Deep-ultraviolet photoelectric detector of amorphous gallium oxide-based thin film transistor

A thin-film transistor and gallium oxide-based technology, applied in semiconductor devices, circuits, electrical components, etc., can solve problems such as small detection range, and achieve the effects of strong breakdown resistance, low power consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

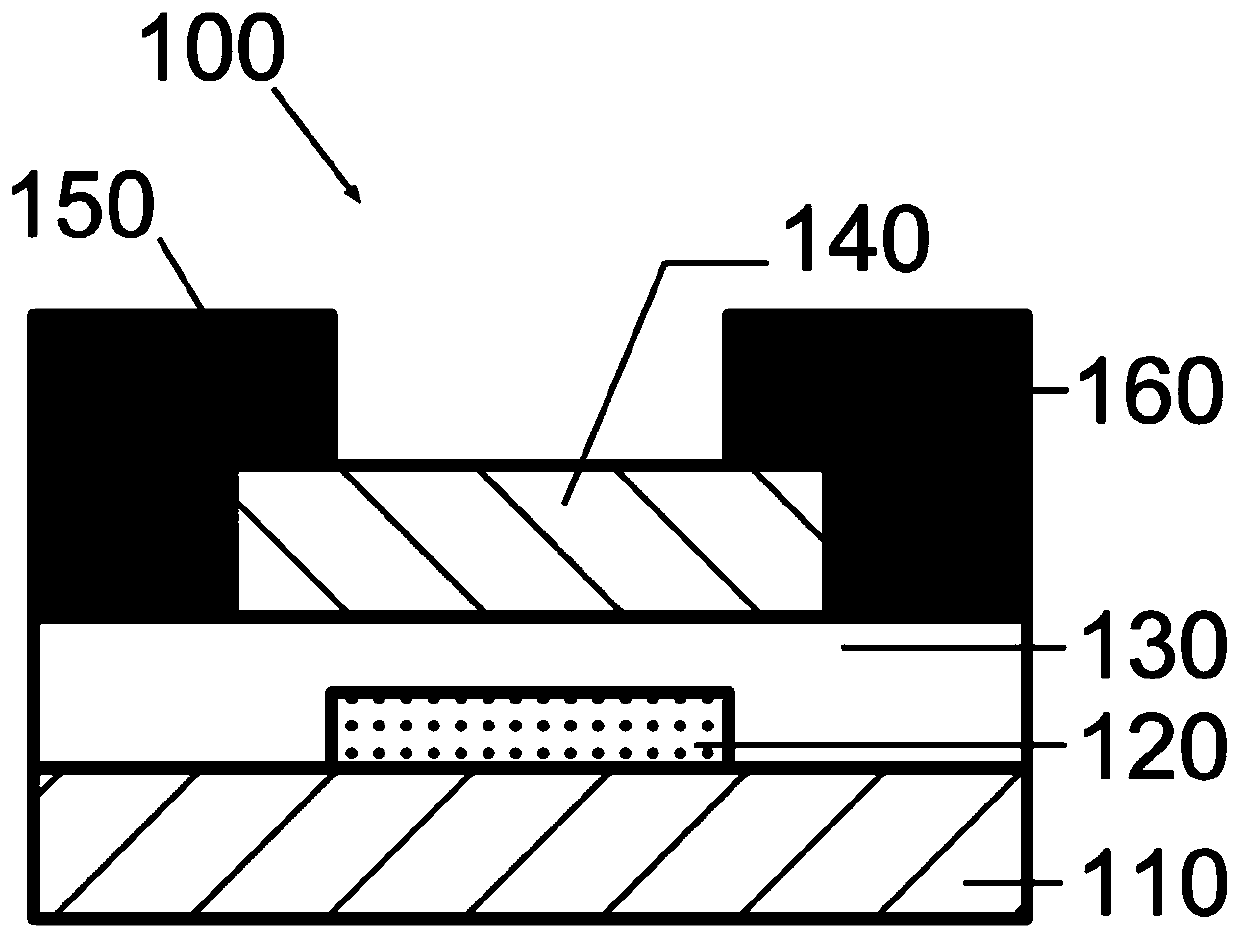

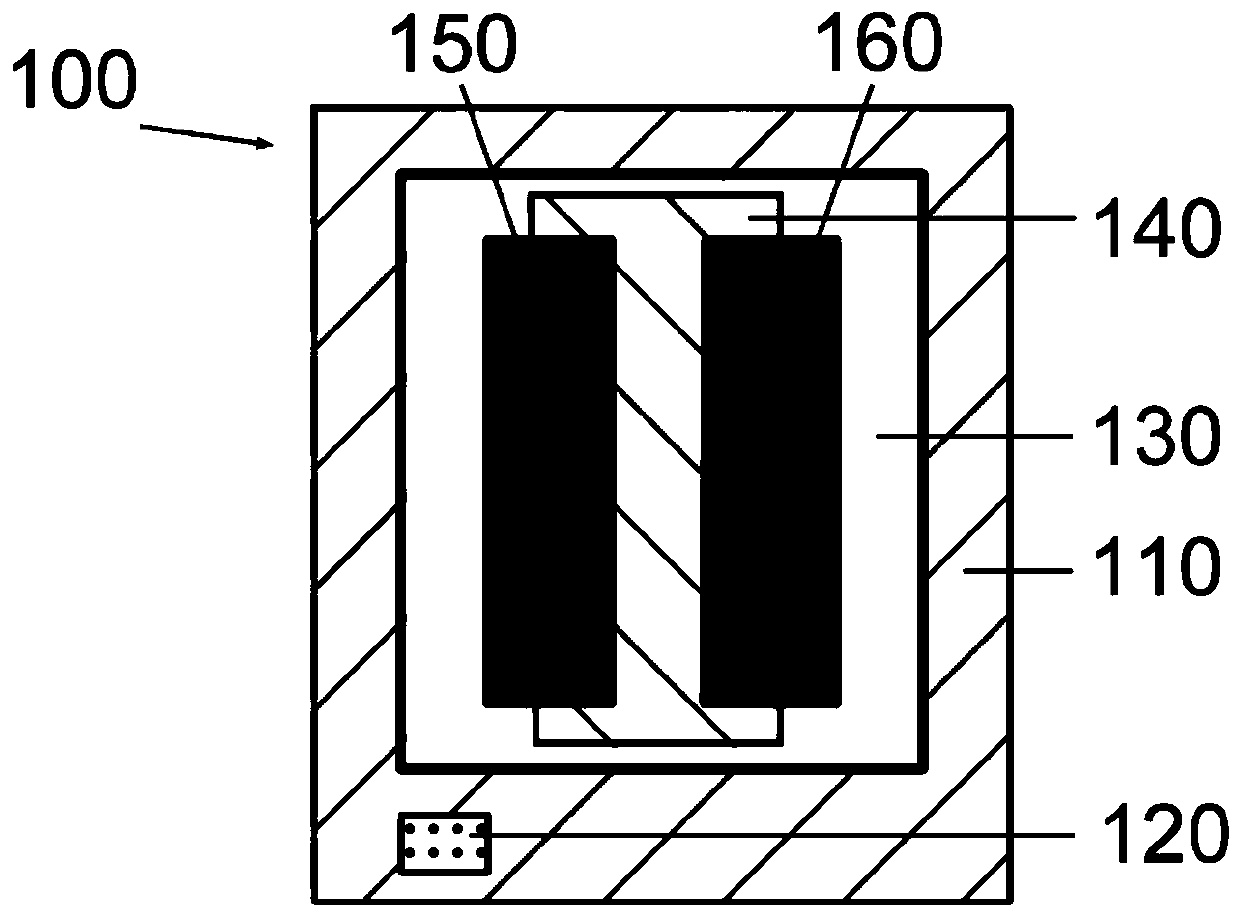

[0049] In this implementation case, firstly through step S110, select p+-Si / SiO 2 (100) Thermally oxidized silicon chip is used as substrate 110, and each ultrasonic cleaning 10min with acetone alcohol deionized water, N 2 Blow dry and set aside.

[0050] Furthermore, through step S120, the following three solutions are configured:

[0051]

[0052] The precursor solution was thoroughly mixed by continuous sonication for four hours at room temperature. After aging for 24 h, filter with a syringe and a 0.22 μm filter to obtain S1, S2, S3 and three precursor solutions.

[0053] Then, through step S130, the surface of the thermally oxidized silicon wafer is cleaned with plasma to increase the hydrophilicity of the surface, the power is 100W, and the time is 2 minutes.

[0054] In the next step, through step S140 , the above prepared precursor solution is spin-coated on the thermally oxidized silicon wafer to form the channel layer 140 . The spin-coating speed is 3000 rpm, ...

Embodiment 2

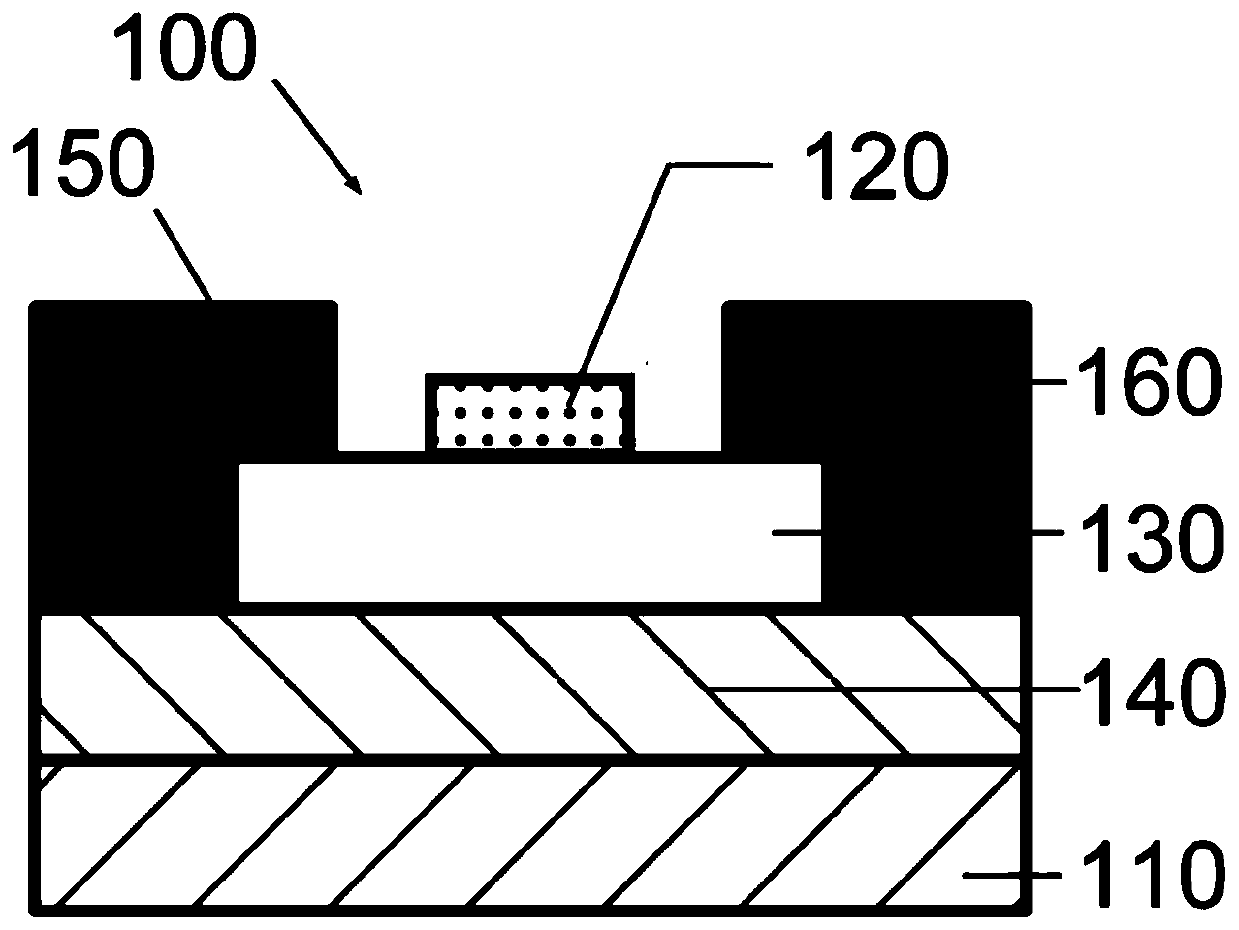

[0061] In this implementation case, firstly through step S210, select p+-Si / SiO 2 (100) Thermally oxidized silicon chip is used as substrate 110, and each ultrasonic cleaning 10min with acetone alcohol deionized water, N 2 Blow dry and set aside.

[0062] Furthermore, through step S220, configure the following three solutions

[0063]

[0064] The precursor solution was thoroughly mixed by continuous sonication for four hours at room temperature. After aging for 24 h, it was filtered with a syringe and a 0.22 μm filter to obtain three precursor solutions of S4, S5 and S6.

[0065] Then, through step S230, the surface of the thermally oxidized silicon wafer is cleaned with plasma to increase the hydrophilicity of the surface, the power is 100W, and the time is 2 minutes.

[0066] In the next step, through step S240 , the above prepared precursor solution is spin-coated on the thermally oxidized silicon wafer to form the channel layer 140 . The spin-coating speed is 3000 ...

Embodiment 3

[0073] For the thin-film transistor deep-ultraviolet photodetector provided in Example 2, the Ga content in the solution configured is 0.75. Under the irradiation of deep ultraviolet light, the degree of leftward shift of the transfer curve under visible light irradiation is relatively high, and its ultraviolet-visible suppression ratio All were worse than S1, S4, S5 and S6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com