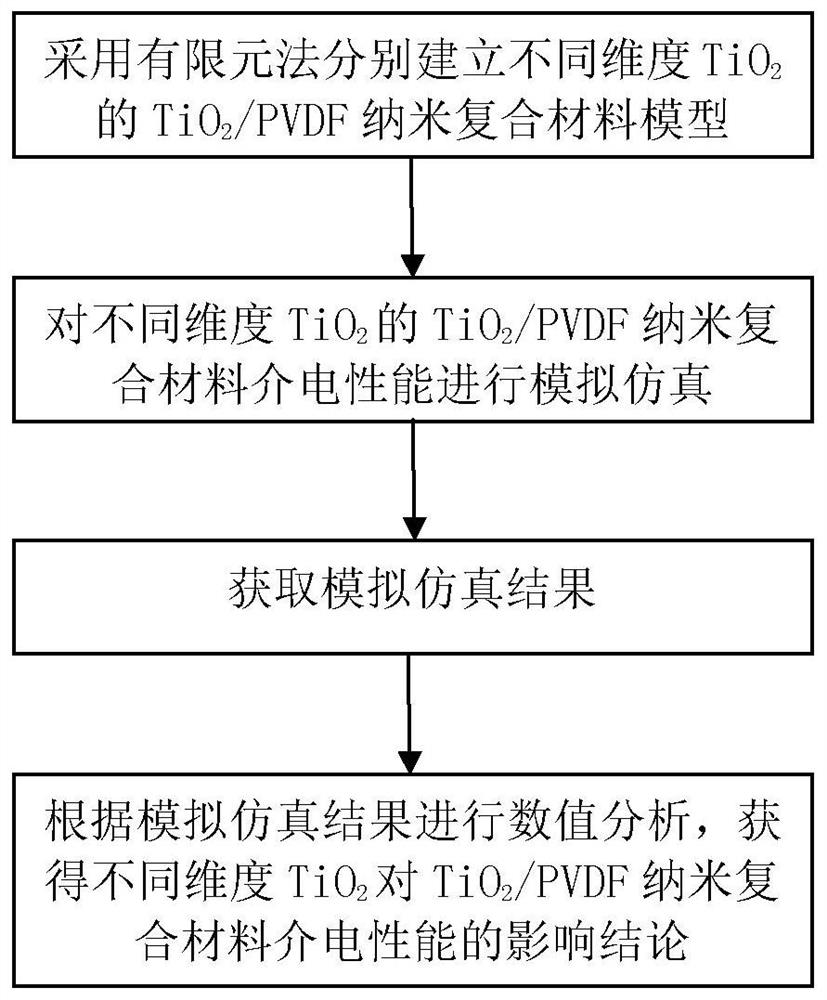

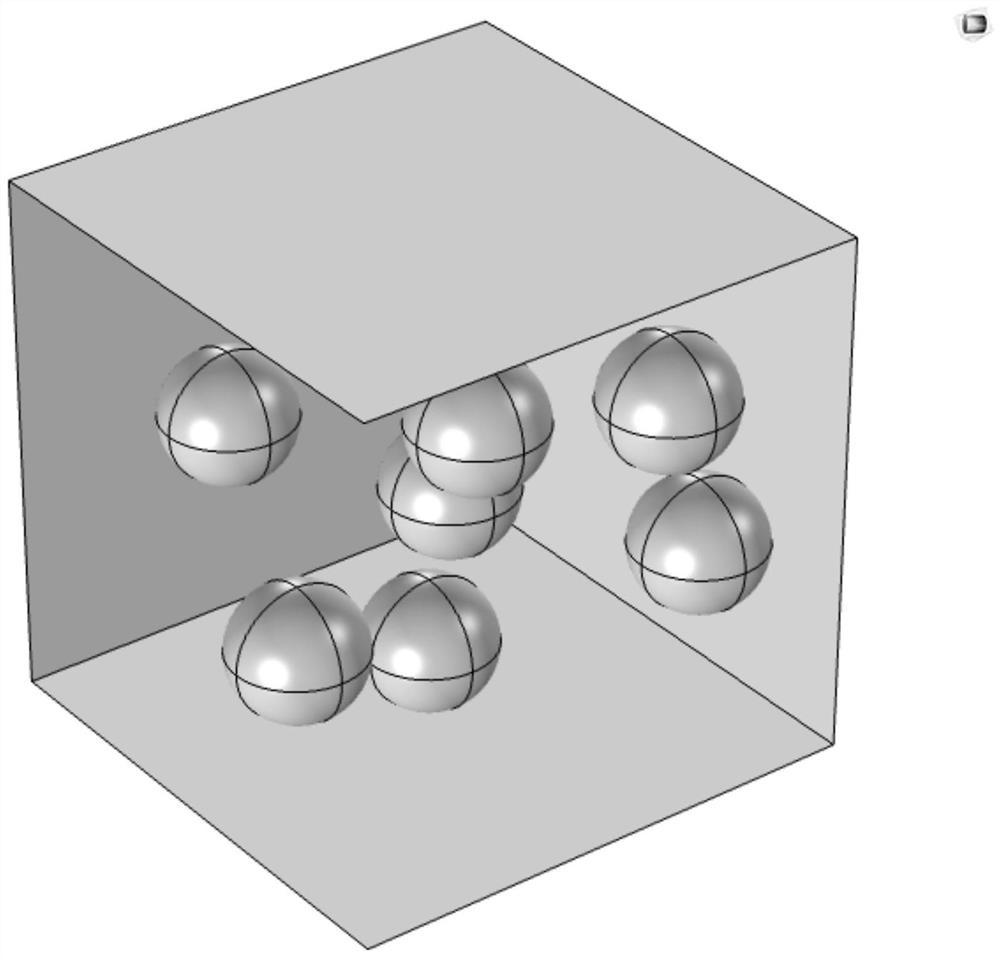

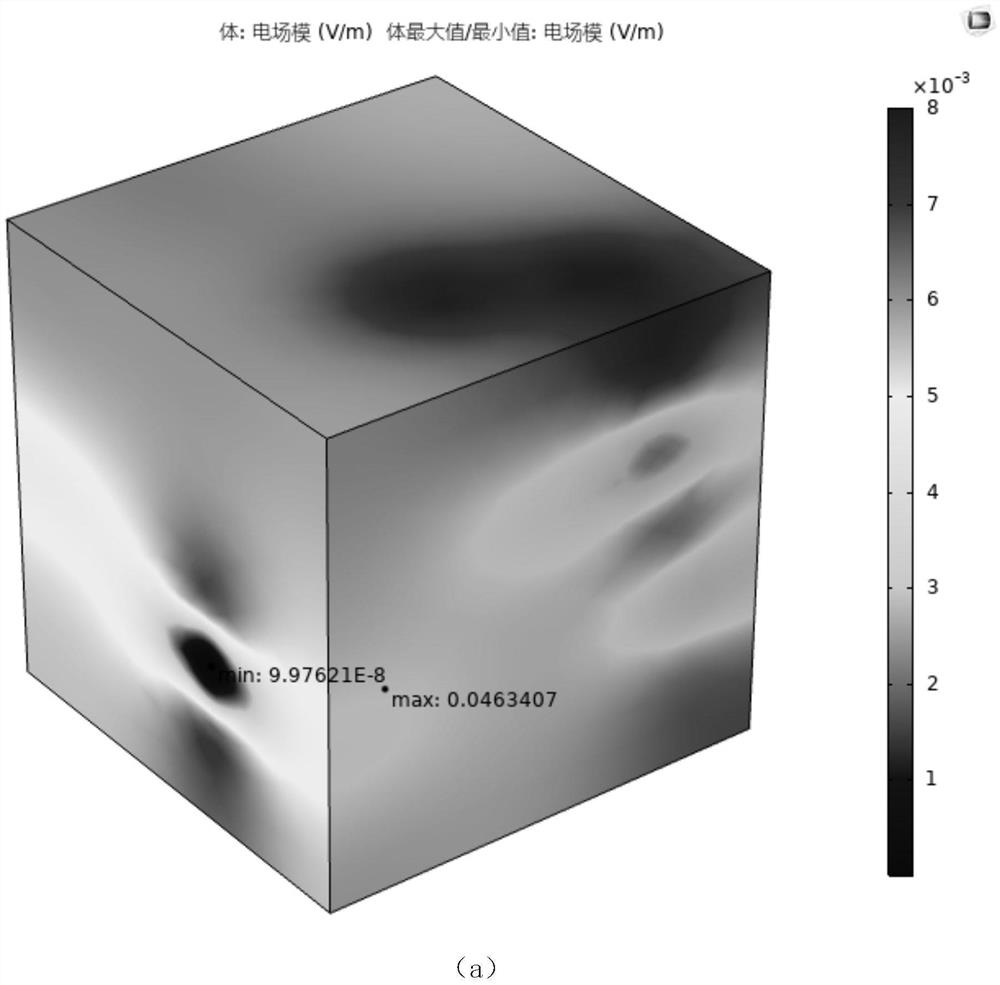

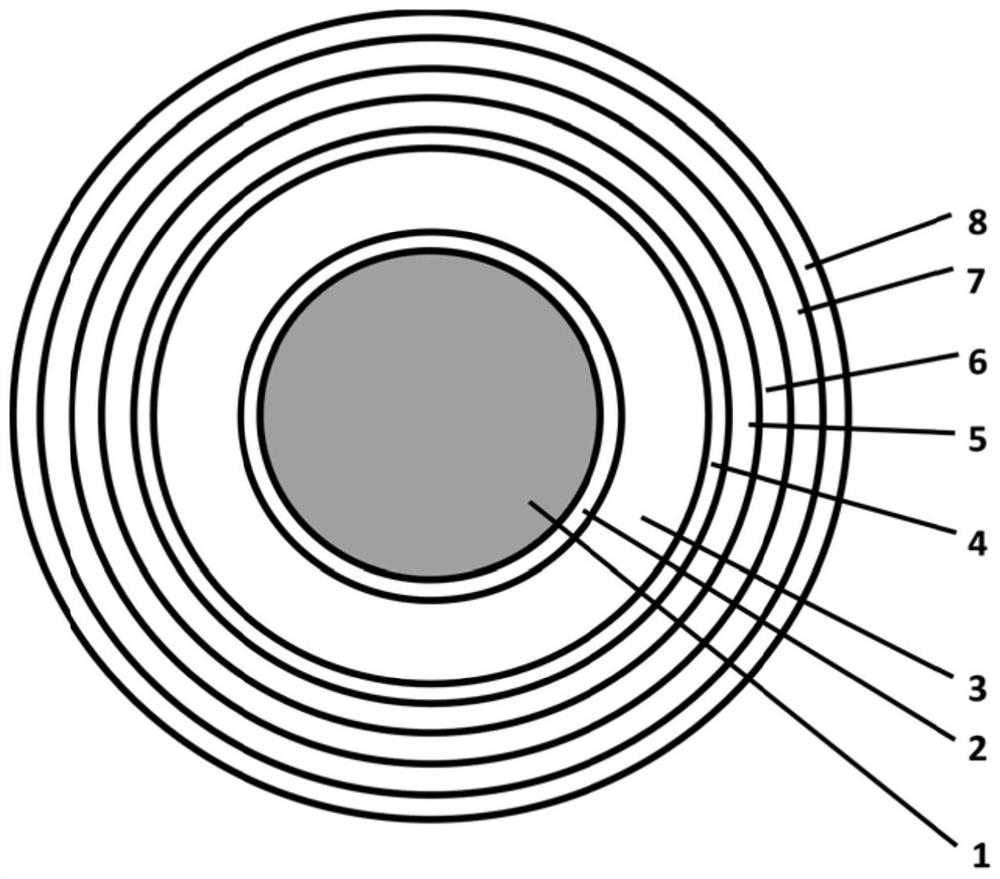

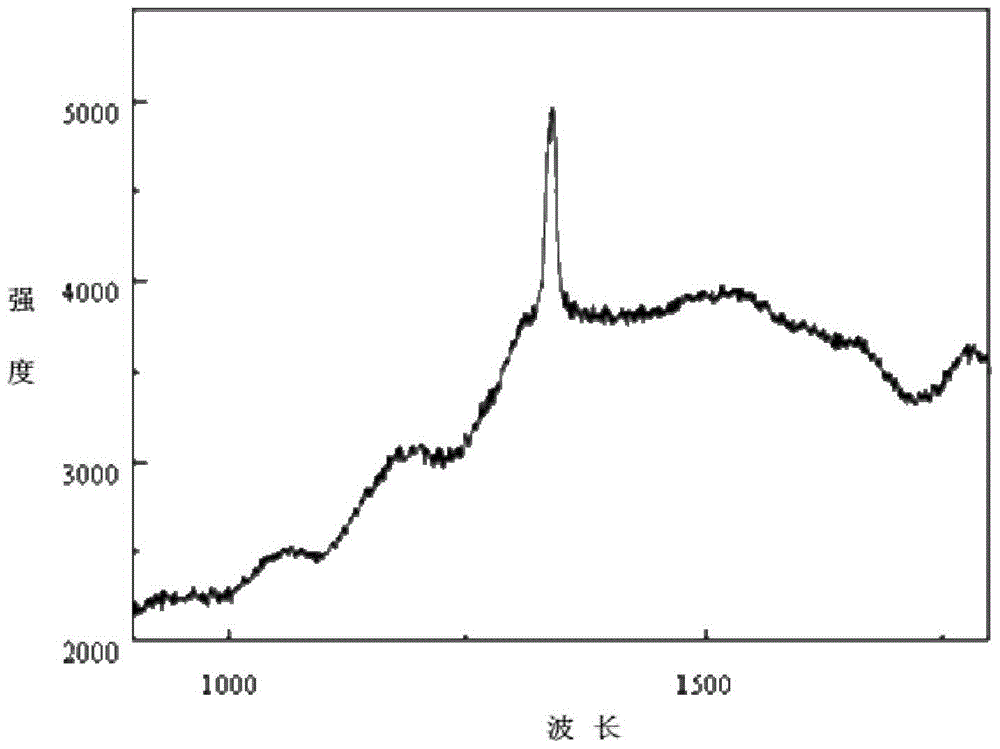

Modeling and simulation method for influence of TiO2 dimension on dielectric property of TiO2/PVDF composite material

PendingCN112329310AUniform leakage current densitySmall distortionDesign optimisation/simulationSpecial data processing applicationsDielectricElectrical field strength

The invention relates to a modeling and simulation method for influence of TiO2 dimension on dielectric properties of a TiO2 / PVDF composite material, belongs to the technical field of composite material dielectric property research, and is used for solving the problem that the influence of TiO2 filler appearance on the dielectric properties of the composite material cannot be better analyzed and determined because the internal microscopic property distribution of the TiO2 / PVDF composite material cannot be intuitively reflected in the prior art. A finite element method is adopted to simulate and simulate the structure and performance of a TiO2 / PVDF composite material system, a two-dimensional model and a three-dimensional model are established, the breakdown mechanism of the composite material is systematically researched from the aspects of electric field intensity, leakage current density and system energy density distribution, and then the influence of filler morphology on the dielectric property of the composite material is researched. Simulation results show that the one-dimensional TiO2 / PVDF composite material has higher breakdown resistance. On one hand, the method is used for systematically researching the dielectric property improvement mechanism of the composite material, on the other hand, the development of the composite material with high energy storage density canbe guided, the research and development cost is reduced, and the research and development period is shortened.

Owner:HARBIN UNIV OF SCI & TECH

Cable with thermoplastic insulating layer

ActiveCN113571235AHigh volume resistivityStrong breakdown resistancePlastic/resin/waxes insulatorsClimate change adaptationPolypropyleneStructural unit

The invention belongs to the electrical field, and relates to a cable with a thermoplastic insulating layer. The cable comprises at least one conductor and at least one electric insulation layer surrounding the conductor, wherein the electrical insulation layer is made of at least one aromatic olefin grafted modified polypropylene material; the aromatic olefin grafted modified polypropylene material comprises a structural unit derived from co-polypropylene and a structural unit derived from a styrene monomer, based on the weight of the aromatic olefin grafted modified polypropylene material, the content of a structural unit which is derived from a styrene monomer and is in a grafted state in the aromatic olefin grafted modified polypropylene material is 0.5-14wt%. The cable provided by the invention has higher working temperature, and has the advantages of thinner electrical insulation layer thickness, better heat dissipation and lighter weight under the condition of ensuring the same voltage class and insulation level.

Owner:CHINA PETROLEUM & CHEM CORP +2

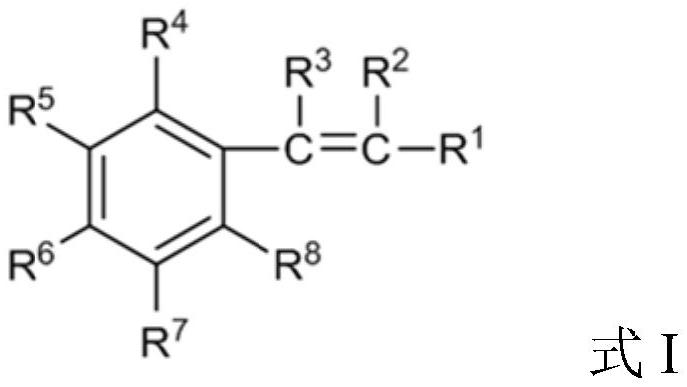

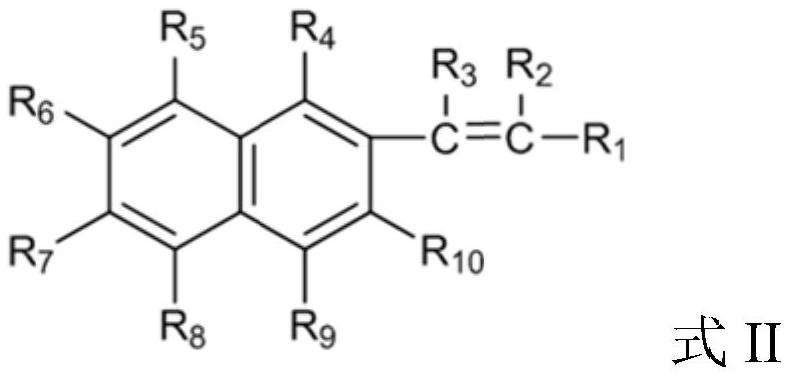

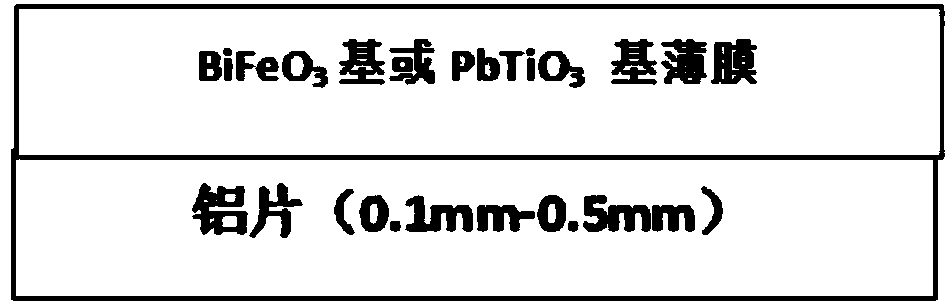

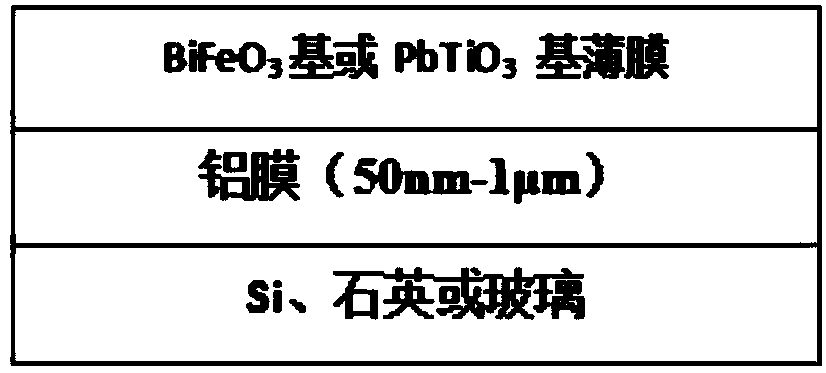

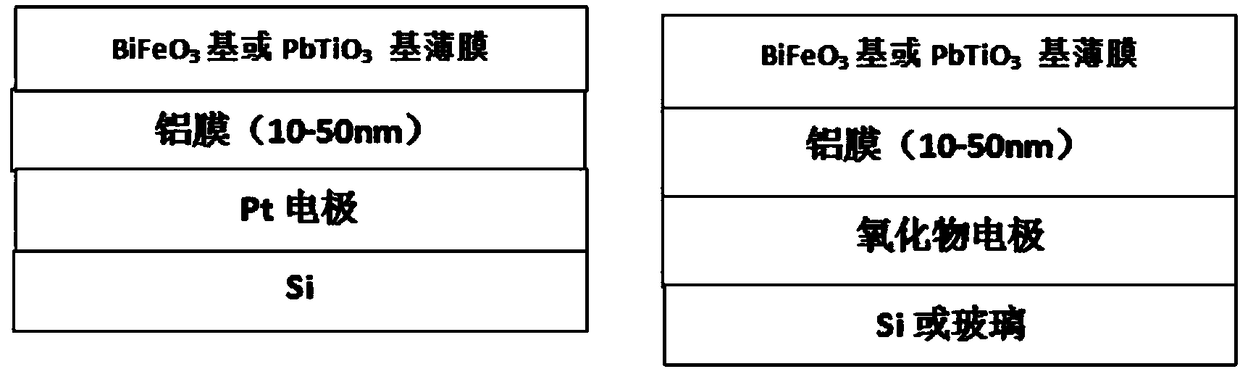

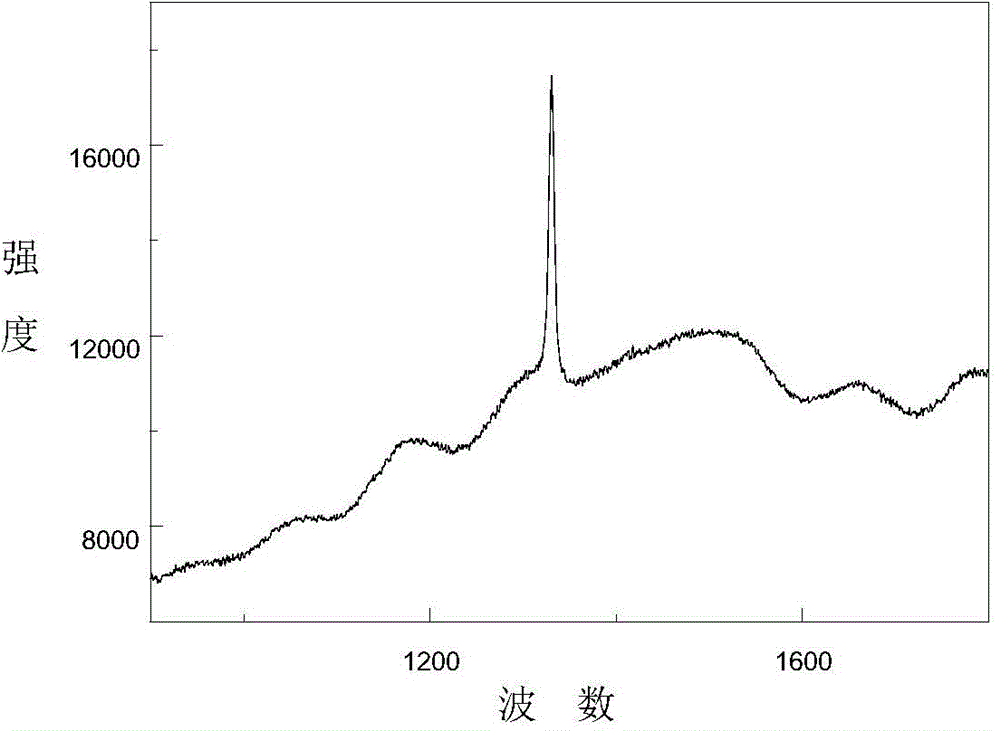

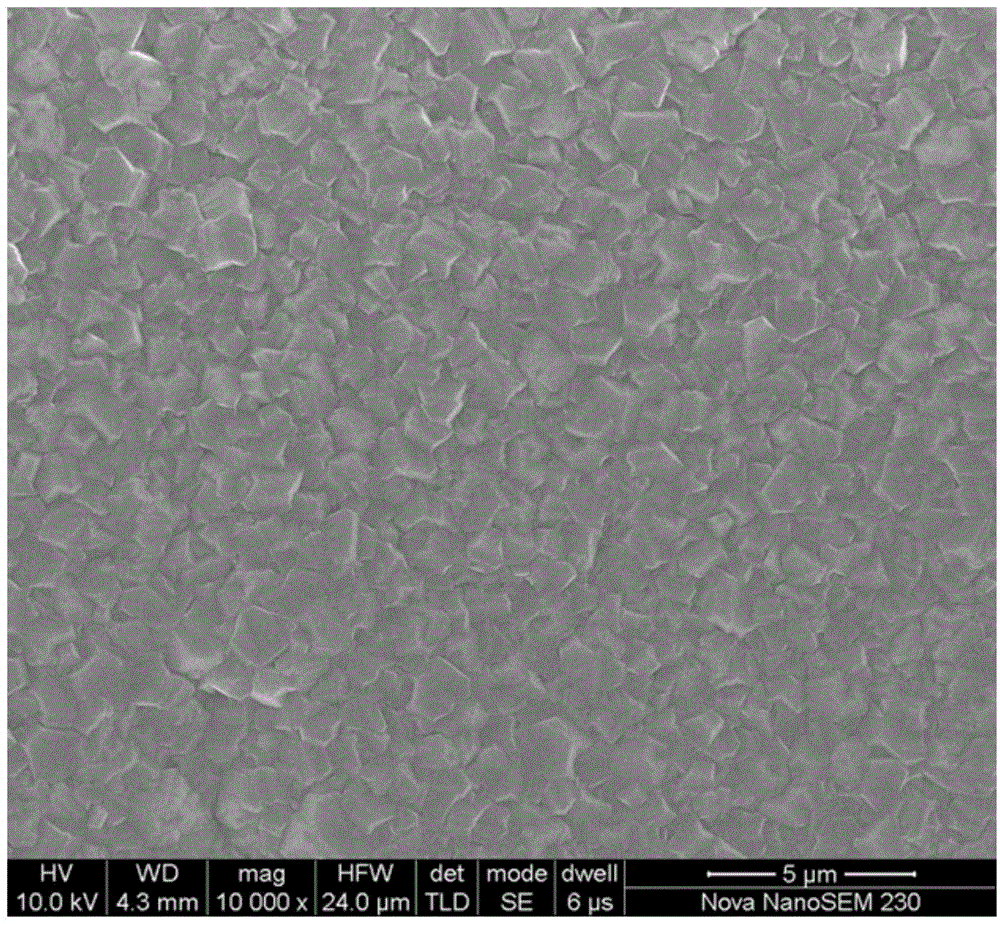

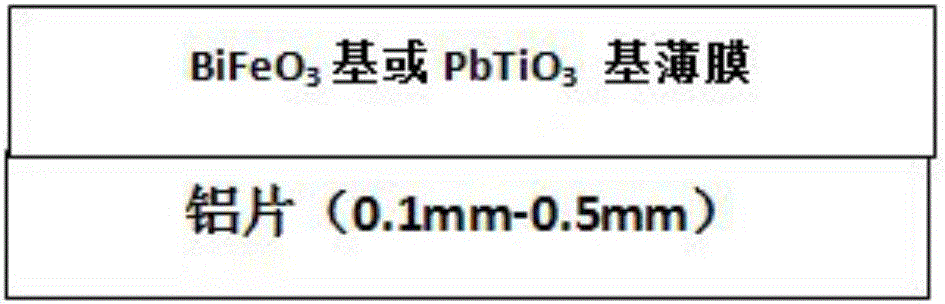

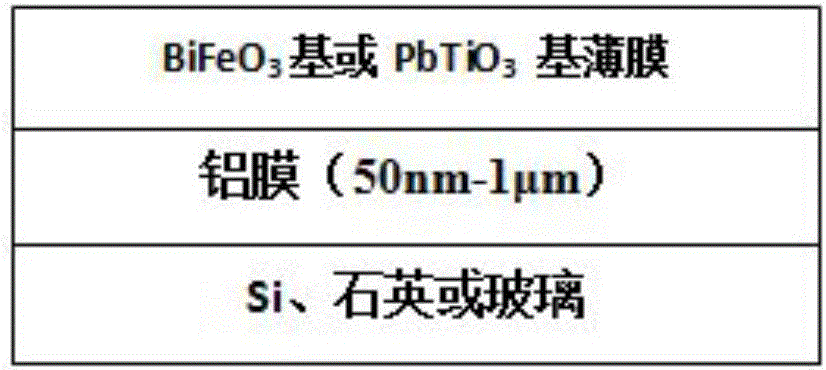

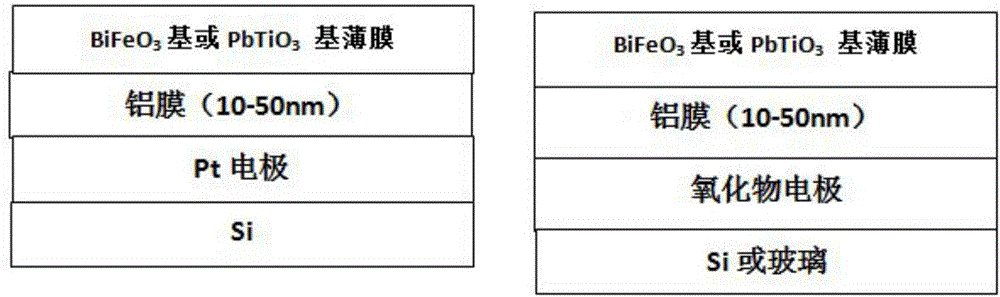

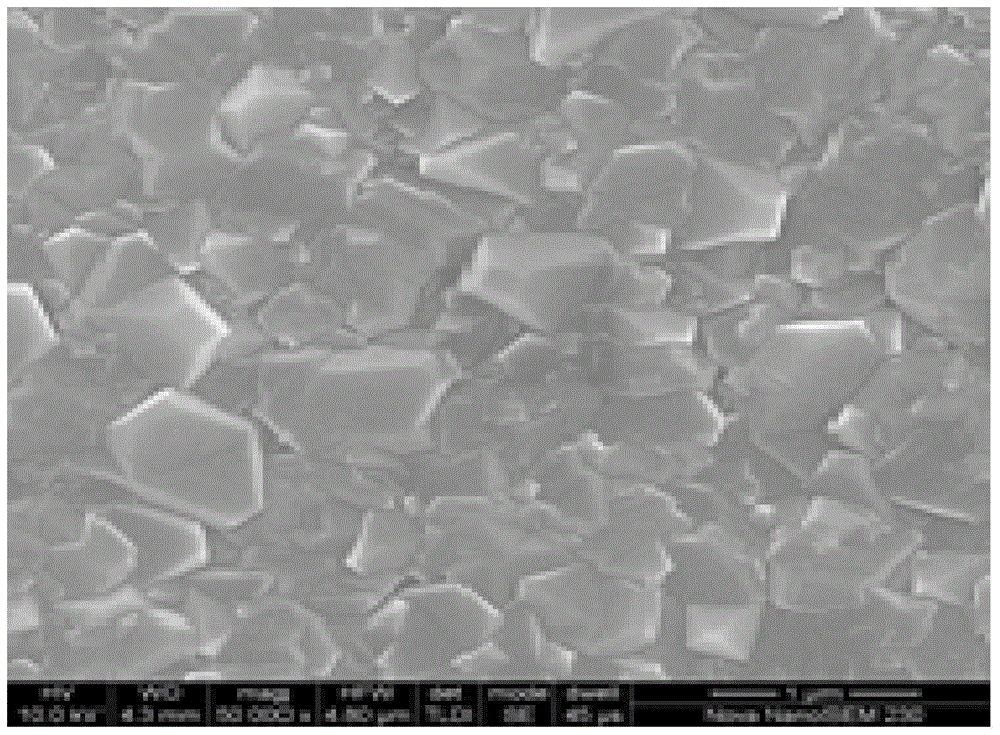

A Method of Improving the Breakdown Resistance of Ferroelectric Thin Films

InactiveCN105932152BImprove breakdown resistanceImprove performancePiezoelectric/electrostrictive device manufacture/assemblyMetallic aluminumFerroelectric thin films

The invention discloses a method for improving the anti-breakdown capability of ferroelectric thin films. In the method, metal aluminum sheets are used as electrodes of ferroelectric thin films, or other materials covered with a layer of aluminum film are used as electrodes of ferroelectric thin films. The electrodes of the electric thin film are pretreated and then the ferroelectric thin film is grown on the pretreated electrode; the electrodes of the ferroelectric thin film are pretreated under gas protection at 300-480°C. The invention first proposes the idea of improving the anti-breakdown ability of the ferroelectric thin film through the selection of electrodes, and provides a feasible electrode. The obtained ferroelectric thin film has strong breakdown resistance, low leakage current, real ferroelectric properties of the thin film can be measured, and has good prospects in the preparation process and device application of the ferroelectric thin film in the future.

Owner:UNIV OF JINAN

Surface discharge type glass substrate for light pumping source and preparation method of surface discharge type glass substrate for light pumping source

ActiveCN104385721AExcellent dielectric propertiesStrong anti-particle erosion abilityLaser detailsGlass/slag layered productsQuartzCorneal ablation

The invention discloses a surface discharge type glass substrate for a light pumping source. The surface discharge glass substrate comprises a quartz glass body and a diamond ablation-resisting coating deposited on the quartz glass body, wherein the diamond ablation-resisting coating is only deposited on the surface of the quartz glass body, so that a surface discharge region is generated. The preparation method provided by the invention comprises the following steps: preparing a diamond-powder-containing turbid liquid; grinding the surface of the quartz glass body by using the turbid liquid, and then performing ultrasonic oscillating pretreatment; shielding a region, in which surface discharge is not generated, on the quartz glass body; and forming the diamond ablation-resisting coating on the surface of the quartz glass body by performing hot filament chemical vapor deposition to obtain the surface discharge type glass substrate. The surface discharge type glass substrate provided by the invention has the advantages of plasma ablation resistance, high reusing time, low cost and the like.

Owner:NAT UNIV OF DEFENSE TECH

Insulator with diamond protective layer and production method thereof

InactiveCN102024534BStrong anti-pollution performanceGood UV resistanceInsulatorsUltraviolet lightsChemical vapor deposition

The invention discloses an insulator with a diamond protective layer and a production method thereof. The insulator comprises an insulator body, wherein the part on the outer surface of the insulator body, which is not contacted with an electric wire, is fully deposited with the diamond protective layer, and the thickness of the diamond protective layer is 60 nanometers to 1000 nanometers; and the method for producing the insulator with the diamond protective layer comprises the following steps of: firstly, shielding the part which is arranged on the outer surface of the insulator body and contacted with the electric wire; secondly, producing the diamond protective layer on the outer surface of the insulator body through chemical vapor deposition to obtain the insulator. The insulator provided by the invention has good anti-pollution performance and excellent ability to resist ultraviolet light, and plays an important role in reducing the occurrence of pollution flashover accidents.

Owner:刘铁林 +1

Method for improving breakdown-resistant ability of ferroelectric film

InactiveCN105932152AImprove electrical performanceImprove performancePiezoelectric/electrostrictive device manufacture/assemblyMetallic aluminumFerroelectric thin films

The invention discloses a method for improving a breakdown-resistant ability of a ferroelectric film. The method for improving the breakdown-resistant ability of the ferroelectric film comprises the steps of using a metallic aluminum sheet as an electrode of the ferroelectric film or using an other material having a surface thereof coated with a layer of an aluminum film as the electrode of the ferroelectric film, carrying out preprocessing for the electrode of the ferroelectric film and then growing the ferroelectric film on the pre-processed electrode; and carrying out preprocessing for the electrode of the ferroelectric film under gas protection and at 300-480 DEG C. According to the method for improving the breakdown-resistant ability of the ferroelectric film, an idea of improving the breakdown-resistant ability of the ferroelectric film through selection of the electrode is firstly proposed, and the feasible electrode is provided. The obtained ferroelectric film has very strong breakdown-resistant ability, the leakage current is very low, the true ferroelectric performance of the film can be detected, and the method for improving the breakdown-resistant ability of the ferroelectric film has good prospect in preparation process and device application of the ferroelectric film in future.

Owner:UNIV OF JINAN

High-performance polypropylene cable

ActiveCN113571237AHigh volume resistivityStrong breakdown resistancePlastic/resin/waxes insulatorsInsulated cablesPolypropyleneStructural unit

The invention belongs to the electrical field, and relates to a high-performance polypropylene cable. The cable comprises at least one conductor and at least one electric insulation layer surrounding the conductor; wherein the electrical insulation layer is made of at least one polypropylene graft containing anhydride groups; the polypropylene graft containing the anhydride group comprises a structural unit derived from co-polypropylene, a structural unit derived from an anhydride monomer and a structural unit derived from an alkenyl-containing polymeric monomer. The cable provided by the invention has higher working temperature, and has the advantages of thinner electrical insulation layer thickness, better heat dissipation and lighter weight under the condition of ensuring the same voltage class and insulation level.

Owner:CHINA PETROLEUM & CHEM CORP +2

Vacuum arc-extinction porcelain shell component and its making technology

ActiveCN101236858BEasy to fixSolve sheddingHigh-tension/heavy-dress switchesAir-break switchesExtinctionEngineering

The invention relates to a vacuum arc extinguishing chamber ceramic shell component and a process for manufacturing the same, wherein the ceramic shell component comprises a ceramic shell and a shielding barrel; the inner wall of the ceramic shell is provided with a stiffener rib on which the shielding barrel is fixed; the edge of an upper opening of the shielding barrel is tightly pressed on thestiffener rib in a form of flanging structure, and the shape of the outer side surface of the upper opening part of the shielding barrel had better adapt to the stiffener rib. When the invention is manufactured, the shielding barrel is arranged in the ceramic shell, and the height of the edge of the upper opening of the shielding barrel is over the height of the stiffener rib of the ceramic shell; the shielding barrel is moved upward, so that the upper opening part of the shielding barrel correspondingly contact the lower part of the stiffener rib; the upper opening of the shielding barrel isforced to tightly press on the stiffener rib in the form of flanging structure. The ceramic component has the advantages of thoroughly avoiding the problem of the falling off of the shielding barrel,along with simple structure and reliable performance, and thoroughly avoids the problem of the dropout of the shielding barrel, and simple manufacturing process, convenient operation, low production cost, high production efficiency and production qualification rate and no environmental pollution due to the adoption of a tightly clamping and pressing structure instead of a welding structure.

Owner:山东晨鸿电气有限公司

Self-circulating three-winding autotransformer and manufacturing method thereof

InactiveCN109285681BEasy to oxidizeReduced service lifeInductances/transformers/magnets manufactureFixed transformersEpoxyPolyester

The invention discloses a high-stability high-reliability self-circulating three-winding autotransformer and a manufacturing method thereof. The three-winding autotransformer comprises a framework, windings, a magnetic core, a shielding cover and a packaging material and is characterized in that the framework is an alumina-based porous foamed ceramic framework with the porosity of 20-30%; the windings adopt red copper wires with 1140 epoxy polyester insulating varnish; the magnetic core is a B-shaped silicon steel sheet magnetic core; gaps between the shielding cover and other parts are filledwith self-circulating insulating heat transfer filler, and the self-circulating insulating heat transfer filler is a mixture of alumina-based porous foamed ceramic, non-vulcanized silica gel and gumrosin; the shielding cover is made of aluminum alloy and packaged by a full-closed structure. The autotransformer has the advantages of small loss, high conversion efficiency, good electromagnetic shielding performance, good insulation, high cost performance and long service life.

Owner:平顶山市恒锐电气制造有限公司

A kind of cable material filler and preparation method thereof

ActiveCN104109366BGood light fastnessImprove heat resistanceRubber insulatorsPolyamideZinc glycinate

Owner:ZHEJIANG XINYUANHONG MACROMOLECULE MATERIAL

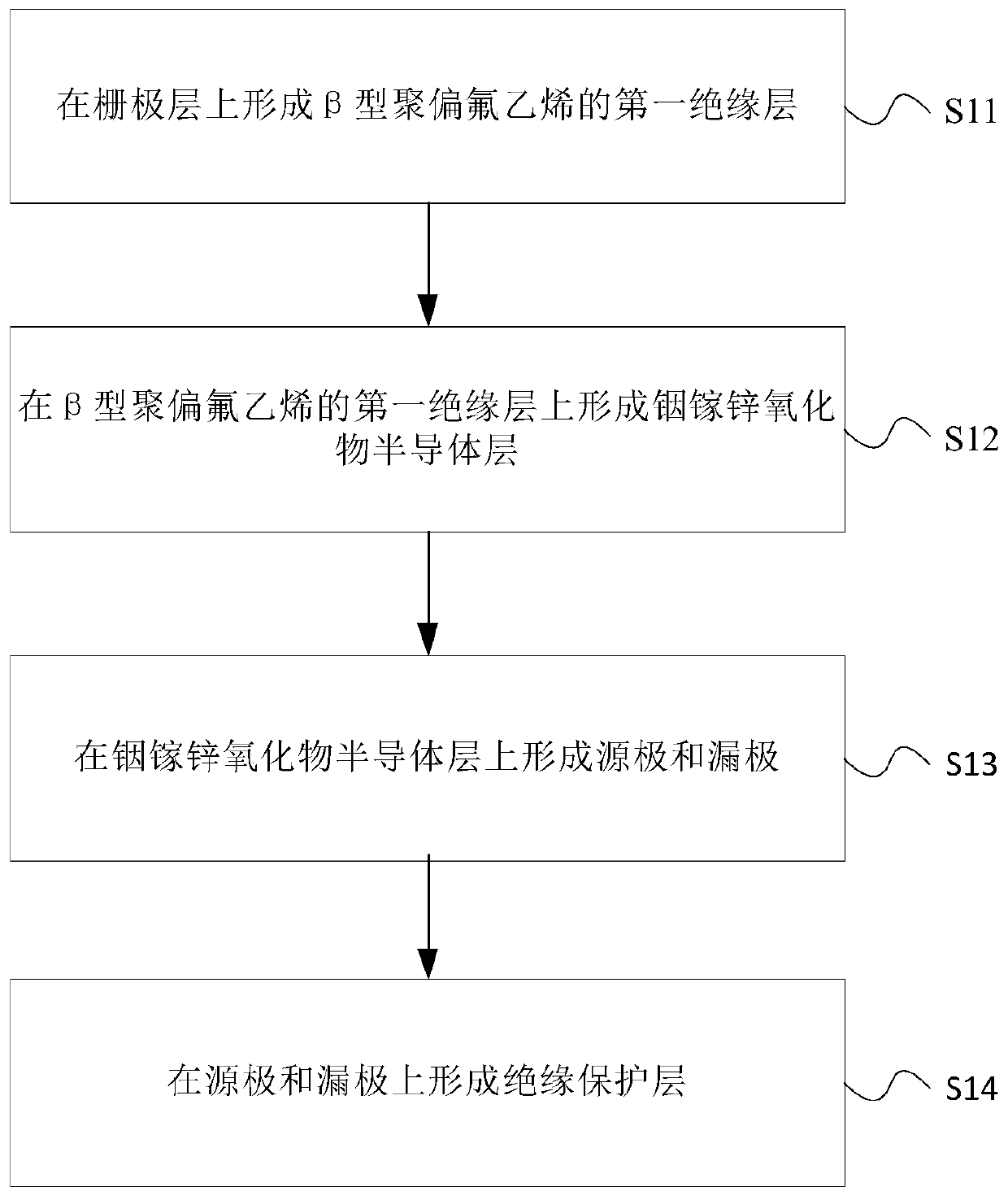

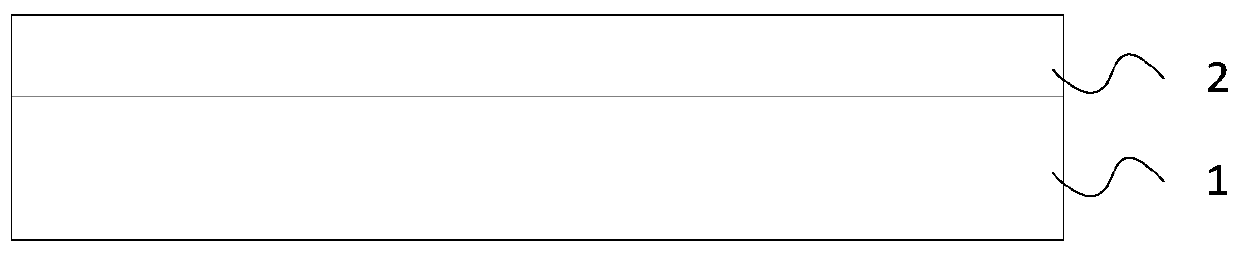

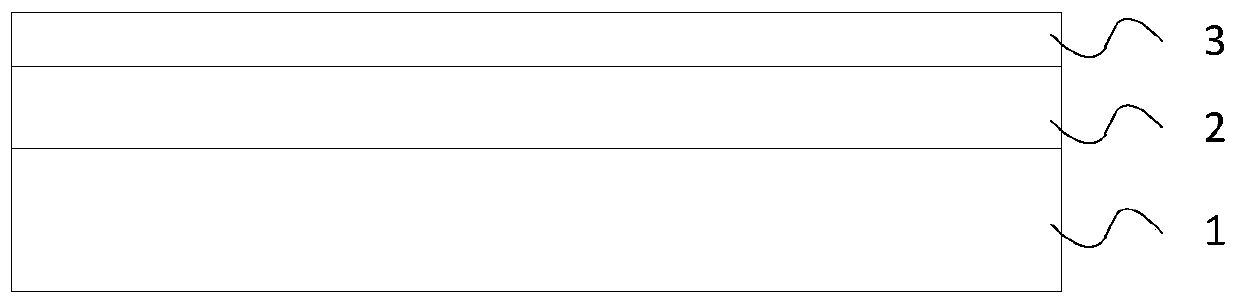

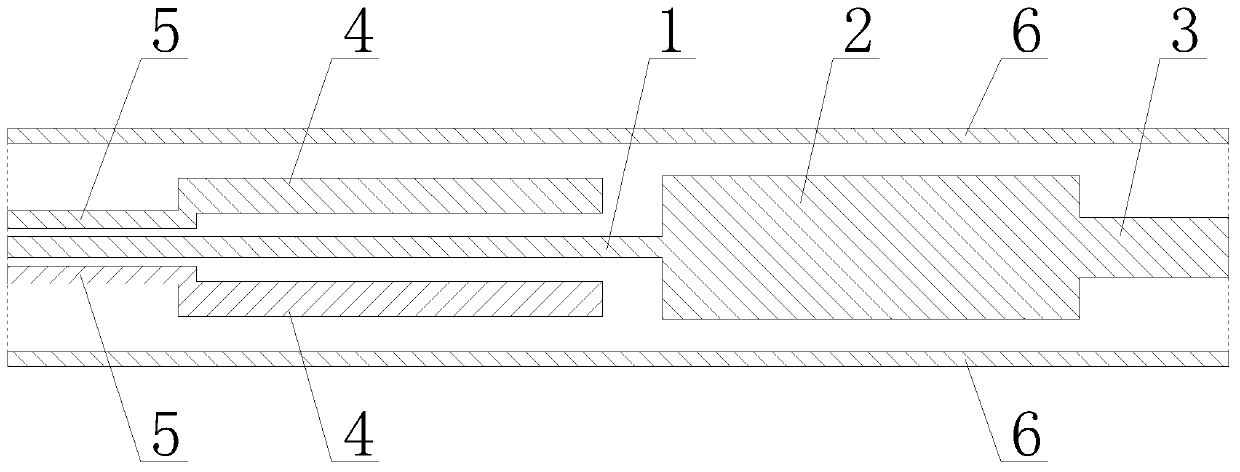

Preparation method of thin film transistor, array substrate and liquid crystal display panel

ActiveCN109616419BChemically resistantWeather resistantTransistorSemiconductor/solid-state device manufacturingInsulation layerLiquid-crystal display

The invention provides a fabrication method of a thin film transistor, an array substrate and a liquid crystal display panel. The fabrication method of the thin film transistor comprises the followingsteps of forming a Beta-type polyvinylidene fluoride first insulation layer on a gate layer; forming a InGaZnO semiconductor layer on the Beta-type polyvinylidene fluoride first insulation layer; forming a source and a drain on the InGaZnO semiconductor layer; and forming an insulation protection layer on the source and the drain. By the fabrication method, the device reliability can be improved.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

A T-shaped coaxial power divider

ActiveCN108258377BImprove pressure resistanceStrong breakdown resistanceCoupling devicesElectrical conductorHemt circuits

Owner:ANHUI SUN CREATE ELECTRONICS

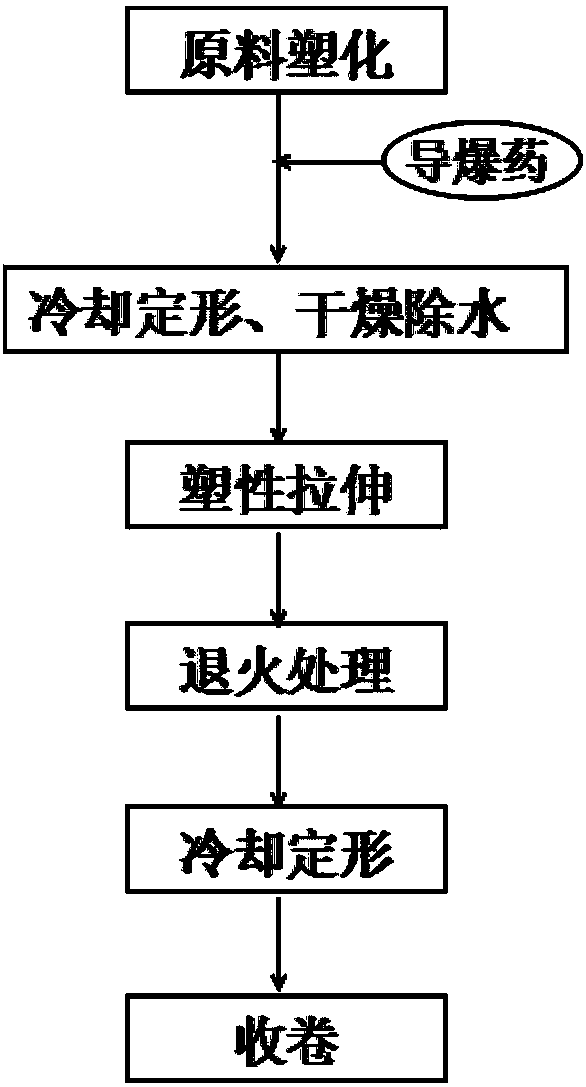

Single-layer high-reliability detonating tube and preparation method thereof

InactiveCN108586863AImprove adaptabilityReduce manufacturing costLow-density polyethyleneLinear low-density polyethylene

The present invention discloses a single-layer high-reliability detonating tube. The detonating tube is prepared from the following components as raw materials in mass percent: low-density polyethylene 40%-60%, linear low-density polyethylene 30%-50%, ethylene copolymer 5%-20%. The present invention further discloses a preparation method of the detonating tube, comprising: (1) feeding the raw materials into an extruder for plasticization according to the formula and extruding into a tube blank through a bush die of the extruder; (2) adhering powder in a hole of an extruder die mandrel to the inner wall of the tube blank by means of a pneumatic device; (3) cooling the tube blank for shaping and drying the tube blank for water removal; (4) carrying out plastic stretching treatment on the tube blank; (5) performing annealing treatment on the tube blank; (6) cooling the annealed tube blank for shaping to form a detonating tube; and (7) rolling. The detonating tube of the present inventionhas the advantages of excellent powder adhesion, high detonation propagation reliability, high breakdown resistance with a tension of up to 15 KG, and the like.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Surface discharge ceramic substrate for optical pumping source and preparation method thereof

ActiveCN104387117BExcellent dielectric propertiesStrong anti-particle erosion abilityHydrofluoric acidOptical pumping

The invention discloses a surface-discharge ceramic substrate applied to an optical pumping source. The surface-discharge ceramic substrate comprises a ceramic body and a diamond ablation-resistant coating deposited on the ceramic body, wherein the diamond ablation-resistant coating is deposited in only a region where surface discharge is generated on the surface of the ceramic body. The manufacturing method of the surface-discharge ceramic substrate comprises the following steps: preparing turbid liquid containing diamond powder; pretreating the ceramic body by using a hydrofluoric acid solution and then planting seed crystals for the ceramic body by using the turbid liquid; shielding the region, where no surface discharge is generated, of the ceramic body; depositing the diamond ablation-resistant coating on the surface of the ceramic body by means of hot filament chemical vapor deposition to obtain the surface-discharge ceramic substrate. The surface-discharge ceramic substrate disclosed by the invention is good in plasma ablation resistance, high in reutilization frequency and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com