Surface discharge type glass substrate for light pumping source and preparation method of surface discharge type glass substrate for light pumping source

A surface discharge, glass substrate technology, applied in chemical instruments and methods, glass/slag layered products, circuits, etc., can solve the problem of short operating life of surface discharge optical pump sources, limitations of high-power repetition frequency XeF applications, alumina Poor thermal shock resistance and other problems, to achieve the effect of easy nucleation and growth, small residual thermal stress, and improved ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

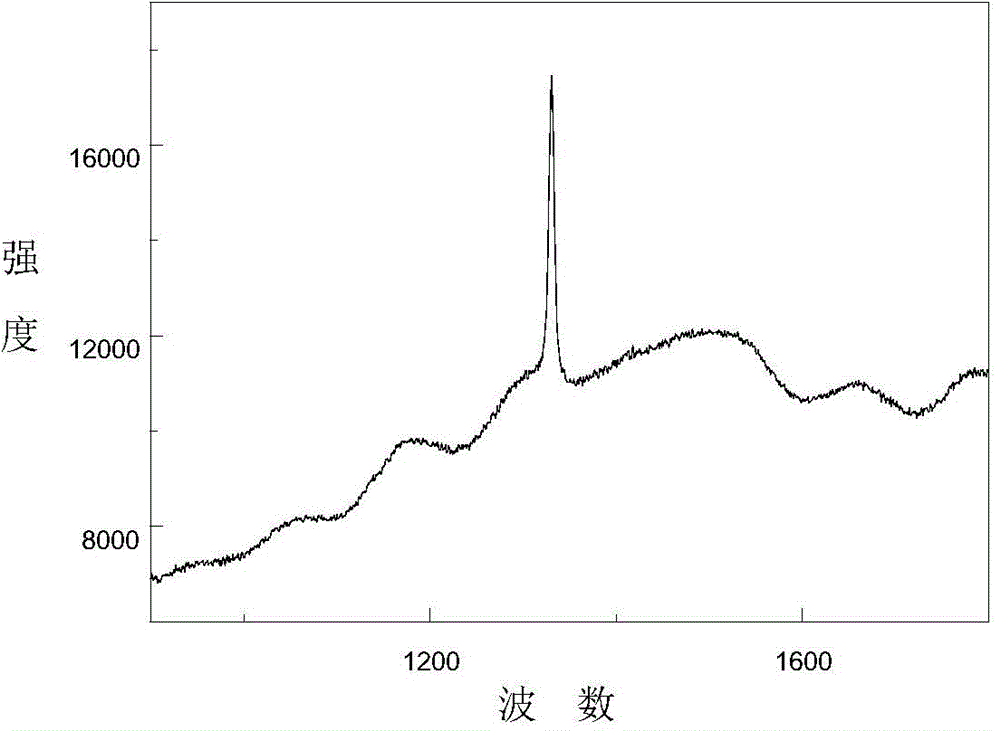

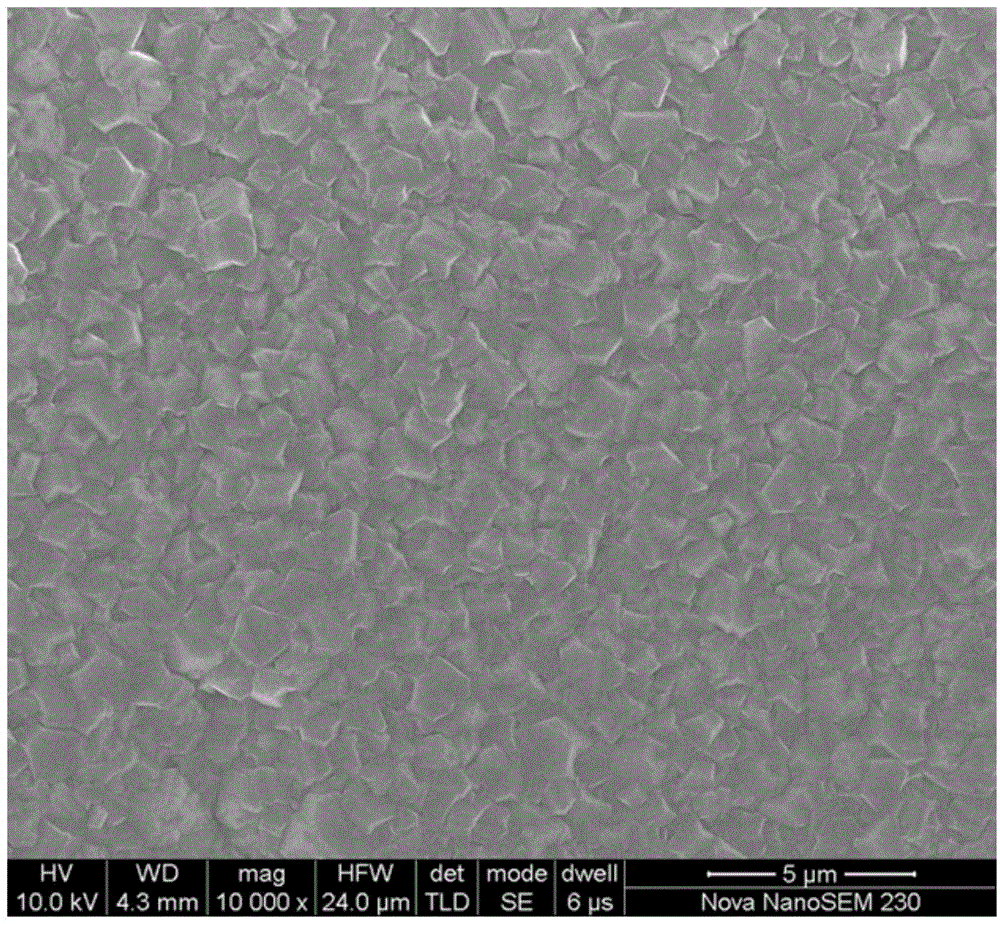

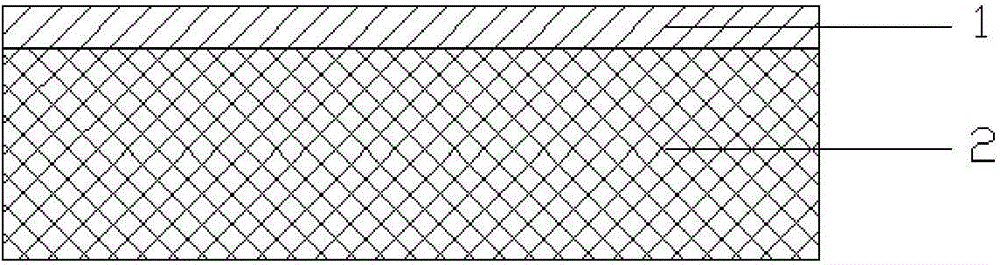

[0034] a kind of like figure 1 , figure 2 and image 3 The surface discharge glass substrate for the optical pumping source of the present invention is shown, the surface discharge glass substrate is a double-layer stacked structure, including a quartz glass body 2 and a diamond ablation-resistant coating 1 deposited on the quartz glass body 2 ( diamond continuous film). In this embodiment, the thickness of the diamond ablation-resistant coating 1 is 140.0 μm, and the surface resistance is 1.0×10 13 Ω·cm.

[0035] The preparation method of surface discharge glass substrate in the present embodiment comprises the following steps:

[0036] (1) select the diamond powder that particle diameter is 5.0 μ m for use, with dehydrated alcohol, diamond powder, magnesium carbonate by mass ratio be 85: 14: 1 and fully mix, promptly prepare diamond suspension;

[0037] (2) First use 80-mesh SiC water-grinding paper to polish a quartz glass body for 5.0min, then use the above-mentioned...

Embodiment 2

[0042] a kind of like image 3 The surface discharge glass substrate for the optical pumping source of the present invention is shown, the surface discharge glass substrate is a double-layer stacked structure, including a quartz glass body 2 and a diamond ablation-resistant coating 1 deposited on the quartz glass body 2 ( diamond continuous film). In this embodiment, the thickness of the diamond ablation-resistant coating 1 is 180.0 μm, and the surface resistance is 4.0×10 13 Ω·cm.

[0043] The preparation method of surface discharge glass substrate in the present embodiment comprises the following steps:

[0044] (1) select the diamond powder that particle diameter is 1.0 μm for use, acetone, diamond powder, magnesium carbonate are fully mixed evenly by mass ratio as 80: 22: 2, promptly prepare diamond suspension;

[0045] (2) Use 80-mesh SiC water-grinding paper to polish a quartz glass body for 5.0 minutes, then use the above-mentioned suspension on 400-mesh SiC water-gr...

Embodiment 3

[0050] a kind of like image 3 The surface discharge glass substrate for the optical pumping source of the present invention is shown, the surface discharge glass substrate is a double-layer stacked structure, including a quartz glass body 2 and a diamond ablation-resistant coating 1 deposited on the quartz glass body 2 ( diamond continuous film). In this embodiment, the thickness of the diamond ablation-resistant coating 1 is 200.0 μm, and the surface resistance is 9.9×10 13 Ω·cm.

[0051] The preparation method of surface discharge glass substrate in the present embodiment comprises the following steps:

[0052] (1) select the diamond powder that particle diameter is 4.0 μ m for use, xylene, diamond powder, magnesium carbonate are fully mixed evenly by mass ratio as 80: 19: 1, promptly prepare diamond suspension;

[0053] (2) First use 80-mesh SiC water-grinding paper to polish a quartz glass body for 5.0min, then use the above-mentioned suspension on 400-mesh SiC water-g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com