Flip-chip solar cell and manufacture method thereof

A solar cell and flip-chip technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as short-circuit current mismatch, and achieve the effects of increased thickness, improved tunneling effect, and improved bandgap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

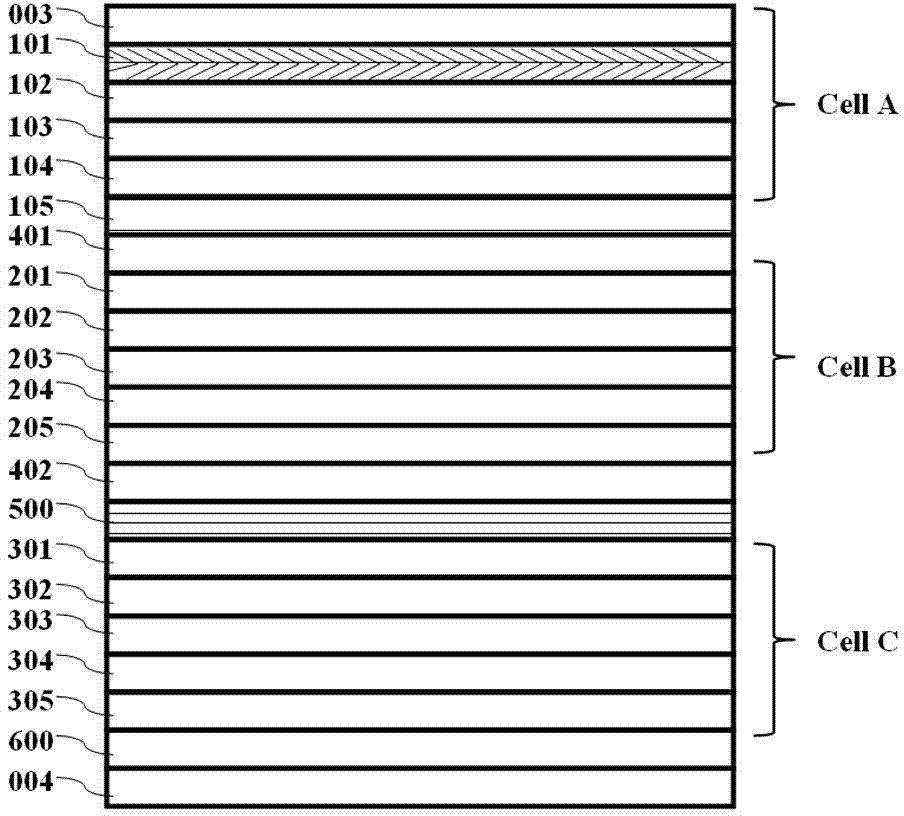

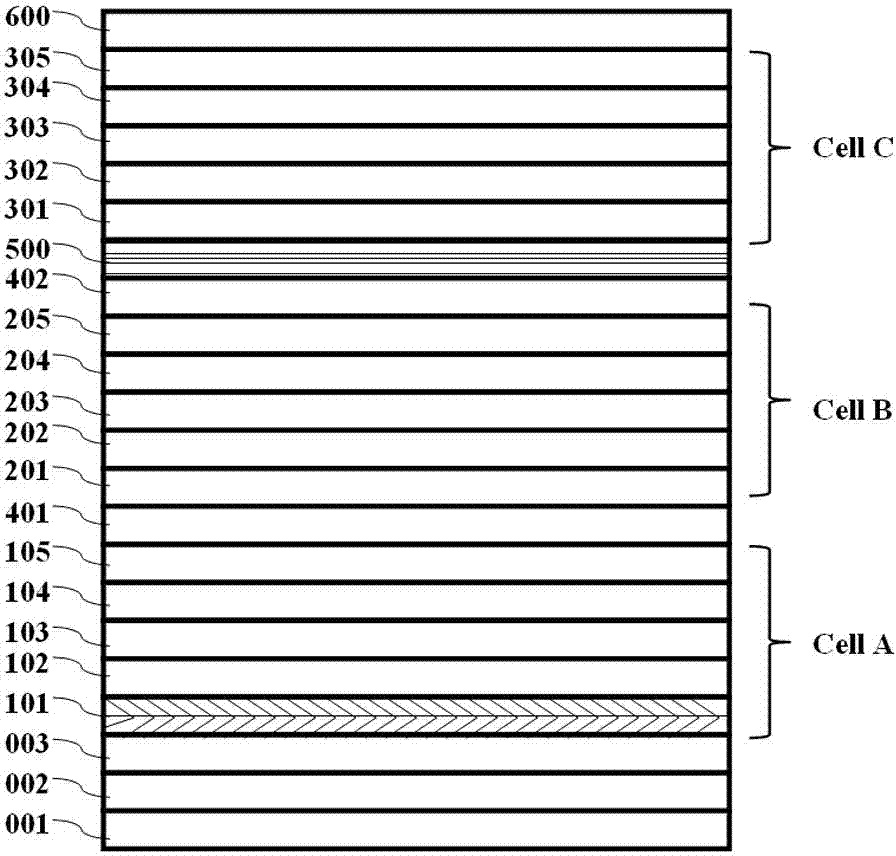

[0045] figure 1 Shown is an epitaxial structure of a flip-chip triple-junction solar cell, including from bottom to top: a growth substrate 001, an etching stop layer 002, an ohmic contact layer 3, a first GaInP sub-cell A, and a second GaAs sub-cell B 、In 0.3 GaAs third sub-cell C, capping layer 600, wherein each junction sub-cell is connected through tunnel junctions 401, 402, and a graded buffer layer 500 is used between the second and third sub-cells to solve the lattice mismatch between the two junction sub-cells. The structure will be described in detail below in conjunction with its preparation method.

[0046] Step 1: In the MOCVD system, the off-angle of n-type doping to the (111) crystal plane is selected as 9 0 The GaAs substrate is used as the growth substrate 001, the thickness is about 350 microns, and the doping concentration is 1×10 18 cm -3 ~4×10 18 cm -3 between. An InGaP etch stop layer 002 and a GaAs ohmic contact layer 003 are grown sequentially o...

Embodiment 2

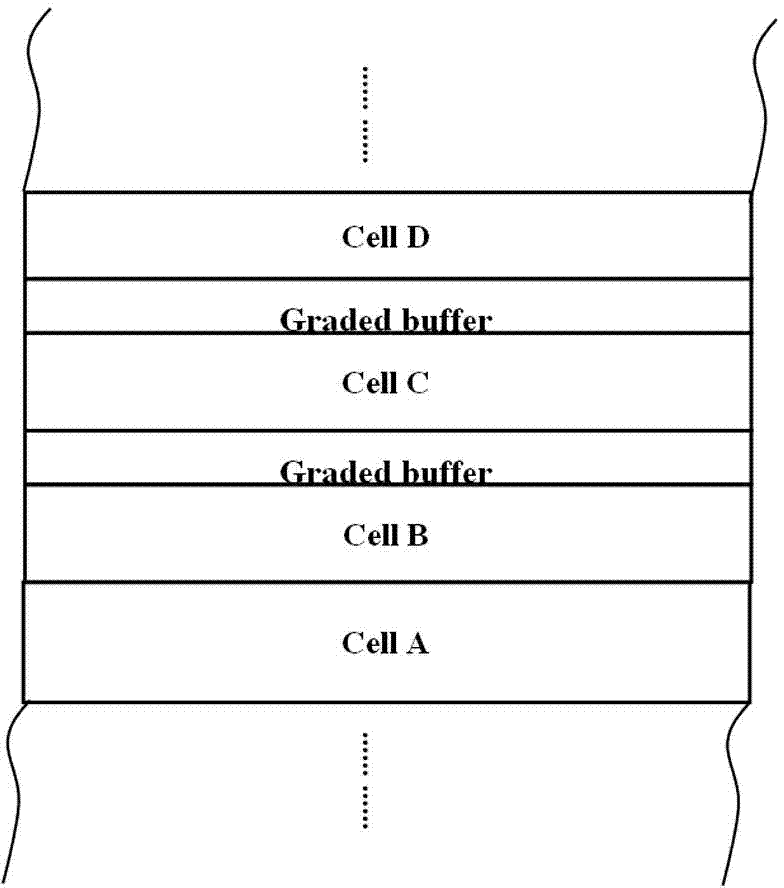

[0057] While satisfying the bandgap distribution as shown in Table 1, on the basis of Example 1, the epitaxial growth of the flip-chip four-junction solar cell (double graded buffer layer) can be continued, and its preparation mainly includes the following steps:

[0058] After implementing step 7 of Example 1, grow the tunnel junctions of the third and fourth subcells, and grow the second graded buffer layer InGaP, and grow 8 layers in total: including the stress release layer InxGa1-xP and the target lattice layer n+-In 0.737 Ga 0.263 P, where the stress release layer InxGa1-xP, the In composition of each layer increases from 0.737 to 1, and the corresponding lattice constant increases from 0.577 nm to 0.587 nm. The thickness of each layer was kept at 250 nm, and the doping concentration was 1×1018 cm-3. The last layer of the gradient buffer layer is the target lattice layer n+-In 0.737 Ga 0.263 P, its and the fourth sub-battery In 0.53 Ga 0.47 As has the same lattice ...

Embodiment 3

[0063] While satisfying the bandgap distribution as shown in Table 1, in the process of epitaxial growth of flip-chip triple-junction solar cells in Example 1, the Al(In)P / In(Ga)P superlattice structure is used instead of n+ - AlInP / InGaP heterojunction as the first sub-cell window 101, the thickness of each period is 10 nm, and the total thickness is 30 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com